tsudakoma rotary table catalogue in stock

Tsudakoma"s relentless pursuit of ultimate performance, productivity and innovative technical advantages has made them the world’s largest and leading manufacturer of rotary tables. The rotary table specialists at CNC Engineering, Inc. can help you choose the right Tsudakoma rotary table and integration package for your application.

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

Notes: 1. For RN-100, RNA-160 and 200 models, “Spindle end” replaces “Table top” 2. Indexing accuracy for tables with scales reflects Heidenhain encoder accuracies.

KOMA Precision, Inc. has updated its DMG-Mori Seiki Tsudakoma Rotary Table Selection Guide to include Tsudakoma"s RNA Series 4th axis rotary table and the Tsudakoma RTT-111, CA, a drop trunnion rotary table designed to utilize a variety of workholding systems.

The DMG-Mori Seiki Tsudakoma Selection Guide is the result of an effort to simplify the selection of Tsudakoma rotary tables specially suited to fit within the working envelope of the listed DMG-Mori Seiki machining centers. In addition to the standard rotary tables shown in the booklet, productivity enhancements include encoders, tailstocks, support spindles, faceplate and rotary joint options and high strength triple-walled stainless steel cabling packages.

"For almost 30 years KOMA Precision has been a source in machine tool productivity innovations. With over 30,000 rotary table installations, KOMA is the largest distributor of Tsudakoma NC rotary tables and indexers," said William Meo, President, KOMA Precision, Inc.

MATSUURA(2016) MODEL VX-1500 CNC VERTICAL MACHINING CENTER, FANUC G-TECH 31i B CNC CONTROL, AI CONTOUR CONTROL II, HIGH SPEED RISC PROCESSOR – 1000 BLOC LOOK AHEAD OPTION, AXIS JERK CONTROL & NANO SMOOTHING, DATA SERVER 4GB + ETHERNET INTERFACE, 67" X 28" WORKING TABLE, TRAVELS: X-60”, Y-27.55”, Z-24.01”, CAT 50, BIG-PLUS SPINDLE, 15,000 RPM, (30) ATC, COOLANT THRU SPINDLE, SIDE DISCHARGE CHIP CONVEYOR, LNS CHIP BLASTER F-SERIES JV40 HIGH PRESSURE 1000 PSI COOLANT SYSTEM, S/N 2000243 (YEAR 2015-12)

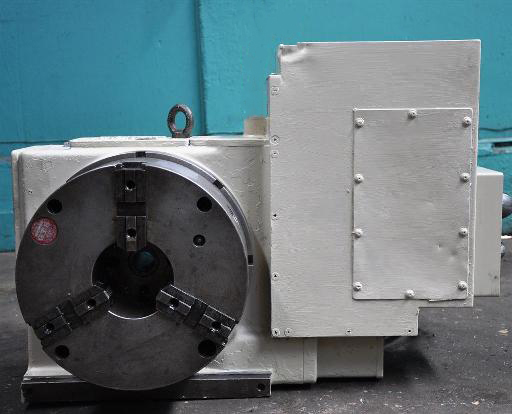

OKK (2007) MODEL VM7 III CNC VERTICAL MACHINING CENTER, FANUC 160iS-MB CNC CONTROL, 4TH & 5TH AXIS INTERFACE, HIGH PRECISION CONTOUR W/ 64 BIT RISC PROCESSOR, 29" X 60" TABLE, TRAVELS: X-61", Y-29", Z-26", CAT 50, (30) ATC, 10,000 RPM, COOLANT THRU SPINDLE, TSUDAKOMA RNCB-402 16” 4-AXIS ROTARY TABLE, CHIP BLASTER JV10 COOLANT 1000 PSI SYSTEM, CHIP CONVEYOR S/N 1070/MA65156

OKUMA (2007) MODEL MILLAC 561 V CNC VERTICAL MACHINING CENTER, FANUC 31iA CONTROL, 53" X 22" WORKING TABLE, TRAVELS: X-41.34”, Y-22.05”, Z-20.47”, CAT 50, (30) ATC, 20/15 HP POWER BIG PLUS SPINDLE, 6,000 RPM, COOLANT THRU SPINDLE READY, S/N 57539

OKK MODEL MCV-860 CNC VERTICAL MACHINING CENTER, FANUC 16i-M CNC CONTROL, EXTENDED MEMORY, TRAVELS: X-80", Y-34", Z-28", TAIL STOCK, 30/25 HP SPINDLE, COOLANT THRU SPINDLE, 6,000 RPM, CAT 50, (60) ATC, CHIP CONVEYOR, 4TH AND 5TH AXIS INTERFACE, TSUDAKOMA TRNC-301 4th & 5TH AXIS ROTARY TABLE, S/N 248

OKK MODEL MCV-660 VMC CNC VERTICAL MACHINING CENTER, FANUC16i-M CONTROL, 4TH AND 5TH AXIS INTERFACE, TRAVELS: X-60", Y-26", Z-26", TSUDAKOMA TRNC-301 12” 4th & 5TH AXIS ROTARY TABLE, CAT 50, TAIL STOCK, (30) ATC, DATA SERVER, 200MM RISER BLOCK ON COLUMN TO INCREASE SPINDLE FACE TO TABLE DISTANCE TO PRESERVE WORKING ENVELOPE ABOVE 5-AXIS, S/N 341

OKUMA & HOWAMODEL MILLAC 7VA CNC VERTICAL MACHINING CENTER, FANUC 11M CNC CONTROL, 31.5” X 79” TABLE, TRAVELS: X-71", Y-31", Z-24", 4-AXIS CAPACITY, CAT 50, (30) ATC, 3,600 RPM, S/N 17144 (MACHINE #11)

OKUMA & HOWAMODEL MILLAC 7VA CNC VERTICAL MACHINING CENTRER, FANUC 11M CNC CONTROL, 31.5” X 79” TABLE, TRAVELS: X-71", Y-31", Z-24", CAT 50, (30) ATC, 3,600 RPM, S/N 17145 (MACHINE #12)

OKUMA & HOWA MODEL MILLAC 6VA CNC VERTICAL MACHINING CENTER, FANUC 11M CNC CONTROL, 70” X 27” TABLE, TRAVELS: X-51", Y-25.5", Z-22.8", (30) ATC, 3,600 RPM, S/N 66527 (MACHINE #7)

OKUMA & HOWA MODEL MILLAC 5VA CNC VERTICAL MACHINING CENTRER, FANUC 11M CNC CONTROL, TSUDAKOMARNCB-402 4TH AXIS ROTARY TABLE, TRAVELS: X-41", Y-21.6", Z-18.78", CAT 50, (24) ATC, 3,600 RPM, S/N 5619 (MACHINE #8)

OKUMA & HOWAMODEL MILLAC 5VA CNC VERTICAL MACHINING CENTER, FANUC 6M CNC CONTROL, TSUDAKOMA TRNC-301 NC TILT & ROTARY TABLE (4-AXIS CONTINUOUS + 1 POSITIONAL) AXIS ROTARY TABLE, TRAVELS: X-51", Y-27.5", Z-31.4", CAT 50, (20) ATC, HAAS TAILSTOCK, 3,600 RPM, S/N 5463 (MACHINE #3)

OKUMA & HOWAMODEL MILLAC 4VA CNC VERTICAL MACHINING CENTER, FANUC 6M CNC CONTROL, TSUDAKOMA TRNC TRNC-201 NC TILT & ROTARY TABLE (4-AXIS CONTINUOUS + 1 POSITIONAL) AXIS ROTARY TABLE, TRAVELS: X-28", Y-16", Z-18", CAT 40, (24) ATC, HAAS TAILSTOCK, 6,000 RPM, S/N 2326 (MACHINE #5)

OKUMA & HOWA MODEL MILLAC 5VA CNC VERTICAL MACHINING CENTER, FANUC 6M CNC CONTROL, 21.5” X 63” TABLE, TRAVELS: X-51", Y-27.5", Z-31", 200MM SPACER, CAT 50, (20) ATC, 15HP, 3,600 RPM, S/N 5467 (MACHINE #4)

OKUMA & HOWA MODEL MILLAC 5VA CNC VERTICAL MACHINING CENTER, FANUC 6M CNC CONTROL, 21.5” X 55” TABLE, TRAVELS: X-41", Y-25", Z-21.7", CAT 50, (30) ATC, 15HP, 3,650 RPM, S/N 5444 (MACHINE #2)

OKUMA & HOWA MODEL MILLAC 4VA CNC VERTICAL MACHINING CENTER, FANUC 11M CNC CONTROL, 16” X 51” TABLE, TRAVELS: X-32", Y-17", Z-18", CAT 40, (24) ATC, 10HP, 6,000 RPM, S/N 02469 (MACHINE #6)

MAKINO MODEL A88 CNC HORIZONTAL MACHINING CENTER, PRO 3 SUPER GI.3 CNC CONTROL, TRAVELS: X-35.4", Y-31.5", Z-38", CAT 50, (40) ATC, HELICAL INTERPOLATION, DATA SERVER, (2) PALLET 24-½“ X 24-½“ W/ 1 DEGREE INDEXING TABLE, 35HP SPINDLE, (40) ATC, 12,000 RPM, COOLANT THRU SPINDLE, OEM COOLANT SYSTEM

SIP MODEL 740 CNC VERTICAL JIG BORING MACHINE, FANUC 11M CNC CONTROL, GLASS SCALES, TABLE 1,600 MM L X 1,240 MM W, TABLE STROKE (X-AXIS) 1,500 MM, HEAD STROKE (Y-AXIS): 1,000 MM, HOLLOW SHAFT STROKE (Z-AXIS): 300 MM, DISTANCE BETWEEN COLUMNS: 1,600 MM, MAX BETWEEN SPINDLE AND TABLE: 1,265 MM, PORTABLE TRAVERSE STROKE (W-AXIS): 900 MM, SPINDLE SPEEDS 30 TO 2,500 RPM, CAT 45, S/N 1704

Large Quantity including: (30) KURT Vises, (15) LANG & SPREITZER “5-Axis” CENTER-CLAMPING VISES, TsudakomaCNC Rotary Tables, CNC LIVE MILLING TOOLING, Vidmar & LISTA Cabinets, LISTA Work Benches, PORTABLE “Metro-Type” WIRE RACKS & PARTS CAGES, Shop Fans, H.D. Pallet Racking, Sand Blast Cabinets, Flammable Storage Cabinets, Work Benches, Granite Surface Plates, Cutting Tools, (400+) #CAT-40, # CAT-30 CNC Toolholders, CNC Tool Carts & Racks, Rotary Tables, V-Blocks, Plastic & Metal Shop Carts, End Mills, Carbide Inserts & Carbide End Mills, Drills, Reamers, Grinding Fixtures, Sunnen Hone Tooling, HUOT Drill Cabinets, Collets, Flex & Spring Collets, Stainless Steel & Wood Top Workbenches, YELLOW Metal Type Fire Extinguishers, Hand Tools, Metal Shop Lockers, Pelouze Scale, METTLER-TOLEDO Balance Digital Scale, Quincy #10 LAB OVEN, NIKON #SMZ-74ST MICROSCOPE w/ Cool-Snap #DYNO Camera System, LECO #736 OXYDGEN ANALYZER, TABER #5135 ABRASER w/ TABER #250 Wheel Refacer & Tabor Cabinet, MORSE Electric Barrel/Pallet Truck, RETCH #AS-200 8” SIEVE Shaker, Wire Caging, D.E. Grinders, Belt Sanders, Sanding/Finishing PAPER Supplies, Parts Wash Tanks, Arbor Presses, Tooling, Bridgeport Tooling, Maintenance Department and Much More!

Large Quantity including: Executive Desks, Office Dividers, Conference Room Tables & Chairs, Credenza’s, Digital Projector, LCD Televisions, Projection Screen, HON Lateral File Cabinets, 4-Drawer File Cabinets, Cafeteria Tables & Chairs, Appliances, Color Copier, Book Shelves, Tables, Chairs and Much More!

Founded in 1981 by mechanical engineer Giorgio C. Gay, ITALPLANT is a professional cam producer and rotary table supplier ranked top in the world. ITALPLANT has fostered and produced its own specific cams cutting and grinding machine; today, the company"s PLC has an accuracy of 0.04 mm. ITALPLANT"s rotary table and oscillator products include Globocylindrical, Parallel Axis, Toroidal, and Globoidal. Among these products, the Toroidal Indexers (TI) are of globocylindrical cam mechanisms with similar function to the other rotary tables manufactured by ITALPLANT, while with difference inside: The TI turns a ring instead of the dial plate. Based on this cradle the toroidal shape of rotary table, which is useful for customers who need bigger space in the central area.

8613371530291

8613371530291