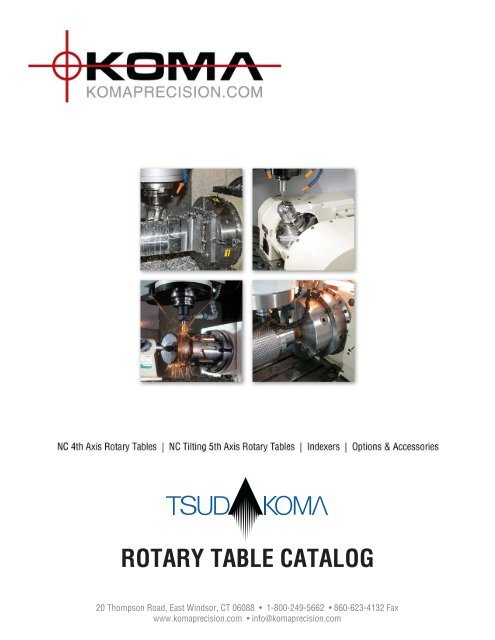

tsudakoma rotary table catalogue manufacturer

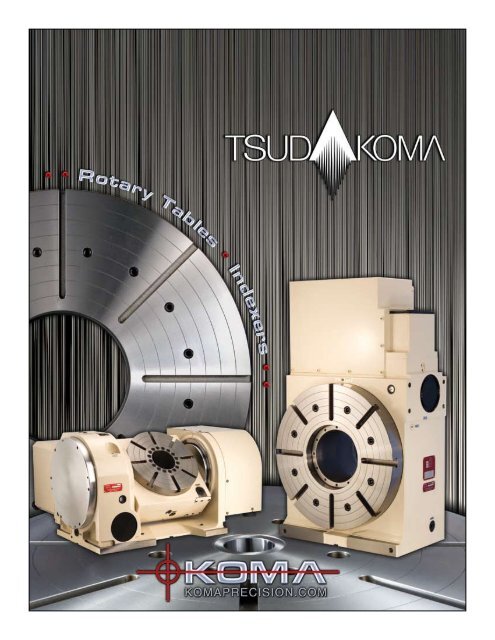

Tsudakoma"s relentless pursuit of ultimate performance, productivity and innovative technical advantages has made them the world’s largest and leading manufacturer of rotary tables. The rotary table specialists at CNC Engineering, Inc. can help you choose the right Tsudakoma rotary table and integration package for your application.

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

Notes: 1. For RN-100, RNA-160 and 200 models, “Spindle end” replaces “Table top” 2. Indexing accuracy for tables with scales reflects Heidenhain encoder accuracies.

In May 1991, the department moved into the Nonoichi production facility in the city of Kanazawa, a port city on the Japan Sea and the administrative center of Ishikawa Prefecture, west of the main island of Japan. With 18,720 square meters, Nonoichi facility is the largest rotary table manufacturing facility in the world.

The precision parts, including the heart of the rotary indexing tables, worm screw and worm wheel, are manufactured and assembled in fully air-conditioned rooms. Equipped with the latest CNC technology and computer-aided production planning

Tsudakoma guarantees precision, quality and consequently customer benefits. Modern CAD programs, 3D measuring machines and special equipment are used.

The data pool, based on a wealth of experience in the development of many special models for machine tool manufacturers and automobile manufacturers, enables Tsudakoma to offer the customer a product that is optimal for his requirements.

Tsudakoma manufactures machine vises, indexers, and NC Rotary Tables. Tsudakoma have a history of 40 years as a pioneer in the manufacturing of rotary tables in Japan, and boast the world’s largest production volume.

In the plant, equipped with computer controlled constant-temperature rooms, integrated and high-precision manufacturing is carried out. Processes include superb-quality gear cutting and grinding of worm gears, which are the most important components of an NC Rotary Tables, as well as ultra-precise assembly.

SU-matic, a worldwide leader in machining technology headquartered in Switzerland, has teamed with Okuma and Okuma distributors worldwide in designing the SU-matic RTSU 200 NC rotary table. This three year collaborative effort has resulted in a premium level rotary table combining innovative design with proven technology to provide exceptional 4th axis machining performance and productivity.

September 15, 2006 - The Tsudakoma TN-130 super compact NC tilting rotary table features massive clamp torque utilizing a newly designed dual disc tapered ball clamping system. The TN-130 is a high speed table with total flexibility for the addition of rotary joints, scales, and hydraulic chucks.

September 15, 2006 - Koma PARR+ precision pneumatic chucks provide ultra precise chucking (up to .00002 repeatability) for accurate thin wall turning and grinding. PARR+ chucks feature integral adjustable pneumatic power and high speed, maintenance free performance. Internal and external chucking is possible with the same unit. Standard models are usable up to 8,000 rpm and special models are available for use up to 11,000 rpm.

September 15, 2006 - KOMA Z+ angle heads effectively create an additional (Z+) axis for a CNC machining center. Equipping a VMC or HMC with a KOMA Z+ angle head reduces fixturing and set-up requirements, resulting in an increase in part accuracy and machine throughput. KOMA Z+ tools are available with 90° and dual 90° outputs, custom fixed angle outputs, and adjustable angle outputs. Heavy duty flange mounted heads and application specific custom heads are also available. KOMA Z+ angle head options...

March 5, 2003 - East Windsor, CT February 24, 2003. . .Tsudakoma combination table for high production engine block manufacturing is designed especially to be encapsulated in automotive flexible transfer lines or built into high production automotive parts machines. The table features an oversize driving mechanism and hydraulic tailstock support capable of handling heavy eccentric loads along with a powerful dual disk hydraulic clamping system on both the driving and outboard side of the cradle. A 10 port...

November 13, 2002 - for immediate release East Windsor, CT October 28, 2002...Koma Precision, Inc. announces the new Tsudakoma multi-faced NC rotary table designed for high production 5th axis applications on horizontal machining centers. Four 6 inch diameter platens rotate simultaneously at 33.3 RPM driven by an additional machine axis, or Tsudakoma"s own TPC-Jr controller with RS-232C interface capability. Powerful 156 N.m clamp for position machining is standard. Accuracy specification is +/- 7.5 arc second...

August 27, 2002 - Koma Precision, Inc. IMTS Booth A 8441 East Windsor, CT June 14, 2002...Koma Precision, Inc., will exhibit the new Tsudakoma TN Series Rotary Tables that feature high clamp torque of up to 625 ft. lbs., and high indexing speed, up to 44 RPM for the rotating axis, 22 RPM for the tilting axis, and a wide tilting range for greater performance, dramatic reductions in machining cycle times, at extremely cost competitive levels. With a smaller footprint, the TN Series compact design suits a wide...

April 10, 2002 - East Windsor, CT March 13, 2002. .Koma Precision announces the addition of the new low cost Tsudakoma RZ Series Indexer package that features compact design, high speed 33.3 RPM performance, high clamp torque of 1400 inch pounds and the TPC Jr controller with 1000 block programming capacity and RS 232C programming function standard--no MDI programming required. With renown Tsudakoma reliability, the RZ Series package is built for small VMC"s, drill and tap centers and pallet machines. The new...

8613371530291

8613371530291