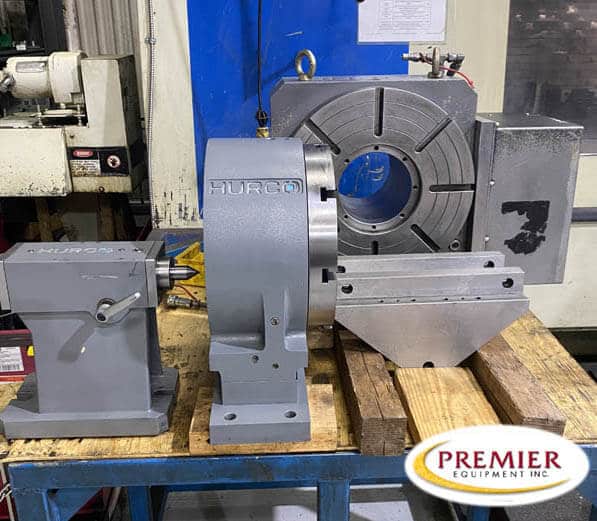

hurco rotary table brands

benchmark data from Modern Machine Shop magazine, 44% of the highest performing shops in the U.S. use 5th axis positioning. Just as Hurco led the industry in the transition from manual machining to CNC machining with the invention of conversational programming, we have led the industry in the transition from 3-axis machining to 5-axis positioning (or 5-sided machining). At Hurco, customer productivity (which leads to customer profitability) is the primary criterion we use when deciding where to devote our research and development resources. Decades ago, the Hurco engineering team determined that 5-axis CNC machining, in particular, 5-sided machining, could significantly increase productivity at job shops. We set a path to become the experts and revolutionized the industry with the development of control technology that optimizes the process for full 5-axis and 5-sided (3+2).

With 5-sided CNC machining, also called 3+2, you reduce setup time, increase accuracy, and expand your shop’s capability for future simultaneous 5-axis work. The key to our success in helping machinists make the transition from 3-axis to 5-sided machining lies within the conversational programming features of the Hurco control, such as Transform Plane and

When you invest in a Hurco 5-axis machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center due to the powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

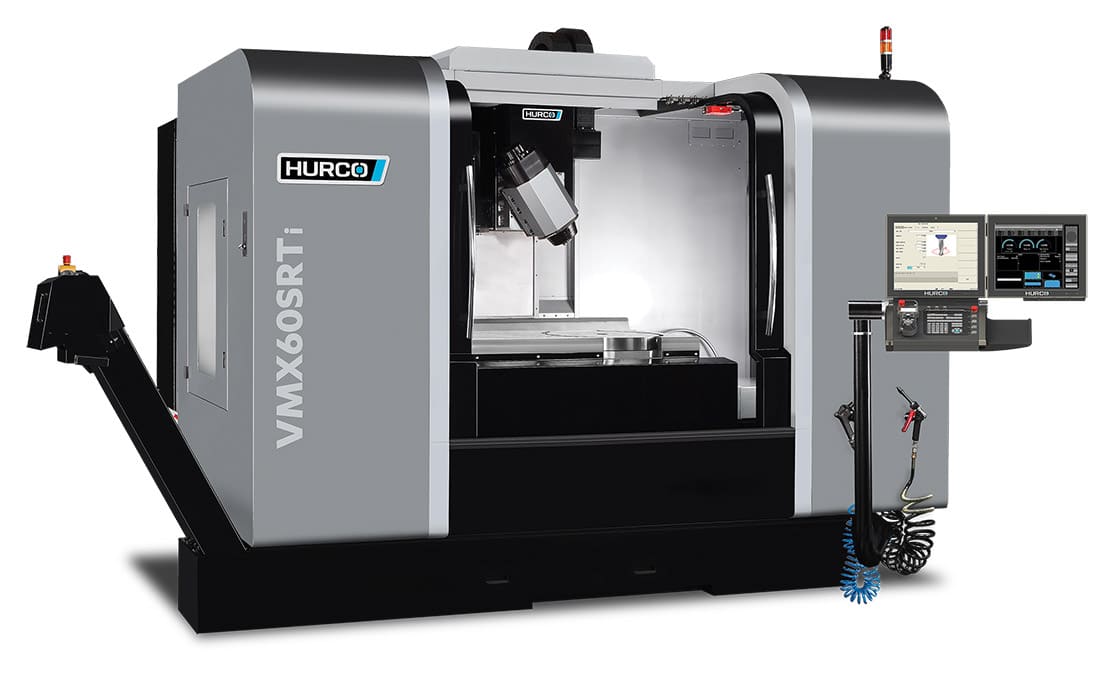

The SRT series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.Request PriceScroll to Machine Specifications

Hurco is an industrial technology company that designs, manufactures, and sells computerized machine tools to companies to companies in the metal cutting industry. Since our founding in 1968, we have pioneered the application of computer technologies for use in machine tools.

Click here to learn more about Hurco’s history. Hurco is focused on delivering its customers products equipped with technologies that help them increase their company’s profitability by increasing their manufacturing productivity.

The Hurco brand is our flagship brand that provides premium technologies and includes sophisticated 5-axis CNC machines and multi-axis CNC lathes in addition to vertical machining centers and turning centers.

MAX5 control powered by WinMax® leverages sophisticated technology to simplify complex processes for our customers. Additionally, the integrated control of the Hurco CNC machines provides customers with the flexibility to program parts using conversational programming or industry standard NC programming.

In addition to our CNC machine brands, Hurco Companies, Inc., has LCM, which offers a line of machine tool components and accessories, including CNC rotary and tilt tables, and swivel heads and electro-spindles. Hurco also opened an automation division in 2019 with a line of collaborative robots that provide the portability and flexibility high-mix/low volume manufacturing companies need to increase their productivity.

The executive offices and principal design and engineering operations of Hurco Companies, Inc., are in Indianapolis, Indiana, USA. We have manufacturing and assembly operations in Taiwan, the USA, Italy, and China. Our company sells its products through direct and indirect sales forces throughout North America, Europe, and Asia. The company has sales, application engineering support and service subsidiaries in Canada, China,

distributors to sell and service our CNC machines. We are proud these family-owned businesses have chosen to represent our products. Since Hurco is located in the heartland (Indianapolis, Indiana), our sales team travels a great deal to make sure all distributors have the information and tools they need to represent Hurco.

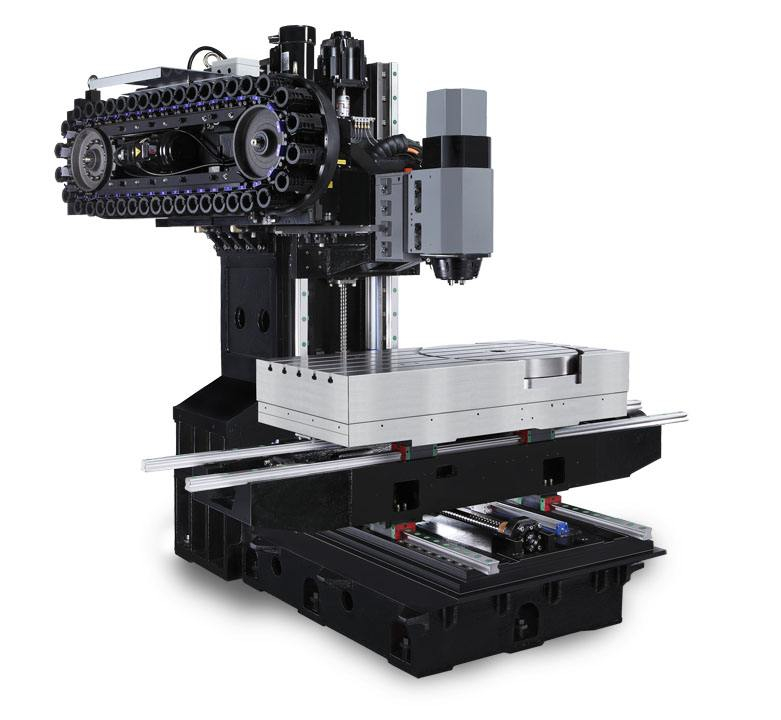

While some brands simply stick a trunnion table on a 3-axis VMC and call it a 5-axis machine, the Hurco U series machines are designed to be true 5-axis machines. If you have 5-axis positioning work on complex multi-sided parts where overall accuracy and reduced setup time are critical, you need a Hurco 5-Axis U Series machining center.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

TheHURCOSR series of5-axisCNC mills offers multiple advantages, starting with the machine"s design and configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Hurco’s Field Service Apprenticeship (FSA) is a two-year program that starts with a 12-week industry training which merges hands-on training and repair of CNC machines with classroom materials.

Hurco has recognized Reynolds Machinery as its 2020 top distributor in unit sales — a first for Reynolds, though it has come close several times in the past.

Combined with Hurco’s Automation Manager CNC feature, the partnership is expected to enable job shops to integrate collaborative robots into their processes with minimal effort.

The Hurco Max5 control now includes a 3D Import feature with 3D DXF technology enabling the user to load the file they receive from their customer directly into the Hurco control.

Machine tool builder Hurco had its five-axis technology on display, and provided attendees with a sneak peek at two other machining center models that will be introduced at this year"s International Manufacturing Technology Show.

Hurco offers its 3D Print Head, an optional, spindle-powered wireless accessory for Hurco VMCs that extrudes plastic PLA filament for 3D printing directly on a CNC machine.

Joe Braun will serve as vice president of marketing and product management, Scott Camloh will serve as national sales manager and Cory Miller will serve as general manager for Hurco North America.

Designed to handle the rigors of high-speed machining, Hurco"s VMX42HSi high-speed mill offers direct-drive servos, an 18,000-rpm integral spindle and X-Y-Z travels measuring 42" × 24" × 24".

Designed to meet the demands of moldmaking applications, Hurco’s VMX6030i vertical machining center provides more Y-axis travel in a footprint smaller than the company’s VMX64.

The swivel-head design of Hurco’s five-axis VMX42SRTi features a flush rotary table that is embedded to provide an additional 3.5" of clearance in the Z axis for taller parts.

The delivery of a TM8 slant-bed turning center from Hurco (Indianapolis, Indiana) to Ferris State University marks the latest in a continuing collaboration among industry partners to support students studying manufacturing technology. The machine, a slant-bed lathe that is said to provide short-run versatility, will be housed in a hands-on applications lab at the university’s campus in Big Rapids, Michigan.

At the inaugural edition of the imX (interactive manufacturing experience) event, Hurco will showcase its control expertise and emphasize the benefits of five-sided machining.

Machine tool builder Hurco (Indianapolis, Indiana) has announced a partnership with the Connecticut Center for Advanced Technology (CCAT), an organization that provides services and resources to entrepreneurs and businesses.

Dreyer & Reinbold Racing (DRR) has partnered with industrial automation company Hurco (Indianapolis, Indiana) for the 2011 IZOD IndyCar Series season.

The VMX30U VMC combines an efficient trunnion table design and five-axis technology to simplify machining for parts and molds with swept surfaces and contours, the company says.

Hurco’s TM18L is a true slant-bed lathe with a maximum cutting length of 79.4" (approximately 2 m) to accommodate longer stock for the energy and mining industries.

Hurco says its largest machining center, the 3-m DCX32, has the capacity to handle large parts and molds for the aerospace and energy sectors. Featuring X-, Y- and Z-axis travels of 126" × 82.

Hurco features 11 machine tools with its integrated control powered by WinMax, which is software is designed to expand a shop’s capability. An interactive space with the control consoles is set up for booth visitors to test.

Hurco’s VM10U small-footprint, five-axis machining center minimizes setups, eliminates scrap by using powerful verification graphics and minimizes benchwork with smoothing algorithms that deliver quality surface finish. The machine has X-, Y- and Z-axis travels of 21", 16" and 19", respectively.

The TMX series of slant-bed lathes from Hurco includes three turning centers: TMX8, TMX8MY and TMX8MYS, all of which include construction and high-performance specifications for efficiency. Specifications include rapids of 950 ipm (X axis) and 1,200 ipm (Z axis), a spindle speed of 14,500 rpm and a 36-hp spindle motor. The all-digital control, drives and motors along with absolute encoders on all linear axes provide superior surface finish capability, the company says.

This shop watched its chosen niche become less profitable. Its response was a dramatic investment in new equipment, along with an information-related change that has made all of the shop’s equipment more cost-effective.

To get maximum leverage from its manufacturing know-how, Krieger Machine, a CNC shop in Stuart, Florida, draws on all of its software resources - CAD, CAM and shopfloor programming. The shop relies on KeyCreator from Kubotek as its main CAD resource. Mastercam from CNC Software is its main CAM resource. On the shop floor, conversational programming on the Hurco vertical machining centers proves to be another vital resource. All three systems help the shop succeed as a reliable producer of precision parts for a variety of industries.

Conventional wisdom about standard milling operations has always been that compared to square shoulder cutters, lead angle cutters are easier on the spindle, can be run at higher table feed rates, and cut freer. Finishes are typically better and, with the addition of a wiper flat insert, finishes could be further improved.

Due to the chip thinning attributes of this type of cutter, actual table feeds can be more rapid, albeit at the sacrifice of some depth of cut compared to a zero lead cutter.

The efficient design of the Hurco 5-axis trunnion table machining centers (U Series) is a key benefit to consider—we use an integrated trunnion table at instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis machine. The integrated trunnion table design provides more clearance in Z compared to other brands.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

As a Hurco Distributor in Indiana we are certified to repair, install, troubleshoot and perform preventative maintenance for all Hurco CNC Machines throughout the ENTIRE state of Indiana.

8613371530291

8613371530291