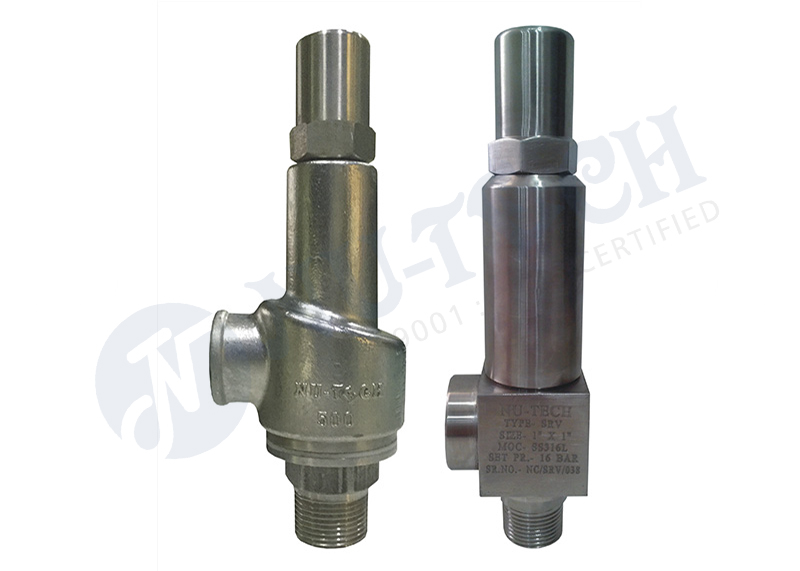

high pressure safety valve supplier

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

![]()

Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous. Generally valves are placed on or near the pump head of the hose, pipe or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves.

This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Like every other type of check valve, relief valves may be constructed from a variety of materials, including PVC, brass, ductile iron, copper, polyethylene, polypropylene, aluminum, steel, stainless steel and rubber. Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas and pressure applications.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

Standard materialsinclude 316 stainless steel bodies and removable seat glands with 17-4PH stainless steel removable stem and stem seats. Standard O-ring material on the stem is Viton Valves may be used up to 400° F.

Inlet connections are for 9/16" O.D. tubing (HF9) with adapters for other sizes available. Outlet connections are 1/2" NPT. These valves are not recommended for use below 1,500 psi, and are not readily adjustable in the field without proper test equipment. Pressure settings are made at the factory and valves are tagged accordingly.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

Standard materials include 316 stainless steel bodies and removable seat glands with 17-4PH stem and seal ring. Standard O-ring material on the stem is Viton. The seat material is Peek. Valves may be used up to 400°F with standard Vtion O-ring or 450°F with the Kalrez O-ring option.

Inlet connections are for 9/16" O.D. tubing (HF9) with adapters for other sizes available. Outlet connections are 1/2" NPT. These valves are not recommended for use below 1,500 psi, and are not readily adjustable in the field without proper test equipment. Pressure settings are made at the factory and valves are tagged accordingly.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required.

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high ...

139 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

Generant manufactures an extensive product offering of pressure relief valves including low pressure/high accuracy and high pressure/ high flow designs. Generant pressure relief valves are relied upon in many diverse industries such as Industrial and Medical Gases, Cryogenics and Chemical Processing. Available in a variety of materials of construction and porting configurations providing product solutions for a wide range of liquid and gas applications.

Also known as pressure relief valves (PRV), pressure safety valves (PSV), and safety valves, these systems act as a safety measure. They relieve excess pressure from equipment failure, process upset, or fire by opening an auxiliary passage to divert the fluid (liquid, gas, steam or air) away from the pressure vessel. Once the pressure in the vessel is released and the danger is over the relief valve closes itself. Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous.

Generally valves are placed on or near the pump head of the hose, pipe, or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves. This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial, and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas, and pressure applications.

Valve Check Inc. is a manufacture of high-quality check valves offered in a variety of sizes ranging from 1/8, 1/4, 1/2, 3/4, 1 inch though 2 inch and up to 4" NPT. Configurations are offered in Male x Male, Male x Female, Female x Male, and Female x Female.

Valve Check specializes in manufacturing the lowest pressure drop check valves and offers the highest flow check valves of any manufacturer. Pressures range from low pressure .5 psi to 500 psi high pressure check valves.

In addition to the small installation space of the above-mentioned compressors, they should be completely covered by an acoustic enclosure to reduce noise emissions. In order to reduce the size of the very cost-intensive sound enclosure, AERZEN requires special valves that are adapted to the available small installation space. Compressors are discontinuous machines for pressure generation.

In order to ensure that occurring pulsations do not impair the function of the safety valve, the set pressure of the valve is adjusted accordingly and an appropriate distance to the pressure line is ensured by design.

The LESER solutionAs a renowned manufacturer of safety valves, it is advantageous to be able to react flexibly to the above-mentioned concerns, primarily to the small installation space, with its portfolio. Being able to change the installation position of safety valves is a clear advantage for the compressor designer. They are much more variable in their design and construction options and can also respond more flexibly to special customer specifications. If the progressive modularization of compressors requires more compact designs, safety valves in different mounting positions, for example, can be an answer to the problem, unlike the classic upright position. In addition, the spindle guide plays a special role here. The friction at the guiding points must be reduced as much as possible so that the spindle runs smoothly. Otherwise, a safety valve can only be installed vertically.

Why LESER safety valves?For a global acting OEM like AERZEN, a specialist like LESER, who has not only the knowledge but also the necessary approvals, is an important component for success. LESER offers a global approval concept that allows safety valves to be used regardless of location. When ordering safety valves, only the applicable regulations must be specified in order to ensure appropriate labeling and material selection. In addition, LESER has tested and approved further installation positions in addition to the conventional installation situation, standing on the inlet pipeline. For example, some types of valves may be installed with a horizontal stem or even upside down, e.g. Types 526 and 441. For horizontal installation, care must be taken to align the outlet. Liquids, e.g. in the form of condensate, should be able to drain off downwards to avoid back pressures and even corrosion. When installed upside down, the inverted weight forces are corrected by correction factors. LESER offers not only safety valves with basic documentation and accessories but also other special documentation and options. From the “Fugitive Emission Test” with helium up to 3.2 ship class castings and from back pressures up to more than 200 bar-g to high pressure heating jackets for up to 30 bar-g, LESER sales engineers develop solutions for customer specific applications as described above for AERZEN.

Being a client oriented organization, we are occupied in presenting an extensive range of Water Blast Pressure Hoses. Provided products are precisely fabricated under the guidance of our experienced professionals using optimum quality raw materials and upgraded technology. In order to ensure their efficiency and quality, theseread more...

8613371530291

8613371530291