troyke rotary table manual made in china

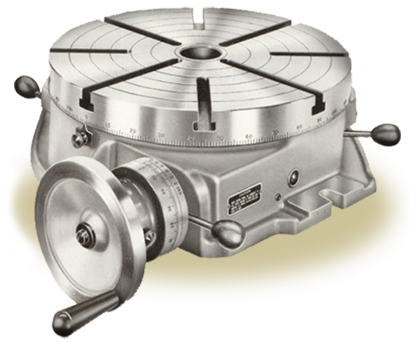

Troyke super precision, heavy-duty manual rotary tables range in size from 10" to 30" in diameter. The Manual Series features a rigid manual rotary table design and can be mounted horizontally or vertically. These precision manual rotary tables are designed to accept dividing attachments, encoders, variable speed drives and a variety of tooling and workholding options.

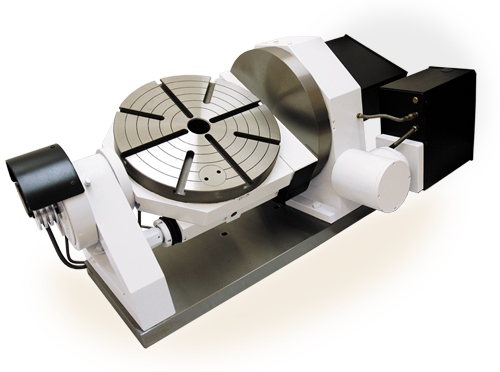

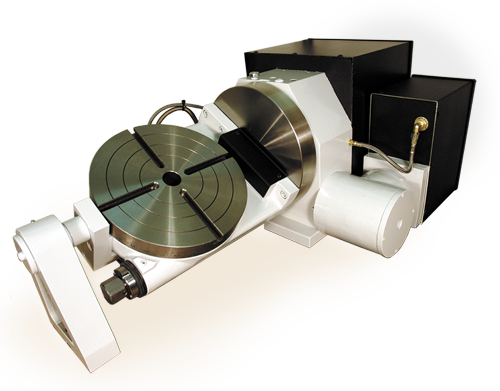

Troyke TDL Series Tilting Rotary Tables range in size from 8” to 25” diameters. The TDL Series is available as a single or dual spindle, (rotary axis) tilting rotary to be used on complex 5 axis machining applications. These heavy-duty tilting rotary tables are interfaced to the machine control as a rotary indexer or full 4th and 5th axis and offer a variety of tooling and work holding options.

Industrial Machinery Manuals Is Proud to Offer 1 Digitally Enhanced Quality Bound Copy Of A: Troyke BH-12, BH and FH Rotary Tables Illustrations Manual This...

Have not heard from you in a while. The Mastercrft table I have,(model 700) I bought from J&L or maby ENCO. It is made in USA, and as for as workmanship, I give it better than average. It"s not Moore but it"s not China. The base mount has 2 holes for tee slot bolts and it has a center 5/8 fine tapped bolt hole. My Gullridge RT has a 5/8 hole in the center, so I just use one bolt to secure the XY table. Eats daylight, though. The RT plus the XY is 6 5/8 high. --Cool project update-- I am now using my RT on my clausing8520 to do some work on a sprocket. It is 12" in dia, won"t fit my atlas10, was gunna take it to work and do the job on the Moriseki lathe, but it was the weekend and I wanted to try out my RT. Job is to bore the 2" center hole out to 3.156 and add 5 holes for bolts on 110mm patern. Started by making an aluminum washer to go from the 2" existing bore to 5/8" hole for the attaching bolt. made this on the atlas. Made it as tight as possible, to minimize out of con stack-up when indicating the sprockrt center with the RT axis of rotation. Bolted the sprocket to the table, using the stepped washer and put a 1/8" aliminum sacrificial plate under the sprocket, as I am going to mill through to cut off the part. Before I did that, I drilled the holes. After that, I milled some test rings in the washer to observe calculated vs. actual cut diameter. Now you know what number to dial in to get the cut to come out the right size. Was able to cut two rings, one at .5 radius and one at .75 radius. I used a 5/32" carbide center cutting 4 flute mill. I had the final hole started last night, got late, gunna funish the job tonight. This sprocket is for my honda ascot 500 motorcycle being converted to have wide knobby ATV tires. I will post pictures, don"t worry.-- Hal, I hope perhaps I gave you some needed info on the table. I am also working on cnc-ing some of my machines. Perhaps that might be a better direction. --Doozer in Buffalo

The small part of me that cringes is when something exceptional is facing some degree of destruction. Some things are limited in existing numbers and every one of them that gets altered/destroyed reduces that available quantity regardless of the purpose. I"ve got a 100 year old vise that is still in good condition (now) and several art pieces that are centuries old because someone took care of them. A Troyke ROTAB isn"t an art piece but it"s not too far a stretch to consider it within that realm for a toolmaker.

I own a Sherline 4" rotab and it is quite good. However, it is also somewhat limited in that it does not accept dividing wheels and it does not have a table release; you have to crank it around to get to your next location. It is quite well made, reliable and accurate. It will mount to a milling table as well as a tilting angle table without eating up that much room in Z.

I also own a Japan-made 6" Yuasa that is pretty much fully tooled up. This is a really fine, fully featured rotab that is probably the most cloned rotary table out there. Vertex makes a clone that is quite close. Smooth, accurate and no longer made.

The only other import I have heard of that might meet your needs is the Warco HV-4: https://www.warco.co.uk/rotary-tables-engineering-tools/124-hv4-rotary-table.html. At that price, I"m pretty sure it will be a Warco design but Chinese made. Cannot attest to how good it is but Warco sells some nice small stuff so you might inquire.

Troyke L Series indexing rotary and 5th axis tilting rotary tables range in size from 8" to 10" diameters. The L Series Rotary Tables are available as a manual or tilting CNC rotary table to be used on complex 5-axis machining applications. These heavy-duty tilting rotary tables are interfaced to the machine control as a rotary indexer or full 4th and 5th axis, and offer a variety of tooling and workholding options.

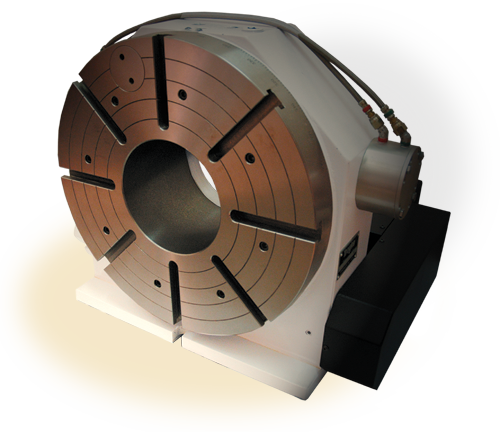

The Troyke DL Series 4th axis precision rotary tables range in size from 6.5" to 25" diameters. The DL Series Rotary Tables feature a rigid rotary table design that can be mounted horizontally or vertically. These heavy-duty Troyke rotary tables are interfaced to the machine control as a rotary indexer or full 4th axis and offer a variety of tooling and work holding options.

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

8613371530291

8613371530291