master bushing rotary table free sample

Special features?Some rotary tables cannot be used to rotatethe string, in which case the top drive isused. Some rotary tables are hydralically-driven to rotate with a low torque and lowspeed only. Above: Rotary table installed new.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 1 INTRODUCTION The large gap in the centre of the rotary bush- For this reason this way of drilling is mostlyThe rotary table used to be the way to drill in ings is referred to as the “bowl” due to its abandoned and replaced by top drives whichthe old days. There are still many rigs in the appearance. The bowl is where the slips are are covered in a later module.industry that use this technique, especially set to hold up the drill string during connec-on smaller land rigs where they don’t have tions and pipe trips as well as the point the drill On more modern rigs the rotary tables areenough space in the mast to house the travel- string passes through the floor into the well used for support use only. This means that ining block, hook, swivel and top drive. The bore. The rotary bushings connect to the Kelly the process of installing the drill bit or making/rotary tables installed on the modern rigs are bushings with either four pins or a square box breaking up pipe the rotary table can be used.now called rotary support tables and are connection to actually induce the spin required These so called rotary support tables do notdifferent in design and power/speed output. for drilling. The biggest downside of this meth- have the same capacity as the standard rotary od of drilling is that one can drill only one joint table; these usually have a maximum speed ofMost rotary tables are chain driven. These at the time plus back rimming is not possible. 25 rpm instead of 150 rpm.chains resemble very large bicycle chains.The chains require constant oiling while in Below: Gearbox rotary table with severely damaged teeth. The design of the rotary table knows four dif-operation to prevent excessive wear. Virtually ferent ways of powering the table. Electric (ACall rotary tables are equipped with rotary locks, or DC), hydraulic power or mechanically pow-one for each direction. Engaging the lock can ered by either the drawworks or on compoundeither prevent the rotary from turning in one rigs driven by the main engine’s power train.particular direction or from turning at all. Thisis commonly used by crews which don’t want Below: Rotary table installed new with anti-slip mats.to use a second pair of tongs to make up orbreak out pipe.

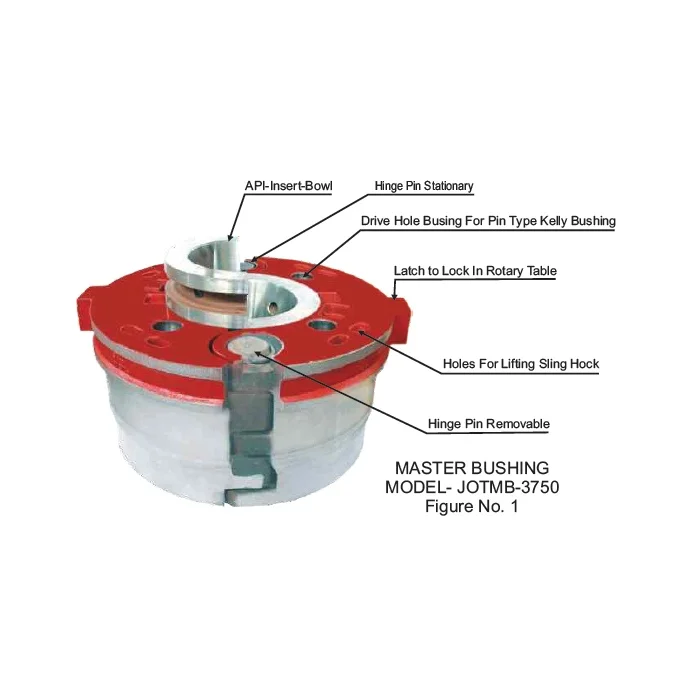

The rotary bushings are located at the centreof the rotary table. These bushings usuallyconsist of the master bushing and the insertbowls. These can generally be removed in twoseparate pieces to facilitate large items, i.e. Right: Pinion from gearboxdrill bits, to pass through the rotary table. severely damaged.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 2 Rotary Table Checklist • Ensure that safety matting fits around Drawings from the Rotary Table Checklist• Check the condition of the air brake the rotary table. housing. • Measure and record any wear on the• Check the condition of the chain and master bushings and inserts; record the sprockets (maximum chain stretch 3% position of the slips inside the drill pipe as per API RP 7F (2003) section A.3.5). inserts of the master bushings.• Ensure that the electrical cables and • Function-test the manual locking system junction boxes have an EX raating of the rotary table in both directions. required for zone 1. • Review the backlash measurement• Inspect the condition and operation of records. the gearbox; check the oil for possible contamination with water.• Review any oil analysis reports and record the frequency of the oil sampling. Cross-sectional model of rotary table air brake• Function test the rotary table at 120 rpm for 30 minutes in a clockwise rotation; check for heat development.• Function test in an anticlockwise rotation at slow speed (20 RPM) for a short period.• when function testing, allow time for the unit to warm through. Then check the noise and vibration levels. Do not run in reverser for prolonged periods.• Check the condition of the main bearing. Above: Rotary table and master bushing.• Ensure that the DC and/or AC motors draw cooling air form outside the hazard- ous areas and that spark arrestors are fitted on the discharge side of the DC motors or discharge outside the haszard- ous area. Example of wear limit on tapered bowls

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 3Above: Cracks found on the outer sideof the master bushings.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 4Above: Cracks in the lugs of the split-typemaster bushings.

Above: Rotary table with clearly worn master bushings and master bushing drill pipe inserts.

Left: The pin and the slots of the rotary master bushings need to be measured to ensure that they are within the OEM maximum wear limits.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 5 Left: Measure the neck of the master bushing inserts to ensure they are still within the OEM maximum wear limits.

Below: New master busning, drill pipe inserts, slips and safety clamp in proper condition.

Below: Clear indications of excessive wearon the tapered inserts and master bushings.The slips are lowered too deep into the masterbushing inserts, indicating excessive wear ofthe master bushing inserts.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 6Above: Disassembled bearing of the rotary table. Top Right: The bearings and bearing raceNote, the lack of lubricaton and the condition of the for this rotary table are completely destroyed.balls and the bearing race.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 7 Below: Brake housings are often found badly corroded.

Above: Damaged race and balls Above Right: Air-operated brake of the rotary table within the rotary table bearing. a new housing installed. Due to the brake’s location, corrosion on the brake housings is often severe, and they need regular replacement.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 8Above: Older totary tables are often driven byDC motors that need spark arrestors fitted to thecooling-air outlets.

Above: Damaged race and balls Above: Rotary table DC motor equipped within the rotary table bearing. new spark arrestors. Note, the purge alarm sensor in between the spark arrestors.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 9Above Left: New hydraulically-driven rotary tableinstalled and the tracks of the Iron Roughnect on top.

Left: Bushing pullers can also crack andneed to be included in the Lifting-Gear register. they reuire NDT inspections according to API RP 8B standards.

The Oil Rig Online International Drilling Systems Academy Training Specialists 1.2 Rotary Table – Page 10

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new rotary table master bushing or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement rotary table master bushing, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new rotary table master bushing are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

Drilling involves pipe handling operations in a wellbore, and this in turn requires a false rotary table, a vital cog in the overall success of the operations. At ShalePumps, the need for constant improvement has resulted in an extensive range of precision engineered equipment, of which the false rotary table occupies the limelight.

This hydraulically driven false rotary table is guaranteed to seamlessly engage the tubulars in the wellbore. Pivotal to drilling operations are the sequence of engaging and lowering tubulars into the wellbore. The false rotary table manufactured at our facility is a fine example of harmony between design, materials and precision engineering.

Featuring a mighty load capacity of 1.3 million pounds operating at a maximum speed of 20 rpm, the false rotary table assists the drilling operations in continuous long drawn operations. Pipe handling requires the seamless and sturdy operation of the false rotary table.

ShalePumps, backed by substantive body of experience and knowhow has developed this high performance false rotary table to ably support drilling operations by incorporating a blend of advanced materials and precision engineering. With a guaranteed long life and trouble free run, the ShalePumps false rotary table spins other models out of reckoning.

The 49 1/2" - 60 1/2" HMB is rated 750 ton. The 37 1/2" - 49 1/2" HMB is rated 500 Ton. Removable 500 ton, 4 taper split insert bowls are available for both models to allow handling capability for 2 3/8" to 13 3/8" tubular products. 750 ton, 4 taper insert bowls are available upon request for the 49 1/2" - 60 1/2" HMB. The HMB can easily be removed from the drill string by removal of one hinge pin. The Den-Con 27 RPH Roller Kelly Bushing is the drive bushing used with HMB 37 1/2" - 49 1/2".

The Den-Con SPB Solid Body Pin Drive master bushing is available for 20 1/2" - 27 1/2" rotary tables and is rated 500 ton. Removable 500 ton, 4 taper split insert bowls are available to allow handling capability for 2 3/8" to 13 3/8" tubular products. Refer to parts tables for casing bowls and sizes.

The Den-Con SMB Split Pin Drive master bushing is available for 17 1/2" - 27 1/2" rotary tables and is rated 500 ton. The SMB is a split master bushing with the API 4 taper machined into the body halves to handle 8 5/8" & smaller tubular products. This bushing is a split design to eliminate the need to strip over the master bushing while running large tools during surface hole work. The SMB does not allow for use of removable insert bowls. All of the pin drive master bushings have Pin drive hole locations to API dimensions.

The Den-Con SSD Split Square Drive Master Bushing is designed as a replacement bushing for all original O.E.M. manufactured bushings. This bushing is available for 17 1/2" to 27 1/2" Rotary Tables and is rated at 500 ton. All bushings have the standard API 4 taper to handle 8 5/8" and smaller tubular products.

The 49 1/2" - 60 1/2" HMB is rated 750 ton. The 37 1/2" - 49 1/2" HMB is rated 500 Ton. Removable 500 ton, 4 taper split insert bowls are available for both models to allow handling capability for 2 3/8" to 13 3/8" tubular products. 750 ton, 4 taper insert bowls are available upon request for the 49 1/2" - 60 1/2" HMB. The HMB can easily be removed from the drill string by removal of one hinge pin. The Den-Con 27 RPH Roller Kelly Bushing is the drive bushing used with HMB 37 1/2" - 49 1/2".

The Den-Con SPB Solid Body Pin Drive master bushing is available for 20 1/2" - 27 1/2" rotary tables and is rated 500 ton. Removable 500 ton, 4 taper split insert bowls are available to allow handling capability for 2 3/8" to 13 3/8" tubular products. Refer to parts tables for casing bowls and sizes.

The Den-Con SMB Split Pin Drive master bushing is available for 17 1/2" - 27 1/2" rotary tables and is rated 500 ton. The SMB is a split master bushing with the API 4 taper machined into the body halves to handle 8 5/8" & smaller tubular products. This bushing is a split design to eliminate the need to strip over the master bushing while running large tools during surface hole work. The SMB does not allow for use of removable insert bowls. All of the pin drive master bushings have Pin drive hole locations to API dimensions.

The Den-Con SSD Split Square Drive Master Bushing is designed as a replacement bushing for all original O.E.M. manufactured bushings. This bushing is available for 17 1/2" to 27 1/2" Rotary Tables and is rated at 500 ton. All bushings have the standard API 4 taper to handle 8 5/8" and smaller tubular products.

n: a device that fits into the rotary table to accommodate the slips and drive the kelly bushing so that the rotating motion of the rotary table can be transmitted to the kelly.

n: the recording of information derived from examination and analysis of formation cuttings made by the bit and of mud circulated out of the hole. A portion of the mud is diverted through a gas-detecting device. Cuttings brought up by the mud are examined under ultraviolet light to detect the presence of oil or gas. Mud logging is often carried out in a portable laboratory set up at the well site.

manual spiders that use standard rotary slips as described in Item c) that are not capable for use as elevators and are installed on or above the master bushing/rotary table

manual spiders that use nonstandard rotary slips not having a taper of 33.333 cm/m (4 in./ft) not capable of use as elevators, and installed on or above the master bushing/rotary table

spring, pneumatic, or hydraulic spiders with integral slips not capable for use as elevators and are installed on or above the master bushing/rotary table

In this simple diagram of a drilling rig, #20 (in blue) is the rotary table. The drill string, while the rotary table rotates it. (Note: Force is not actually applied from the top (as to push) but rather the weight is at the bottom of the drill string like a pendulum on a string.)

A rotary table is a mechanical device on a drilling rig that provides clockwise (as viewed from above) rotational force to the drill string to facilitate the process of drilling a borehole. Rotary speed is the number of times the rotary table makes one full revolution in one minute (rpm).

The rotary table is also called a turntable. Most rotary tables are chain driven. These chains resemble very large bicycle chains. The chains require constant oiling to prevent burning and seizing. Virtually all rotary tables are equipped with a rotary lock". Engaging the lock can either prevent the rotary from turning in one particular direction, or from turning at all. This is commonly used by crews in lieu of using a second pair of tongs to makeup or break out pipes. The rotary bushings are located at the center of the rotary table. These can generally be removed in two separate pieces to facilitate large items, e.g. drill bits, to pass through the rotary table. The large gap in the center of the rotary bushings is referred to as the "bowl" due to its appearance. The bowl is where the slips are set to hold up the drill string during connections and pipe trips as well as the point the drill string passes through the floor into the wellbore. The rotary bushings connect to the kelly bushings to actually induce the spin required for drilling.

Most recently manufactured rigs no longer feature rotary drives. These newer rigs have opted for top drive technology. In top drive, the drill string is turned by mechanisms located in the top drive that is attached to the blocks. There is no need for the swivel because the top drive does all the necessary actions. The top drive does not eliminate the kelly bar and the kelly bushings.

8613371530291

8613371530291