how to use a rotary table and dividing plates pricelist

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

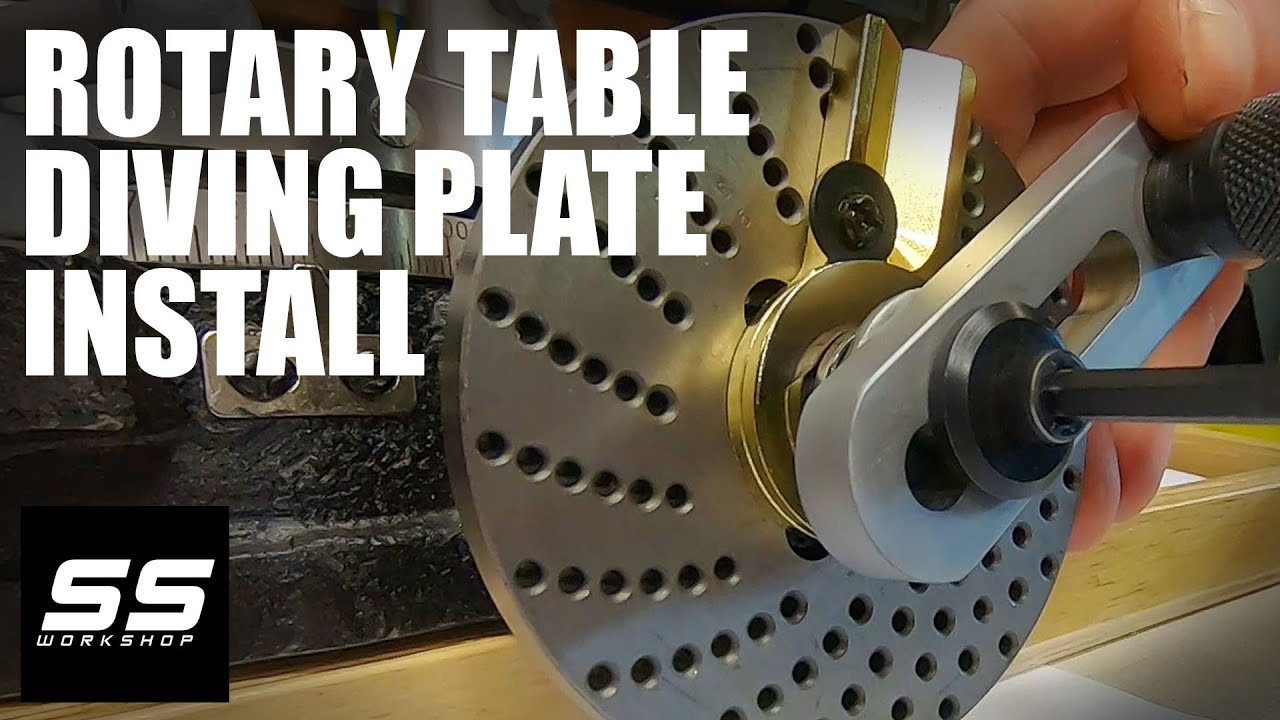

The indexing plate is a machine tool accessory that holds the workpiece on the chuck or between two pinnacles and rotates, indexing and positioning it. Plate connected with rotary indexing table is in Diameter: 4"/100mm and Thickness: 0.28"/7mm, good for rotary tables in Model HV-3, HV-4, HV-5, HV-6, TS160. Perfect to use with dividing head for milling table.

**Please contact Sales@freertool.com for all lead times before placing your order. Once paid for, any cancellations will have a 4% cancellation fee.**

These indexing plates are used in conjunction with both the Axminster 100189 and 200247 rotary tables to enable the table to be rotated by an exact fraction of a complete turn, a particular requirement when machining gears, sprockets, etc. on a vertical mill. There are three indexing plates in the set which together provide all the subdivisions up to 50 (although 28 and 44 carry very small errors). There are a further 26 subdivisions available between 51 and 100 plus others above 100. The spring loaded index pin locates positively in the holes in the index plates and the two brass setting plates help to keep count of the number of holes moved by the pin.

In 1987, Metal - Kovis d.o.o. started as a small company with distribution of used machines and tools. With dignified work and with emphasis on quality and customer satisfaction, Metal - Kovis d.o.o. soon became the leading company in the region for the distribution of used machines.

The dividing plate set consists of one plate with two sets of holes. One circle has 15 holes and the other has 28 holes. This lets you divide a circle into 1/3 degree increments, among many other combinations.

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent.

Founded in 1969 under the motto of “Always Thinking Productivity”, Cutting Tools Inc.is the premier distributor for the Automotive, Aerospace, Defense, Energy, Firearms and Medical manufacturing industries. To get in touch, contact us at cs@cuttingtoolsinc.com

Are there any books on the rotary table ? I know there are several on the dividing head but information on the rotary table seems to be scarce. When i was serving my time we done a fair amount of work on the dividing head, what it could do, the maths involved etc, when i asked about the rotary table i was told that in production situations and general commercial engineering that cnc had made them nearly obsolete. A friend gave me an old table a year or two back and i have amused myself cutting arcs etc on bits of scrap, but i feel there is a gap in my knowledge of the thing.

You can use a rotary table to cut gears or drill a number of equaly spaced holes without dividing plates. Just divide 360 (The number of degrees in a circle.) by the number of teeth (Or holes) you want. For example if you wanted a 33 tooth gear 360/33 = 10.90909 Deg Most rotary tables are marked in degrees, minutes and seconds so you neet to convert the decimal value to this format.

So 0.90909 degreed is 60 * 0.90909 minutes = 54.5454 Then 0.5454 minutes is 0.5454 * 60 seconds = 32.724 seconds. You could use a spreadsheet to do the calculation and list all the table positions.

In the example you would cit the first tooth with the table set to 0 deg 0 min, 0 sec. for the second tooth move the table to 10 deg, 54 min, 33 sec (32.742 rounded to nearest second) For the third tooth set the table to 21 deg, 49 min, 5 sec. And so on. You are more likely to make errors using this method than dividing plates. Here is some information on rotary tables that you may find useful.

You can also use tham for non regular spacings such as a series of radial holes and tangental surfaces. The part below was done with the R?T vertical then rotated for the two angled faces and the four different angles for the holes then laid on its back for the curves all of which radiate from the same centre point

I do loads of jobs on my (home made) rotary table as its much more rigid than my (home made) dividing head. The handle is graduated to 1/10 of a degree and I find that accurate enough. Any technique that works with a dividing head can be applied to a rotary table, if you add dividing plates to the handle.

Thanks for the replies and links everyone, the rotary table is just something i have never seemed to use somehow. I have one now and just wondered how to do some of the trickier work, cam milling for instance ?

That rather depends on the cam cutting method, you can do it without the calculations if its a short cam. With the R/T laid flat and the work held in a 3 jaw just wind the handle in approx increments, no fine setting of the cutter for every increment

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent. More information

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item so that we can evaluate the issue and make it right.

Certain types of items cannot be returned, like custom products (such as special orders or personalized items), and personal care goods (such as beauty products). We also do not accept returns for hazardous materials, flammable liquids, or gases. Please get in touch if you have questions or concerns about your specific item.

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

8613371530291

8613371530291