how to use rotary table quotation

If you send the data entered in the contact form by clicking on the following button, you agree that we may use your details to answer your enquiry or contact you. As a matter of principle, data will not be passed on to third parties unless applicable data protection regulations justify such a transfer or unless we are legally obliged to do so. You can revoke your consent at any time with effect for the future. In the event of revocation, your data will be deleted immediately. Your data will otherwise be deleted once we have processed your request or the purpose of storage has ceased to apply. You can inform yourself at any time about the data stored about your person. Further information on data protection can also be found in the data protection declaration of this website.

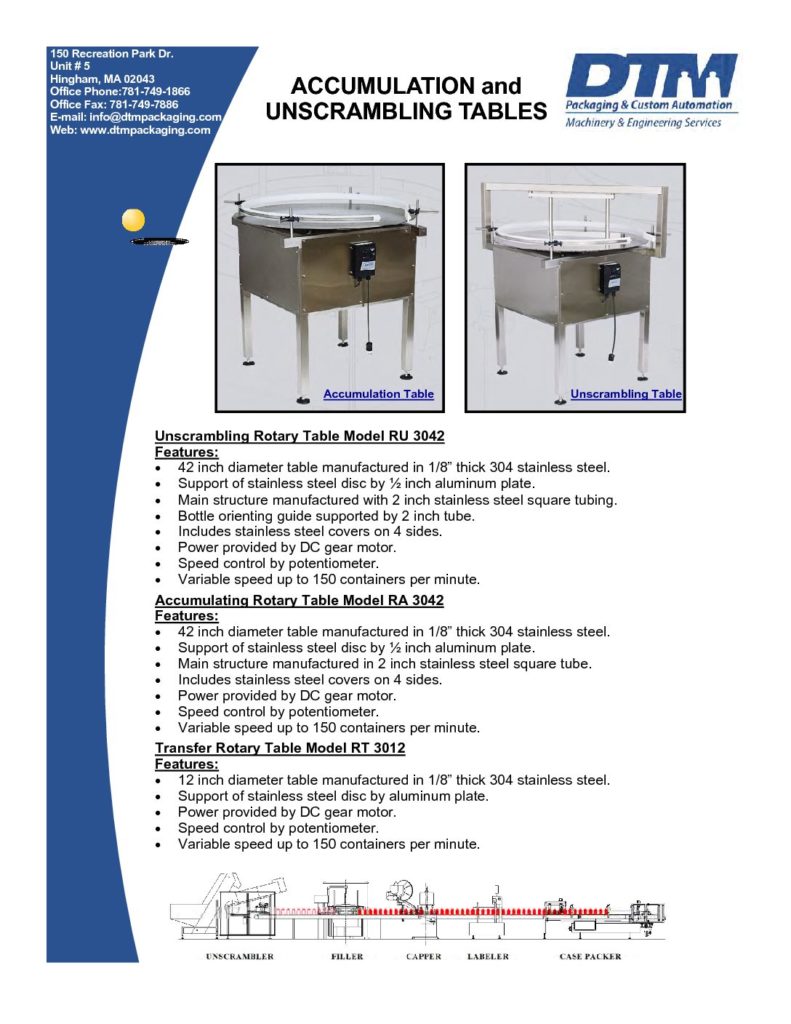

Located at the entrance of a conveyor belt, or directly to the machine that has to feed, performs the function of “station of accumulation and distribution”. The products can be loaded manually or by conveyor belt. The adjustable deflectors allow you to sort and align products to the food evenly and without interruption the machine that receives them. Positioned at the exhaust of a conveyor belt or in the output of a packaging machine, filling machine, labeling etc., Performs the collection and accumulation of products function. The rotary tables are equipped with a speed variator to adapt to the various needs. The rotating disc may be provided in a slippery plastic material or stainless steel.

The Cup Rotating Table is situated at the end of the packaging line they are used as an “Accumulation station” to ease the product unloading stage at packaging machine output and to help the operator in pickup and boxing operations.

The end-of-line rotary tables are made completely in stainless steel, with concave or flat trays and mechanical or electronic (inverter) speed variator.

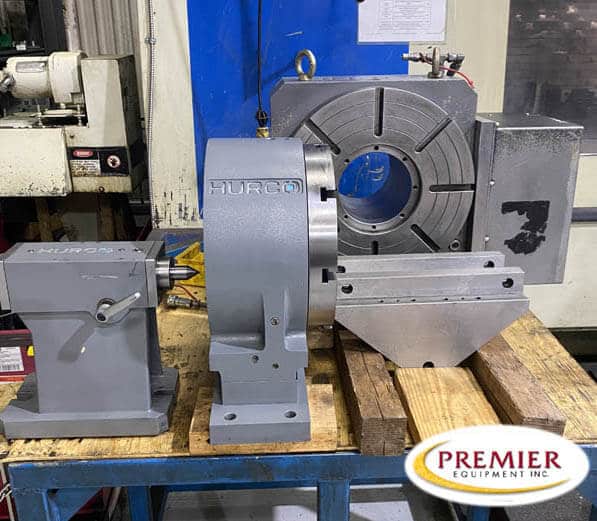

For medium to large parts, the VH-11 rotary table has an 11" (280mm) diameter platter with a 6.75" center height. A 10" or 12" chuck or fixture can easily be bolted to the table using the six precision T-slots. Its large 4" through-hole can be used for bar feeding and special fixture-locating requirements. The spindle and worm have two bearings for front and back support. As always, the worm wheel is helically cut and throated for greater surface contact between the wheel and worm. There is an optional 10" or 12" manual 3-Jaw chuck and adapter plate available as well as a manual or pneumatic tailstock with matching center height.

The Index Designs VH-11 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

For holding medium to large parts or fixtures, the HRT210 rotary table is the answer. This rugged, heavy-duty table can be mounted vertically or horizontally for added versatility. Chucks and fixtu...

Our HRT210SS Super Speed rotary table uses a heavy-duty cycloidal drive system to provide a maximum indexing speed of 490° per second – nearly five times the speed of our standard HRT210. The unit’...

Technitron has been integrating rotary tables and accessories on machine tools since 1992. Over the past 30 years Technitron has pioneered new technology and techniques to allow us to set the industry standard for rotary table and accessory integrations. By utilizing our vast experience, we have been able to meet and exceed our customers’ expectations. No other company has our experience on a variety of machines and controls.

Technitron is dedicated to supplying high quality Integration Services to the Machine Tool Industry. Our Turn-Key Integration Services are designed to enhance the productivity from both new and existing machine tools. We have installed more than 3500 rotary tables to date.

Sector 37D, Gurugram, Haryana 122006, Gurgaon, Dist. Gurugram Nath Tools Company , Garauli Khurd, main Pataudi Rd,, Sector 37D, Gurugram, Haryana 122006, Gurgaon - 122006, Dist. Gurugram, Haryana

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Hofmann Rotary Tables has developed a solid reputation for high-quality and affordable indexing devices, rotary tables, and tailstocks. Superior Spindle is proud to be a factory service partner for all, including the HPRS, HTH, R, and WR series.

When you experience issues with your Hofmann products, you can count on our ISO-certified and factory-trained technicians at Superior Spindle. We can repair all types of NC and manual indexing devices, tailstocks, and chuck stands.Our average turnaround time is usually between 10 and 14 business days.

We know that downtime is costly and strive to repair your equipment as quickly as possible. If you’re in an emergency situation, we also provide expedited repair services (based on part availability) with a turnaround time between 1 and 3 business days.

Our Repair ProcessDisassembly & Free Evaluation: When you send your Hofmann rotary table to us, our team will fully disassemble it in our HEPA Class 10,000 cleanroom and evaluate all components for signs of wear and tear or damage.

Repairs: Once you accept your quote, our team will get to work repairing and replacing components, including handles, spears, worm drives, bearings, and more.

Testing & Inspection: After repairs are complete, our team tests the rotary table to ensure optimal performance. Before your table is shipped back to you, our Quality Assurance team will perform a final inspection.

Shipping: All shipping and handling is covered by Superior Spindle. When you receive your newly refurbished table, we will provide you with a list of all components that were repaired/replaced as well as recommended maintenance.

Ourcutting-edge facility allows us to offer a wide array of additional services. Beyond our standard and expedited Hofmann rotary table repairs, we also provide vibration analysis, engineering recommendations, and retrofitting. Superior Spindle understands precision and is able to hold tolerances to 1 micron.

At Superior Spindle, our top priority is your satisfaction. As an ISO-certified business, we ensure quality every step of that way, offer exceptional turnaround times, and back every repair with a peace-of-mind warranty.

Superior Spindle has been a trusted provider of Hofmann rotary table repairs for over a decade and provides services to manufacturers throughout North America. If you’re experiencing issues with your rotary table, or are looking for design upgrade recommendations, call (734) 224-4778 orfill out our online formtoday.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

American Block offers a complete line of drilling rotary tables that range from 17 ½ to 60 ½ . These tables are designed to withstand the harshest drilling conditions. All rotary tables feature a fabricated frame, heavy duty main thrust bearing and precision machined spiral bevel gear that results in superior strength, toughness and durability.

American Block can also provide unitized rotary table assemblies (IRD). Our unitized skid packages are ideal for new builds or can be retrofitted to existing rigs. Featuring a heavy-duty oilfield skid and an extend life transmission. The rugged design ensures that when the equipment is mounted it remains rigid during operation and rig moves. Other rotary table options include hydraulically operated tables and high torque tables (25% more torque), which are ideally suited for top drive operation.

Portal and virtual trade fair for the industry, with Industry Plaza you will compare the products and get in touch with industrial suppliers, in order to get free quotes or information.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

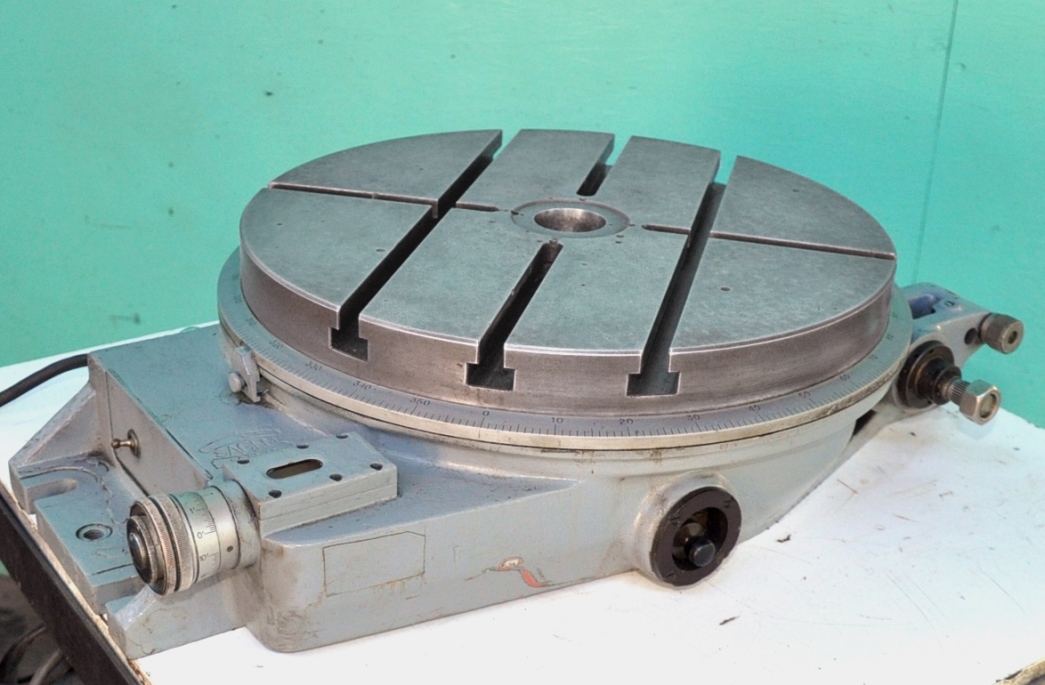

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

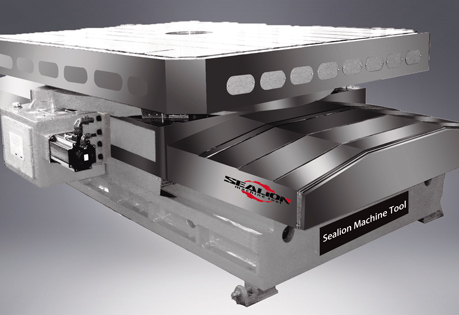

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product"s lifetime, Matsumoto Machine Corporation (MMK) has taken a pragmatic two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Founded in Japan in 1948, Matsumoto Machine Corporation is a technology-leading provider of innovative, high quality jaw chucks and numerically controlled rotary tables used by industrial machine tool makers throughout the world. A key feature of MMK"s CNC rotary tables is a patented worm and wheel gear assembly developed by OTT GmbH, Germany. Unlike double lead worm gears, the OTT worm and wheel gear is able to minimise backlash, ensuring outstanding accuracy and long life, efficiency and durability.

Shaped in order to maximise gear surface contact area, thereby reducing adverse surface pressure effects, the OTT worm gear teeth are split into separate right and left parts (shank worm and hollow worm) connected by a span ring. This unique structure enables backlash adjustment simply by reducing the distance between the two parts. This design also ensures that only one side of a worm gear tooth is in contact with the wheel gear, leaving a clearance on the other side. As a result, the 2-piece split gear design will not seize up, even with zero backlash.

A further advantageous characteristic of the MMK CNC rotary table is a large diameter through-hole in the table spindle. This greatly increases machine versatility and rigidity, supporting a wider variety of chucks and jigs and the machining of longer workpieces.

By enabling most metal-machining operations to be undertaken on a single machine, the benefits of MMK CNC rotary table are far-reaching. These include the time and cost saving of single machine set-up and single fixturing setup, reduced parts handling and the elimination of tolerance errors as workpieces pass from machine to machine.

Of critical importance in this one-hit machining centre scenario is ensuring the high accuracy of CNC rotary table indexing and control throughout its working lifetime.

As with any form of precision equipment that is integrated into a machining centre by a third party machine tool maker, and which in turn is used by an end user in any number of industrial sectors, assuring consistent accuracy and performance over time presents a challenge.

As with a machine tool"s linear XYZ axes, the rotary axis is just as susceptible to uncontrollable events that may introduce angular positioning or axis alignment errors. Risking the production of defects in finished parts, these errors can be due to a number of reasons including, mistakes made in the initial machine installation, impact damage caused by collision or general wear-and-tear in use.

With its global reputation for product quality and design innovation, MMK therefore sought to equip its CNC rotary tables with a highly accurate and reliable means of tracking and controlling the indexing of its product throughout its lifetime, irrespective of the type of machine tool, workpiece complexity and duty cycle.

At the same time, in an increasingly competitive global market for CNC rotary tables, MMK also wanted to further enhance its product quality inspection processes. Specifically, the company set itself the task of augmenting index angle measurement as a key component of pre-shipment quality assurance procedures.

To provide machine tool makers and users with the ability to accurately track and control CNC rotary table indexing, MMK elected to integrate Renishaw"s super-compact TONiC™ non-contact optical incremental encoder system. Simple to install and with a compact readhead measuring just 35 mm x 13.5 mm x 10 mm, the TONiC encoder presented MMK with a minimal footprint solution capable of supporting machine speeds up to 10 m/s and resolutions down to 1 nm.

The rotary table readhead was designed to be used in conjunction with Renishaw"s RESM, a one-piece stainless steel ring marked on its periphery with 20 µm pitch graduations and featuring the IN-TRAC™ optical reference mark. With its low profile, large internal diameter and wide choice of diameters from 52 mm to 550 mm, the high stability RESM ring provided MMK with a versatile and easy to integrate scale that is well-suited to the company"s wide range of CNC rotary tables.

For improved reliability and higher immunity to any scale degradation over time, the TONiC readhead incorporates third generation filtering optics, tuned for low noise (jitter) and further enhanced by dynamic signal processing. The outcome is an ultra-low sub-divisional error of typically ±30 nm. The TONiC encoder is compatible with industry standard controllers and features a detachable analogue or digital interface inside a robust D-type connector, which can be located up to 10 m from the readhead.

MMK selected Renishaw"s compact and lightweight XR20-W rotary axis calibrator to verify the accuracy of its rotary tables during manufacturing and immediately prior to shipment. The XR20-W was used in conjunction with Renishaw"s XL-80 laser interferometer to provide a non-contact reference measurement, independent of the axis under test, with an accuracy of ±1 arc second.

Motorised by a servo-controlled drive and with data capture synchronised to axis movement, the XR20-W requires no operator intervention during measurement. Being lithium battery powered and Bluetooth enabled, it ensures quick and easy setup, and the avoidance of trailing cable hazards. The calibrator"s modular design and flexible mounting systems allow far easier setup than alternative solutions and can be readily configured for a wide variety of rotary tables, chucks and spindles.

By integrating Renishaw"s TONiC non-contact optical encoder system into its CNC rotary tables, MMK has further assured the accuracy and reliability of its products in the field, along with an overall superior motion control performance. For a wide range of different machine tools and end uses, the rotary tables" combination of compact readhead and one-piece stainless steel ring scale has delivered a higher level of tolerance to dust, scratches, grease and oil, and a reduction in indexing errors. The encoder system"s ability to output highly stable position signals of unrivalled purity and ultra-low sub-divisional error have provided smoother velocity control, improved scanning performance and increased positional stability.

MMK"s introduction of Renishaw"s XR20-W rotary axis calibrator and XL-80 laser interferometer has reduced product measurement times by a half compared to conventional autocollimator techniques. Measurement procedures have been simplified and automated. Capable of taking accurate measurements at any indexing angle pitch, the calibrator enables evaluation of the accuracy of the worm and wheel gear-driven table for ultra-fine pitch measurement movements as small as 0.001°. This has allowed any loss of motion control or worm and wheel gear efficiency to be evaluated in detail and addressed. Product performance is now backed by a thorough analysis meeting ISO quality standards.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product’s lifetime, Matsumoto Machine Company has taken a pragmatic

two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

8613371530291

8613371530291