koma rotary table manufacturer

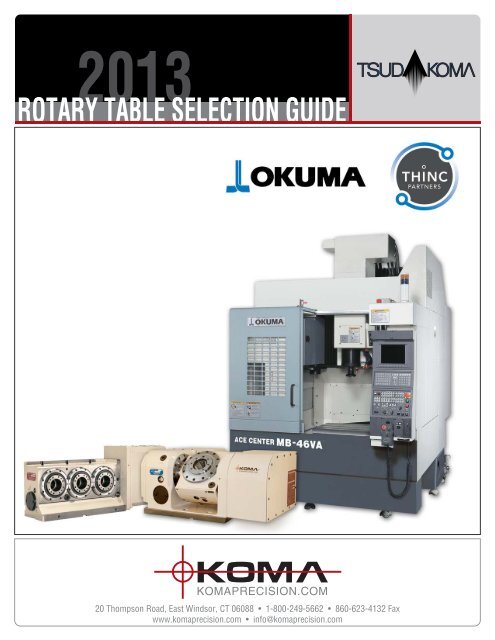

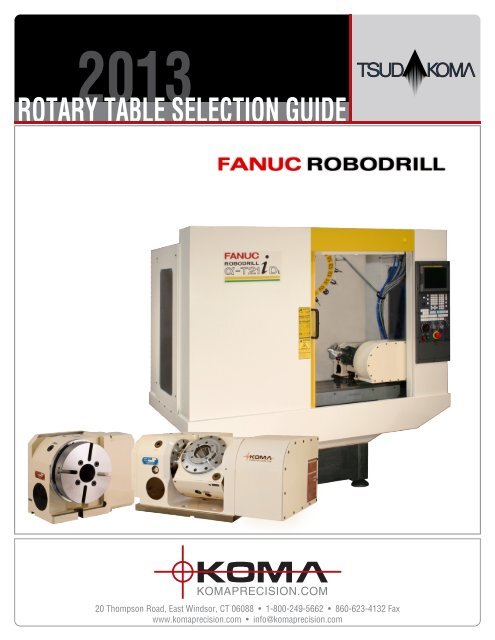

Since 1982, Koma Precision, Inc. has supplied the world’s highest quality attachments and accessories through a nationwide distributor network. We are the exclusive importer, national distributor and service center for Tsudakoma rotary tables, Alberti angle heads & live tools, Romai angle heads, Inbis swiss tools and our own line of elite Tool Presetters.

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

For years, Martin Trunnion Tables has been a proud integrator and fixture builder for KOMA Precision rotary tables. We help support and develop trunnion packages for automation solutions, high-mix job shops, and everything in between. Below you will find a variety of solutions ranging from 4-sided tombstones to fully cast, single-sided Stallion Trunnions. If the featured solutions aren"t exactly what you are after, don"t hesitate to reach out to our team.

Note 1: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 1: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 1: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 2: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 2: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 2: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 2: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 2: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Note 2: When using a machine with a T-slot pitch other than the above, use suitable clamping blocks and bolts that are available on the market, or order custom-made ones from KOMA (opt.)

Notes: 1. For RN-100, RNA-160 and 200 models, “Spindle end” replaces “Table top” 2. Indexing accuracy for tables with scales reflects Heidenhain encoder accuracies.

KOMA Precision Inc. has introduced a new line of high performance, attractively priced 4th axis rotary tables from Tsudakoma. The RNE Series 4th axis rotary tables are compact, high-performance tables offered at economy line pricing.

Four new models are available, ranging from the RNE-160 with 6.3" (160mm) face-plate capacity to the RNE-320 with 12.6" (320mm) face-plate capacity. The RNE Series tables feature speeds ranging from 25 to 44.4 RPM and indexing accuracies ranging from 10 to 12.5 arc seconds. Various options such as chucks, tailstocks, support spindles and faceplates are available. Pneumatic and hydraulic rotary joints for automatic load and unload of the work piece are also available.

Like all Tsudakoma rotary tables, the RNE Series feature heavy-duty construction, combining Tsudakoma casting material with Tsudakoma"s dual lead worm gearing system featuring the largest tooth engagement of any rotary table manufacturer. This proprietary gearing system generates up to 85 percent torque transfer efficiency. These tables also feature Tsudakoma"s ultraprecision cross roller bearings that support radial, axial and movement loads four times the level of stiffness as angular contact bearings.

"Koma Precision Inc. and Tsudakoma share a commitment to providing quality products that maximize the performance of machine centers," states Hiro Ichikawa, OEM Sales Manager for KOMA Precision. "The features offered on the RNE Seriesare ideal for those looking for economical ways to improve the flexibility and productivity of their operation without compromising rigidity and accuracy."

KOMA Precision is one of the word’s largest distributors of NC rotary tables and indexers, with over 30,000 rotary table installations as of 2015. KOMA is also the world’s largest supplier for Alberti, with over 12,000 angle heads and live tools installations.

KOMA Precision, Inc., distributes the finest the world has to offer in machine tool productivity innovations. Our rotary table product line features Tsudakoma - the world"s largest and leading manufacturer of NC rotary tables. Our angle head and live tooling product line features Alberti - Europe"s finest manufacturer of angle heads and live tooling. KOMA Precision, Inc. also offers its new line of presetters. Designed and manufactured in Italy by the companys partner, Elbo Controlli, Koma Precision, Inc. will now sell, service and support a range of tool presetters consisting of nine models: LARTH, SETHY, SETHY SIX, HATHOR, HATHOR SIX, KHYAN, KHYAN TW, ANKH and AMON RA. All components of Elbo Controlli tool presetters are design and realized in house by Elbo Controlli"s expert engineers.

Our mission is to always be committed to quality and innovation with responsive and proactive service. Our platform differentiates us in the market for several key reasons. KOMA Precision, Inc., application engineering ensure products purchased from KOMA Precision, Inc., will be the best available for the required machining operation. All KOMA Precision, Inc., products are assembled, optimized, and customized to ensure reliability and customer satisfaction. Application specific products are engineered, assembled and shipped in a time frame comparable to that of standard off the shelf products. KOMA Precision, Inc., also stocks the most comprehensive parts inventory and has the greatest service department expertise than any other in the machine tool accessory business. These unrivaled systems in place deliver precision and improved productivity above and beyond customer demands. Koma Precision distributes:

KOMA Precision, Inc. has updated its DMG-Mori Seiki Tsudakoma Rotary Table Selection Guide to include Tsudakoma"s RNA Series 4th axis rotary table and the Tsudakoma RTT-111, CA, a drop trunnion rotary table designed to utilize a variety of workholding systems.

The DMG-Mori Seiki Tsudakoma Selection Guide is the result of an effort to simplify the selection of Tsudakoma rotary tables specially suited to fit within the working envelope of the listed DMG-Mori Seiki machining centers. In addition to the standard rotary tables shown in the booklet, productivity enhancements include encoders, tailstocks, support spindles, faceplate and rotary joint options and high strength triple-walled stainless steel cabling packages.

"For almost 30 years KOMA Precision has been a source in machine tool productivity innovations. With over 30,000 rotary table installations, KOMA is the largest distributor of Tsudakoma NC rotary tables and indexers," said William Meo, President, KOMA Precision, Inc.

KOMA Precision"s 25,000 sq. ft. facility features a completely equipped machine shop, state-of-the-art inspection equipment, a product demonstration showroom and a multi-million dollar new product and spare parts inventory.

Koma Precision introduces the Index series of angle heads from Alberti, designed with the aim of meeting the need for performing machining operations in several directions.

Koma Precision offers custom-designed angle heads by Alberti, including fixed angle heads, offset angle heads, multiple-output heads and long-reach angle heads.

Elbo Controlli’s E46L and E46L TW tool presetters, available from Koma Precision, feature an increased measuring range of 600 mm on the Z axis and a 22" HD touchscreen display along with optical autofocus and a new electronic control.

Available from Koma Precision, the Elbo Controlli 66B and 68B presetters have the capacity to handle larger, heavier tools with a measuring range of 800 mm on the Z axis.

Available from Koma Precision, Elbo Controlli’s Hathor Six floor model and Sethy Six bench model tool presetters offer an increased axis-measuring range to 600 mm (23.62").

Koma Precision’s bench-mounted Larth tool presetter features a ground granite base and column, stainless steel construction and ergonomic design combined with a 5.7" TFT LCD touchscreen.

Fanuc FA America (Hoffman Estates, Illinois), CNC Engineering (Enfield, Connecticut) and Koma Precision (East Windsor, Connecticut) have joined forces to support the manufacturing technology program and Asnuntuck Community College in Enfield, Connecticut. For its part, CNC supplier Fanuc FA America recently donated three control systems to staff and students.

Designed and manufactured in Italy by the company’s partner, Elbo Controlli, Koma Precision will now sell, service and support a range of tool presetters consisting of six models: LARTH, SETHY, HATHOR, KHYAN, ANKH and AMON RA. All tool presetters are constructed with a solid granite column and base.

Koma Precision (East Windsor, Connecticut) has entered into an exclusive North American distribution agreement with Meda, Italy-based Elbo Controlli, a designer and manufacturer of tool presetting solutions.

Distributed by Koma, the Tsudakoma RT-111,AA drop-trunnion tilting rotary table features a design in which the top surface of the spindle is the center line of the tilt axis. Two pneumatic rotary joints on the rotary axis allow automated clamping/unclamping of the System 3R chuck and pallet system.

Koma Precision stocks Alberti Slimline T90sl-0,3 angle heads, which are customized for Makino MAG3 HMCs. The angle heads feature an HSK 80F shank and a high speed NSK output, which can be equipped with a variety of micro-machining NSK tools.

The RNA-S, RBA-S and RBA-K, S series rotary tables have an indexing speed ranging to 88. 9 rpm. These high speed rotary tables are said to increase productivity not only by decreasing cycle times, but also by enabling smoother surface finishes, thereby reducing secondary machining requirements.

Tsudakoma TN-101, TN-131, TN-161 and TN-201 compact, high speed, tilting rotary tables from Koma Precision use a dual taper, double-disc braking mechanism, which generates massive clamp torque—an increase of 320 percent when compared to previous models. The one-piece monoblock frame construction permits maximum rigidity. The tables feature an indexing and tilting repeatability of ±2 arcseconds and are available with a full range of options including rotary scales and various chucks and collets.

This tool manufacturer had to automate its processes after switching from low-volume special orders to high-volume production runs. Since implementing Tsudakoma tilting rotary tables along with robotics and a pallet conveyor, the shop has increased sales by 400 percent.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Koma Precision, located in East Windsor Conn., will provide CCAT with a Tsudakoma RBA-320R rotary table for use on a Toyoda FV-1680 Vertical Machining Center at the AMC. The RBA series rotary table incorporates Tsudakoma technology including hydraulic clamping and a worm wheel spindle assembly.

For more than 30 years, Koma Precision has been a worldwide distributor of Tsudakoma NC rotary tables and indexers and installed more than 30,000 rotary tables. With over 12,000 angle heads and live tools distributed and in operation, Koma is also a supplier for Alberti productivity tooling. In addition, Koma is now offering a line of tool presetters from Elbo Controlli, a manufacturer of electronic equipment for machine tools.

“We are privileged to be collaborating with a recognized world leader in machine tool productivity and innovation,” comments Bob Torrani, AMC director at CCAT. “Koma’s rotary table will provide a fourth axis on our 3-axis 50 taper vertical machining center, providing a realistic configuration of the machine tool set-ups used by regional manufacturing shops. It will greatly enhance our capacity to help regional manufacturers increase their productivity through machining optimization.”

“Koma is pleased to collaborate with CCAT to provide manufacturers with state-of-the-art machining technology at the AMC,” states Barry Agosti, vice president, Koma Precision. “We are looking forward to a productive and rewarding relationship.”

Koma Precision Inc.’s RBS fourth-axis rotary table series is suitable for single-axis VMCs and was built using a ball drive system featuring zero backlash, improved cycle times, energy conservation and a lifetime adjustment-free transmission system.

For Koma Precision and Tsudakoma, IMTS 2016 heralds the arrival of the Tilt Ball Drive System Rotary Tables into the North American market. The Ball Drive system features advantages like zero backlash, improved cycle times, energy conservation and a lifetime adjustment-free transmission system.

Tsudakoma"s relentless pursuit of ultimate performance, productivity, and innovative technical advantages has made them the world"s largest and leading manufacturer of rotary tables.

8613371530291

8613371530291