how to use a rotary table and dividing plates brands

This plate can be used either directly, or through a geared dividing mechanism. In direct indexing the workpiece and plate rotate in a 1-to-1 ratio, and holes are used directly. That is, a plate with 12 holes can divide the workpiece into 2, 3, 4, 6, or 12 equal segments. A dividing head incorporates an internal gear ratio (usually 40:1, 60:1, or 90:1) with the same plates. In doing so, the dividing head enables many more combinations than just direct indexing.

For example, imagine a plate with 15 equally-spaced holes and a dividing head with a 40:1 gear reduction. In direct indexing, a workpiece could be divided into 3, 5, or 15 equal segments. Using the dividing head, the same workpiece could be divided into 2, 3, 4, 5, 6, 8, 10, 12, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 300, or 600 segments. Essentially, the dividing head acts as if it’s a direct indexer with 600 holes; 15 holes in the actual plate * 40:1 gear ratio. Let’s look at how some of these combinations are possible.

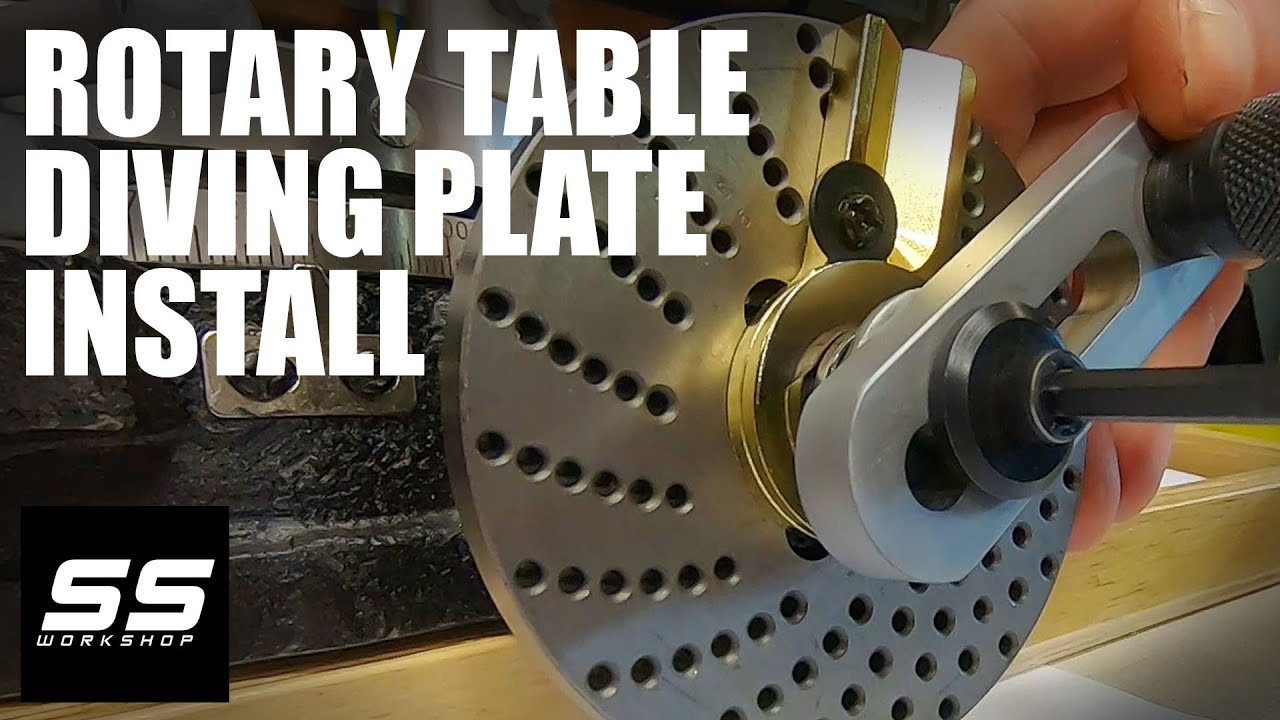

You remove the nut holding the hand wheel on and pull the handwheel off. They are usually on a keyed shaft that also has two flats on it. Behind this are three tapped holes to take one of the three plates you should have with the table.

Fit one plate { more on this later } then fit the spacing arms over the shaft. Some have a bush that fits the keyed shaft, some require you to remove the key.

Most popular dividing heads use a 40:1 ratio and the tables published reflect this. Rotary tables are usually 90:1 or 60:1 so you will need a set of tables to cover this ratio. This is why you need to choose which plate you use carefully as you need a plate with a row of holes to match your divisions at the required 60 or 90:1 ratio.

Many metalworking products contain metals that are included in the latest Prop 65 warning. Exposure to the elements can be harmful. May cause cancer and reproductive harm.

The settings you specify here are stored in the "local storage" of your device. The settings will be remembered for the next time you visit our online shop. You can change these settings at any time (fingerprint icon in the bottom left corner).

I think as rotary table with index plates and a tailstock might be a bit more versatile than a dividing head. You can use its flat table to clamp projects down on,like a face plate. You can add a chuck. You can still cut gear teeth with the dividing attachment. A universal index head can tilt,but a rotary table can too,if you mount it on a tilting table. Less rigid on a tilting table,but I like using the flat table better than other short comings it might have.

They both use worms to rotate in precise increments. The difference is in the details as each is set up to be better for different tasks. But, yes you can divide on a RT. Many, dare I say all of them, can be fitted with dividing plates. Or you can just find the angular positions and go to each of them in turn. That may be more prone to error than using plates and an arm with a pin, but it does work. I have done it.

Is the size of a RT really in the way. Well, perhaps, but I have never been unable to work with it and I have a 10", which is BIG. And heavy! I dropped it once. Big ding in the floor, no noticeable damage to the RT. It is BIG and MASSIVE. And probably a lot more accurate than most dividing heads.

PS: If your RT did not come with dividing plates and none are available, you can make a set using the table itself. I previously posted this elsewhere, so I am quoting myself;

You CAN make a set of circles on your own, using ONLY the dividing head or rotary table you already have. They WILL be just as accurate as your worm gear is, with a small bit of random error due to the uncertainties of the machining process. I have described this process several times and you can search this site (Activity Stream - The Home Shop Machinist & Machinist"s Workshop Magazine"s BBS) for these lengthy explanations, but here are the short strokes:

As someone stated above, a second generation plate made with YOUR existing head will be 30 (or 40 or 90) times more accurate than the first generation plate used to make it. The worm gear acts as a "precision amplifier". So if you have a one degree error in a first generation plate, the second generation plate will have only a 2 minute (1/30 of one degree) error. And when you use that second generation plate, the error on your work will be only 1/30 of that or 4 seconds of arc. I will guarantee you that your worm is not that accurate and no further precision is needed.

1. Make a first generation plate using any layout technique that you want. Literally ANY technique: the accuracy DOES NOT MATTER. If you can get the holes within 2 or 3 degrees of the correct positions that is 100% good enough. You do not even have to drill these holes, simple pencil marks on a paper disk and a pointer on the shaft will work. And by "will work" I mean that it will provide the accuracy I have stated above on a third generation plate.

That"s it, you are done and your work with this second generation plate will, WHEN USED ON YOUR HEAD, will be the third generation and will be at the accuracy that I stated above (4 seconds of arc or better plus the error in your worm). Thus you have made one "paper plate", the first generation and a second generation metal one.

One small note. The second generation plate made above is not at the high level of accuracy I claimed above BUT it will provide that level of accuracy when used on your head. If you want a highly accurate plate for direct use instead of one to be used on your head, then you would need to make a third generation plate to get that accuracy.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

This item is backordered from our supplier. We will ship as soon as it is received. Your credit card will not be charged until shipped. Please Note: For shipments to locations outside the USA, backordered items must be placed on separate orders.Remove From Cart

PO Box, Africa, Albania, American Samoa, Andorra, Armenia, Azerbaijan Republic, Bangladesh, Bhutan, Bosnia and Herzegovina, Brunei Darussalam, Cambodia, Central America and Caribbean, China, Cook Islands, Ecuador, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Greenland, Guam, Jordan, Kazakhstan, Kiribati, Kyrgyzstan, Liechtenstein, Macedonia, Marshall Islands, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Nauru, Nepal, New Caledonia, Niue, Norway, Pakistan, Palau, Papua New Guinea, Russian Federation, San Marino, Solomon Islands, Svalbard and Jan Mayen, Taiwan, Tajikistan, Tonga, Turkmenistan, Tuvalu, Ukraine, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Vietnam, Wallis and Futuna, Western Samoa

It works well. Functionally, it’s pretty great.It comes with some extras, but not much of an explanation. Because it can mount parallel or perpendicular, it lacks a way to clamp it to the table for parallel use. I had to machine a toe clamp to hold the other end. Thankfully, I have a mill. But, it’d have been so much easier to include one since it’s necessary.Otherwise, the 90 turns for 360 (1 for 4), works out pretty well for any angle divisible by four - 72, 60, 120, etc. I had to machine a way to attach my lathe chuck. Spent a half hour making the little piece I pictured… worked well for not using the dividing plates.Solid. Fairly precise. Works. But you’re going to have to make things to use it.

8613371530291

8613371530291