two axis rotary table manufacturer

Our rotary indexing tables can be used on all EDM, laser, and HSC machines and are completely sealed (IP68) from dielectric fluid (water, oil). The final product details are determined in a consultation with you and/or the machine manufacturer and optimized to your requirements, (with or without clamper, electrical design, etc.). For most new machines, rotary indexing tables are controlled and programmed by the machine control system (A-axis). Older equipment often needs an additional control system for use with the rotary indexing table. Please verify all technical requests in advance with our sales staff or our technical department.

Used in newer machines the rotary indexing table mostly can be controlled and programmed by machine control system (A-axis). For older machines an additional control system is necessary to operate the rotary indexing table. Please clarify all technical requirements in advance with our sales team and our technical department.

Rusach International & Innovative Rotary Table Solutions are a leading worldwide supplier of small to medium sized compact CNC rotary tables, standard and application oriented designs, high accuracy, compact rotary tables. Thru bore rotary tables, horizontal rotary tables, vertical rotary tables, combination/convertible H-V rotary tables, multi spindle rotary tables, 2-axis tilting rotary tables, direct drive rigid and flexible rotary tables. Production style rotary tables to fit any machine.

Innovative Rotary Table Solutions has a full line of accessories like tail stocks, magnetic plates, rotary supports, steady rests, rotating tail stock supports and controllers, all designed to fit your application. Contact Rusach International today with your application.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

Kitagawa"s new GT200 rotary table is a through hole unit capable of withstanding high cutting loads. It features a 200mm diameter table and provides ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages ...

... , photonic component alignment, high-accuracy laser machining and precision wafer inspection. These rotary stages can also be configured as multi-axis gimbals.

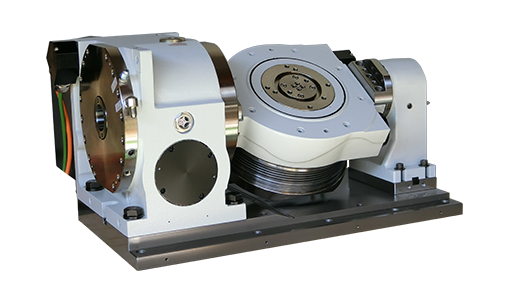

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small vertical ...

... secured. High positioning accuracy ensures precise results for 5-axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

The TRT70 dual-axis rotary table from Haas Automation, Inc. (Oxnard, CA) delivers high speed and accurate positioning for 3+2 and full 5-axis machining of small, complex medical parts. The unit’s ultra-compact size and light weight make the TRT70 the perfect dual-axis solution for even the smallest machining center. The TRT70 uses powerful brushless servomotors to provide 60 ft-lb (81.3 Nm) of torque on the tilt axis and 40 ft-lb (54.2 Nm) on the rotary axis; indexing speeds of 410 deg/sec on the tilt axis and 620 deg/sec on the rotary axis ensure short cycle times. The unit provides ±120 deg of tilt and 360 deg of rotation to position parts to almost any angle for machining. The precision-ground 70 mm (2.76 in) platter features multiple bolt patterns and a precision through-bore for versatile fixturing. It will swing parts up to 4.0 in (102 mm) diameter. The maximum platter capacity is 3 lb (1.4 kg).

At just 18.5 in (470 mm) wide and 10 in (254 mm) deep, the TRT70 easily fits into even the smallest machining center or can be mounted on one end of a larger machine’s table, freeing up the remainder for additional fixtures or vises. It is the perfect complement for the new CM-1 Compact Mill or existing OM-Series Office Mills. The TRT70 can easily be removed when not needed. It is built in the U.S. and is backed by a worldwide network of Haas Factory Outlets for support and service.

CNC tilting rotary tables are dual-axis (such as 4th & 5th axes) units. This series is also known as a dual-arm type tilting rotary table because it contains support axes (such as a tilting axis & supporting axis) on both sides to meet various application requirements. It can rotate the component in two axes, making a machine capable of accessing the areas which can not be reached with only 3 axes (such as the X axis, Y axis & Z axis). Tilting rotary tables can also be used for multi-angle simultaneous machining to generate some profiles such as impellers. The additional tilting rotary table convents the standard 3 axes machining center into the 5 axes machining center to meet various application requirements.

There is no mechanical reduction mechanism such as a worm system in a rotary table with a DD motor. DD (Direct Drive) motor is built in the rotary table to drive directly. The compact two-axis direct drive rotary table enables rapid acceleration/deceleration and high-speed rotation. Its biggest advantage is the super high speed up to 2000 rpm. Thus, it can work as a mill/turn component. As a result of the lack of a mechanical reduction mechanism, the driving torque of the rotary table is not strong. It is necessary to choose an application for the rotary table with a DD motor.

A high torque motor drives the direct drive rotary table directly. There is no backlash or abrasion generated during rotation because it is not driven by worms and gears. Typically, these rotary tables are used in applications requiring high accelerations and decelerations, such as blade machining. For high-speed drilling centers with very important indexing times, a two-axis direct drive rotary table is an excellent choice.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

The TRT70 dual-axis rotary table from Haas Automation delivers high-speed and accurate positioning for 3+2 and full 5-axis machining of small, complex parts – like those found in the medical, dental, and jewelry industries. The unit’s ultracompact size and light weight reportedly make the TRT70 the perfect dual-axis solution for even the smallest machining center.

The TRT70 uses powerful brushless servomotors to provide 60 ft-lb (81.3 Nm) of torque on the tilt axis and 40 ft-lb (54.2 Nm) on the rotary axis; indexing speeds of 410 deg/sec on the tilt axis and 620 deg/sec on the rotary axis ensure short cycle times. The unit provides ±120 degrees of tilt and 360 degrees of rotation to position parts to almost any angle for machining. The precision-ground 70 mm (2.76") platter features multiple bolt patterns and a precision through-bore for versatile fixturing, and will swing parts up to 4.0" (102 mm) diameter. The maximum platter capacity is 3 lb (1.4 kg).

At just 18.5" (470 mm) wide and 10" (254 mm) deep, the TRT70 easily fits into even the smallest machining center, or can be mounted on one end of a larger machine’s table, freeing up the remainder for additional fixtures or vises. It is the perfect complement for Haas Automation’s new CM-1 Compact Mill or existing OM-Series Office Mills. Like all Haas rotary tables, the TRT70 can easily be removed when not needed.

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

The Peiseler rotary indexing table is at the heart of the rotary indexing machine, which has five stations for drilling and milling processes plus a loading and unloading station. "The key requirements for our design went beyond the need to achieve a maximum power density for highly dynamic indexing times in the smallest possible installation space", says Gronau. "In order to minimise the tolerances present, we had to position each of the two-axis rotary tilt tables as precisely as possible, both as standalone units and in relation to one another". Providing the media required to close, release and monitor the workpiece clamping device was also a complex task. A rotary manifold with eight ports was ultimately fitted for this purpose.

"This rotary indexing table is not only the largest we"ve built to date, but also a customer-specific solution that will shorten cycle times and reduce unit costs in the production of electric vehicle components", explains Gronau. As a high-precision manufacturer of trunnion tables, rotary tables, two-axis rotary tilt tables, swivel heads and workpiece changing tables, Peiseler is helping to build the reliable production processes that will lay the foundations for our future mobility.

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

8613371530291

8613371530291