ucam rotary table pricelist

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

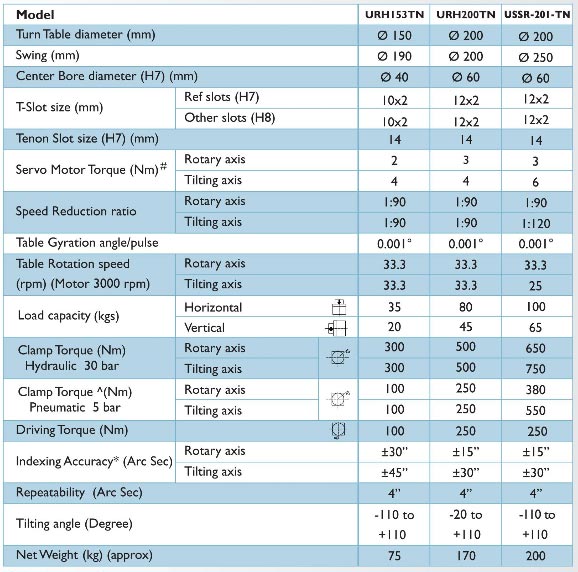

Ordering code for CNC RotaryTables S-Special None-Standard Braking System H-Hydraulic Clamping P-Pneumatic Clamping Motor Mounting B-Rear Mounting L-Left Mounting R-Right Mounting TableTop None-Round Sq-Square Size of the table CNC RotaryTables * Higher Accuracy ± 5" on request ** Motor RPM 2000 # Check motor models on Page No. 70 ## Option available with pressurisation - Please contact us

Factory: Plot No. 297 & 298, 1st Stage, Sompura KIADB Industrial Area, Dobbaspet, Sompura Hobli, Nelamangala Taluk, Bangalore Rural Dist - 562111. INDIA, Engineering Excellence. Exactly. www.ucamind.com Catalogue No. UCAM-Gen-2017/2/6. UCAM reserves the right to change specifications and dimensions without prior information.

CNC Tilting Rotary Tables are two axes (4th & 5th Axes) units and can rotate the component in two axes making a machine capable of accessing the areas which can not be reached with only 3 axes. Tilting tables can also interpolate with machine axes to generate profile such as impellers. Using Tilting Rotary Table a standard 3 axes machine can be converted into a 5 axes machine.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

UCAM founded in 1986 is a well renowned brand in machine tool industry. We specialize into manufacturing of precision CNC Rotary Tables, Index Tables and Pallet Changing Solutions for Machine Tool applications.

UCAM products are known for their quality, reliability and performance in challenging and high demanding applications in various industries such as Automobile, Aerospace, Power Generation, Medical & Orthopedic Implants, Oil & Gas exploration, Pumps & Valves, General Engineering etc.

Use of State of the Art, cutting edge technology, continuous product innovation through R&D and pro-active Customer relation management has made UCAM a global brand in the Machine Tool industry.

Bengaluru-based Ucam claims to be the largest manufacturer of CNC rotary tables in India. Their wide range of CNC rotary tables and custom built rotary tables which can be used vertically and horizontally based on the application

Ucam Private Limited, established in 1986, has a wide range of products such as 4th axis rotary tables, 5th axis rotary tables, large size rotary tables, value added accessories, etc. The company exhibited its range of R+W bellow couplings, Nimble Electric torque motors, CNC rotary table at the ENGIMACH 2021

Vijay Zaritaklikar, National Sales Manager, Ucam Private Limited, said, “Our company is having a market share of around 70 per cent. We are preferred partner for OEMs and end customers. We mainly manufacture CNC rotary table which is a sub-system for vertical machining centre (VMC). With the help of our CNC rotary tables you can expand the VMC to fourth and fifth axis machining”.

“Through Nimble Electric, a subsidiary of Ucam private limited, we started manufacturing torque motors for our own purpose. But then Nimble Electric motors found applications in many places such as electric vehicles, robotics, defense systems, textile motors, renewable energy, healthcare motors, transportation, etc”.

Ucam Private Limited has its business verticals such as Ucam Mechatronics, Nimble Electric and Nimble Machines. Ucam Mechatronics is involved in the trading of products like spindles, bellow couplings, torque limiters, rotary union and linear motion products. Nimble Electric specializes in the design and manufacturing of high performance torque motors. Nimble Machines designs and manufactures precision gear hobbing machines.

Rotary tables are used for perfection metalworking. They"re generally made with a solid base that can be clamped on to another institution. The table is a slice that rotates freely or by use of a worm( hand coil).

A rotary table is a slice- shaped metalworking device used to gain precise workpiece positioning. It enables a metalworker to cut or drill a workpiece at precise intervals around a vertically or horizontally fixed axis. A rotary table can be both manually or computer numerical controlled. Certain types of rotary tables are designed to be used with indexing plates or dividing plates for technical operations. A rotary table used together with one of these positioning plates is generally appertained to as a dividing or indexing head.

The rotary table device generally has a solid base that can be attached to a separate institution or table using clamps. This device is principally a rotating slice which holds the workpiece in place during slice or drilling operations. The slice portion of a rotary table can be freely rotated for indexing procedures or turned by an attached control arm known as a worm wheel. Tables used in high perfection operations are generally turned by a duplex- type worm wheel to compensate for counterreaction. Rotary tables used in automated essence working processes are turned by computer numerical controlled ministry.

Rotary tables are most frequently used in a flat position with the table’s axis having a perpendicular exposure. They"re occasionally mounted with the axis acquainted in a vertical fashion so that a tailstock can be used to support the free end of the workpiece. When this device is attached to a secondary table, the workpiece can be centered on the rotary table’s axis which is also centered on the slice tool’s axis. In this configuration, the axes of the rotary table, secondary table, and cutting tool are coextensive to grease concentric slice operations. This configuration also permits the secondary table to be neutralize for drilling equidistant holes in a workpiece.

8613371530291

8613371530291