manual indexing rotary table supplier

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

The RTBA is a unit manufactured by Kalamazoo company. It is a rotary table with a 6" table index. Furthermore, it has a numerous index combination by changing of index ring on a 36 spaces ...

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

The GCT Series is Ganro Industrial Corporation’s horizontal manual precision index table design. This product is what Ganro (formerly Golden Sun Industrial Co.) was built upon in the nineteen seventies. Ganro’s horizontal manual index tables can be used in various areas of manufacturing but are ideal for horizontal boring mill applications. This index table design is available with table top sizes ranging from 300mm (11.81”) to 1400mm (55.11”) square. The GCT Series of index tables are designed with a two piece Hirth coupling that provides high indexing accuracy while maintaining high rigidity during heavy cutting. The GCT index tables are available in 1° and 5° minimum index increments and require a pneumatic or hydraulic connection for the clamp/unclamp operation. As the exclusive importer and dealer of Ganro products in the United States, CNC Indexing & Feeding Technologies stocks the most popular Ganro rotary and index table models, accessories and spare parts.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

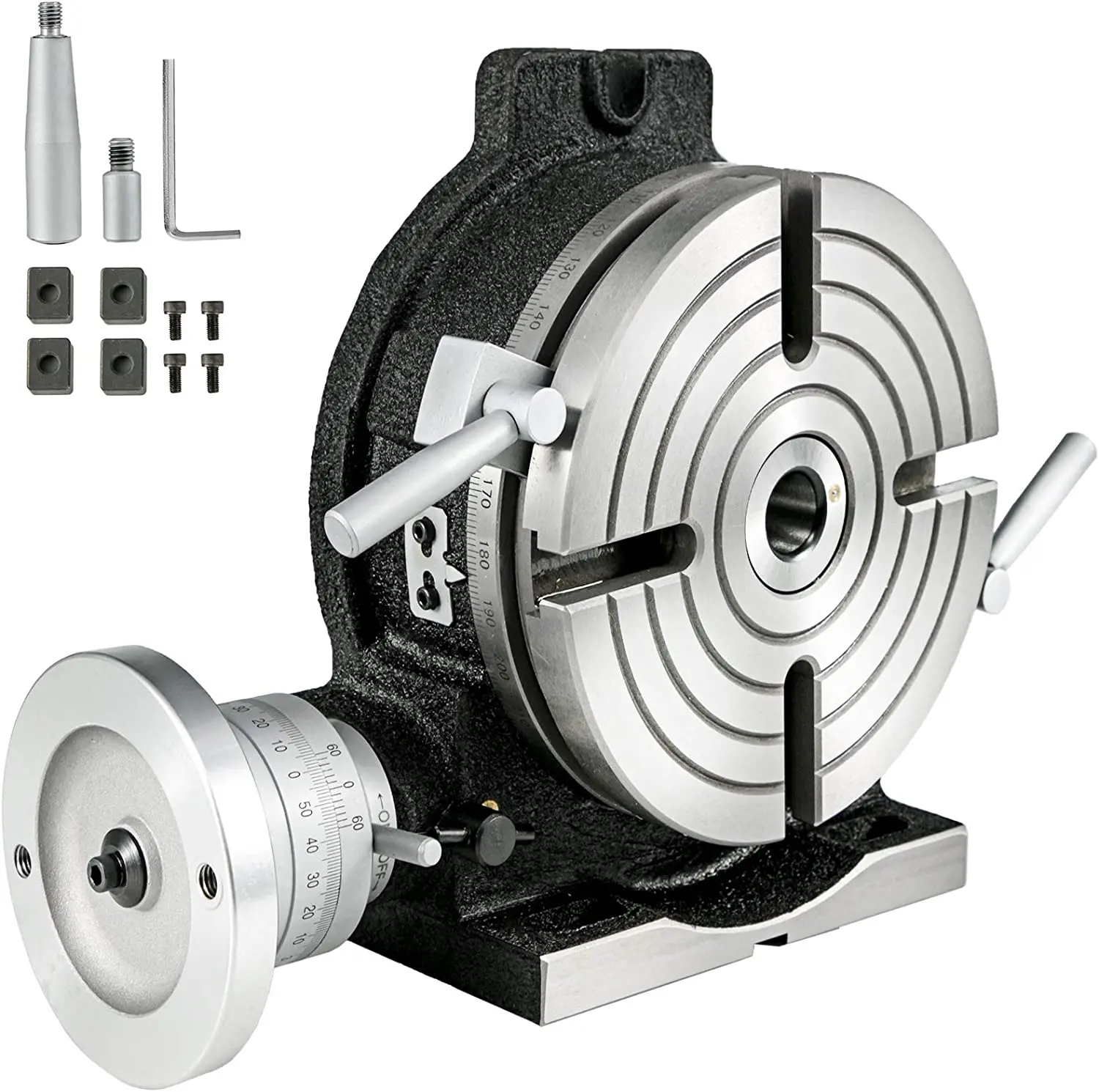

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Alibaba.com offers 55 manual tilting rotary table products. About 29% % of these are other machine tools accessories, 18%% are dividing head, and 14%% are table.

A wide variety of manual tilting rotary table options are available to you, such as manufacturing plant, machinery repair shops and energy & mining.You can also choose from 1 year, 1.5 years and 5 years manual tilting rotary table,As well as from not available, {2}, and {3}. and whether manual tilting rotary table is bearing, gear, or motor.

Explore rotary table indexing with simple designs on Alibaba.com for efficient metal cutting and strong support for the workpiece while cutting or grinding. The devices are vital components to various grinding equipment, and they are typically easy to mount. Standard machines that apply rotary table indexing as installable or built-in parts include milling machines, boring tools, and drill presses. Some device applications include gear cutting, devising milling cutter flutes, and making bolt hole circles.

The innovative indexing head features a sturdy head and footstock or indexing centers for steady and reliable operation. Alibaba.com delivers different types of rotary table indexing, including plain, optical, spiral, and universal spiral machines to cater to unique project requirements. The device components may operate as a unit or with extra attachments for enhanced accuracy and precision levels. Explore various direct index heads for fluting taps, milling squares, octagons, and many more.

Shoppers can use rotary table indexing to verify precision angles, proportions and measures up to seconds of a degree using optical lenses for sensitive projects. Universal designs are well-suited for all forms of head indexing since they are configurable at any angle. Make indexing work more comfortable and enjoyable by having these machines in the workshop.

Compare mind-blowing rotary table indexing options and exclusive deals on machinery on Alibaba.com. The quality-assured products come with sustainable warranties and are easy to operate and maintain. Customization for orders and aftersales support is also available from trusted dealers and distributors.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

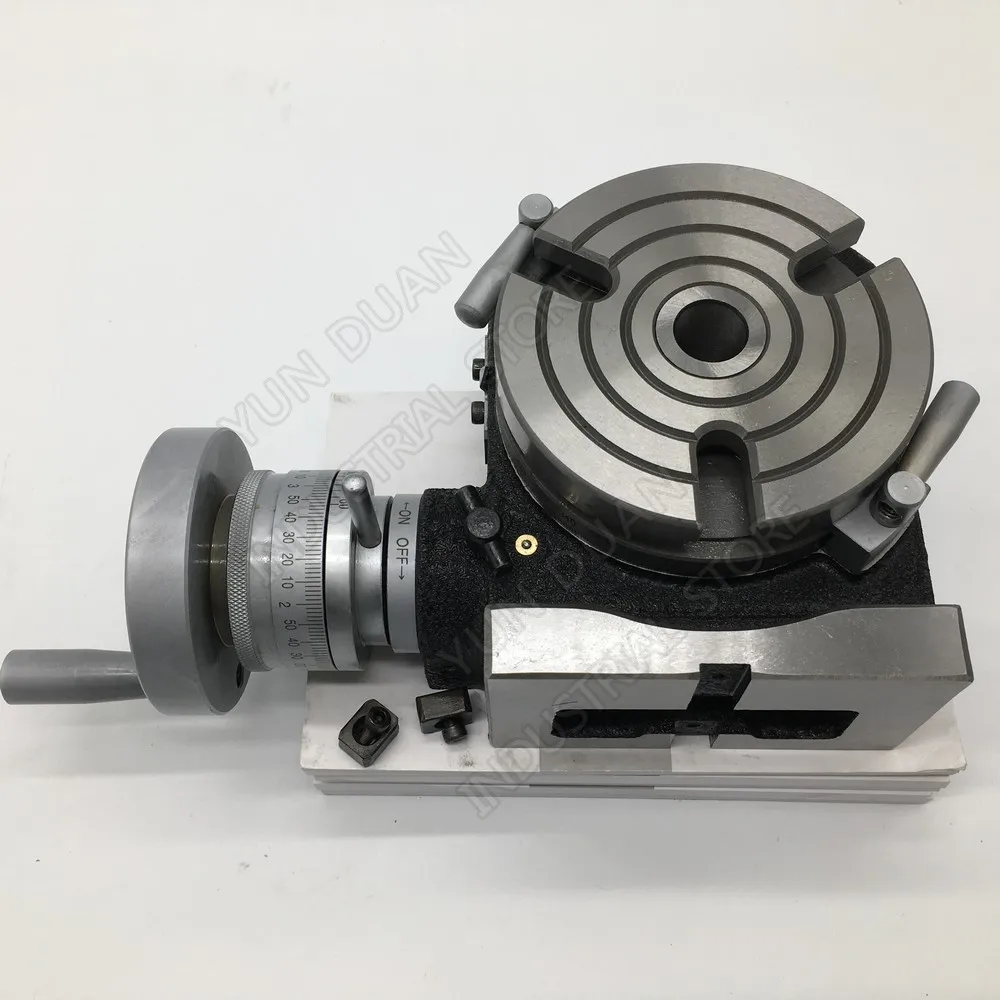

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

with the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Rotary tables have many applications, including being used in the manufacture and inspection process of important elements in aerospace, automation and scientific industries. The use of rotary tables stretches as far as the film and animation industry, being used to obtain accuracy and precision in filming and photography.

Over four decades we have accumulated a vast experience in the design and production of mechanical devices, producing well-received customized cams, automatic tool changers, and intermittent indexing drives for automation applications.

We hold expertise in offering an exclusive range of Manual Rotary Table to our esteemed clients. The offered rotary table is designed by latest technology according to the requirements laid down by our patrons. Apart from this, the offered rotary table is carefully inspected on each section in order to supply fault free range.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

The 100 oz-in stepper motor has a resolution of 400 steps/rev., which, when coupled to the rotary table"s worm gear drive, divides a circle into 28,800 steps (�.006�/step). Rotation speed is programmable from 1�/sec to 50�/sec. Once the worm gear backlash is mechanically adjusted to a minimum amount, the remaining backlash can be compensated for electronically so that the table can be advanced and then returned to previous settings with a high degree of accuracy.

A manual rotary indexer, also called a manual rotary index table, is a type of rotary tables that is applied with the milling machine or lathe, which is used to allow the workpieces that are clamped on the table to be able to rotate in order to accommodate to the requirement of angular cuts when the milling machine is operated.

The manual rotary indexer is set beside the head of the milling machine or lathe against the tool holder, and this machine is mainly used for clamping on the workpieces for being machined. Although the clamping forces of the manual rotary indexer in combination with the milling machine or lathe can be either pneumatic or hydraulic, the indexing or positioning of the workpieces on the table when the workpieces are not clamped is by the manual force of the operator instead.

A rotary indexer plays a vital role in the completion of angular cutting for intricate parts of the products and the alignment of the cutting tools when the cutting processes are conducted on the milling machine or lathe.

Since to produce a complex part of a product requires cutting with different cutting tools from various angles. The former technique can be achieved by the operators who change the tools manually or the automatic tool changing device on the machine, while the latter requires the different setups of the tool holder or the work holding device.

Here we focus more on the work holding device, which means to attain the angular cuts with the setup of the table, a rotary table must be adopted. With a rotary table, it frees the operators from turning the workpieces manually when the other sides of the workpieces are supposed to be cut.

The variation of the manual rotary indexer installation is depending on how the connected milling machine or lathe is operated. There are two types of installation methods for these tables, including the horizontal mounting and the vertical mounting.

For the horizontal mounting, the rotary table is installed on a horizontal surface, and the cutting orientation is supposed to be parallel to that of the rotary table, which is suitable for cutting relatively smaller workpieces.

As for the vertical mounting, the rotary table is installed vertically, and the cutting tools would cut through the surface of the workpieces axially or radially from the sides. In other words, no matter the cuts are conducted axially or radially, the cutting orientation is perpendicular to the surface of the workpieces.

A manual rotary indexer is mainly formed with the rotary table, the T-slot, and the table locking mechanism, and a right-angle tailstock is used optionally.

The rotary table, which contains the clamping system, is the main device for the manual rotary indexer. It supports and clamps the workpieces in place while rotating during the operation, which means it should be capable of receiving the forces that are given from the machine, either hydraulic or pneumatic, that it can holds the workpieces firmly without slipping during the processes.

The T-slot on the rotary table is used to allow for the rotary table to turn relative to the base under it, which is one of the components that stabilize the table when it rotates.

The table locking mechanism that is on the base of the table not only ensures the stability of the rotary table by locking the table to avoid it from moving, but also facilitates the smooth performance when the machine is operated.

The manual rotary indexer is primarily adopted for the smaller workpieces. When there is the need to cut the larger or heavier workpieces on a vertical milling machine or lathe, the tailstock would be used. It can help clamp the workpieces from the other side of the machine, which offers better support for the cutting processes.

As the above introduction has mentioned, the main purpose of a manual rotary indexer is to clamp on the workpieces for being cut, and the stabilizing of the workpieces would be clamping and indexing. The workpieces can be clamped hydraulically or pneumatically. While for the indexing process of the manual rotary indexer, opposite to the automatic indexing on the CNC rotary index table, the operators take the place of indexing the workpieces instead.

8613371530291

8613371530291