indexing head vs rotary table in stock

Rotary tables are mounted horizontally, and most can also be mounted vertically. In both cases only at 90° to the mill table. A Dividing Head is always vertical, but can be tilted through 90°.

Dividing heads are always fitted with "indexing plates" (holed wheels and clock hands), allowing a wide range of angles to be turned. The indexing mechanism can do intermediate angles. Rotary tables can be fitted with indexing plates as an accessory, but usually the number of angles supported is limited compared to a dividing head. (A generalisation. And, because rotary tables do all common angles, the limitation may not matter.)

Rotary tables are more convenient for general work because most jobs are mounted at 90° or 180° relative to the milling table. Possibly more robust than a dividing head for rough work. When close accuracy isn"t needed, jobs can be spun rapidly by the rotary table without cranking the handle - a time saver. When accuracy is needed the handle and worm are engaged. Usually there"s a vernier scale sufficiently accurate for most work. The handle is also relatively fast because most simple angles can be produced with it. For example, easy to crank from 0, 60, 120, 180, 240, 300, 0 to cut a hexagon head. Unfortunately not all angles are "simple"!

Indexing plates are useful for awkward angles. Cutting a 19 toothed gear requires 19 steps of 18.9474°, which is the hard to remember sequence 37.89, 56.84, 75.78, 94.74, 113.68, 132.63° etc. The Index plate and clock hand mechanism remove the need for the operator to track the sequence but they are still a pain to use in my opinion!

Indexing plates are so awkward that driving a Rotary Table with a stepper motor and microcontroller is popular. You simply tell the controller how many divisions are needed, press "Go", and the computer does the rest. Apart from reducing brain strain and automating a tedious task, the computer eliminates most mistakes. Computers don"t get sums wrong, have excellent memories, and are hard to distract! Also, a computer and stepper motor will do a good job of angles too complicated for the Indexing plates.

Generalising again, I suggest most people, most of the time, only need a rotary table. I see Dividing Heads as specialist tools and have never felt the need for one. For the same reason I drive an ordinary small car rather than a Land Rover. The closest I get to off-road driving is a supermarket car park! You might live on a farm...

Unless there"s a specific reason for needing a Dividing Head, I wouldn"t spend money on one. My rotary table is used a lot, in contrast a Dividing Head is only "nice to have".

Dividing heads allow you to divide a circle into equal fractions conveniently. Anything that involves regular action around a circle is a candidate for a dividing head.

A rotary table has no stops so it is not convenient to do large numbers of things at equal intervals because you would have to painstakingly determine the interval. Also, the rotary table does not divide the circle. For example, if you were making 13 equally spaced operations using a rotary table you would have to calculate some wierd angle for each operation and dial it in--a tedious process. For example, here are the 13 angles for a circle division:

Do you want to manually set each of these values? Have fun doing that. Now, imagine doing it for 53 divisions. You will be there all night. Not only that, the error will be a lot more than a dividing head.

I have used it in the vertical position to cut a 107 tooth gear which isn"t covered by any of the dividing head wheels I"ve got. I set up an excel spreadsheet with the angle required for each tooth which isn"t as easy as it sounds as the rotary table is calibrated in degrees/minutes/seconds rather than decimal degrees so it took a bit of figuring out how to do it.

I always thought that a dividing head was used to divide a 360° circle into a fixed number of positions, where a rotary table can be turned to an infinite number of positions.

They can both do almost the same thing, but each has it"s advantages. If you need accurate positioning to a fixed number of positions and you had the correct dividing plate, if you were cutting a gear for instance, it would be easiest to use the dividing head. If you needed to mill an arc of 42° then you would use the rotary table.

If you have a rotary table with dividing plates then you can use the table to divide 360° into a fixed number of positions, otherwise the dividing is only a accurate as the Mk. I eyeball.

I have an 8" Rutland horizontal/vertical RT made in Taiwan that is about all I want to carry around without mechanical help. It has done all I ask of it, and a larger fixture plate mounted to the top of the table could be up to any diameter I care to make it. It is a high quality RT, and I am happy with it. Just went out and weighed it on a bathroom scale, said ~55 pounds. I also recently picked up a beautiful old adjustable height tailstock for it. It is also very heavy and solid, maybe 25 pounds.

I also have a 6" swing dividing head (no maker"s mark, WWII?) with two sets of three dividing plates, two D.E. Whiton 1-3/4" 8 tpi mount chucks (3 and 4 jaw, also marked Rivett!}, and #9 B&S spindle tooling for it as well, and a mill mounting table adapter plate that holds the dividing head and the tailstock to it for quick mounting to the mill table. Throw it on the mill, tighten 4 bolts, and it is ready to use, with less than .001" tolerance fit everywhere.

Given the choice between dividing head and rotary table, I vote for both! The jobs they do are mostly quite different, and one does not work for the other very well. In a pinch, yes, it can be done.

An indexing head is intended for making EVEN rotary divisions of any desired number, is generally smaller and usually has the dividing plates as a basic part of the head. It also generally uses a chuck or collet to hold parts although faceplates can be fitted to them. Thus, an indexing head is ideal for making things with evenly spaced divisions, like gear teeth, hole circles, N sided bodies, etc. It is not very good if different spacings are needed, but they can be done. Also, it is generally good for smaller parts but larger ones can be accommodated.

A rotary table has a faceplate built in and is generally larger than an indexer. But both come in all sizes so this is far from absolute. And you can mount chucks or collet closers on them, it is just a bit harder to do. They may or may not come with dividing plates for ease in making any arbitrary number of even divisions, but they usually have accurate markings in degrees, minutes, and seconds. Due to these absolute scales, it is easier to make odd angles between features. They will mount larger work on their faceplates and it is easier to make circular arc cuts when milling on a RT than it would be on an indexer. Many of them do come with dividing plates and virtually all of them can have them added if that is desired. Another thing that is normally made on a RT is a spiral: this requires external gearing or CNC control.

Each of them can do all of the above. It is just EASIER to do some of these things on an indexer and others on a RT. I have a 10" RT as my first purchase and have not regretted that choice. I got a bargain so I took advantage of that. However, an indexer would have also been a good first choice if a similar bargain would have been possible there. In the end, I will probably get both. I also plan to make some dividing plates for my RT when I have time as they do make the job of doing even divisions a lot easier. For now, I just use a table of angular settings and hope I do not make any mistakes.

These days it"s pretty trivial to create a spreadsheet to figure out the required degrees/minutes/seconds for some arbitrary number of divisions n, so it"s not all that big a deal to use a rotary table for dividing. A dividing head is, as others say, probably a bit more convenient both in ease of dividing oddball numbers of divisions and in less mass to get in the way of what you"re machining...but a rotary table will be more flexible. If you want to substitute for a dividing head, be sure to get a horizontal/vertical rotary table, as you"ll want "vertical" mode for dividing (and making gears).

If the rotary table has a Morse #3 center hole (or whatever), in vertical mode you could probably use Morse taper collets for workholding, which might be pretty handy. The only thing is, as hinted above, in vertical mode there may be a lot of rotary table in the way of what you"re trying to machine, if you need to get in close. It"s do-able, but you may to need to be a bit creative in workholding to arrange necessary clearance to get the tool where you need it.

This plate can be used either directly, or through a geared dividing mechanism. In direct indexing the workpiece and plate rotate in a 1-to-1 ratio, and holes are used directly. That is, a plate with 12 holes can divide the workpiece into 2, 3, 4, 6, or 12 equal segments. A dividing head incorporates an internal gear ratio (usually 40:1, 60:1, or 90:1) with the same plates. In doing so, the dividing head enables many more combinations than just direct indexing.

For example, imagine a plate with 15 equally-spaced holes and a dividing head with a 40:1 gear reduction. In direct indexing, a workpiece could be divided into 3, 5, or 15 equal segments. Using the dividing head, the same workpiece could be divided into 2, 3, 4, 5, 6, 8, 10, 12, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 300, or 600 segments. Essentially, the dividing head acts as if it’s a direct indexer with 600 holes; 15 holes in the actual plate * 40:1 gear ratio. Let’s look at how some of these combinations are possible.

An indexing rotary table is one of the most efficient methods of moving parts through an assembly cell. They are specifically designed to make repetitive moves around a platform. Indexing Rotary Tables can be used in many applications including manufacturing, inspection, and assembly tasks in industries ranging from medical and aerospace to automotive and food & beverage.

We offer top of the line indexing rotary tables, which provide many capabilities to milling operations. Indexing rotary tables can be used to cut arcs, circles, complex curves and large diameter holes, bore holes, and make any straight angle cut.

CNC Indexing & Feeding Technologies is proud to be exclusive importer/reseller of the complete line of Ganro Industrial Corporation products in the U.S. Established in 2008, Ganro is an ancillary company of Golden Sun Industrial Co., Ltd., which has been manufacturing the highest quality rotary tables for more than 3 decades. Ganro recently released the latest catalog of their […]If you need indexing capabilities for a horizontal boring mill, one of the best and most cost-effective ways to do this is with a horizontal index table from CNC Indexing & Feeding Technologies. Our GCT series of manual horizontal indexing tables are ideal for several applications, including machining, assembly and inspection processes. These Ganro Industrial […]Are you looking to end the year with a bang? Take your productivity to new levels with cost-effective, high-quality rotary tables, bar feeders, high pressure coolant systems and more from CNC Indexing & Feeding Technologies. We have the most popular models in stock for quick delivery before the new year. Iscar Cut-off Tool with Bar […]A recent study from Accenture and The Manufacturing Institute highlights a growing need for skilled workers in the U.S. manufacturing industry. According to the research, U.S. manufacturers may be losing as much as 11 percent of their annual earnings because of increased productions costs that result from this shortage. Other highlights of the study, which […]

Yukiwa Manual Indexing Head DMB series is used in milling machine, drill press, and slotter, and can make your indexing process easily and efficiency, and contributes to improve your productivity.

“Unclamping, Indexing, Clamping” can be done only by one reciprocating operation of the lever. The clamp is rigidly, and the index accuracy is precise.

Precision rotary table tiltable type UT300, precision rotary table can be used horizontally and vertically, for milling, drilling, grinding and marking work.

1 pair of prismatic blocks without clamping brackets, suitable for clamping round material, prismatic incision 90°, made of special cast iron, supplied in pairs

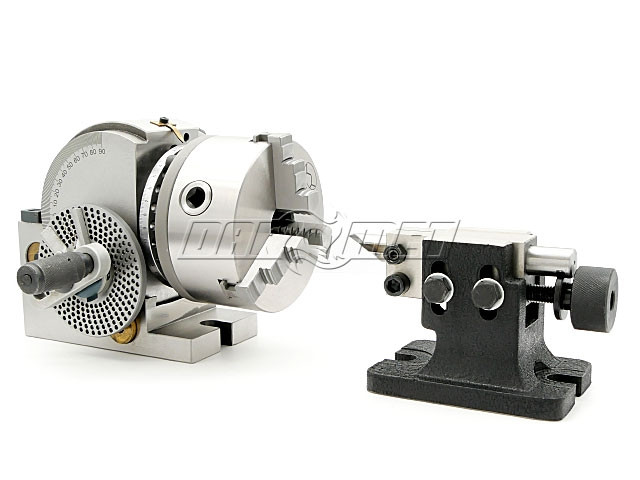

Universal dividing head, HOMGE, type BS-2, incl. tailstock, flange and 3 dividing discs, as milling machine accessories for direct and indirect dividing.

Clamping tables, swivelling ±45 degrees in both directions, with rotating plate rotatable through 360°, type HAP, with reinforced construction in special cast iron.

Precision rotary tables HOMGE type HHV, universal dividing head for milling, drilling, boring, grinding and marking work, for horizontal and vertical use.

Semi universal dividing head ZENTRA, type HUT, with indexing plate with 24 holes for direct dividing, including tailstock, flange and 2 dividing plates.

ZENTRA precision rotary table RT with a gear ratio of 90:1 / for milling, drilling, boring, grinding and marking work is horizontally and vertically versatile.

Precision rotary table dividing head ZENTRA type RT-DF, mounted lathe chuck for milling, drilling, boring, grinding, scribing work, for horizontal and vertical use.

Direct dividing attachment Zentra TA, for direct dividing including three-jaw lathe chuck and indexing disks as milling machine accessories ✅ order now!

Zentra dividing head with handwheel and three-jaw lathe chuck, clamping disk and indexing plates, for horizontal / vertical use as milling machine accessories.

ZENTRA indexing disks for precision rotary tables type TS for the production of precise, indirect graduations as for example in gear milling ✅ buy now!

Universal dividing head ZENTRA VUT-200KPL, incl. lathe chuck, tailstock, turning and drilling jaws and 2 dividing discs, for direct and indirect dividing.

Universal dividing head, ZENTRA, type VUT-2A, incl. tailstock, flange and 2 dividing discs as milling machine accessories for direct and indirect dividing.

8613371530291

8613371530291