manual indexing rotary table brands

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

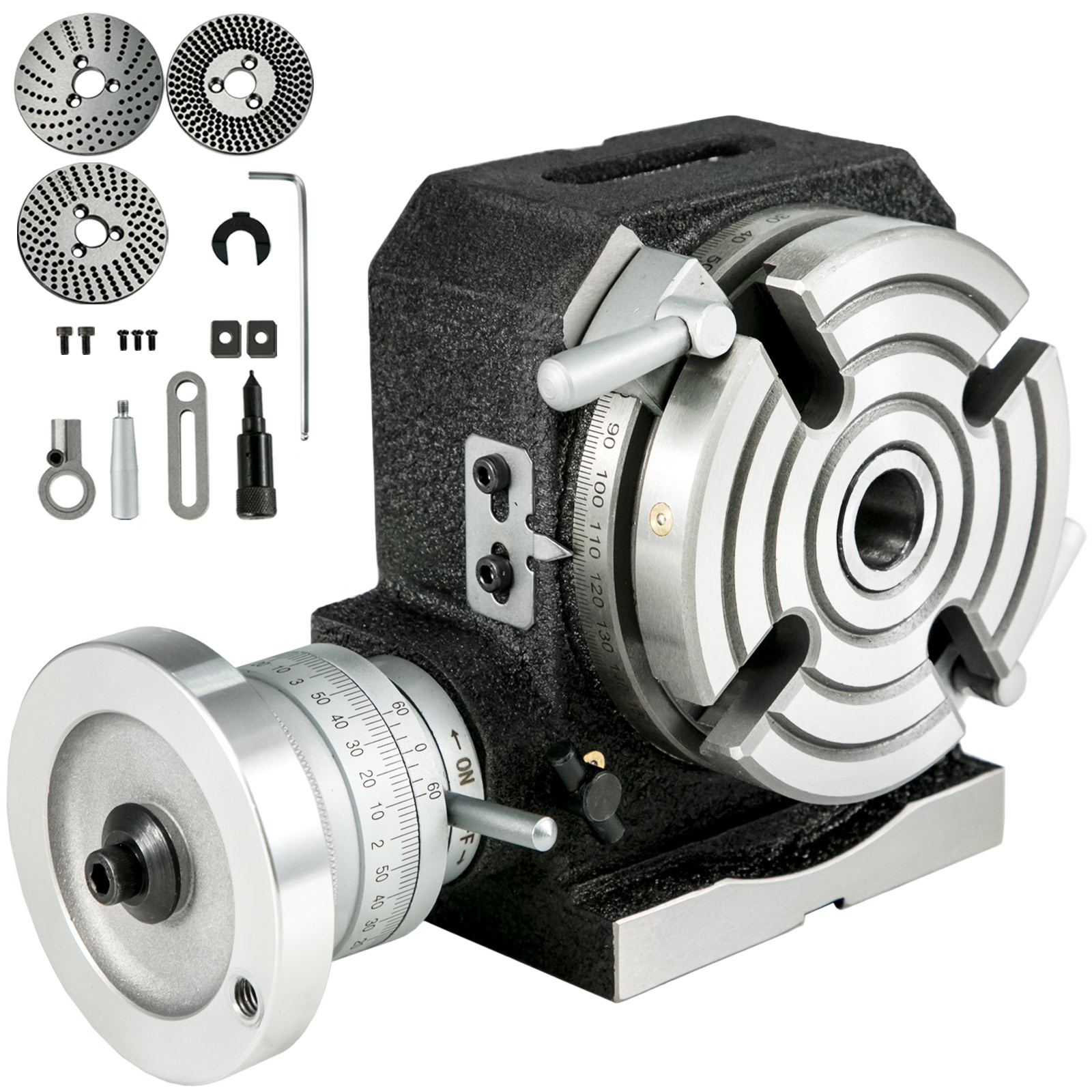

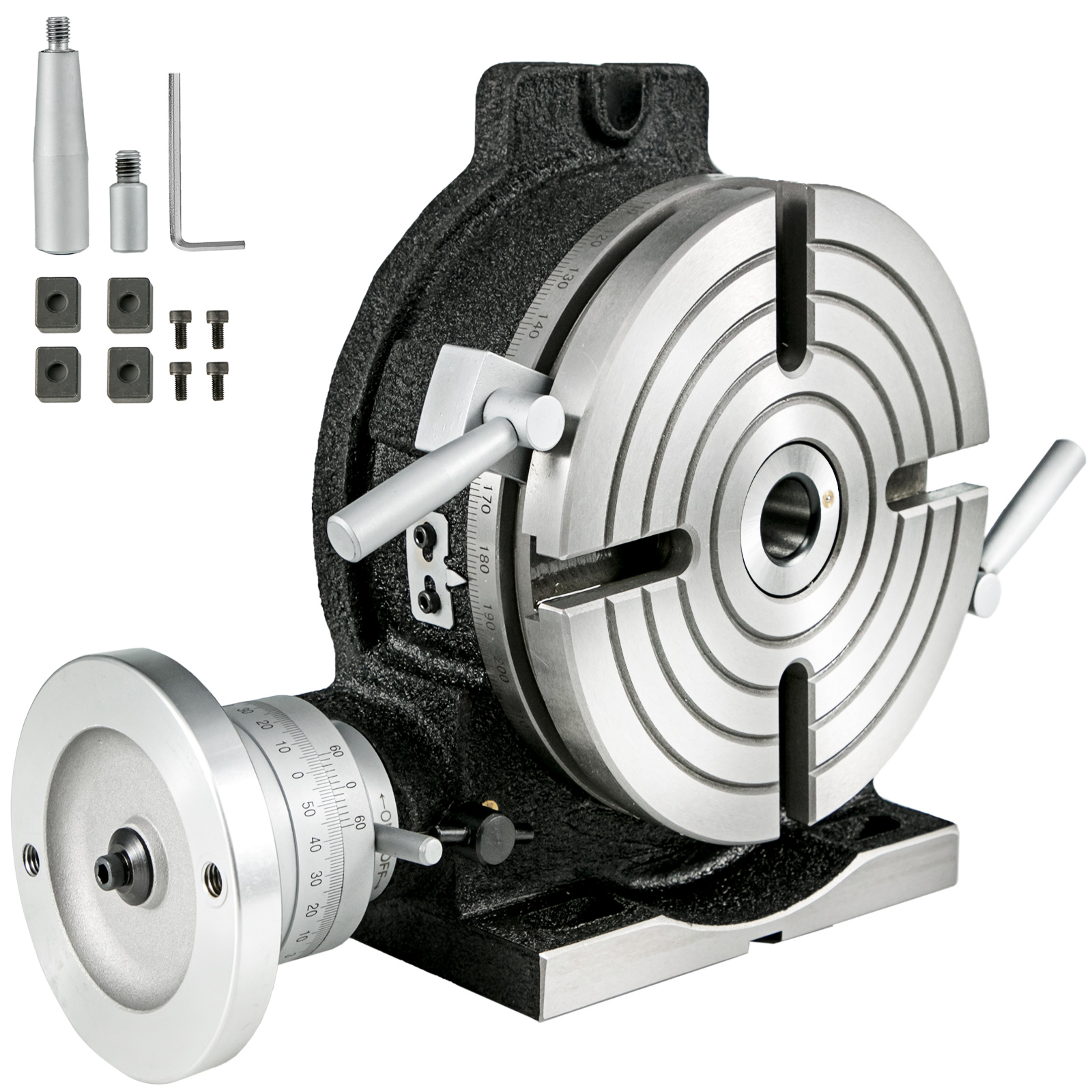

The RTBA is a unit manufactured by Kalamazoo company. It is a rotary table with a 6" table index. Furthermore, it has a numerous index combination by changing of index ring on a 36 spaces ...

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The ITP Series are the package version of the IT Rotary Tables. They are equipped with a gearbox and three-phase induction motor for a shorter lead time and fast delivery ...

The TRP Series are the package version of TR Rotary Tables. They are equipped with gearbox and three-phase induction motor for a shorter lead time and fast ...

The FTP Series are the package version of FT Ring Tables. They are equipped withgearbox and three-phase induction motor for a shorter lead time and fast reaction to the market ...

The “HOMGE” PRECISION INDEXING TABLES are constructed with an AIR CYLINDER between the mating surfaces. This system ensures reduces friction when heavy loads are applied to ...

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ppr.

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product such as robot guided ...

G.P.A. Italiana pneumatic rotary indexing tables are available in two versions: TAR 270 and TAR 160. TAR 270 can handle bigger loads, aided by the hydraulic control and double cylinder ...

The NC combines robustness and durability with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives ...

Rotary indexing tables provide an indexing axis for mounting workpieces on machine tools. They are designed to position workpieces at precise angles for different machining operations.

These devices are used on CNC machining centers, lathes, presses and other types of production or manufacturing machines. A CNC milling machine uses a rotary indexing table to provide a fourth or even a fifth axis for certain machining operations.

Such tables can be mounted either vertically or horizontally. The rotary drive can be manual, electric, pneumatic or hydraulic. It uses either a rack and pinion, or a servomotor and gearbox. Some models have multiple rotating tables, providing multi-axis workpiece mounting.

When selecting a rotary indexing table, be sure to determine the mounting orientation: horizontal, vertical, multi-axis and tilting. Other factors are table diameter, maximum load capacity and indexing accuracy.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

In many cases, the work pieces created through CNC machining would be impossible without computer assistance. The code used to communicate between the CNC machine and computer software is specialized. Older machines, or manual machines, used hard wired controllers. However, new CNC machines rely on modern devices like CDs, USB drives, networks and so on.

A lathe or milling machine requires its own set of parts to work sufficiently. For example, an indexing head is needed to allow circular shaping. The indexing element allows the piece to be rotated at an angle or even divided into sections.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions. They are used on wire and sinking EDM machines, HSC machines, and laser equipment for precise angle positioning (index and burn). Our rotary indexing tables can also move simultaneously with one or more machine axes while operating (turn while burn).

All rotary indexing tables can be equipped with a precise clamping system for quick manual or pneumatic change of workpieces. Our sales staff will be pleased to give you any advice you may need, on site if requested.

Single-axis rotary index/turn while burn table with a 100 mm diameter faceplate. For vertical use only, with a maximum workpiece weight of 15 kg. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 100 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 15 kg can be machined. In vertical use, a workpiece with a maximum weight of 25 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 120 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 60 kg can be machined. In vertical use, a workpiece with a maximum weight of 40 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 140 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 80 kg can be machined. In vertical use, a workpiece with a maximum weight of 120 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 226 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 100 kg can be machined. In vertical use, a workpiece with a maximum weight of 300 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 340 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 300 kg can be machined. In vertical use, a workpiece with a maximum weight of 1000 kg can be machined. Available in bronzed or stainless steel. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 500 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 500 kg can be machined. In vertical use, a workpiece with a maximum weight of 2000 kg can be machined. Available in bronzed or stainless steel. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with either HSK A63 or HSK F63 tapers. In horizontal use, a workpiece with a maximum weight of 30 kg can be machined. In vertical use, a workpiece with a maximum weight of 50 kg can be machined.

Single-axis rotary indexing table with either SK50 or CAT tapers. In horizontal use, a workpiece with a maximum weight of 30 kg can be machined. In vertical use, a workpiece with a maximum weight of 50 kg can be machined.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

We hold expertise in offering an exclusive range of Manual Rotary Table to our esteemed clients. The offered rotary table is designed by latest technology according to the requirements laid down by our patrons. Apart from this, the offered rotary table is carefully inspected on each section in order to supply fault free range.

8613371530291

8613371530291