troyke rotary table parts made in china

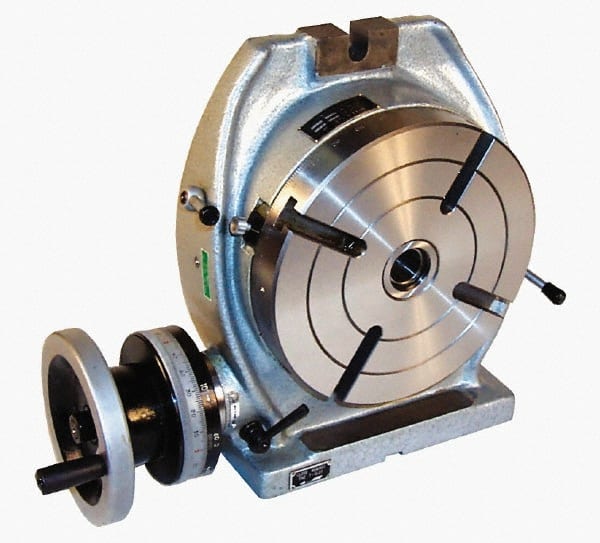

Troyke super precision, heavy-duty manual rotary tables range in size from 10" to 30" in diameter. The Manual Series features a rigid manual rotary table design and can be mounted horizontally or vertically. These precision manual rotary tables are designed to accept dividing attachments, encoders, variable speed drives and a variety of tooling and workholding options.

I have a Jet JTM-830 vertical mill with a 7-inch wide table. Would there be anything wrong with using a 10-inch rotary table? It would hang over a bit, but it seems like it would allow for easier clamping, and machine table movement would allow me to cover the whole table. I obviously don"t want one so large or heavy that it affects the machine, but on the other hand, a 6-inch rotary table seems like it would have too many limitations.

I have a 12" Van Norman rotary table (probably 125lbs+) I use on all our machines, from the Grizzly Millrite copy to the VN 22L. I wouldn"t LEAVE it bolted to the table of the Grizzly, especially run way over to one side, but if the knee won"t hold that up, it probably shouldn"t be called mill. Get a big "un.

The 10" and 12" rotary table is fairly common in shops with standard Bridgeport mill types having a 9" table. The 10" should be adequate and a lot lighter than the 12"s. There are also 8" rotary tables. I doubt weight would be an issue for these smaller sizes.

Your assessment is right on the money. Buy the largest table you are comfortable in handling. I use a 12" and wouldn"t want one any smaller. It"s just too damned hard to make acceptable setups on small tables. If it weren"t for the difficulty of handling the 15" Bridgeport table, I"d have bought that in place of the 12" one I own.

I"d have to admit that the majority of RT setups using toe clamps do eat up the outer 1"+ of the table surface. Thereby reducing the working envelope if no other means of work holding are available.

That"s the one place size can work against you. I have the right angle plate for my Bridgeport, and it"s all I can do to put the rotary table on the mill when it"s mounted to the plate. A lifting device certainly wouldn"t be a bad idea, especially now that I"m older and don"t have the physical strength necessary to handle the table. I guess my advice might be tempered with the comment that it depends on how you"d use your table--------the smaller tables can be easier to use when doing horizontal work, and don"t eat up spindle clearance quite as much.

You could always buy a smaller table and then add an aluminum sub table to it to make it larger. My table is 8" and I plan to make a 12" table top 1" thick. Then you can drill and tap it for clamps or whatever you prefer.

You could always buy a smaller table and then add an aluminum sub table to it to make it larger. My table is 8" and I plan to make a 12" table top 1" thick. Then you can drill and tap it for clamps or whatever you prefer.

That"s an excellent way to extend any rotary table. I have a plate that is about 16" diameter that pins to the center hole of my table for quick setup. I also drilled and counterbored the mounting holes so nothing is above the surface when it"s installed. As you suggest, it"s easy to drill and tap holes as necessary.

This is how that can work. This operation is milling radiused cheek horn slots (to 11"R) on locomotive axleboxes. The "plank" is a piece of 3/4" steel plate picked up as scrap and surface prepped. The DTI at right is placed so as to indicate rise of table and therefore exact depth of cut.

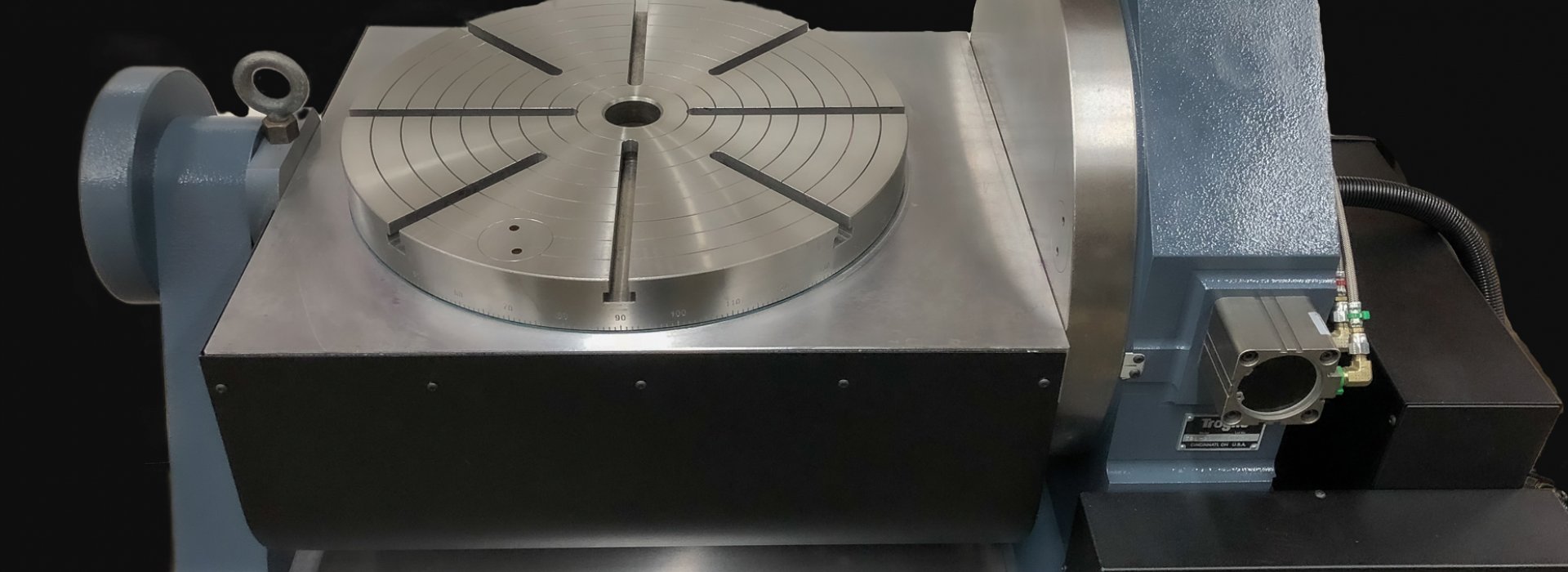

The rotary table is a restored 9" Troyke (ca 1949), a grimey lump picked up for peanuts on eBay but which turned out to be virtually unused under the grunge. I"m not sure of the weight of this but it"s about the heaviest table I"d want to lug around the workshop and keep off the machine and mount it each time I needed to use it.

The small part of me that cringes is when something exceptional is facing some degree of destruction. Some things are limited in existing numbers and every one of them that gets altered/destroyed reduces that available quantity regardless of the purpose. I"ve got a 100 year old vise that is still in good condition (now) and several art pieces that are centuries old because someone took care of them. A Troyke ROTAB isn"t an art piece but it"s not too far a stretch to consider it within that realm for a toolmaker.

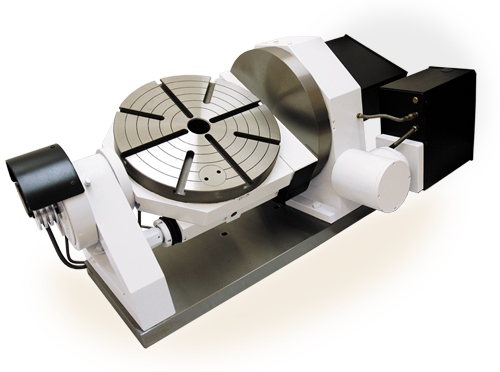

Troyke TDL Series Tilting Rotary Tables range in size from 8” to 25” diameters. The TDL Series is available as a single or dual spindle, (rotary axis) tilting rotary to be used on complex 5 axis machining applications. These heavy-duty tilting rotary tables are interfaced to the machine control as a rotary indexer or full 4th and 5th axis and offer a variety of tooling and work holding options.

If the 36:1 ratio isn"t too coarse for your needs, and you can deal with the T slots being cut right through your degree marks on the edge of the table (lol), then it may be ok. Based on my experience with Chinese and Indian tooling, expect that the lash between the worm and worm wheel will vary as the table turns, so you have to find a balance between the tight spots and loose spots.

I considered this same table for some time, but it wouldn"t do for the type of work required. I looked to the Sherline table instead, which is supposed to be really good, and eventually decided to build my own, based on a scaled down Troyke design. It"s going to take a long time, but it"ll be nicer than any miniature rotary table I could buy even if I wanted to spend the money. Plus, it"ll keep me off the streets and out of trouble.

5. Payments. PIS must receive the balance of the total purchase price no later than the close of business on the day following the auction (the "Final Payment Date"). All payments must be by cashier"s or certified check, federal wire transfer of immediately available funds or a corporate check accompanied with a bank letter of guarantee, and all of the foregoing must be in form, scope and substance acceptable to PIS. Credit cards are only accepted for Electronic bidding registration and for Liquidated Damages in the event of a default. If paying by credit card, the exchange rate for sales conducted in foreign currencies will be posted the day of the sale and will be based upon the current currency conversion rates. Without limiting PIS discretion, no corporate checks without a bank guarantee and no personal checks will be accepted. No title shall pass to Buyer until the total purchase price and all Taxes have been paid to PIS in collected funds.

6. Taxes. Buyer must also pay to PIS on or before the Final Payment Date, all sales, export, use and other taxes due to any federal, state or local taxing authority (the "Taxes") as a result of Buyer"s purchase, including without limitation, any taxes arising from any Buyer"s Premium (as defined below). To receive the benefit of any tax exemption, Buyer must supply PIS with a sales tax exemption certificate acceptable in form, scope and substance to PIS in PIS sole discretion.

8B. Goods weighing more than 100 pounds must be removed by a qualified, insured rigger. Before any removal, Buyer must provide PIS with a certificate of insurance from the rigger, which certificate must be in form, scope and content acceptable to PIS in PIS sole discretion. Without limiting PIS discretion, such certificate must show that the rigger carries comprehensive liability insurance written by an insurance carrier of national standing and in an amount of not less than two million dollars ($2,000,000.00). Policy must also carry a Workers’ Compensation rider. Without limiting the generality of the foregoing, Buyer shall restore and repair all real and personal property that is altered or damaged as a result of Buyer"s removal of the Goods. PIS shall have no responsibility to disconnect utilities to the sold asset, including electric, gas, waste and water lines. Buyer is solely responsible to properly remove and store in appropriate containers all fluids, oils, hazardous chemicals, etc., from machinery purchased. Buyer does hereby indemnify PIS, the owner of the Goods and the owner of the premises in which the Goods are located, from any and all claims, damages, and losses arising from Buyer"s actions or actions with respect to the Goods and Buyer"s presence on the premises in which the Goods are located, including without limitation, injuries to persons or property and environmental violations or contamination. Risk of loss on any Goods shall pass to the Buyer upon payment in full to PIS of all sums due from Buyer in respect to the Goods.

Industrial Machinery Manuals Is Proud to Offer 1 Digitally Enhanced Quality Bound Copy Of A: Troyke BH-12, BH and FH Rotary Tables Illustrations Manual This...

Here’s what I see in that picture of the engine throat being machined. It’s a CNC manufacturing center maybe, but not a lathe. I think that is a rotary 4th stage on a CNC mill or a CNC manufacturing center. It looks small, maybe even like a hobby table top machine. Comparing the size of the shank in comparison with the coolant nipple makes me think that’s a 1/4” shank, 3/8th max. Which means that collet is only ~ 1 inch. Again, hints of a small machine. The handle on the tailstock might be a good source for a dimension. Most clamping handles are standard. Check the link for candidate lengths.

Unfortunately, the link that I had for the video has broken. (Perhaps other wonk-readers know where it is duplicated?) But it was a montage of very short clips that showed little, if any, additional parts of the milling machine (thanks for correcting me) or manufacturing center.

Looks like the rotary table is made by a high end machinery company from Ohio called Troyke (www.troyke.com). I think it might be a DL-10-B series. Typical. Iranians love American equipment. Iran reminds me of pre WWI Germany when they lamented that the English would not let the Germans love them. A lot of Iranians I met in school lamented the same about the USA. Either way, another clue to throw out.

I concur with Andrew generally. This is a vertical CNC mill with a 4th axis rotary table. The cooling hose is adjustable by bending arbitrarily at each of the bumps. They are pretty standard and about 1/2” per bump. Also, the coolant opening is usually a little more than 1/4” (remember that flow goes more or less as pipe size cubed, so the dimensions can’t be very far from that else the coolant flow is zilch or a fire hose). That is consistent with a hand crank cross section of about 1/2” also. The implication is that this is a pretty small machine – and a pretty small rocket nozzle.

Perhaps it’s a thruster for 3rd stage post burn out trimming? Or maybe a small pressure fed ullage engine? Regen cooling is for hot, high Isp engines that burn a long time. All that plumbing requires a large amount of minimal fuel per burst if it were a thruster. Most thrusters are cooled by radiation. I’m more in favor of the vernier theory. That is assuming it’s a flight engine. No new news on what machine it might be. The uniformity in paint makes me think that the rotary table might have come with the machine which if true throws out the Troyke DL-10-B theory. Still chewing on machine ID.

Update from CNC wonks. The CNC wonks have come in with a first pass at the machine ID. Looks like I was wrong about the rotary stage after all. The best opinion yet is that the machine is a Fehlmann Picomax 20. Made in Switzerland. One CNC wonker says that Iran has a manufacturing license with a German company called Deckel. Deckel machines are held in high esteem around the world. Looking at this picture the spindle and spindle guide look pretty close if you accept that the Iranian video is flipped about the vertical axis.

Might it be local per SAE’s find? Sure, I still consider this problem open, but at least we’re starting to get some candidates. I think the clincher might come from the roatary table as it looks like the 4 axis came with the machine by nature of the paint being an exact match.

Following SAE’s Iranian link you’ll find they manufacture 2 mills. Looking for further information about these mills based on model numbers shows them to be remakes of Deckel equipment. I cannot find any good images or drawings of the spindle, but at the paint level, and the milling table, any of those two local machine might be it. Good catch.

8613371530291

8613371530291