two axis rotary table pricelist

Increase efficiency and production of your CNC machine with our Dual VH-8. Perfect for making 2 parts at a time thus reducing the number of tool changes and allowing the operator more time to complete other tasks. The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The Dual VH-8 has twin 8.25" spindles (210mm) with dual tapered roller bearings supporting the front and back of each spindle. The VH-8 worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There are optional 8" 3-Jaw chucks and adapter plates available as well as a 5C nose pieces with either manual or air collet closers for your workholding needs.

The Index Designs Dual VH-8 is a true 4th-axis rotary table with two platters,complete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

Kitagawa"s new GT200 rotary table is a through hole unit capable of withstanding high cutting loads. It features a 200mm diameter table and provides ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages ...

... , photonic component alignment, high-accuracy laser machining and precision wafer inspection. These rotary stages can also be configured as multi-axis gimbals.

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small vertical ...

... secured. High positioning accuracy ensures precise results for 5-axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

Our rotary indexing tables can be used on all EDM, laser, and HSC machines and are completely sealed (IP68) from dielectric fluid (water, oil). The final product details are determined in a consultation with you and/or the machine manufacturer and optimized to your requirements, (with or without clamper, electrical design, etc.). For most new machines, rotary indexing tables are controlled and programmed by the machine control system (A-axis). Older equipment often needs an additional control system for use with the rotary indexing table. Please verify all technical requests in advance with our sales staff or our technical department.

Used in newer machines the rotary indexing table mostly can be controlled and programmed by machine control system (A-axis). For older machines an additional control system is necessary to operate the rotary indexing table. Please clarify all technical requirements in advance with our sales team and our technical department.

The Double Sided Stallion Trunnion Table takes efficiency to the next level by holding double the amount of parts as the Stallion 9/23. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Trunnion Table minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

The robust geared rotary tables of the 500 series are extremely flexible to use and, thanks to the combiFLEX® modular system, can be converted or extended at any time to meet new machining tasks. The rotary tables are not only suitable for positioning operation, but can also be used for short simultaneous machining operations. The preloaded gear and the powerful bearings allow high long-term accuracies as well as large spindle loads. The maximum clamping force of up to 7,000 Nm leaves hardly anything to be desired.

Visit Alibaba.com for your rotary table 5 axis and find a wide range of exemplary products in this category. In this platform, you do not only find these amazing rotary table 5 axis but at the same time, you can get them at extremely low prices.

Filter the Alibaba router listings to find the ideal rotary table 5 axis. You can search for specific wood router models and toggle specifications like weight, power rating, cutting style, throughput rates, table configuration, and many other important features. That way, you can pick a fixed router for heavy processing or the most portable wholesale routers for on-site carpentry. Whether you are cutting dado rails for home construction projects or working on complex sculptures, the wood router selection at Alibaba has what you need.

With a rotary table 5 axis from the Alibaba store, you can shape wood to create the perfect form. Shave the edges to create beveled surfaces, add definition to tables or chairs, and create recessed elements for joints. Whatever your carpentry challenge, a rot table axis can Al Alabaaba"s store features an extruder machine to make life easy. So filter and search until you find the perfect wholesale.aryary 5 5isis you every,, Alibative.com"s wholesale store is the place to head when you need replacement rotary tools. Explore a vast range of testing tools, pick up PPE for hands and face, find basic equipment kits for home users, or equip factories and work sites with heavy duty generation tools. rotary tables 5 axi are to in every demand, and with Alibaba.com you"ll find something for everyone.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

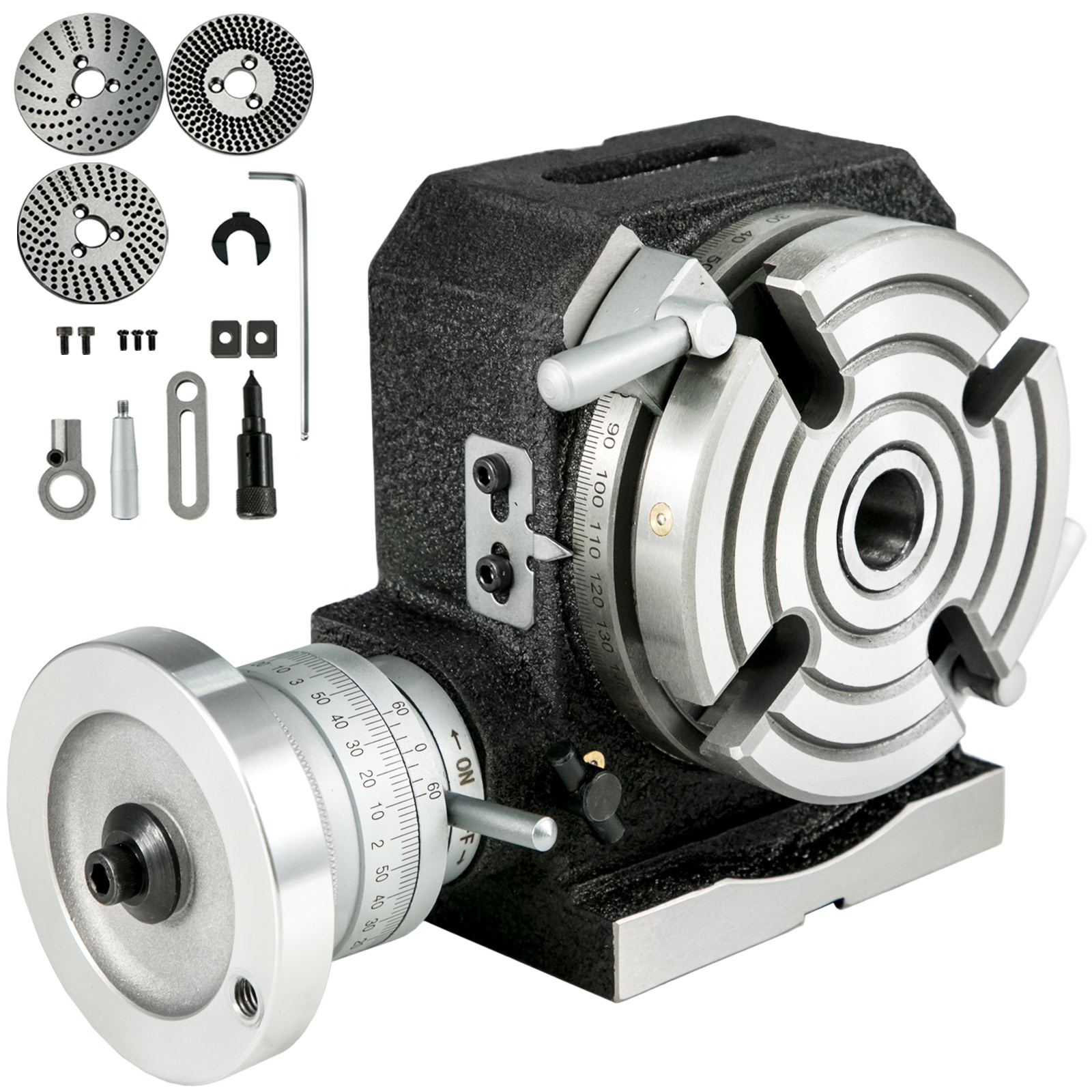

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Koma Precision showcases the dual platter Tsudakoma TWM-250 five-axis rotary table. This high precision unit has two 10" platters that can be equipped with rotary unions for hydraulic or pneumatic work holding actuation. The unit can be setup for 12-16" between platters, which Koma says enables for a variety of work holding and workpiece shapes and sizes.

The TWM series is said to be ideal for high-production single or dual spindle VMC’s that require five-axis machining. The TWM series unit can be setup for simultaneous five-axis movement or 4+1, enabling the machine to get around five sides of the workpiece. The hydraulic brake on the tilt axis reportedly provides 3100 Nm of brake torque, which enables the machine to take heavier cuts at more aggressive speeds and feeds while maintaining the accuracy of the part. According to Koma, the machine tool is only as accurate as the work holding and rotary table; therefore, the rigidity is critical to the entire throughput rate and quality of the cutting process.

X2F says the addition of a rotary table to its machine reduces cycle times and opens up higher-volume production possibilities—up to four million parts per year.

8613371530291

8613371530291