torque motor rotary table for sale

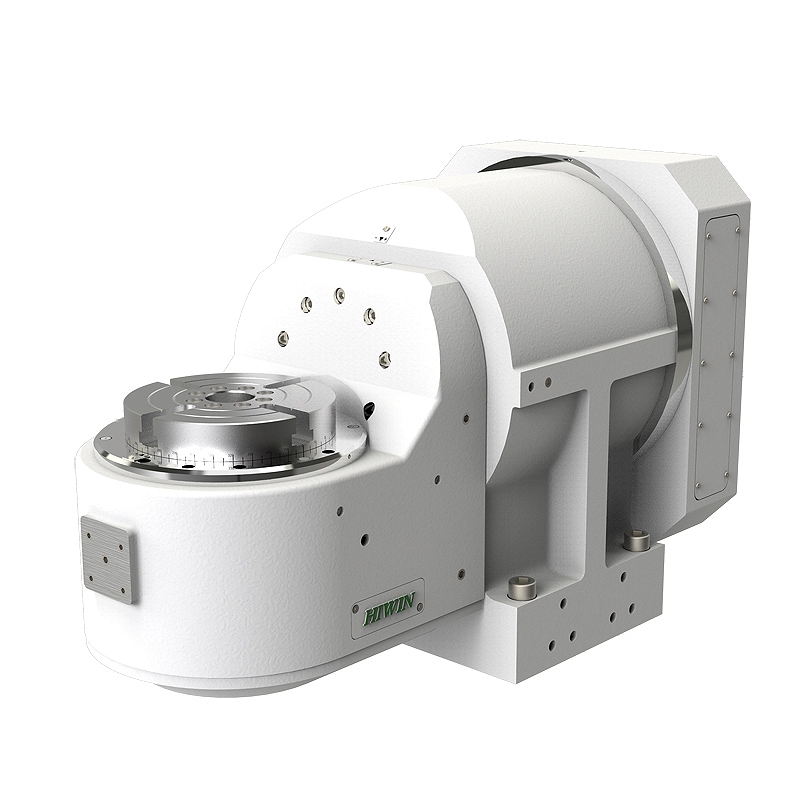

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

The direct drive rotary tables of the RAS series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled ...

The horizontal rotary tables of the RCH series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled ...

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

Rotary tables are direct-drive rotary motors designed to drive loads directly without the need for a transmission mechanism, such as gears or belts. A rotary table consists of guides, torque motor, encoder feedback and cover. The advantages of a direct-drive rotary table are high dynamic response, high system rigidity, compact design and low noise level. Direct-drive rotary tables are ideal for high torques at low speed, scanning applications and for point-to-point movements.

TJR provides torque motor rotary tables with excellent acceleration and deceleration capabilities. Our torque motor rotary tables are zero-backlash, extremely rigid, wear-free durability, have high dynamic accuracy, are suitable for a wide range of automated production machining.

Ensure that your servo drive can handle the Nominal- and Peakcurrent of the Motor. An adjustment of the Speed and DC Bus Voltage can be done after consultation. The nominal data in this datasheet are based on an ambient/coolant temperature of 20°C.

Because the exact duty type depends also on the thermal connection of the motor, the embedded thermal monitoring system has to be analysed and attented. However, attention has to be payed that the temperature sensors do not show the exact temperature of the winding and this could be up to 20 K higher due to thermal capacities. Despite an electrical insulation towards the winding, you are only allowed to connect the sensors to your controller by using a galvanic separation in between.

A new report released by Market Research Update is Torque Motor Rotary Tables Market 2023. This report provides up-to-date information on the market and also pinpoint all the opportunities for Torque Motor Rotary Tables market growth. The report begins with a market outlook and offers market basic introduction and definition of the worldwide Torque Motor Rotary Tables industry. The overview part of the report contains Torque Motor Rotary Tables market dynamics which includes market growth drivers, restraining factors, opportunities and Torque Motor Rotary Tables current trends along with the value chain analysis and pricing structure study.

Torque Motor Rotary Tables market is segmented by region, players, by Type, and by Application. Players, stakeholders, and other participants in the global Torque Motor Rotary Tables market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region, by Type and by Application in terms of revenue and forecast to 2029.

The report also includes the effects of the ongoing global crisis. COVID-19, on the Torque Motor Rotary Tables Market and what the future holds for it. It provides an analysis of the impact of the pandemic on the global economy. The epidemic has directly disrupted demand and the supply chain. The report also analyzes the financial impact on businesses and financial markets. This Torque Motor Rotary Tables report have gathered information from several industry delegates and have been involved in primary and secondary research to provide customers with data and strategies to address market challenges during and after the COVID-19 pandemic.

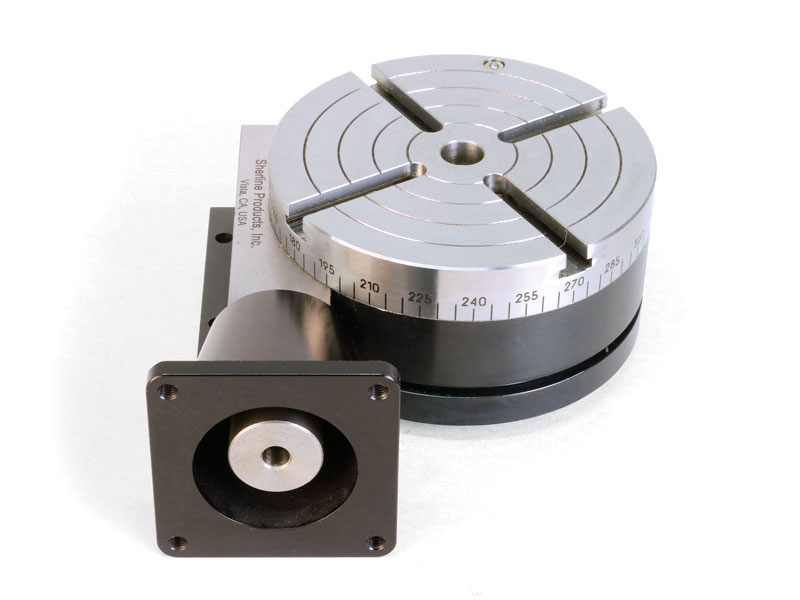

Top Key Players of the Torque Motor Rotary Tables Market:Hiwin Corporation, Motor Power Company, Velmex, Tecnotion BV, PARKER, SMC Corporation of America, Kitagawa, FIBRO INC, Techsystem, Magtrol, Sherlineipd, Newmark Systems Incorporated, Sankyo Automation, ZOLLERN GmbH & Co. KG

The global, regional, and other market statistics including CAGR, financial statements, volume, and market share mentioned in this report can be easily relied upon in light of their high precision and authenticity. The report also provides a study on the current and future demand of the Global Torque Motor Rotary Tables Market.

With the present market standards revealed, the Torque Motor Rotary Tables market research report has also illustrated the latest strategic developments and patterns of the market players in an unbiased manner. The report serves as a presumptive business document that can help the purchasers in the global market plan their next courses towards the position of the market"s future.

Torque Motor Rotary Tables market competitive landscape provides details and data information by players. The report offers comprehensive analysis and accurate statistics on revenue by the player. It also offers detailed analysis supported by reliable statistics on revenue (global and regional level) by players. Details included are company description, major business, company total revenue and the sales, revenue generated in Torque Motor Rotary Tables business, the date to enter into the Torque Motor Rotary Tables market, Torque Motor Rotary Tables product introduction, recent developments, etc.

In the end, the Torque Motor Rotary Tables Market report includes investment come analysis and development trend analysis. The present and future opportunities of the fastest growing international industry segments are coated throughout this report. This report additionally presents product specification, manufacturing method, and product cost structure, and price structure.

Products and technology are only valuable when coupled with skilled people and services to support them. ORIENTAL MOTOR U.S.A. CORP. has dedicated over 33 years to establishing a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Haas Model TRT70 Dual-Axis Tilting Rotary Table, 2.76" Platter, 3 lb. Max. Part Weight, 410°/sec Max. Tilt and Rotary Speed, 0.001° Resolution, 4.22" Aux. Platter, New 2017. VIRTUALLY UNUSED

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

The motor drives are designed to accommodate a wide range of precision motion applications such as optical metrology; circular geometry gages; and micro machining with ultra-precision scanning, velocity control, speed regulation and precision indexing.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

8613371530291

8613371530291