using a rotary table on a mill quotation

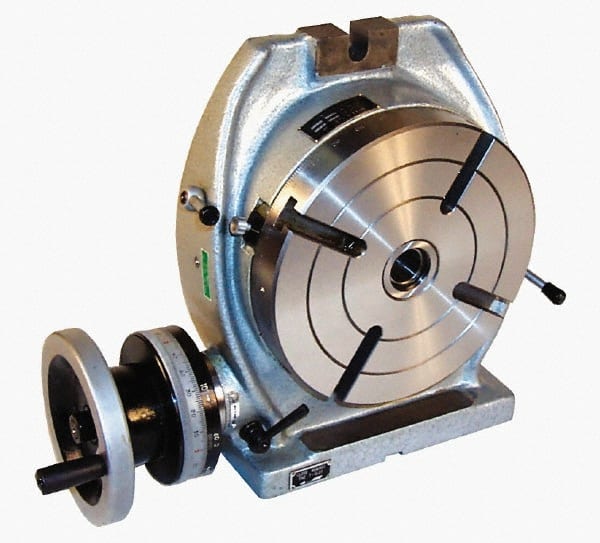

Years ago, before I learned CNC, I owned a Phase II 8″ horizontal/vertical rotary table that I purchased from Kap Pullen’s Getmachinetools.com store. He has them at a good price, BTW, and he’s a darned nice fellow to deal with as well as being a frequent HSM contributor. Anyway, its a nice little table, but I hadn’t done a whole lot with it for quite a while after purchasing it. As is so often the case, one day, a project landed on my doorstep and I was glad to have it.

Before I could get started, however, I had to make some accessories for it. Basically, I needed some T-Nuts to fit the table, as well as a little fixture that makes it easy to hold a plate up off the table through a hole in the center so you can machine it. The latter, what I call a “plate machining fixture”, was inspired by something similar I saw the Widgitmaster of CNCZone fame using to make Dremel clamps for his mini-router:

The Plate Maching Fixture and 3 Homemade T-Nuts. T-Nuts are easy to make: square a block to the proper dimensions, mill the side reliefs, drill, and tap. These are much smaller than the mill’s Bridgeport standard T-slots, so I made them myself and I’m using 1/4-20 bolts with them. They’re made of mild steel.

I turned the round spigot using the 4-jaw on the lathe. I’m making the fixture out of MIC-6 aluminum plate, which is pre-ground very flat on the sides. This is a 5 inch by 3 inch piece. I’ve clamped it to the rotab using my T-nuts and the regular mill clamps and step blocks. It is sitting on parallels to make sure I don’t cut into the table. You can also see how I’ve clamped the rotary table to the mill table using a big cast iron V-block I have. You can never have to many blocks with precision faces hanging around!

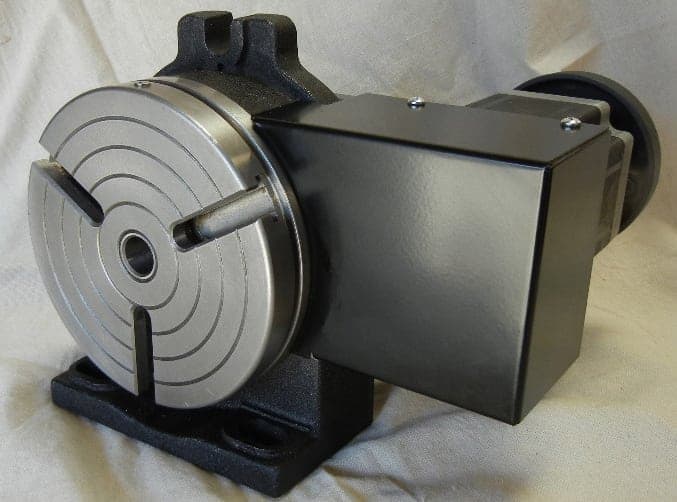

Having a 4-jaw chuck on your rotary table is mighty handy! Because it’s a 4-jaw, you can dial in the workpiece by adjusting the jaws until it is perfectly concentric with the table’s axis of rotation. The best way is to make an adapter plate that attaches to the back of the chuck in the same way that your lathe does so you can exchange lathe tooling with the rotab. Here is an example:

For the example, the chuck is threaded onto the adaptor plate, and then the holes in the adapter plate’s flange are used to bolt down to T-nuts on the table.

In my case, I bought a 4-jaw from Shars brand new, and simply drilled some through-holes in the chuck to mount to the table directly without an adapter plate:

First, you want to make sure your part is properly centered on the table. To do that, I clamp the table down on the mill table (no special place is needed), put my Indicol indicator holder on the mill spindle, and find some round feature on the part to indicate on. For example, on the plate milling fixture above, indicate on the round boss, or on the center hole. Spin the table and bump the part in until spinning the table doesn’t move the indicator.

Second, locate the center of rotation directly under the mill spindle. You can simply use the X and Y table handwheels to do this. Use that Indicol to indicate off of a circular feature you want centered under the spindle. Turn the indicol around on the spindle and adjust the handwheels until the indicator stays put relative to the spindle position. A Blake Coaxial indicator will make this last even simpler.

When you’re rounding partially by cranking a part around on the rotary table, it’s really easy to go a little too far and screw things up. The answer is to drill the end points to make the exact stopping point on the rotab a lot less sensitive:

Centering with a Blake indicator is really fast, but what if you don’t have a Blake, or worse, what if your mill is too small to accomodate one? Here is a nice solution I found on a German site. This fellow has made an ER collect fixture for his rotary table, and has taken care that when installed on the table, the axis of the collet is aligned with the table’s axis. He can then place a dowel or other straight pin in the collet and line up until it will go into a similarly sized collet on the spindle. Nice trick! It’s similar to how Widgitmaster showed me to align a drill chuck on a QCTP to the lathe centerline with a dowel pin held in the lathe chuck.

A rotary table is a precision device that is ideal for work positioning. Such table is used in metal works as it makes the job of drilling easier for the metal worker. Other than this, the metal worker can also cut the piece on fixed axes during specific interval with the help of a rotary table. Rotary Tables are available in varieties. Some of these tables use indexing plates for operations related to indexing whereas, others enables the user to fit dividing tables and leads to a better work positioning.

What make rotary tables important for metal industry are its numerous uses. Here is a list of few: Rotary tables are used for machining spanner flats on bolts. For cutting round pieces. For drilling holes at equal distance on circular flanges. A metal worker can also create large diameter holes on milling machines with these tables. Rotary tables are also used for cutting complex curves and mixing helixes.

There are different parts and components in rotary tables and all have different functions. Work table is the most important part of the table. It has spherical working area with four t-slots, which are used for mounting work pieces. There is a clank handle on rotary tables that enables the user to rotate the tables in clockwise and anti-clockwise directions. Rotary tables also have two bases, one is meant for vertical rotation whereas the other one is meant for horizontal rotation. At times, rotary tables are also mounted flat on planes similar to the way cutters are placed on vertical milling machines. If we look closely, rotary tables play a crucial role in the metal industry. Because they are used to perform different jobs, there is a specialized variety of rotary table to meet industry specific needs.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

... conventional machines. Axis movement is performed by high quality servomotors, increasing accuracy and efficiency. Simple handling and reliability make this model very popular.

... approximation of the motorized table, automatic advance of the rod, square guides on Y / Z axes, tilt front / rear of 45 ° and centralized lubrication as standard.

... stainless steel structure, these machines feature multi-station rotary tables for optimized processing time, and automatically manage the unwinding and winding of the cloths; the moving ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

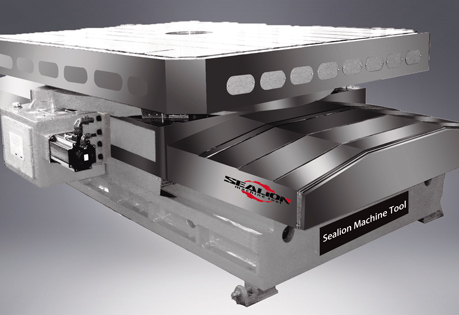

Lagun’s BM RT is a bed type mill with C-Axis rotation and equipped with a rotary table. With a compact and robust design, this milling machine is ideal for machining bulky workpieces on all 5 sides.

Lagun’s BM RT mill is built with a modular configuration, which means all models in this spectacular line have interchangeable slides, rams and columns. This design method endows each machine with enhanced rigidity, precision and ergonomic working comfort for the operator.

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The hardy table, measuring at 63” x 47” (1600mm x 1200mm), column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges.

*Note: Interested in more bed type milling machines? Take a look at our BM-C and BM-BL bed mills. Or browse all machining centers offered by Lagun Engineering here.

The rotary table helps robots to be more maneuverable and to perform even better processing. In SprutCAM, you can program robot with one, two or more redundant axes. Learn more about redundant axes handling in SprutCAM Robot.

Our dealer and auctioneer members offer the most extensive selection of used machinery in the world, with thousands of machines available in warehouses and plants across the globe.

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

Our facility has up-to-date lathes with turning capacities of 72-inch diameter and center-to-center distances of 320 inches. Our manual lathes are fully equipped with DRO (digital readout) systems.

WWMW utilizes CNC and manual horizontal boring mills, CNC vertical machining centers, and universal mills. Our boring mills have large table capacity up to 25,000 pounds, and our manual mills are fully equipped with DRO (digital readout) systems. For projects such as motor bases, gear boxes, platens or just large weldments, WWMW has the machine to fit your needs.

With the valuable assistance of skilled team of professionals, we are engaged in offering an extensive range of high quality Rotary Table.Owing to its unique attributes such as easy maintenance and high strength, this product is highly appreciated by our renowned clients. Additionally, to provide the best quality, the providedread more...

Our range of rotary table can be availed from us as per the desired specifications and requirements. These are suitable for metal processing and casting work.

We make the clients satisfied by offering Rotary Table with high durability and accurate construction. Our Rotary Table makes the working of milling machines smooth.

Vishavkarma Colony, Ludhiana 12683,ST.NO.6,,VISHVKARMA COLONY 12683,ST.NO.6,,VISHVKARMA COLONY, , Vishavkarma Colony, Ludhiana-141003, Vishavkarma Colony, Ludhiana - 141003, Dist. Ludhiana, Punjab

Owing to our expertise, we have been able to offer our clients an excellent quality Rotary Table. This table is manufactured using high grade raw material and latest techniques in varied specifications for our clients to choose from. It is tested on well defined parameter in order to deliver defect free range. Further, clientsread more...

Industrial Area A Extension, Ludhiana 66 B INDUSTRIAL AREA-A, DELIGHT MACHINE TOOLS INDUSTRIAL AREA A Near Ghoda Factory, Industrial Area A Extension, Ludhiana - 141003, Dist. Ludhiana, Punjab

We are looked upon as one of the reliable Rotary Table Manufacturers in India. Rendering the requirements of the national as well as international clients, the company has acquired noteworthy position amidst the reliable Precision Rotary Table Exporters. The Rotary Tables are ideally designed for metalworking i.e. drilling orread more...

The Bison 5901 / 5911 series indexing fixture can be used vertically or horizontally. The compact design allows for two types of indexing; 1. Basic 2,3,4,6,8,12 and 24 divisions, 2. Angular 360° in 1...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

8613371530291

8613371530291