lehmann rotary table pdf pricelist

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Our customers live in different time zones, speak a variety of languages and need information at different times of the day and night. In the Download area, pL LEHMANN offers a wealth of information at no cost – 24/7 365 days a year.

pL LEHMANN holds the copyright for all data available herein. The brand name pL LEHMANN is internationally protected by copyright. Pictures and diagrams are only intended for the use in promotional documents and technical documentation and only for OEM customers (original equipment manufacturers) of pL LEHMANN. Any other use is subject to copyright terms. In case of doubt, please don’t hesitate to contact us.

Usually, the data is updated on a weekly basis. Possible amendments are agreed with the customer in the case of running orders, provided that these orders are affected by such amendment. pL LEHMANN shall not be liable for any data used prior to placing of orders or after delivery.

Ordering code for CNC RotaryTables S-Special None-Standard Braking System H-Hydraulic Clamping P-Pneumatic Clamping Motor Mounting B-Rear Mounting L-Left Mounting R-Right Mounting TableTop None-Round Sq-Square Size of the table CNC RotaryTables * Higher Accuracy ± 5" on request ** Motor RPM 2000 # Check motor models on Page No. 70 ## Option available with pressurisation - Please contact us

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Customers fundamentally expect high precision and quality from Swiss machining service providers. To be able to meet these expectations at marketable prices, service providers need not only machining know-how but high-performance machinery as well. Appenzell-based AITech AG reveals how, together with suppliers pL LEHMANN and Schunk, it has turned a three-axis DMG standard machining center into a «marvel» of flexibility that reduces tooling times to the absolute minimum too.

To that end, AITech employs two horizontal 4-axis machining centers automated with pallet systems. When, in 2020, two vertical milling machines had reached the end of their useful life and had to be replaced, Bösch wanted to see multi-point clamping and complete machining implemented here as well. He envisioned a three-axis vertical milling machine equipped with an additional rotary axis: «Because the four axes allow us to machine workpieces on five sides, and even clamp round parts and machine their lateral surface at the same time where necessary.»

So Bösch and his milling technology team decided to invest in a DMG MORI CMX 1100V. The three-axis drilling-milling center offers high stability and good accessibility thanks to its C-frame concept. The high degree of precision required is guaranteed, among other things, by a direct displacement measurement system; the positioning accuracy is 6 µm on all axes. «The large machining range is also important for us, especially the X travel of 1100 mm,» emphasizes Thomas Bösch. «Although we very rarely have workpieces that long, this allows us to set up an additional rotary table in the work area and install even more vises or special fixtures for multi-point clamping next to it,» he says, explaining his basic idea.

First and foremost, the precision machinists wanted their new milling center to be completely flexibility in terms of component diversity. The idea was to reach this goal by means of an integrated CNC rotary table and flexible clamping technology. When it came to the rotary table supplier, there was only one choice for AITech – pL LEHMANN from the Swiss town of Bärau. Thomas Bösch had worked with products from this rotary table specialist in the past, experiencing only the best in terms of quality and precision. The preferred supplier for the clamping systems was Schunk. The background: AITech has always purchased its vises from Gressel AG, which has been part of Schunk GmbH & Co. KG from Lauffen, Neckar since 2014. In Switzerland, the two clamping technology specialists work closely together at the Aadorf site.

pL LEHMANN and Schunk gathered at AITech to collect and evaluate ideas and ultimately develop a concept to guarantee the shortest possible tooling times and maximum flexibility.

The details were discussed there and then. The pL sales manager for Switzerland suggested the EA-520.L-M1 rotary table version, a model that perfectly matches the machine and the intended machining spectrum in terms of drive power, clamping forces and precision. The pL rotary table needed to operate as a separate axis when required, but also together with a bridge plate or a tailstock. Not a problem for pL LEHMANN. The product range includes standard additions such as rotoFIX bridge plates and the longFLEX tailstock. However, the company is also open to special requests: pL LEHMANN offered to make the tailstock movable, and did in fact do so.

Point 1: The EA-520 pL rotary table is attached to the machine table by two Gressel gredoc zero-point clamps. If needs be, it can be completely removed in less than 15 minutes and reinstalled without lengthy calibration procedures. «This doesn’t happen too often,» admits Ettemeyer, «because we positioned it at the very edge of the table, beyond the traversing range of the X-axis. As a result, it leaves enough space for several vises or fixtures for multi-point clamping and can remain on the machine most of the time, even when it is not needed.» That said, the rotary table did have to be removed several times last year. According to Ettemeyer, this made the relatively small additional financial outlay for the zero-point clamps worthwhile.

omationPoint 2: The vises, multi-point clamping devices, counter bearings and tailstock are also fixed to the machine table with a zero-point clamping system. The choice fell on a VERO-S eight-point clamping station from Schunk. The pneumatic system proposed by the regional sales manager of the Swiss sales office SCHUNK Intec AG appeared to be the best solution for all parties involved.

This is a spring-loaded system, opened pneumatically at an actuating pressure of 6 bar. The clamping station is suitable for holding all common clamping pallets as well as clamping devices with the associated gage. Because AITech also wanted to keep the automation facilities flexible, Schunk met the special request of controlling the chucks in pairs, as opposed to the standard version of using a single cable to control the overall system.

The fact that a total of two different zero-point clamping systems were selected is down to the diverse requirements to be met. The clamping of the pL LEHMANN axis on the machine table mentioned above can easily be handled by the gredoc mechanical zero-point clamping system, a system set apart by low overall dimensions, high precision and a very good price-performance ratio. Besides the gredoc double clamp for mounting on the machine table, AITech uses a single clamp of the same model for the spindle of the pL LEHMANN rotary table. With its 20 kN of pull-in force, this zero-point clamp is the perfect solutions for such applications. It allows machine operators to interchange a three-jaw chuck with the adapter flange for the rotoFIX bridge plate and vice versa in no time at all.

This QR code can be used to call up an animated graphic showing the flexible use of the EA-520 pL rotary table in combination with zero-point clamping systems.

… the Swiss manufacturer of CNC rotary tables and other components for metal machining, is an experienced machine construction company, whose rotary and swivel axes have proven their worth in production for over 40 years. In addition to these products, which often make three-axis drilling and milling machines into more productive four- or five-axis machining centers, you can also find a variety of workpiece clamping systems in the product line.

Founded in 1960 strictly as a contract manufacturer, pL LEHMANN has been developing and producing CNC rotary tables for over 40 years. With innovations and Swiss quality, the family-owned company in the Swiss town of Bärau (Emmental) succeeded in opening up new opportunities for its customers and developing lean machining solutions characterized by high productivity through use of additional NC axes. One of the highlights of the company’s history is the powerful and flexible Series 500 – developed in 2009 – which is ideal for the most demanding tasks thanks to its modular design. With the backlash-free, preloaded PGD gear unit – developed in 2014 – pL LEHMANN reached another milestone. In 2017, the company introduced, among other things, the new pL-iBox generation, making their rotary tables ready for Industry 4.0 and digital production. This was followed in 2019 by the introduction of the Series 900 DD (Direct Drive) rotary tables with speeds of up to 5,450 rpm. As an additional new product, the AM-LOCK system, a special zero-point clamping system for 3-D printing, including preprocessing and postprocessing, was presented for the first time in 2019.

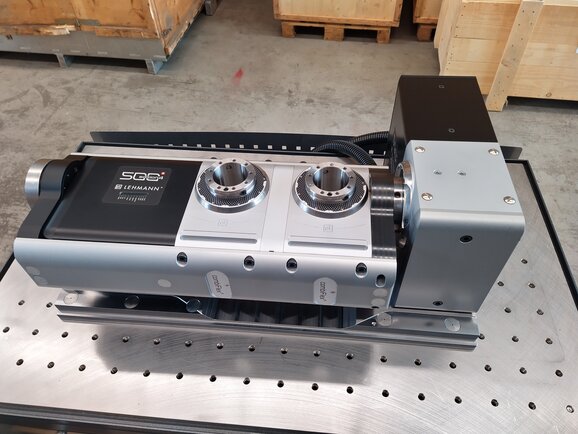

The key to high flexibility and shorter tooling times: the pL LEHMANN EA-520 CNC rotary table mounted on the far right edge of the machine table (shown here with rotoFIX bridge plate), combined with zero-point clamping systems from Schunk and Gressel.

New at AITech: the DMG MORI CMX 1100V three-axis drilling-milling center, upgraded by the pL LEHMANN EA-520 CNC rotary table and a broad range of accessories (in the foreground, the movable tailstock, the adapter flange for the bridge plate, its counter bearings and the three-jaw chuck that can be mounted via the gredoc zero-point clamping system).

Thanks to the large machining range (X-travel of 1100 mm), the pneumatically releasable eight-point clamping system VERO-S from Schunk can be mounted next to the pL rotary table. This prepares the machine for robot loading.

With its 20 kN of pull-in force, the gredoc zero point clamp is perfectly suited to the rotary table spindle – shown here with clamped adapter flange for the rotoFIX bridge plate. A quick changeover to the three-jaw chuck is guaranteed.

The pL rotary table EA-520.L-M1 is a perfect match for the machine in terms of drive power, clamping forces and precision. It also allows heavier machining operations.

The longFLEX tailstock supplied by pL LEHMANN is placed on the VERO-S zero-point clamping system. In order to adjust the position to the length of the component to be supported, it was designed to be movable.

The spindle of the pL rotary table EA-520 is equipped with a gredoc zero-point clamping system, into which the three-jaw chuck shown can be inserted in the shortest possible time.

8613371530291

8613371530291