mazak 4th axis rotary table brands

The VERTICAL TRAVELING COLUMN (VTC) 200C Vertical Machining Center features a powerful 40 Taper spindle, full traveling column design and fixed table for machining of extremely long and heavy workpieces. Or with a table center partition the machine work envelop can be transformed into two separate work areas that allow the machine to be in cycle in one work area, while a part is being set up in the other work area. The machine also delivers fast rapid traverse rates to reduce non-cut times.

Mazak SmoothG CNC Control, 4th Axis Programmable with Mazak MR-250RAM01 Rotary Table with 250mm Faceplate and Tailstock, Renishaw Wireless RTS Tool Probe and OMP 600 Parts Probe System, Grundfos 213 PSI Through Spindle Coolant, 48 Station Expanded Tool Changer, Remote Jog Handle with LCD Screen, Synchronized Tapping, Cylindrical Interpolation, Ethernet Port, 8MB Expanded Program Storage, Tool Life Management and Breakage Detection, Jorgensen Chip Conveyor, Coolant System with Tank and Pumps, Full Top Enclosure Option, Machine Manuals. Mazak Dealer Demo sold in August 2020. Note: Vises, Tool Holders, Chick Fixture plate, Mist Collector - NOT INCLUDED WITH QUOTED PRICE.

CNC ROTARY TABLE CARBIDE WORM SYSTEM ■ WORM WHEEL Worldwide Field-proven, NIKKEN CNC Rotary Table NIKKEN Carbide Worm Screw System Ion Nitrided Worm Wheel HV980 NIKKEN produce all worm wheels in their CNC Rotary Tables from custom specified steel. During the production process the material is further hardened and ion-nitrided, giving unbeatable performance in service due to exceptional friction-resistance. The tooth surface and core material hardness is shown below. Depth 0.1mm HV 980 Phosphor Bronze Worm Wheel Inside HRC 36 Hardness of Worm Wheel Backlash Compensation Carbide Worm Screw ■...

VCS-430A CNC ROTARY TABLE OPTIONS CNC202MA CNC202MA Specifications • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

• Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle

VCS-530C CNC ROTARY TABLE OPTIONS CNC202MA • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole 530

CNC260LMA Specifications • Diameter of Table 0mm : 0260 • Max Work Load (kg) : 350(H) 175(V) • Rotation Speed : 16.6(min"), 33.3(min") • Indexing Accuracy (sec) : 20 • Clamping Torque (Nm) : 588 • Net Weight (kg) : 120 • Diameter of Spindle Hole : 08OH7 ■ Diameter of Table 0mm ■ Max Work Load (kg) ■ Rotation Speed ■ Indexing Accuracy (sec) ■ Clamping Torque (Nm) ■ Net Weight (kg) ■ Motor Type ■ Diameter of Spindle Hole

• Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle • Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle

CNC ROTARY TABLE OPTIONS VTC-200C-II & VTC-530C 255 ST (265 ST) • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-200C-II and VTC-530C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-200C-II and...

CNC ROTARY TABLE OPTIONS VTC-300C-II & VTC-760C 380 ST • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-300C-II and VTC-760C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-300C-II and VTC-760C are...

CNC ROTARY TABLE OPTIONS VTC-300C-II & VTC-760C 380 ST • CNC Rotary Tables for VTC-300C-II and VTC-760C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm : Ø200 • Max Work Load (kg) : 60(0 to 30°) 40(30° to 90°) • Rotation Speed : 22.2 min-1 (Rotary) : 16.6 min-1 (Tilting) • Indexing Accuracy (sec) : 20 (Rotary), 60 (Tilting) • Clamping Torque (Nm) : 588 (Rotary), 612 (Tilting) Clamping System 3.5MPa • Net Weight (kg) : 160 • Motor Type : HF-H105T-A48 (Rotary) : HF-H105T-A48 (Tilting) • Diameter of Spindle Hole :...

VTC-800/30SR ROTARY TABLE OPTIONS CNC401MA • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

VTC-800/30SR ROTARY TABLE OPTIONS 800 410 • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

CNCB450MA Specifications 1 Diameter of Table 0mm 1Max Work Load (kg) 1Rotation Speed 1 Indexing Accuracy (sec) 1Clamping Torque (Nm) 1 Net Weight (kg) 1Motor Type 1 Diameter of Spindle Hole CNCB630MA 800 CNCB630MA Specifications • Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

The Mazak VCN-510C is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

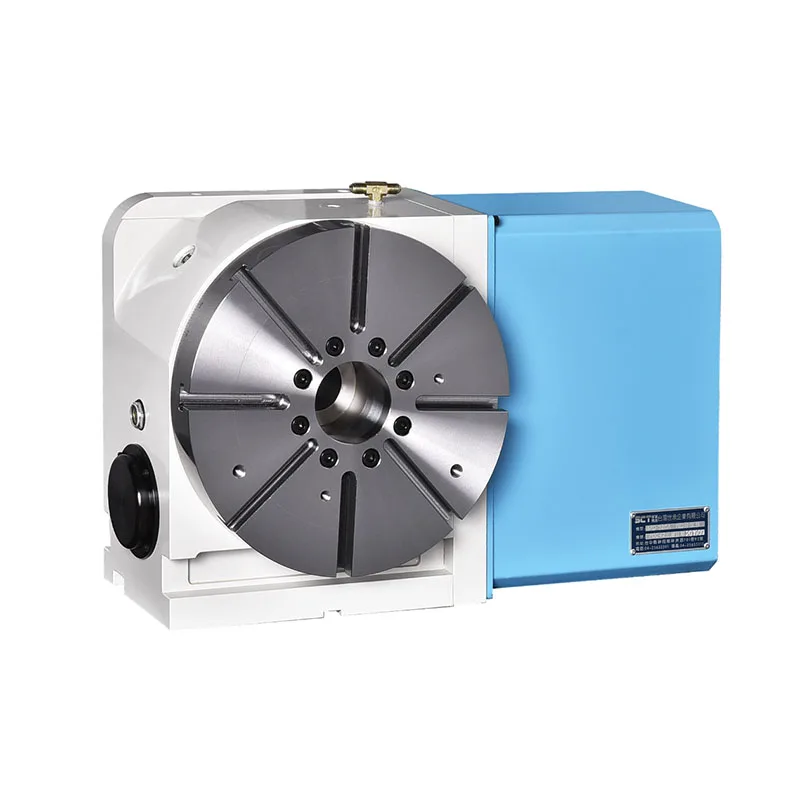

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

Whether your CNC control has AC or DC drives, uses Fanuc, Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build your rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we also supply the parts you need; such as amplifiers, drives, cables and connectors. If your application does not require simultaneous 4th axis cutting, we offer an easy-to-program, single-axis control box that can be M-function interfaced to your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

KME CNC Rigid Cast Iron Trunnion Tables are one of the leaders in the industry for accuracy, surface finishes and repeatability. Allowing you to speed up your cycle times, these tables are ideal for high volume production applications. Powerful and compact trunnion design ensures smooth operation over the entire travel range.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

8613371530291

8613371530291