indexable rotary table factory

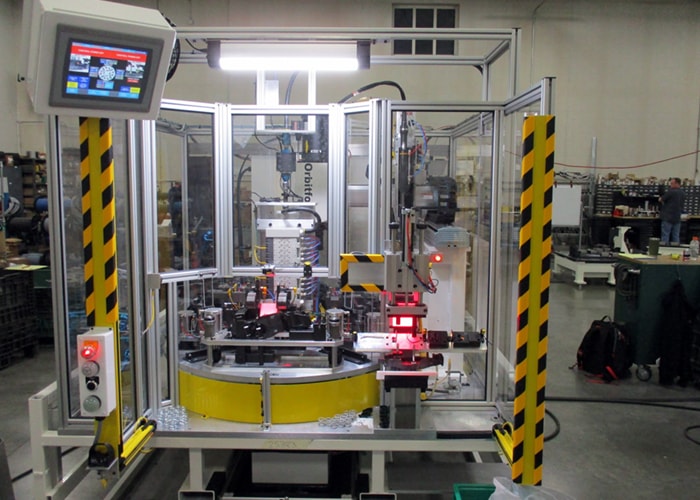

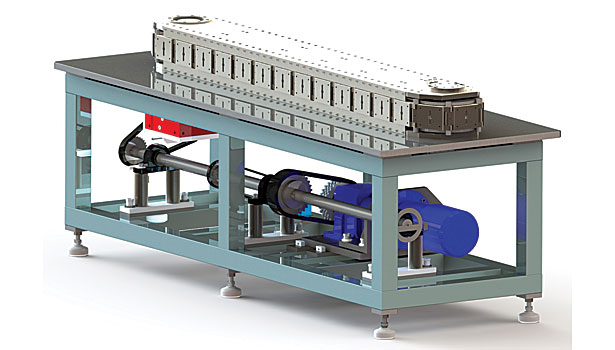

Indexing tables are used in a multitude of industries and in numerous applications. Their design is optimal for many manufacturing jobs, and they are a critical component in most automated manufacturing systems. Indexing tables are best defined as a machine tool positioning device. They carry components in a manufacturing environment with a repeating process of indexing (rotating) around an axis, stopping, dwelling while an operation is performed, then indexing again to repeat the process. They are usually made of circular steel plates, with one or more spindles, a drive system, encoders, sensors, controllers and slots or mounting holes to hold components.

Virtually any manufacturing operation can be performed on a part held by an indexing table including welding, grinding, drilling, assembly, painting, inspection, testing and more. In order to maximize operational efficiency, the machine doing the operation must also be built for the same intended application as the indexing table for them to work in synch. Similarly the machine that loads the indexing table with parts must also be synchronized. They must have the same capacity and be able to manage to the same dwell time for the system to work.

Industries that use indexing tables include automotive manufacturers, bottling companies, microchip manufacturers, pharmaceutical makers, consumer products companies and many more. They are invaluable to manufacturers pushing for automation and increased efficiency in their factories, turning work that used to take days into work that takes only hours. If a simple assembly task is required on small parts in a factory, there is no better way to complete the task than by coupling an assembly tool and an indexing table.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ppr.

The RTBA is a unit manufactured by Kalamazoo company. It is a rotary table with a 6" table index. Furthermore, it has a numerous index combination by changing of index ring on a 36 spaces ...

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

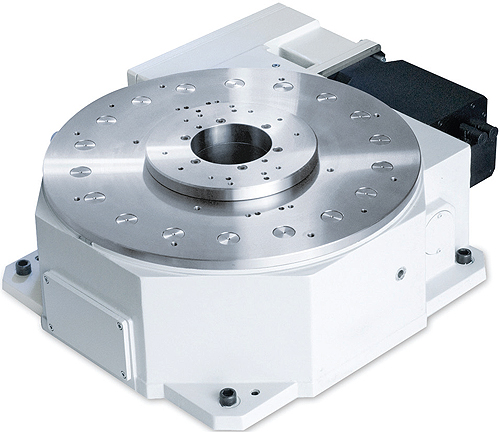

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

A indexable rotary table comprises three main elements, including the torque concept, electric motor and the gearbox. The torque concept is the rotating force measured in pounds per foot. When torque and execution time are combined, the result is energy. The output drive shaft of an electric motor has an operational speed and a particular force expressed in horsepower. Both its power and its speed determine the torque a motor can produce. This is what determines whether or not a load will turn. Lastly, a gearbox is a method of transmission. It comprises several mechanical parts that allow for proper torque distribution and speed reduction. All of its components are equally crucial, and they all require flawless geometry and composition for the system to function properly. This includes crown wheels, plain bearings, washers, pulleys, gears, and pinions.

There are several benefits of using a indexable rotary table. First of all, it helps you to save on the costs of the operating system. It also helps in increasing the efficiency and reliability of your motor applications. Another advantage of a indexable rotary table is that it reduces environmental pollution since it lowers the amount of gas emitted by fossil fuel. When Choosing a indexable rotary table, there are several factors that you need to consider, including its speed, duty cycle, overhung load and torque.

For a wholesale indexable rotary table, visit Alibaba.com. This online shopping platform works with various Chinese wholesalers to offer you various speed reducers. Therefore, you can be sure to find one that suits your needs and budget. This platform also operates 24/7, so you can place your order at any time with a few clicks.

Among the many indexer manufacturers, what sets Pascal’s indexing table apart is undoubtedly its brakeless design, compact size, and durability. It has an ample amount of ports lending itself well to automation.

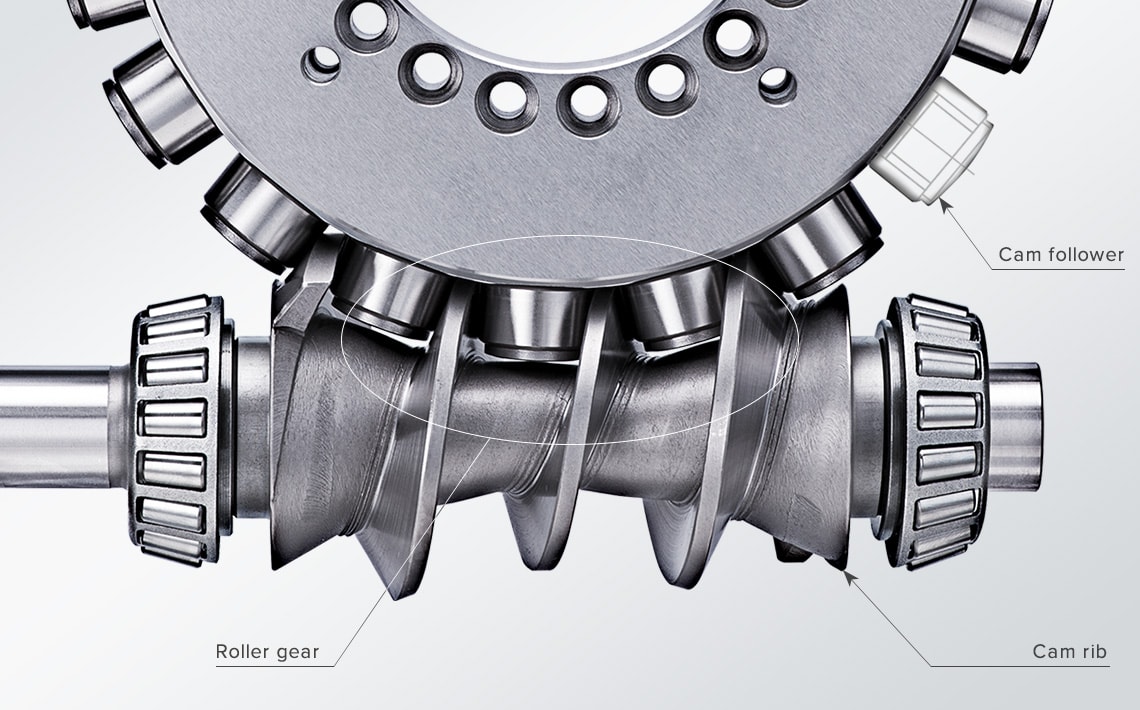

Pascal’s MDF index table operates with a 90° index 0.5 sec. Its unique rolling gear transmission is maintenance free and can operate with high index speed and accuracy for a long time unlike traditional worm gear. Traditional worm gear undergoes abrasive wear that can lead to backlash causing machining failure and degrading index accuracy.

Pascal’s high-performance rotary unions are integrated to enable clamp sensing and actuation but also provides a footprint 20% smaller than its competitors. Ideal for indexing large workpieces in compact machining centers, you will also achieve increased production capacity. As one example, our rotary indexing table can allow a machining center to increase their production capacity from 16 robodrill units to 24 units in the same amount of space.

The MDF index table has a total of 20 ports, lending itself well to automation. 18 of those ports can be used for hydraulic and air, while 2 are for coolant. A double acting cylinder with sensing can be used instead of a single cylinder, and its rotary joint accommodates a 7MPa pressure circuit.

Pascal is confident in the quality and reliability of our rotary indexers so much so that we use them in our own factories. That is also why these indexers are utilized in the factories of major automakers around the world.

We combine rotary index tables with industrial automation systems so each task of your manufacturing process blends seamlessly into the next. For example, in the past we’ve created industrial automation systems that join rotary indexing machines with pick-and-place units for some of our clients. Contact us to see what we can do for you.

Rotary indexers are just one part of the equation when building a custom assembly cell. It’s important to remember the entire scope of the project and be cognizant that the rotary table should be able to move precise distances before stopping cleanly, with no backlash or wobbling. It needs to be balanced and capable of handling the tasks at hand.

Our automation experts have years of experience in consulting with our customers to create machines that suit their needs. We incorporate rotary tables from industry leaders like WEISS, Fibro, and Camco into our machines to create the perfect fusion of form and function. Our dedication to quality is unmatched in the world of custom machinery.

We seamlessly integrate rotary indexing tables into our automated machinery to provide you with custom solutions that work for your business. If you’re looking to take your manufacturing process to the next level, give the custom machine builders at Paramount Tool a call at (616) 582-5300 today. We’re always happy to answer any questions you may have about our rotary indexing machines or the machine building process as a whole. For a free quote, fill out our contact form and we’ll get back to you as soon as we can.

Many rotary table manufacturers outsource gear fabrication to lower costs. While that strategy may offer short term cost savings, Index Design’s American made rotary tables are built with gears cut in house. This is the only way to closely monitor and control tolerances, consistency and performance.

Our rotary tables incorporate large diameter high tensile bronze worm gears mated against hardened steel drive shafts. The combination of metal gives superior wear properties for long lasting operation. As the rotary table is run, the properties of a tin bronze gear develops a low friction deposit on the mating steel drive shaft. These deposits fill in microscopic pores of the mating surface. Over time, as these deposits are embedded on the surface, wear decreases followed by a reduction in frictional forces within the gear assembly.

In addition, the data gathered from our automated calibration procedure allow our engineers to assess, monitor and improve the static and dynamic performance of prototype rotary tables during the design phase.

Our engineers have a long and rich history in the machine tool business, they combine decades of both CNC machine tool and rotary table manufacturing experience with the latest design tools to produce rotary tables with superior performance and dependability.

Our CAD/CAM software is used to analyze displacement and stress for each component, sub-assembly and total assembly. However, the best software and technology is worth next to nothing if no one understands the craftsmanship. This is particularly true when manufacturing precision rotary tables which involves many steps. Despite all the modernization and automation available, a large part of the manufacturing process is still completed by hand. At Index Designs, we understand and appreciate craftsmanship, It is designed and built into our products.

For over 50 years, Pfiffner has been developing rotary transfer machines that offer high precision and flexibility, marketing the most cost-effective solutions for high-volume workpieces. Thanks to our solution-oriented approach, well-developed expertise in the market, and a passionate innovative spirit, we"ve established ourselves as a leading partner for innovative industry sectors all around the world. Our success is based on a clear vision: We always remain a leap ahead of the times, ensuring satisfied customers every single day.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

is a specialist in the design and manufacture of a wide range of CNC rotary tables and index tables. At TANSHING we are dedicated to research and development and technological innovation continually.

From design, and precision machining, to rigorous quality control, great care is taken to ensure an international quality level. TANSHING"s products are widely recognized in both domestic and overseas markets. The innovative dual lead worm drive system has been patented in Taiwan which is indisputable proof of the superior R&D capability of TANSHING. TANSHING has been certified by AQSR ISO-9001 (U.S.A.). In order to ensure very high precision parts, TANSHING has invested heavily in various advanced machining equipment. 90% of our in-house parts machining allows us to fully control the accuracy of the parts, which provides a solid foundation for the superior quality of TANSHING CNC rotary tables and index tables.

8613371530291

8613371530291