testing gas safety valve made in china

Used for testing all kinds of safety valve, such as spring directly load safety valve, Power assisted safety valve, Supplementary loaded safety valve, fully open, slightly open, flange, thread type safety valve. Safety valve test bench is to use high pressure air or nitrogen as the medium to test the sealing performance of the safety valve, jump pressure, back seat pressure, etc., for a variety of safety valve set pressure adjustment, set pressure test, discharge pressure test, back seat pressure test, test the pressure sealing performance of the safety valve, leakage rate. Safety Relief Valve Test bench has obvious advantages in techniques, test accuracy, safety etc.

1. Automatic hydraulic clamping, Adjustable clamping force, equipped with gauges displaying corresponding clamping forces, The material of the clamping valve fittings is stainless steel.

2.The same valve size, TEREK products can test bigger pressure; The same pressure, TEREK products can test bigger valve size; Provide quicker and more accurate clamping force. Control panel with different gauges for reference .

3. With Our self Products air driven booster pump , build up pressure quickly and Holding pressure constant; With high pressure stainless needle valve, installed in either direction, high pressure resistant, high durability;

4.Normally we use double stage air driven high pressure gas booster pump and High pressure air driven liquid pump for building into the safety valve test bench. We are able to provide our customers better technical support, price and service.

5. Test various relief valves such as full-open, micro-open, metric, flanged and threaded etc. Safety valve test bench is used for various safety valve setting pressure adjustment, the whole set pressure detection, discharge pressure detection, back seat pressure testing, assessment of its pressure safety performance etc.. , Safety Relief Valve Test bench has obvious advantages in techniques, test accuracy, safety etc.

Safety valve test bench is used for various safety valve setting pressure adjustment, the whole set pressure detection, discharge pressure detection, back seat pressure testing, assessment of its pressure safety performance etc Main technical data for Manual/ Computer control safety valve test bench

Provide Provide High pressure test connecting pipe, high pressure gas pipe of nitrogen cylinder,operation instruction, operation video, repair kit, seal gasket, screw fitting, Seal ring, joint fitting, PU air pipe,Provide flange connection fittings and threaded connection fittings of corresponding specifications .USB disk(Including equipment pictures, operation instructions and operation video files.)etc

1)Power system Air drive gas or nitrogen booster pump, air driving pressure 3-8bar;Maximum Output pressure 480bar; Provide high pressure for valve test.

Simple maintenance:Compared with other air-driving pumps,the pneumatic booster pump can perform the same job as other gas drive pumps, but with fewer parts and seals, and easier maintenance.

Used for testing all kinds of safety valve, such as spring directly load safety valve, Power assisted safety valve, Supplementary loaded safety valve, fully open, slightly open, flange, thread type safety valve. Safety valve test bench is to use high pressure air or nitrogen as the medium to test the sealing performance of the safety valve, jump pressure, back seat pressure, etc., for a variety of safety valve set pressure adjustment, set pressure test, discharge pressure test, back seat pressure test, test the pressure sealing performance of the safety valve, leakage rate. Safety Relief Valve Test bench has obvious advantages in techniques, test accuracy, safety etc.

The safety valve checkout platform is a device that simulates the working environment of the safety valve offline and makes the internal pressure rise to the safety valve lift.

The test pressure can be checked to check the starting pressure (also called opening pressure, setting pressure) of the safety valve. Suitable for performance testing of fixed pressure, backseat pressure and tightness of direct loading and pilot safety valves.

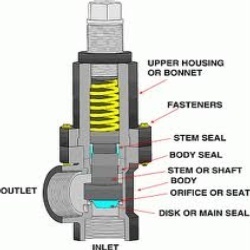

NSV Spring Loaded Safety valve is a valve that act as a protection of equipment from exploding or damaging and it is mainly installed in pressure vessels such as chemical plants, electric power boilers and gas storage tanks.

Safety Valve is a type of valve that automatically actuates when the pressure of inlet side of the valve increases to a predetermined pressure, to open the valve disc and discharge the fluid (steam or gas ) ; and when the pressure decreases to the prescribed value, to close the valve disc again. Safety valve is so-called a final safety device which controls the pressure and discharges certain amount of fluid by itself without any electric power support.

A safety valve protects the system and equipment from overpressure. Overpressure develops when the pressure exceeds the system’s maximum allowable working pressure (MWAP) or the pressure under which it has been designed. Safety valves have a short opening time to discharge gases or liquids immediately. A safety valve opens when a certain pressure is reached; it opens partially at first to eliminate undesirable pressure from the system as rapidly as possible.

Safety valves are utilized to stop pressure rises that might cause malfunctions, fire risks, or explosions. Safety valves are utilized when electrical or pneumatic safety systems malfunction since they only have mechanical components. The system’s media fully activates a safety valve, keeping it operational in the case of a power failure.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Our company has been awarded such honors as High & New Tech Enterprise, Key Enterprise in National Torch Planning Project, Famous Trademark in ZheJiang Province, Famous Brand Product in ZheJiang Province, Special Valve R&D Center in ZheJiang Province, Deputy Director Member of China Valve Association, National Valve Standards Setter. We have obtained most international certificates like DNV ISO9001:2008,ISO14001:2004,OHSAS 18001:2007Certificates, Our products designed and manufactured according to API standard,Ball valve with fire safe certificates API 607,API 6Fa.as well as TUV Germany Rhine Company CE Certificate and Pressure Pipe Fittings Manufacturing License TS Safety Certificate issued by the State Bureau of Quality and Technical Supervision, and the certificates from Russian GOST-R, RTN. Our company is the approved vendor of China National Petroleum Corporation(CNPC), China National Offshore Oil Corporation(CNOOC), SINOPEC, China Aluminum Group Corporation, China National Chemical Equipment Corporation, China Gas, Beijing Gas and also the supplier of international Oil Gas company like BP,Gazprom,LUKOIL, EIL, PDO, GE Oil & Gas, SABIC, SWCC, SAUDI MA"ADEN,Ecopetrol.

WuZhou Valve is also the exclusive supplier of high pressure large-diameter fully welded ball valves designated by the National Energy Administration, National Development and Reform Commission and PetroChina, and, our products have been widely applied in Phase 2 and 3 in the project of Natural Gas Transmission from West to East China.

Our company produces 10 major series of products totaling 1,200 varieties and specifications of high temperature, high pressure, high wear resistant, and large-diameter ball valves, gate valves, butterfly valves, gate valves, globe valves, check valves, ore slurry valves, power station valves, as well as non-standard and special valves with auxiliary devices for petroleum, chemical industry, metallurgy, light industry, coal chemical industry, power station, urban construction, water supply, oil, gas and natural gas transportation, long transportation pipeline and other projects. Nominal diameter DN10~4500mm(1/2"~64"), nominal pressure 1.6MPa ~ 42Mpa(150Lb ~ 2,500Lb), working temperature -196℃ ~ 750℃. Valve materials: carbon steel, stainless steel, heat resistant alloy steel, Monel, low temperature steel, and other special types of steel. Driving modes include manual, electric, pneumatic, gear transmission, worm gear and worm transmission, pneumatic and hydraulic combined, electric and hydraulic combined, and computer programmed control system. The products sell well throughout China and are exported to USA, Europe, Africa, the Middle East, Singapore, and other places in the world. By insisting on the corporate policy of Quality First, Customer Foremost, and Credibility-based, seeking the goal of “Three Merits” of Usability, Creditability, and Reliability, and establishing the first class brand of “WuZhou”, our company will make further contributions to the economic development of China and other countries with high quality products, favorable prices and excellent services.

Gases like nitrogen, argon, and hydrogen present unique challenges that demand special gas-handling components. For more than 60 years ZECO has produced standard and custom valves and fittings specifically designed for cryogenic and extreme heat environments. Whether it’s for a compressed gas fill plant, a cryogenic test bench, or any other gas handling application involving extreme temperatures and pressures, count on proven valves to move your gas.

In an effort to finest meet up with client’s requirements, all of our operations are strictly performed in line with our motto “High High quality, Competitive Rate, Fast Service” for High-Pressure Metal Ball Valve, Pneumatic Casting Steel Globe Valve, Pneumatic Forged Steel Globe Valve, Floating Ball Valve, A Gate Valve. We have now deep cooperation with hundreds of factories all over China. The goods we give can match your different calls. Choose us, and we won’t make you regret it! The product will supply to all over the world, such as in Europe, America, Australia, Czech, Armenia, Panama, Netherlands. We will initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

High pressure butterfly valve means the pressure is higher than the PN25 or Class 150Lb butterfly valve. We design and manufacture this kind of valve pressure up to ANSI Class 900# (15.0MPa) maximum. So for a lot of projects, it is a reasonable choice instead of a ball valve and gate valve with much cheaper cost and high performance.

Under normal circumstances, industrial valves are not subjected to strength tests when in use, but the body and bonnet or the valve body and bonnet damaged by corrosion should be tested for strength after repair. For safety valves, the set pressure and return pressure and other tests shall comply with the specifications and relevant regulations. The strength and tightness test of the valve installation should be done. 20% of low-pressure valves should be checked randomly. If they are unqualified, 100% should be checked; medium and high-pressure valves should be 100% checked. Commonly used media for valve pressure testing include water, oil, air, steam, nitrogen, etc. The pressure testing methods for various industrial valves including pneumatic valves are as follows:

Floating ball valve tightness test: put the valve in a half-open state, introduce the test medium at one end, and close the other end; rotate the ball several times, open the closed end when the valve is in the closed state, and check the sealing performance at the packing and gasket at the same time. There must be no leakage. Then introduce the test medium from the other end and repeat the above test.

Trunnion ball valve tightness test: before the test, rotate the sphere without load several times, the fixed ball valve is in the closed state, and the test medium is introduced from one end to the specified value; the pressure gauge is used to check the sealing performance of the inlet end, and the accuracy of the pressure gauge is Level 5 to 1, the range is 1.5 times the test pressure. Within the specified time, there is no decompression phenomenon as qualified; then introduce the test medium from the other end, and repeat the above test. Then, put the valve in a half-open state, with both ends closed, and the inner cavity filled with medium, check the packing and gasket under the test pressure, and there should be no leakage.

Check valve test state: The lift check valve disc axis is in a position perpendicular to the horizontal; the swing check valve channel axis and disc axis are in a position approximately parallel to the horizontal line. In the strength test, the test medium is introduced from the inlet end to the specified value, and the other end is closed. It is qualified if there is no leakage in the valve body and bonnet. In the sealing test, the test medium is introduced from the outlet end, and the sealing surface is checked at the inlet end. No leakage at the packing and gasket is qualified.

The strength test of pressure reducing valve is generally assembled after a single-piece test, and it can also be tested after assembly. The duration of the strength test: 1 min for DN150mm. After the bellows and the components are welded, apply 1.5 times the highest pressure after the pressure-reducing valve, and conduct a strength test with air.

The sealing test shall be carried out according to the actual working medium. When testing with air or water, perform the test at 1.1 times the nominal pressure; when testing with steam, perform the test at the highest working pressure allowed under the working temperature. The difference between the inlet pressure and the outlet pressure must not be less than 0.2MPa. The test method is: after the inlet pressure is adjusted, gradually adjust the adjusting screw of the valve so that the outlet pressure can change sensitively and continuously within the range of the maximum and minimum values, without stagnation or jamming. For the steam pressure-reducing valve, when the inlet pressure is adjusted, the valve is shut off after the valve is closed, and the outlet pressure is the highest and lowest value. Within 2 minutes, the rise in the outlet pressure should meet the requirements in Table 4.176-22. At the same time, the pipeline behind the valve The volume meets the requirements in Table 4.18 as qualified; for water and air pressure-reducing valves, when the inlet pressure is adjusted and the outlet pressure is zero, the pressure reducing valve is closed and the tightness test is performed. No leakage within 2 minutes is qualified.

The strength test of the pneumatic butterfly valve is the same as that of the stop valve. The sealing performance test of the butterfly valve should introduce the test medium from the end of the medium flow, the butterfly plate should be opened, the other end should be closed, and the injection pressure should reach the specified value; after checking the packing and other seals without leakage, close the butterfly plate, open the other end, and check the butterfly No leakage at the plate seal is qualified. The butterfly valve used to adjust the flow can not be tested for sealing performance.

When the plug valve is subjected to a strength test, the medium is introduced from one end, the remaining passages are closed, and the plug is rotated to the fully open working positions for the test. The valve body is qualified without any leakage.

During the sealing test, the straight-through plug should keep the pressure in the cavity equal to that of the passage, rotate the plug to the closed position, check from the other end, and then rotate the plug 180° to repeat the above test; three-way or four-way plug valve The pressure in the cavity and one end of the passage should be kept equal, the stopper should be rotated to the closed position, in turn, the pressure should be introduced from the right-angle end, and the other end should be inspected simultaneously.

Before the plug valve test, it is allowed to apply a layer of non-acidic dilute lubricating oil on the sealing surface, and no leakage or enlarged water droplets within the specified time are qualified. The test time of the plug valve can be shorter, generally 1~3min according to the nominal diameter.

In the diaphragm valve strength test, the medium is introduced from either end, the valve flap is opened, and the other end is closed. After the test pressure rises to the specified value, it is qualified to see if the valve body and bonnet have no leakage. Then reduce the pressure to the tightness test pressure, close the valve flap, and open the other end for inspection. No leakage is considered qualified.

For the strength test of the stop valve and the throttle valve, usually put the assembled valve in the pressure test rack, open the disc, inject the medium to the specified value, and check the valve body and valve Whether the cover is sweating and leaking. The strength test can also be performed on a single piece. Only stop valves are used for the sealing tests. During the test, the valve stem of the shut-off valve is in a vertical state, the valve flap is opened, and the medium is introduced from the bottom end of the valve flap to the specified value. Check the packing and gasket; close the valve flap after passing the test, and open the other end to check for leakage. If both the valve strength and tightness tests are to be done, the strength test can be done first, then the pressure is reduced to the specified value of the tightness test, and the packing and gaskets are checked; then the valve flap is closed and the outlet end is opened to check whether the sealing surface is leaking.

Open the gate to increase the pressure in the valve to the specified value; then close the gate and immediately take out the gate valve to check whether there is any leakage at the seals on both sides of the gate or directly inject the test medium into the plug on the valve cover to the specified value, Check the seals on both sides of the gate. The above method is called the intermediate pressure test. This method is not suitable for sealing tests on gate valves with a nominal diameter below DN32mm.

Another method is to open the gate to increase the test pressure of the valve to the specified value; then close the gate and open the blind plate at one end to check whether the sealing surface is leaking. It fell further, to make the above test repeated engagement until the grid.

The strength test of the safety valve is the same as that of other valves. It is tested with water. When testing the lower part of the valve body, the pressure is introduced from the inlet I=I end and the sealing surface is closed; when testing the upper part of the valve body and the bonnet, the pressure is introduced from the outlet El end and the other ends are closed. No leakage of the valve body and bonnet within the specified time is qualified.

For the sealing test and constant pressure test, the general use medium is: steam safety valve uses saturated steam as the test medium; ammonia or other gas valves use air as the test medium; water and other non-corrosive liquid valves use water as the test medium. For safety valves in some important positions, nitrogen is often used as the test medium.

The sealing test shall be conducted with the nominal pressure value as the test pressure, the number of times shall not be less than twice, and no leakage within the specified time shall be qualified. There are two leak detection methods: one is to seal the joints of the safety valve and use butter to seal the thin paper on the flange of the outlet. The plastic plate or other plate seal is attached to the lower part of the outlet flange, and the valve disc is sealed with water. It is qualified if the water does not bubble. The safety valve’s constant pressure and return pressure test times are not less than 3 times, and it is qualified as conforming to the regulations. The various performance tests of safety valves refer to GB/T 12242-1989 Safety Valve Performance Test Methods.

After unpacking all valves should be visually inspected, comprising a plate on the valve body is complete, the product quality documents, the valve is closed, the other can not damage the like blue surface, no Dirty, both ends of the anti-protection Cover, etc.

The valve pressure test JHA is perfect, and the operator should be familiar with the safety hazards of the valve pressure test and reverse transportation and take corresponding preventive measures.

The valve pressure test process is the valve shell strength test, upper seal test, and seal test.The test medium for the strength of the valve shell is water, the pressure is 1.5 times the nominal pressure of the valve, the pressure holding time is 5 minutes, and no drip or moisture is qualified.

The sealing test medium on the valve adopts water, the pressure is 1.5 times the nominal pressure, the holding time is 15s for DN≤50, the 60s for 65≤DN≤300, and the 120s for DN≥350. No leakage is qualified.

Valve sealing test: Low-pressure sealing test is carried out. The test medium is air (gate valve), the pressure is 0.6MPa, the pressure holding time is 15s for DN≤50, the 60s for 65≤DN≤150, and the 120s for DN≧200. The requirement is qualified.

After the pressure test, the valves should be stacked separately according to the type and specifications of the device, and the unqualified products should be stacked separately; each stacking area should be erected with a clear sign. After the pressure test, the valve should be closed and sealed, and covered and protected with colored cloth in the stacking area.

After the valve pressure test, the “Valve/Pipe Fitting Test Record” should be filled in time according to the device, and the model column should be filled in with the purchase contract number on the valve body.

Main products include On/Off gas valves, safety valves, thermostats, heating controls, solenoid valves and burners which are the key component for commercial cooking appliances. 100% In-house leakage test on all valves to ensure high precisions safety standard & reliable quality assurance for global clients.

Certification: TS licensing A1, A2, B1, B2, API-6D, CE, ISO9001, ISO14001, OHSAS18001, TUV issued by the API 6FA gate valve, API607 ball valve fireproof test

Neway Valve is one of the leading manufacturers of butterfly valves in China. It has a world-class valve plant that covers an extensive valve program to meet the needs of clients.

The company’s entire manufacturing process is completed in-house helping them ensure the quality of their products. They have their own Research and Development center, three foundries, and a high-end assembling and testing plant.

Neway butterfly valves are available in a number of series including T Series for concentric butterfly valves, TB Series for double offset butterfly valves, and TC Series for triple offset butterfly valves. These valves are used largely in chemical, nuclear, offshore, power, oil and gas, mining, and air separation industry.

Chaoda Group Wenzhou E-business Co., Ltd is an entirely owned branch of the Chaoda Valves Group Co., Ltd to market and sell valves, forging, casting, flanging, gas meter, etc. The company has earned special titles such as “Zhejiang Famous Product,” “Zhejiang Famous Brand,” and “Zhejiang Exporting Famous Brand.”

Chaoda houses a variety of cryogenic valves that are suitable for many different industries. They feature cryogenic globe, butterfly, check, trunnion ball, floating ball, check, gate, and other valves.

Chaoda forged steel cryogenic lift check valve is immersed in liquid nitrogen (-196 degree C) for 2 to 6 hours, then returned to normal temperature during production. This cycle is repeated twice to ensure the valve’s cryogenic abilities are top-notch. The valve can be made of carbon steel, stainless steel, alloy steel, and duplex stainless steel. It can be operated manually, by gear, electrically, or pneumatically. The valve can be used with oil, chemicals, natural gas, petrochemicals, coal chemicals, and more.

Beijing Valve General Factory Co., Ltd, or BVMC,was founded in 1953. With more than six decades of experience in the industry, the company has earned the position of vice chairman of National Valve Industry Association.

Beijing Valve General Factory has more than 60 years of experience in valve design and manufacturing. The company is actively involved in many national projects and also exports valves to more than 70 countries and regions around the world.

Their cryogenic ball valve can be used in temperatures ranging from -196 to 121 degrees C. The valve can be used with LNG and liquid nitrogen and is fire-safe and anti-static. The valve stem is extended and has extra packing ensuring any anti-flow. You can operate the valve with a handwheel, worm wheel, electric actuator or pneumatic actuator.

VTB is the Chinese lead Valve Test Bench Manufacturer in Designing, Engineering and manufacturing of valve testing system. Since 2001 VTB have been supplying valve test bench throughout the valve industry to Petrochemical, Refining, Oil, Gas, Nuclear Power, Automotive and Diesel Engine industries, Governments and Government Contractors, Valve Manufacturing Companies, Valve Repair Companies and a host of related industries. We are proud for delivering quality test equipments that have performed stable and safely for years in the field.

We specialized in hydrostatic and pneumatic testing for valves. We offer a complete line of valve testing systems and services to satisfy custom testing requirements. Our systems can exceed API-598, API-576, API-527, API-6D, ASME B16.34, MSS & ISA standards. The main parts of test bench has high quality. Water passage pipes use 304SS material. Using pressure regulating valve, it can supply low, medium & high air pressure for valve testing. Hydraulic valve test bench has unique structure and hydraulic clamp system. The clamp force can be regulation.Test medium water, air or nitrogen for optional. We also have servo system “ Touch screen & PLC “ intelligent control system and “ safety door “ for optional.

Our hydraulic valve test bench with the international similar products quality, and with competitive price. Hydraulic valve test bench used by many enduser in china and abroad. We carefully nurtured talents and increase investment of technical research & develpoment and make every effort to provide all kinds of advanced technology, high quality valve test equipment and satifsactory service for our valve industry.

The world is rapidly changing. As the industries we serve face increasing pressure to reduce their carbon footprint, digitally transform processes and optimize operations, the Valves team at Baker Hughes is ready to help our customers meet those challenges. Our culture of innovation and legacy of quality make us uniquely positioned to recognize and adapt to changing industry trends. From staying abreast of new manufacturing processes and materials sciences development, to converting our facilities and processes to reduce our own carbon footprint, we are creating solutions to help customers achieve their goals.

Our company has a certain share in the global market thanks to our excellent Conventional Slotted domed Disc, Spring valve used in Low Temperature, Safety Valve used in Low Temperature, high-quality employees, unique corporate culture and innovative teamwork spirit. Based on the creed of "sincerity-oriented, trustworthy", we have built an efficient, professional and fast service platform to continuously optimize and improve service quality. We hope to realize technological innovation and management innovation through modernization, informatization and standardization of management concepts and methods. Your needs are the driving force of our growth, your affirmation is the cornerstone of our development, we are willing to grow together with you.

Spring Safety Valve can stop valve the membrane disk by the spring pressure, when the system is overpressure, the devices will be opened, the pressure will be relief. According to the high of valve opening, it can be divided into full open and little open. Full opening, it is exhaust is huge, well spring, designed for liquid and gas. And little opening is used in liquid.

After years of hard work, our company has accumulated rich experience in the Yh-3000 Safety Valve Online Testing Machine industry, and we look forward to cooperating with you sincerely. Welcome to negotiate business. We have advanced production line equipment, strong technical force, perfect enterprise management and high-quality after-sales service to ensure quality and timely delivery. We guarantee the continuous improvement of product quality and ensure the common interests of both parties and the value of products.

Because of different of drive source, SSV can dividedinto Hydraulic safety valve and pneumatic valve ; With thermal and high voltage explosion-proof device ; Actuators and prepare two parts of the valve, standard interface, easy replacement and maintenance .

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to prevent the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

(1)The pressure of the disc is balanced through the lever and heavy hammer and the valve is ensured seal by moving the for ton of heavy hammer and changing the weight of heavy hammer to reach the required set pressure.

(3)At the top of valve is equipped an electromagnet to open and another to close the valve. The actions of the mechanism and the electric appliance are separate and will not affect each other.

(2)Impulse safety valve shall be installed vertically and the lever shall be kept level. The clearance from the lever to both sides of guide fork shall be even.

(4)A long distance between the leading pipe of the impulse safety valve and the inlet pipe of the main safety valve shall be kept. And the distance between the electric contact pressure meter and the inlet pipe of the main safety valve shall be no less than 5 times of the diameter of the inlet pipe, for feat that the validity of the mater and the impulse safety valve may be affected by the steam releasing process of the main safety valve.

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to present the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

1,When the medium pressure rises to the set pressure, the in-pulse safety valve opens, and the medium in the impulse pipe enters into the piston chamber of the main safety valve from impulse pipe, forcing the piston to descend, and then the valve automatically open-s; when the impulse safety valve closes, the disc will slash automatically close.

2,The main safety valve shall be fastened upon the gallows, which sustains the back-seat force produced in the steam discharging process of the main safety valve.

3,The exhaust pipe shall contain a special gallows to prevent the force of its weight directly applying on the main safety valve. The connecting Lange At the lowest point of the exhaust pipe, water drainage shall be taken into consideration to avoid producing water hammer while discharging set between the main safety valve and exhaust pipe shall eliminate any extra stress.

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Gas Safety Valve, Pipe Clamp Fittings, Oil Tanker Valve, 2 Pipe Clamp,Stainless Steel Boat Propeller. For more information, please send email to us. We are looking forwards the opportunity to service you. The product will supply to all over the world, such as Europe, America, Australia,Roman, Turkey,Japan, European.Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you"ll be served with good quality consultant service by our after-sale team. They"re about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

8613371530291

8613371530291