how to use a rotary table on a mill made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new universal milling machine rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement universal milling machine rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new universal milling machine rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

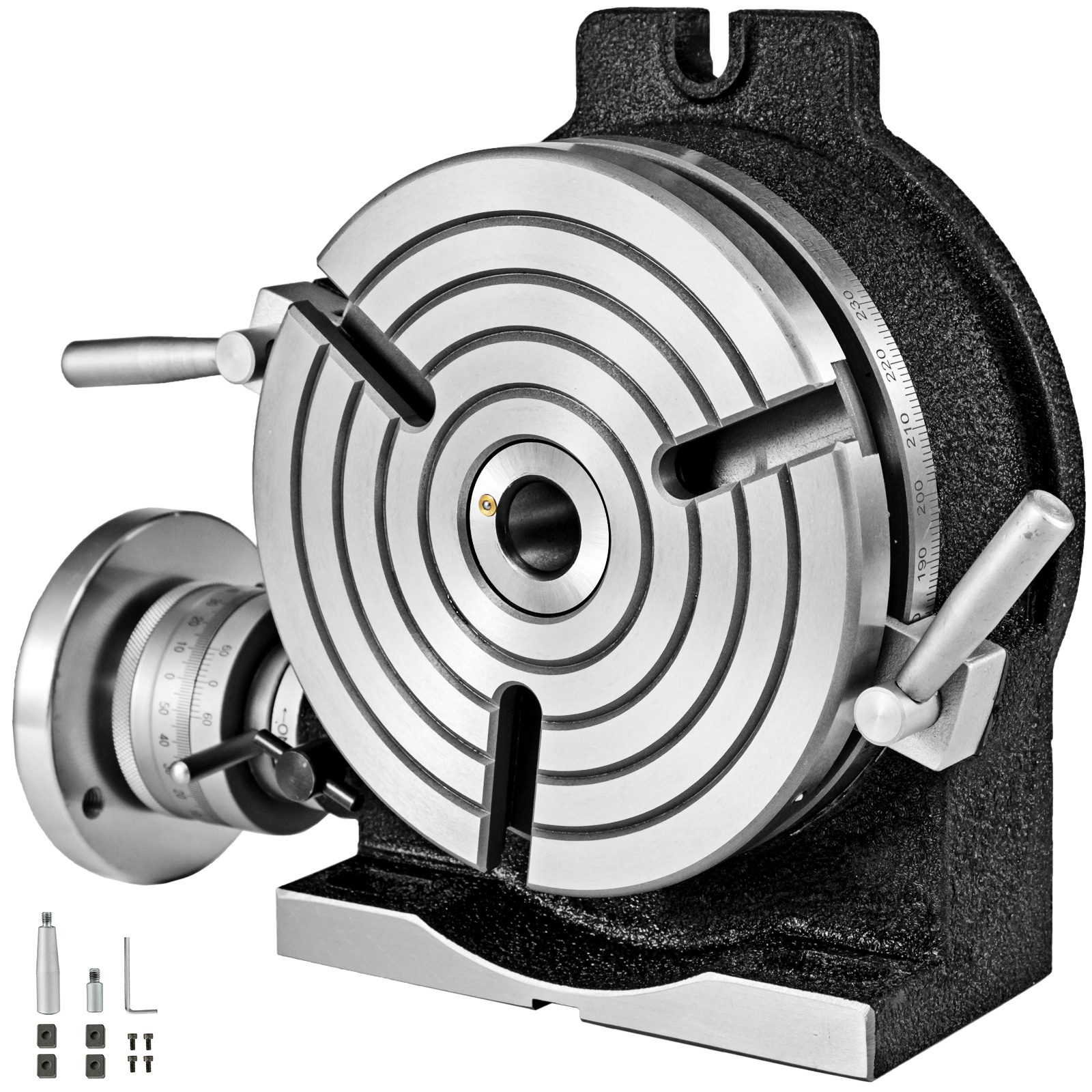

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

Lathe slides are designed to resist only turning forces which is usually directly down onto the slide. You are milling which puts loads on the slide it wouldn"t normally see. Make sure that the gibs on your slides are snugged up to reduce any lift or lash and if you don"t intend moving the slide during your milling, lock it up tight.

Another thing I would do it add some support to the rear of the table. If you can fix an angle or block to the base and clamp it down then you"ll find it a lot more rigind.

Finally your clamping of the part leaves a lot to be desired. You"re milling a long way from the clamp and if that flat bar is even slightly bowed it will hinge all over the place. You could put a second clamp on it ir if you don"t have the room for that without fouling the cutter try at least putting some low level stops in the dis-used slots to prevent hinging. Another thing you could do is put a piece of paper under the part near each edge of the table. That will improve clamping forces a lot.

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Another plus for the Sherline RT is Sherline sells a bunch of accessories for it as well. There is a 5" tooling plate, a tilting angle table, and a variety of center adapters to mount a chuck to the RT. They also have a full CNC conversion including a CNC indexer if you ever wanted to go that way.

I was going to say I didn"t see that much of a price advantage on the no name Ebay rotary tables, but the Sherline is almost $300. I didn"t remember it being that much, in fact I paid less for my 6" Taiwan RT although it was lightly used.

In favor of the import rotary tables some of them are available with indexing plates and tail stocks allowing them to be used as an indexer as well as a rotary table.

Product broken, Tried to use product support won"t let add photos so could get replacement part. Don"t think that"s going to work. Guess will see if anyone tries to help me.

Update: got an email asking if I could buy replacement part locally and they would give me a 35% discount or wait 2 or 3 weeks for replacement part, so I chose to wait.

Get an email the next day saying that region is locked can"t get replacement part and should try local shop to get part repaired and they offered 65% discount. ( I had already taken part to machine shop and they said they would not repair broken part but would make new part at a cost around 200 dollars).

when I was young, strong, healthy, and thought nothing of lifting it, a 10" H & V was my first choice. I still think it was a good choice for the work I mostly do, and this is where you may decide to compromise. If you do small work, an 8" table is much lighter and more convenient to set up. Stood vertical, it interferes less with the spindle to reach center. I don"t think a 6" is a good choice unless you know you will only be working miniature stuff. You use a considerable percentage of a small table just for set ups and hold down clamps on a lot of work, and a small table does not leave much room.

I like 90:1 gear ratio for circular milling, which is presumably your primary interest with a rotary table. My 10" table is 90:1, and that is a pretty good ratio for milling diameters (hand cranking) out to 12" or so. My 20" table is also only 90:1, and out near or past the rim (I do one part at 32" diameter) that always seems _very_ coarse.

If most of your work is small, round to begin with, and will actually be dividing work, where you index the table, lock it, and then drill a hole or mill a slot with the machine axis drive, you might find a dividing head more useful. For instance, I"ve made gears on a vertical rotary table, and in a spin index. On the table, you need an insert collet chuck or other arrangement in the center hole to get the work out far enough to clear the cutter. It"s a lot more convenient on a dividing head. OTOH, I don"t find it fun or convenient to do much circular milling on a dividing head if the work diameter is much over a few inches.

Dividing heads typically are 40:1, so faster to index, position to positon. But the milling capability on a radius is limited by the "coarse" ratio to smaller diameters, as is the usual work holding (collet or chuck) arrangement. A dividing head will tilt from below horizontal to past vertical, so you can mill, drill, bore or shape profiles at any angle in between.

an 8" H & V with dividing plates and set up, can usually be arranged somehow to do most of the work you might want to do on it. It is relatively light to move, and convenient to set up with reasonable space (spindle clearance, e.g.)limitations to be considered. A little bigger (10") is better, if you will ever need the capacity.

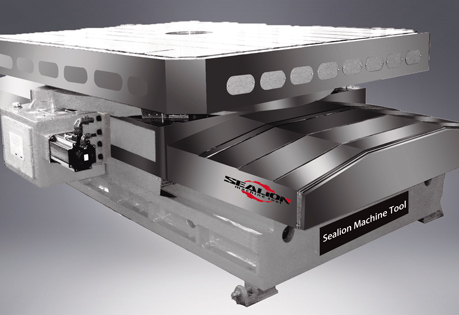

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

This forum is dedicated to those hobbyists with the 3-in-1 metalworking machines. Mill-Drill-Lathes. Tips, techniques, modification and use of these machines is topical.

I"m considering getting a rotary table for my V10 Maximat. I"ve seen the array of stuff on eBay and from the various suppliers. I don"t feel much like paying the asking price for an original Emco, which is only 4" anyway.

Anybody got any recommendations/comments as to which is the best ? I fiddled around with an 8" Phase 2 at a friend"s place recently, and found it to be kind of ratchety.

As to the milling base: The same friend has an Emco-Maier tabletop milling machine (I forget the model designation), which has the same head and column as on my V10, but has a much longer/deeper table than is possible on the V10. He showed me some old literature (from American Edelstaal) that listed the base unit as an accessory, allowing you to convert the V10 (or I suppose the V7) to two machines.

I can see already that I will be having to disassemble it and rework the insides because it turns very rough and the hand wheel has a whole degree of backlash.

I don"t have your experience or expertise to modify/re-machine the "Out of the East" stuff, so I don"t think I"ll try to make one of the Chinese-junk tables work.

I"ll keep looking for an original (or maybe East-European, they"re still good) rotary table. I may have to budget kind of tight for a few months, but good tools are worth it.

I even doubted about these mini airplane engines until I actually talked on the phone to the man, Robert Vought, who is recovering from a very serious cancer operation.

PeteH wrote:I"m considering getting a rotary table for my V10 Maximat. I"ve seen the array of stuff on eBay and from the various suppliers. I don"t feel much like paying the asking price for an original Emco, which is only 4" anyway.

Anybody got any recommendations/comments as to which is the best ? I fiddled around with an 8" Phase 2 at a friend"s place recently, and found it to be kind of ratchety.

As to the milling base: The same friend has an Emco-Maier tabletop milling machine (I forget the model designation), which has the same head and column as on my V10, but has a much longer/deeper table than is possible on the V10. He showed me some old literature (from American Edelstaal) that listed the base unit as an accessory, allowing you to convert the V10 (or I suppose the V7) to two machines.

Well, I"m strictly a "hobby machinist", which is why I"m on this BBS and not on "Practical Machinist". I just don"t have the skills to do some of the things I read about. I hope to gain them, though.

My professional background is chemistry and project management - and I was/am very good at both. I learned the little I know about machining by watching other guys work, and by asking questions. One guy who taught me a lot was a Czech gunsmith, another was an Austrian tool-and-die maker. I probably know only 10% of what I should, but hey, this whole life is a learning process, and now that I"m "semi-retired", I have more time to study.

My main interest in the rotary table was originally making gears... which I since found out is a messy business - and with some research, usually unnecessary. But the idea of being able to mill an O-ring groove (or a carburetor spacer) is very appealing.

I had to buy and American style steady rest and then found out that I had to adapt it big time because the Maximats have a .750 off-set spindle center line from the center line of the bed.

I saw the assembly and thought that I could use the gears and the motor for replacement but found out that none would fit the Maximat lathe or mill head.

So, I have opted to do the best I can and ended up having to buy Chinese garbage and make it work, because none that I have bought meets quality requirements expected here in the USA for most old timers that where blessed with working with the best machines available for most of their active lives.

I bought it from a posting in craigslist and I thought that I could have replacement gears and a motor. Came to find out that nothing would fit my Maximat, not even the motor.

I found out recently that Emco used to sell the base only, so you could remove the milling column and have it transported it this larger, more stable base.

I did not know that before I sold the power feed assembly. I hope I will not end up kicking myself you know where later on because I am looking for a separate mill.

Thanks, Jose... I think I"ve seen that same unit from several vendors, priced in the same general range. I believe you can get indexing plates for it for $50-$75 extra. I didn"t know it was horiz/vert, though - that makes it much more attractive.

Wouldn"t 4" be kind of small for any real work, though? (Keeping in mind that the Emco mill, with only 1/3 hp, really isn"t a "production" tool, it still would be more useful to hold a bigger workpiece.)

Adding a larger table would be a solution but then the clearance distance to the spindle would be so reduced specially if a chuck is being used, that will render the milling head almost useless.

8613371530291

8613371530291