how to use a rotary table on a milling machine made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

2. It permits maching operationgs at a higher dimension than that of ts type. It can be used in a vertical position to enable to carry out center work with the help of tailstock.

3. A flange is special supplied, and be packed independent. And the dividing plates accessory allows the operator to accurately divide the 360°ratation of the clamping surface into division of 2 through 66, and all divisible of 2,3 and 5 from 67--132.

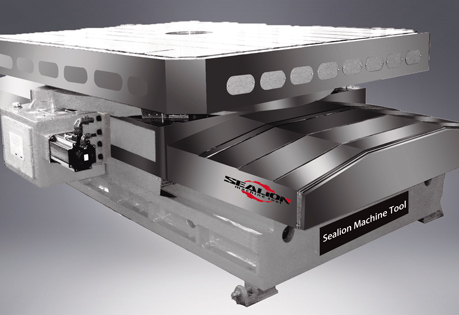

The rotary table is an accessory for the CNC floor type boring and milling machine. It can be working together with the floor type boring milling machine for milling angle, reverse boring, polyhedral machining, and other complex machining processes. It could do five sides machining if the main machine equipped the angle milling head.

CNC rotary table is a common part of CNC milling machine, often used as a servo axis of CNC milling machine, namely C axis of vertical CNC milling machine and B axis of horizontal CNC milling machine. The CNC rotary table includes the foot of the turntable, a round turntable surface, four rolling bearing parts arranged on the upper surface of the foot of the turntable, and a center with a self-aligning bearing installed at the center of the upper surface of the foot of the turntable. Support, each rolling bearing component includes a rolling bearing and a support that supports the rolling bearing through the axle. The center of the lower surface of the turntable is provided with a vertical downward axle. The turntable is installed on the foot of the turntable. The inner ring of the self-aligning bearing is fixed, and the rotating surface of the rolling bearing is in rolling contact with the lower surface of the turntable surface.

The CNC rotary table has an inclinometer with two orthogonal test axes as the test tool. The inclinometer is set at the center of the turntable surface to be leveled, so that the two orthogonal test axes of the inclinometer are parallel to the turntable surface, by adjusting the milling machine turntable. The leveling mechanism under the base makes the tilt angle value output by the two test shafts of the inclinometer turntable in the leveling state.

CNC rotary table and swing head are the key components of multi-coordinate CNC machine tools. Traditional rotary tables and swing heads using high-precision worm gears and other transmissions are not only difficult to manufacture, costly, but also difficult to achieve the speed and accuracy required for high-speed machining. Therefore, it is necessary to develop a new electromagnetic drive system for the CNC milling machine turntable and swing head in a different way to realize the zero-drive drive of the rotational motion coordinates of the CNC machine tool.

1. The CNC turntable uses modular design technology. The PAN turntable and TILT turntable are independent components, which are easy to disassemble and can be controlled by linkage or individually.

2. The use of AC servo motor drives the harmonic wave reducer transmission system to ensure that the equipment not only runs stably at low speeds, but also has fast dynamic response performance.

3. The automatic control system is composed of a PC and a motion controller based on DSP, which ensures the openness and convenience of expansion of the automatic control system.

4. The control software developer platform uses the Windows platform, which can make full use of various data visualization development tools, which greatly simplifies the progress of experimentation, research, and research and development.

Kunming Machine Tool Company Ltd, China, (KMTC) has developed a variety of ‘China"s first" high performance machine tools, leading the development of machinery and the machine tool industry in China. As a market leader in metrology, Renishaw has provided KMTC with advanced solutions in machine calibration and performance evaluation, including XL-80 laser interferometer, QC20-W telescoping ballbar system, XR20-W rotary axis calibrator and AxiSet™ Check-Up.

KMTC has a very strict quality control where each machine has to be calibrated twice: in manufacture and at the client site before it goes into production. Some large machine tools need to be dismantled after first calibration in manufacture, and calibrated again after re-assembly on site. Mr. Yang, supervisor of KMTC Metrology Centre, says “We used to adopt laser interferometers from another supplier before we started the partnership with Renishaw. Although the other supplier"s system performance was good, it was a problem when travelling to customer sites as we had to carry the full system kit in 3 large cases. We found many advantages when we switched to Renishaw"s first generation ML10 laser interferometer system which was compact and portable. We now widely use Renishaw"s latest XL-80 laser interferometer system in our production and benefit from its extended functionality.” KMTC has purchased 18 laser interferometer systems.

In KMTC"s current machine tool models, the accuracy and resolutions are up to 3 µm/m and down to 1 µm/m respectively. KMTC engineers are now able to finish the calibration on an axis of 2 to 3 metres travel distance in 30 minutes.

Axis length can be up to 60 metres on some models. Renishaw"s XL-80 laser interferometer offers accuracy of ±0.5 µm/m at normal environmental temperature. It can provide a resolution of 1 nm at a speed of 4 m/s as well as measuring distance up to 80 metres, which is long enough to satisfy most of the machine tools manufactured.

Rotary axes are becoming more popular in use with the growth in 5-axis machine tools. Conventional rotary axis assessment is not only time consuming but also requires skilled operators. Mr Yang said “We used to adopt a multi-tooth indexing table working with a quasi laser tube or a 24 face prism with auto-collimator to measure positioning accuracy of rotary axes. During the measurement, the upper half of the multi-tooth indexing table is lifted off manually and turned to a defined measuring angle. Then, we counter rotate the rotary table by the same angle to re-align with the laser tube. As a result, the errors can be measured. The accuracy of this approach is quite high, up to ±0.2 arc seconds but the tradeoff is time consumed; even an experienced technician has to spend one day to complete the measurement. The 24 face prism projects images on its reflective surface via the light tube. However the limitation is the measuring angle interval must be a multiple of 15 degrees.

The Renishaw XR20-W rotary axis calibrator has transformed the way we calibrate rotary axes on machine tools. The XR20-W works with the XL-80 laser, allowing the measurement to be completed within 2 hours, reducing labour costs. The operation is quite simple, available with a software user interface in Chinese language, where operators with basic computer knowledge are able to get started quickly."

The Renishaw XR20-W rotary axis calibrator employs wireless operation where data capture is synchronized to axis movement, with accuracy up to ±1 arc second, allowing automated measurement at any defined angle interval. All calibrators are factory calibrated and delivered with traceable certification. The XR20-W also supports off-axis measurement, allowing measurement even when the calibrator is not directly installed on the rotary axis pivot point. It is one of the frequently used functions by KMTC.

“The XR20-W features many improvements over its RX10 predecessor, including Bluetooth wireless technology which makes the data capture process more reliable. Renishaw has a strong reputation in metrology so some of our customers specifically request that we use Renishaw"s calibration products for commissioning, despite us explaining that traditional methods, such as multi-tooth indexing table, are able to offer comparable accuracy too", concluded Mr Yang.

Apart from laser interferometers, KMTC has also started to incorporate use of the Renishaw QC20-W ballbar system into its production. With a simple and quick ballbar test a user can identify the overall performance of their machine tool, as well as diagnosing problems. This enables customers to measure conventional 3-axis machine tools in accordance with ISO 230-4.

Renishaw has launched Ballbar Trace software, which it offers to existing ballbar users for free. This provides verification for 4 and 5-axis machine tools in accordance with ISO 10791-6 using XCal-View data analysis software.

KMTC also uses Renishaw"s AxiSet Check-Up to perform a fast and accurate health check of rotary axis pivot points on multi-axis machine tools, and automatically update parameters and compensations for rotary axis pivot point position errors. This has greatly improved the precision performance of 5-axis machine tools.

Renishaw sales engineers are always very helpful and provide invaluable technical knowledge and support. They always respond to us quickly and provide useful suggestions. They are happy to share information about updates and notify us of new products, which is one of the key reasons why KMTC and Renishaw maintain such a long term partnership.

KMTC is capable of developing systems with technology and specification comparable with the top manufacturers in the global machine tool market. Mr. Liang Feng Peng, Vice President of KMTC said "We have produced parts such as bearings and accessories for some German manufacturers. In future, KMTC will continue the development in industries such as wind power, automotive, aerospace and engineering machinery. At the same time, we will allocate more resources in horizontal machining centres. We have recently provided a custom solution of automatic production lines for a well-known automobile parts manufacturer."

Manufacturers encountering technical issues during machine tool measurement need support and guidance to help them achieve optimum measurement results. “KMTC has been collaborating with Renishaw for more than 10 years. Renishaw sales engineers are always very helpful and provide invaluable technical knowledge and support. They always respond to us quickly and provide useful suggestions. They are happy to share information about updates and notify us of new products, which is one of the key reasons why KMTC and Renishaw maintain such a long term partnership." Mr Yang said.

Kunming Machine Tool Company Ltd (KMTC), a subsidiary of Shenji Group, is a leading machine tool manufacturer in China. Established in 1939, KMTC has successfully developed over 400 products over 70 years, among which was China"s first precise horizontal machine centre and high precision jig borer. KMTC is in the ‘Top 100 Chinese Companies of Excellent Quality". Its product lines cover jig borer, floor boring and milling machines, planer boring and milling machines, horizontal boring and milling machines, gantry boring and milling machines, horizontal machining centres and machine tool accessories.

Kunming Machine Tool Company Ltd, China, (KMTC) has developed a variety of ‘China’s first’ high performance machine tools, leading the development of machinery and the machine tool industry in China. As a market leader in metrology, Renishaw has provided KMTC with advanced solutions in machine calibration and performance evaluation, including XL-80 laser interferometer, QC20-W telescoping ballbar system, XR20-W rotary axis calibrator and AxiSet™ Check-Up.

Lathe slides are designed to resist only turning forces which is usually directly down onto the slide. You are milling which puts loads on the slide it wouldn"t normally see. Make sure that the gibs on your slides are snugged up to reduce any lift or lash and if you don"t intend moving the slide during your milling, lock it up tight.

Another thing I would do it add some support to the rear of the table. If you can fix an angle or block to the base and clamp it down then you"ll find it a lot more rigind.

Finally your clamping of the part leaves a lot to be desired. You"re milling a long way from the clamp and if that flat bar is even slightly bowed it will hinge all over the place. You could put a second clamp on it ir if you don"t have the room for that without fouling the cutter try at least putting some low level stops in the dis-used slots to prevent hinging. Another thing you could do is put a piece of paper under the part near each edge of the table. That will improve clamping forces a lot.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Japan was pretty much on board making quality stuff by the early 1970"s. We started seeing Honda motorcycles in the early 60"s. At first the Japanese machines had more bells and whistles than the made in US or European machines and were generally high quality. However, the early Japanese machinese were on the light duty side. When put under a load the Jap stuff was a bit wimpy compared to the domestic machines. Under light loads the Jap machinese were fine. This changed by the 80"s and the "best" Jap machinese were as good as any. Today, I"m proud to own Japanese stuff but still drive Fords.

Not so sure about Taiwan. My 9 x 42 JET mill was made in 1999 in Taiwan and has performed fine for me. I think the Taiwan stuff is somewhere between Japan and China from a quality point.

My 13 x 40 JET lathe was made in China and was bought new in 1999. It has served me well and I expect (hope) it will continue. Chinese machines are not that bad in my opinion. Those screwless vices and parallel sets that ENCO sells are great. The Chinese crash and burn when it comes to cutting tools and house hold items. I do not believe the Chinese use real high speed steel in their cutting tools. Their cutting tools are fine for machining low carb steels and nonferrous materials but not when machining D-2. Beware of anything made in China and purchased in your local hardware store.

I think you will be fine with you mill and the vise and turn table that came with it. My advise for running Asian made machines and tools is take it easy. Their short commings will surface when under stress like taking heavier cuts than the machines was intended or capable of. People get into trouble when they think there equipment is indestructable.

PO Box, APO/FPO, Africa, Alaska/Hawaii, American Samoa, Armenia, Azerbaijan Republic, Bangladesh, Bhutan, Bosnia and Herzegovina, Brunei Darussalam, Cambodia, China, Cook Islands, Ecuador, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Greenland, Guam, Guernsey, Jersey, Jordan, Kazakhstan, Kiribati, Kyrgyzstan, Marshall Islands, Micronesia, Moldova, Mongolia, Montenegro, Nauru, Nepal, New Caledonia, Niue, Pakistan, Palau, Papua New Guinea, Republic of Croatia, Russian Federation, San Marino, Solomon Islands, Svalbard and Jan Mayen, Taiwan, Tajikistan, Tonga, Turkmenistan, Tuvalu, US Protectorates, Ukraine, Uzbekistan, Vanuatu, Venezuela, Vietnam, Wallis and Futuna, Western Samoa

TJR Precision Technology, a known manufacturer of Rotary tables, is found in 2009. Since its establishment, we have focused on the R&D and manufacturing of high-precision key components for CNC machine tools, such as CNC Rotary Table, Rotary Table, index Table, and other accessories with high precision and stability. Our products are mainly used in the aerospace industry, high-tech electronics industry, automotive component manufacturing, multi-faceted spiral processing industry and various industrial machinery. We have the best research and development team that integrates the applications of machine centers and Rotary tables, and have the strictest quality control to ensure the highest quality. We also have the most active customer service to make the Rotary Table work in the optimal condition....

TANSHING ACCURATE INDUSTRIAL CO., LTD. is one of the Rotary Table and index Table manufacturer. We have passed the ISO9001 quality system certification. We insist on the concept of "Quality first, prestige important", and after continuous innovation and development, the products have been widely used in many fields. Not only the products sold well in the world"s market, but also have enjoyed a good reputation in the markets. We offers the customers with Rotary Table of excellent quality and best service, hope to build a new brilliant with you in the future.

Spintop has been specialized precision Rotary Tables for more than two decades. Our CNC/NC Rotary tables are designed with many different size apertures, Table diameters, and mounting options to provide the ideal solution for your industrial automation application. Our products are widely used in industrial robots, fiberoptics and photonics, vision systems, machine tools, semiconductor equipment, medical component laser machining, electronic manufacturing, and other high-performance industrial automation applications. Welcome to visit our showroom to view relative products: CNC Rotary Table, Double Axis Tilting CNC Rotary Table and Tailstock Rotary Table, NC Rotary Tables and more. If you need the further details of our Rotary tables, please kindly contact us at any time.

Found in 2000, Ocean Techologies Co., Ltd. is one of leading manufacturers and supplier of drilling EDM and EDM parts such as wire EDM, Rotary Table, PNC drilling EDM, ceramic guide, and so on. Also, we obtained CE certificated. In 2005, we sold over 200 sets machines worldwide. After years" efforts, we have become one of the leading manufacturers in this field. To meet the severe competition and to serve the customers more. We are strict to our quality of product standard in order to make customer have good right. Besides, we also provide excellent service to our customer. We guarantee we must make you satisfy with our product and service. Welcome to visit our website and hope you could get the products which you are interested in or more information.

On a manufacturing area of 12,000 square meters, HOSEA PRECISION has been focusing on producing high precision Rotary tables that meet the quality standards in western markets. Our Rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers. More and more manufacturers across Europe cooperate with us and make use of our 5 axis Rotary tables, Rotary Table and other products. With a Hosea Rotary Table you always know what you get: a quality product that was manufactured in a quality production process - from start to finish. With this attitude and as a member of the Taiwan Machine Center Alliance, we continue to provide the best products for the high-tech machine tool industry of today and the future.

Multiplas Enginery Co.,Ltd. was established in 1988 and is the professional injection molding machines and Rotary Table manufacturer in Taiwan. We believe that our professional experience and reasonable prices will help you in your market bring much more business for you. Your suggestion always welcome, and we are looking forward to cooperating with you and a mutually profitable relationship. If you are interested our products, contact us, we will offer you the best price and superior high quality. We wish to have a long term business relationship with you.

Pan Uni Technique Co., Ltd. is a factory specializing in Rotary Table, plastic welding machines, PP case sealing machines, folding machines, plastic forming machines and so on. Recently, with the speedy technology advances, keen competitive markets and strict quality standards, the materials for plastic products have been keeping on innovating and developing. To keep up with the trends, we replace the human-manipulated machines with advanced and wholly automatic machinery and make strict demand on processing quality and figure examination. Only making relentless efforts on the fields of technique and production management can we meet the customers" need. If you want to get more information about our products, please feel free to contact with us.

Saynen manufactures CNC Rotary tables for machining centers with rich experiences, vast industry knoledge and expertise. Based on our nearly 50-year experience in this field, we can produce high-precision Rotary tables. All our products can be used in both vertical & horizontal directions to accommodate the requirements of various machining facilities. To ensure our quality, we developed an inspection system with the Mechanical Industry Research Lab at Industrial Technology Research Institute. Due to the mentioned experience and new investment, we are able to produce major parts in house, under strict QA system in order to best control the quality. We deeply believe that our Rotary tables can compete with those similar products made in Japan, USA, Germany and so on. Contact us for more!

Kinn Shang Hoo Iron Works has spent 40 years of experiment and research to manufacture food processing machinery, adopt automatic machines to reduce cost and lower the price for the customers. Our food machinery including meat mincer, Rotary Table, oven, meat slicer machine, mixing & seasoning machine, boiler, smasher, dryer and shaping machine. Due to our consistent high product quality and reasonable price structures, our products have won popularity among clients around the world. Now express heartfelt thanks to the supports. We will increase output to reduce the machines’ cost and as soon as possible to improve the quality of products. To supply a reasonable price for customers. Thanks for comments.

In the CNC Rotary Table industry, Exact Machinery is a national-wide famous provider who specializes in the design, production and sale of a variety of Rotary tables. All tables can be position in horizontal and vertical used. Each model with a standard-size tabletop fitted with or without T slots and a precision center pilot hole for alignment and clamping of the fixture or piece parts. With our years of experience and technical know-how, we are confident that we have the ability to supply CNC Rotary tables available to suit most applications in the metal cutting industries. We also provide lots of different Rotary tables for special application such as with pallet changer system by request. Please feel free to inquiry us to get more information.

Gin Chan Machinery Co., Ltd. was established in Taipei in 1988. With an expert team dedicated to the production of milling and grinding components and accessories, a first 5000m² factory with 70 employees was established.

In 1997, a second branch of Gin Chan was established in Dong Guan City, China. The goal was to expand the production of mold and die accessories as well as increase sales. This factory has 10000m² floor space and about 200 employees working there.

We are always striving towards product improvements, and so Gin Chan received ISO9001 certification in 2003. At the same time, Gin Chan started implementing a new “Continuous Improvement and Employee Empowerment” management system.

A proverbial saying that "the devil’s in the detail " which explain no matter what a work likes painting, art craft or architecture, a perfect work is born with a series of details.

GANRO make every Rotary Table based on this conception from every single part to a complete Rotary Table. Even a small screw will decide if a machine center can achieve the most profitable function.

From 1978, Golden Sun Industrial Co., ltd. holds the spirit of the devil’s in the detail to make Rotary tables released in the market. With the advanced technology, GANRO Industrial Corp. was established in 2008 to meet the high standard and demands from our customers over the world. The spirit of pursuing perfection of Golden Sun is fully passed on to GANRO. We stand on solid ground and innovate more...

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC Rotary tables (the 4th and 5th axis). The main products are CNC Rotary Table, CNC index Table, and other accessories with high precision and stability.

The products are mainly applied in aerospace industry, high-tech electronics industry, automobile parts manufacturing, multi-faceted spiral manufacturing, and other mechanical industries.

We have the best research and development team that integrates the applications of machine centers and Rotary tables, and have thestrictest quality control to ensure the highest quality. We also have the most active customer service to make the Rotary Table work in the optimal condition.

Hann Kuen is a specialized manufacturer of milling spindle, drilling spindle, milling spindle units, drilling spindle units, tapping spindle units, various spindles, hydraulic slide, cutting tools and relative machinery accessories with more than 30 years" experience. Besides manufacturing, Hann Kuen also represents many well-known brands from Taiwan and worldwide, i.e. SAFEWAY- vise、STANNY-boring system、CHANDOX-chuck; SKODA-live center from Czech Republic、NAREX-milling angle head from Czech Republic、BLAKE-centering indicator from USA etc…

The body material of our boring and milling head unit is made of FC30 casting , which is under highly precision of process by boring and honing. The Alloy Steel is under process of heat-treatment as spindle parts and assembled with NSK or SKF bearing as...

We are the professional CNC machine tool company that specialized in manufacturing tooling systems of machine tools and marketing our products by brand "RBH" & "ACmaxin" in domestic & overseas markets.

The production line has CNC machine centers, CNC turning lathes, CNC grinding machines and also the precise measuring devices to control our superior quality.

In the recent years, the demand for machine tool has increased in the whole world. After the blooming in European and American market, the Asia area is also very prosperous. The name “Sauter” is synonymous with quality and innovation all over the world. For Decades, Sauter has been one of world’s leaders in the development and production of innovative tool carrier systems. This reputation gained in part by utilizing the latest manufacturing technologies, production techniques and technically experienced, highly motivated personnel.

The Machinery industry in Taiwan already is upgrading into the precision machinery and towards high accuracy, high speed and compounded machines. Further more, it formed the complete and compact industry village phenomenon....

GSA TECHNOLOGY CO., LTD. established in 1978, from time to time, our growing of devotion work stable, keeping in mind of honesty, faith, profession and innovation, nonstop communication and promotion of critical quality procedure, ensure every products could meet high quality of duration and precision.

Further we display our products at IMTS-Chicago, EMO-Hannover, JIMTOF-Tokyo and TIMTOS-Taipei, and receiving reputation from the customer of the worldwide.

To meet the request of customer, both upgrading the quality of our produces and purchasing new machinery of testing and inspection, collecting update technology to develop value-added products.

detron Machine Co., Ltd. is a professional manufacturer of CNC Rotary tables. With the company"s policy of sincerity, practicality, professionalism and perseverance, we have dedicated ourselves to technological R&D and innovation. This is combined with our rigorous quality control system to ensure each Rotary Table from detron will present outstanding quality. In addition, we have also invited several machine tool design engineers to join together with our R&D team. This joint force enables us to achieve the best possible integration between the machine tool and the Rotary Table, therefore maximizing the Rotary Table performance. The outstanding quality of detron CNC Rotary tables is competitive with imported products and this is the major reason why detron CNC Rotary tables have been recognized...

MATSUMOTO MACHINE CO., LTD. is a manufacturer and sales of peripheral equipment for machine tools, Hydraulic chuck and 2 to 9 jaws and/or long stroke special chucking systems High speed High accuracy NC Rotary Table.

Taiwan Winnerstech Machinery Co., Ltd. was established as a job-shop in 1992 from a town at Taichung in the central Taiwan. With the spirit of "Pursuing Excellence, Winning Respect” we take it as the philosophy of enterprise.

Taiwan Winner has introduced AP & APC series Tapping/Drilling machine to the worldwide market with the leading brand of "Winner", are extremely popular among users since 2008.

Taiwan Winner designs the most appropriate machines to meet the customers’ request. For full range of VMC-A/D/E/Lseries vertical machining centers have been completed by sizing from 650mm up to 2100mm for X-axis travel.

Gn Chan Machinery Co., Ltd. was established in Taipei in 1988. With an expert team dedicated to the production of milling and grinding components and accessories, a first 5000m² factory with 70 employees was established.

In 1997, a second branch of Gin Chan was established in Dong Guan City, China. The goal was to expand the production of mold and die accessories as well as increase sales. This factory has 10000m² floor space and about 200 employees working there.

We are always striving towards product improvements, and so Gin Chan received ISO9001 certification in 2003. At the same time, Gin Chan started implementing a new “Continuous Improvement and Employee Empowerment” management system.

In Taiwan, AENY INTERNATIONAL INC. is the professional maker of ATC, and various key components of machine tools as well as SPM. We have top R & D design / mechanical / electrical engineering teams, many well-trained assembly technicians plus an excellent customer support team to serve our valuable customers.

What"s more important is, we offer customers a total solution of all the supplied products by doing market & customer driven design engineering, manufacturing, assembly, inspection, quality assurance, logistics and customer support. In other words, we are supplying the value-priced products to be globally competitive in order to ensure total customer satisfaction.

CNC Rotary tables are attachments for machining centers. It is known as the 5th axes in Taiwan. A good 4th axis must basically possess the characteristics of “indexing accuracy” and “repeated accuracy.” In order to achieve high accuracy, the 4th axes must have good warm gears and warm sets, as well as precision construction. Based on our nearly 50-year experience in producing high-precision gears, we are able to produce high-precision warm gears and warm sets. In addition, we specially purchased a CNC boring machining center from Toshiba, Japan to produce high-precision construction. Also, to ensure our quality, we developed an inspection software with the Mechanical Industry Research Lab (MIRL) at Industrial Technology Research Institute (ITRI). Due to the mentioned experience and new investment,...

NCT tables are designed with axial - radial bearings to provide excellent load and thrust capabilites. The hydraulic clamp produces a massive holding power and the housings withstand any twisting or flexing. The large center bore series provides for added flexibility when adding work holding devices.

1. Hydraulic Clamping adapted wholly circular hydraulic clamping system. It can assure the heavy and steady cutting without any deviation from the center.

2. The feature of wear resistant alloy double-lead worm gear is high mechanical efficiency of power transmission, high indexing accuracy and easy adjusted on the backlash.

1. Hydraulic Clamping adapted wholly circular hydraulic clamping system. It can assure the heavy and steady cutting without any deviation from the center.

2. The feature of wear resistant alloy double-lead worm gear is high mechanical efficiency of power transmission, high indexing accuracy and easy adjusted on the backlash.

2. The feature of wear resistant alloy dual-lead worm gear is high mechanical efficiency of power transmission, high indexing accuracy and easy adjusted on the backlash.

1. Pneumatic clamping adopted the disc of clamping system to enlarge clamping force and can ensure heavy-duty continuous cutting. The feature of wear resistant alloy Double-Lead Worm Gear is high mechanical efficiency of power transmission high indexing accuracy and easy adjusted on the backlash.

NCT-RB Tables have a rear mounted drive motor, especially suited for use on compact machines and where the workspace is limited. High rigidity and excellent thrust force capabilities due to its optimal structure design.

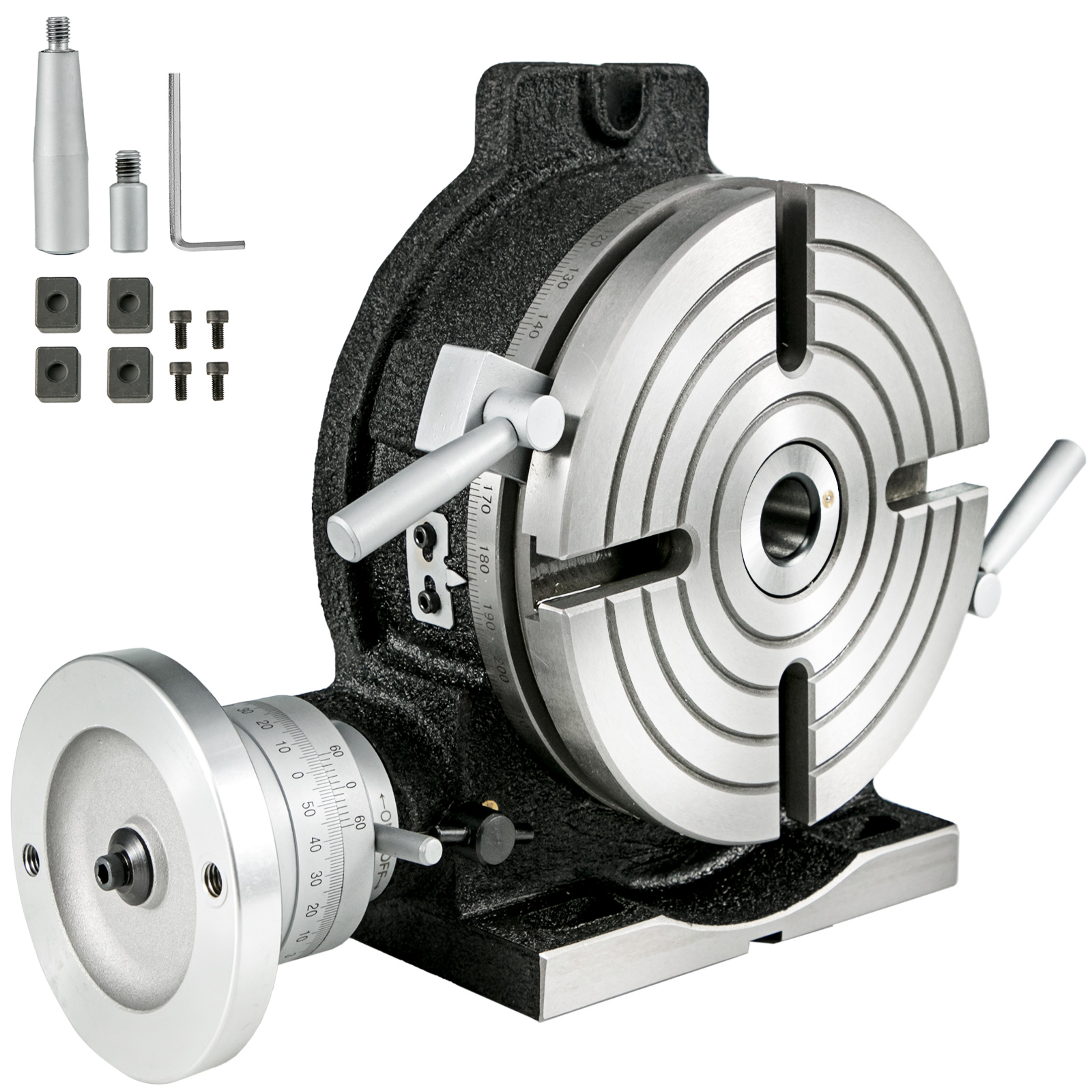

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

* To create large-diameter holes, via milling in a circular toolpath, on small milling machines that don"t have the power to drive large twist drills (>0.500"/>13 mm)

* With the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

when I was young, strong, healthy, and thought nothing of lifting it, a 10" H & V was my first choice. I still think it was a good choice for the work I mostly do, and this is where you may decide to compromise. If you do small work, an 8" table is much lighter and more convenient to set up. Stood vertical, it interferes less with the spindle to reach center. I don"t think a 6" is a good choice unless you know you will only be working miniature stuff. You use a considerable percentage of a small table just for set ups and hold down clamps on a lot of work, and a small table does not leave much room.

I like 90:1 gear ratio for circular milling, which is presumably your primary interest with a rotary table. My 10" table is 90:1, and that is a pretty good ratio for milling diameters (hand cranking) out to 12" or so. My 20" table is also only 90:1, and out near or past the rim (I do one part at 32" diameter) that always seems _very_ coarse.

If most of your work is small, round to begin with, and will actually be dividing work, where you index the table, lock it, and then drill a hole or mill a slot with the machine axis drive, you might find a dividing head more useful. For instance, I"ve made gears on a vertical rotary table, and in a spin index. On the table, you need an insert collet chuck or other arrangement in the center hole to get the work out far enough to clear the cutter. It"s a lot more convenient on a dividing head. OTOH, I don"t find it fun or convenient to do much circular milling on a dividing head if the work diameter is much over a few inches.

Dividing heads typically are 40:1, so faster to index, position to positon. But the milling capability on a radius is limited by the "coarse" ratio to smaller diameters, as is the usual work holding (collet or chuck) arrangement. A dividing head will tilt from below horizontal to past vertical, so you can mill, drill, bore or shape profiles at any angle in between.

an 8" H & V with dividing plates and set up, can usually be arranged somehow to do most of the work you might want to do on it. It is relatively light to move, and convenient to set up with reasonable space (spindle clearance, e.g.)limitations to be considered. A little bigger (10") is better, if you will ever need the capacity.

This tailstock was designed for use with my rotary table. This has a centre height of 85 mm. I have made the height fully adjustable from 20 mm to 90 mm since it may be useful a...

8613371530291

8613371530291