troyke rotary table manual factory

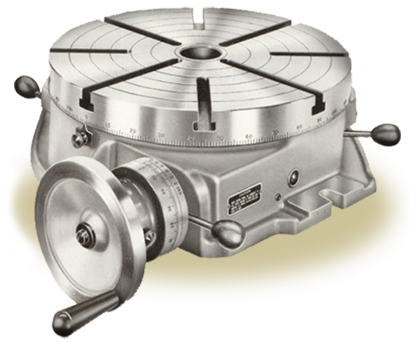

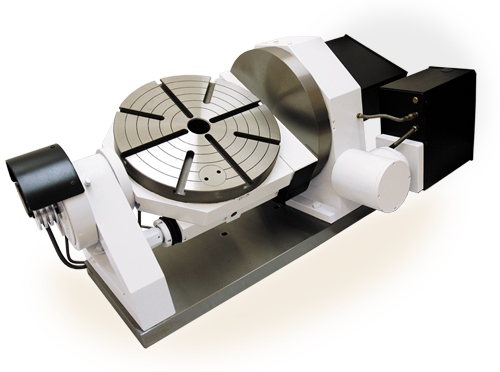

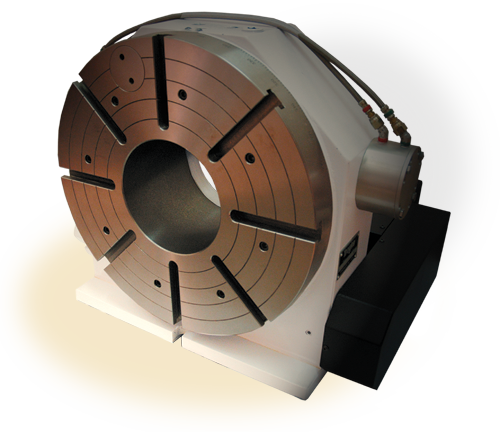

Troyke super precision, heavy-duty manual rotary tables range in size from 10" to 30" in diameter. The Manual Series features a rigid manual rotary table design and can be mounted horizontally or vertically. These precision manual rotary tables are designed to accept dividing attachments, encoders, variable speed drives and a variety of tooling and workholding options.

Troyke Manufacturing Company has been manufacturing Rotary Tables since 1939. During that period they have evolved from a manufacturer of Manual Rotary Tables to a manufacturer of 4th and 5th axis Rotary Positioning Systems that will increase productivity on any Vertical Machining Center. The Troyke rotary table specialists at CNC Engineering, Inc. can help you choose the right table and integration package for your application.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

I"m very interested in this discussion. I have a Jet JMD-18. My rotary table is an Enco 6" dividing head that rotates from horizontal to vertical. The vulnerability of smaller RT"s is rigidity during cut. On a few occasions, I have had minor rotation during the cut, and it"s difficult to re-set the point of origin after that.

I, too, am contemplating an 8" table. Still, 83 lbs dead lift ... My 100 year old L.W. Chuck 6" vise is about 60 lbs. I"m no weakling, but it"s a challenge.

Industrial Machinery Manuals Is Proud to Offer 1 Digitally Enhanced Quality Bound Copy Of A: Troyke BH-12, BH and FH Rotary Tables Illustrations Manual This...

Since way oil is designed specifically for sliding surfaces and it"s a low rpm and load situation I just use Vactra no. 2 also. My older Vertex 6" has one needle roller bearing in it. They later changed that to plain cast iron sleeve bearings. Mine used some type of grease from the factory for the worm and wheel. Unless it"s a properly designed and sealed R/T meant to be used half full of oil, then random when you remember to do so oiling seems to work well enough. I disassembled and washed mine out after buying it. There was hardly any grinding grit in it, but enough I still think it was worth doing. I don"t know the torque on that nut either. It"s meant to hold the table together obviously, but also remove any axial movement between the table surface and the base casting. Get it too tight and it can start to be felt with the hand wheel and you"ll vastly increase the wear. If I remember correctly I used maybe a 1/8th- 1/4 of a turn past finger tight and it seems ok. That was about what mine had when I pulled it apart. Gently prying up between the base casting and the table with an indicator tip on the table will show if that preload nut isn"t tight enough.

8613371530291

8613371530291