subsurface safety valve pricelist

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale subsurface safety valve on Alibaba.com. When you search for subsurface safety valve and related items, you will be able to find many types of subsurface safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of subsurface safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

Subsurface safety valves (SSSVs), which are standard and often statutorily required in the oil and gas industry for upper completions, were first developed in the late 1930s. Operators sought to drill more high-pressure wells, often near populated areas or, conversely, offshore or very isolated areas, making the need for a device to protect the wells from uncontrolled flow increasingly apparent. The need was made even more urgent by the fact that the uncontrolled flow could be caused by accident or by damage to the surface equipment, which at the time was quite common.

Modern developments in SSSV design have sought to address the industry’s challenges and the issues that arise in more complex reservoirs and harsher downhole environments through additional testing and research to optimize the valves’ technical specifications. While the basic functionality of the valves has not changed for some time, the standard to which the valves are engineered and manufactured is now shifting, thanks in part to a new partnership between Tejas Research & Engineering and National Oilwell Varco (NOV). It is a partnership bolstered by Tejas’ involvement on the American Petroleum Institute’s (API) 14A standards subcommittee.

Tejas Research & Engineering sprang from the Camco tradition that pioneered many pivotal developments in SSSV design. The R&D and engineering for safety valve products are conducted in Tejas’ HP/HT facility in The Woodlands, Texas, where SSSVs with pressure requirements of 25,000 psi and 260 C (500 F) are designed, tested, qualified and produced.

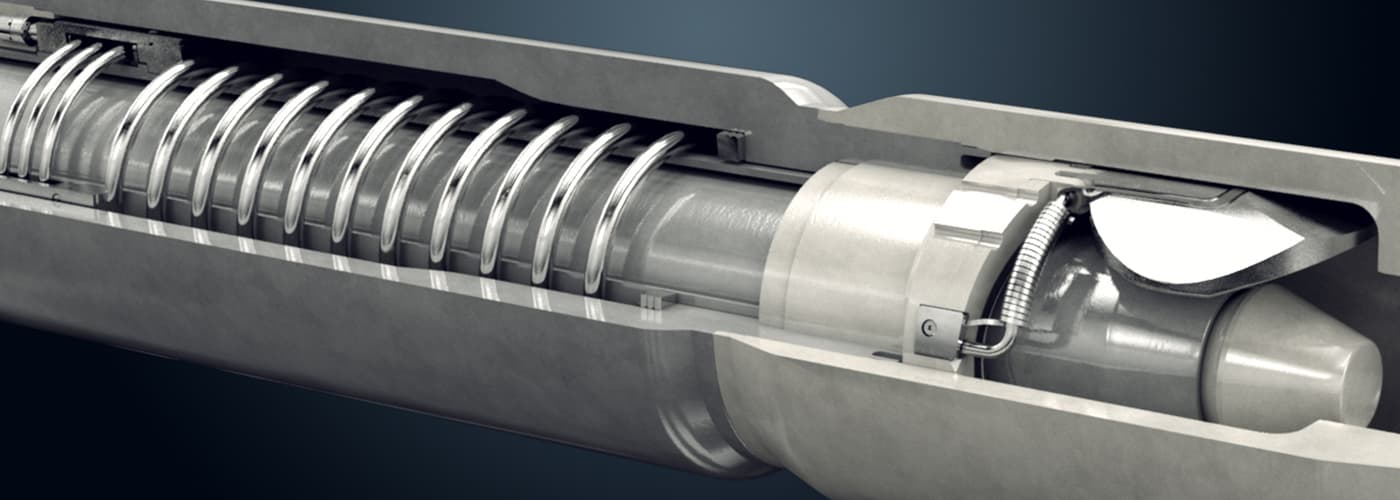

Tejas’ model TRSV(E) SSSVs are tubing-retrievable, surface- controlled, normally closed devices installed in oil and gas wells to control tubing fl ow. Metal-to-metal seals are used in 100% of Tejas’ tubing-retrievable product line, which has products that are rated to 10,000 psig and are suitable for temperatures up to 176 C (349 F) at moderate setting depths. Higher temperature/pressure/setting depths/slimline diameters are available for custom order. The TRSSSV series are API-14A V1 certified and adaptable to any standard or premium tubing thread. The system features a large fullbore, where the inside diameter (ID) is equivalent or greater tubing than the tubing ID to which the SSSV is attached. Additionally, it has either flat flappers (2⅜ in. to 3½ in.) or curved flappers (4½ in. to 7 in.) and a single rod piston featuring nonelastomeric dynamic seals. The TRSSSV is available in either equalizing or nonequalizing trims. The valve is controlled hydraulically with a ¼-in. control line in the well’s annulus, enabling valve closure during an emergency shutdown.

The new safety valve builds upon lessons learned in valve design over Tejas Research & Engineering’s entire history. Previous valves have achieved significant milestones— including one design that has more than 8,000 valves in use without a single failure or degradation in performance. Completions have evolved since those early designs, and new valves need to withstand significantly higher temperatures, working pressures and setting depths as well as accommodate different diameters. The new valve product line meets the rigorous quality standards outlined in API Specification 14A and tested beyond the specifications in Revision 12, including Annex H, which specifically addresses the verification and validation requirements for use in HP/HT environments.

An evolution in safety valve standards means the industry can be more confident that well control incidents will not occur. As regulations continue to change and become stricter, it is imperative that safety valves maintain their rigorous quality and durability while being able to handle even more challenging well environments.

As the last line of defense in protecting life, property, and the environment, subsurface safety valves (SSSVs) are arguably the most critical downhole-completion component. When held to the highest standard of integrity, SSSVs help to assure that wells deliver their full production potential.

With more than 10,000 years of cumulative service life and zero failures, Optimax series safety valves have proven reliable in the field. Photo from Weatherford.

Over the years, SSSVs have evolved dramatically in both form and substance to meet the industry’s need for enhanced performance in increasingly challenging fields. Flapper-closure mechanisms have replaced the ball valves of 50 years ago, and have seen further enhancements from flat flappers to streamlined super-curved flappers that enable the same internal diameter, or production area, with a smaller outer diameter. Instead of concentric pistons, modern SSSVs use highly efficient rod pistons with modern non-elastomeric seals designed to last for more than 25 years.

As operators have continued to move into deeper, hotter, and more pressurized reservoirs, safety valve design has kept pace with higher setting-depth, temperature, and pressure capabilities. With ongoing improvements in valve designs, customers have gained the confidence to routinely install tubing-retrieval safety valves (TRSVs) as the primary safety barrier in new wells, with wireline-retrievable safety valves (WRSVs) serving as a contingency in the event of a failure.

While safety valve capabilities have vastly improved, SSSV reliability remains a concern for operators. With a heightened focus on health, safety, and environmental risks—in addition to the challenge posed by low commodity prices—operators need to know that the safety valves installed thousands of feet below the ocean floor will provide a long-term, high-integrity barrier against production losses, expensive interventions, and the need for abandonment.

Applying its decades of experience as an international provider of advanced downhole tools, Weatherford developed a broad platform of modern SSSV solutions. All Weatherford SSSVs are engineered for reliability, with an emphasis on hydraulics, and validated under a robust program that includes more than 3000 rigorous test cycles. The resulting valves are durable and reliable, which helps customers to avoid the production losses and intervention expenses associated with valve failures.

The Weatherford Optimax series includes TRSVs and WRSVs with advanced features that directly address the historic failure points of SSSVs. Rod-piston, flapper-style TRSVs eliminate sleeves, plugs, and other failure-prone mechanisms. The valves are actuated hydraulically via a single control line. The rod-piston assemblies feature non-elastomeric, dynamic seals to mitigate fluid-compatibility and explosive-decompression issues; glide bearings to centralize the piston in the borehole and help maintain sealing under eccentric loads; and metal-to-metal piston-stop seals to provide maximum sealing when the valve is fully open or fully closed. Additionally, Optimax series valves include through-the-flapper self-equalizing systems, which enable technicians to safely match pressures above and below a closed flapper, thereby eliminating the cost of rerouting gas from a nearby well or bringing in pressurization equipment

To date, Weatherford has installed more than 7000 SSSVs worldwide. Of those, nearly 5000 are TRSVs that have provided more than 10,000 years of cumulative service life with zero failures attributable to design or quality issues. No Optimax TRSV has ever failed; however, as a contingency, a Weatherford WRSV can be deployed on slickline to land inside a damaged TRSV. An insert safety valve effectively bypasses the TRSV and helps to restore production at a fraction of the cost of replacement workover.

To reassure operators that wells could be closed in during blowout conditions, Weatherford performs special high-velocity slam-closure tests. One such test was conducted on a 7in TRSV. The valve was successfully slam tested at 460ft/s (140m/s)—which is equivalent to a production rate of more than 480 MMscf/d (13.59MM cm/d)—making it one of the highest gas-slam-rated valves on the market.

Attorneys have cited the absence of a safety valve in lawsuits on behalf of residents that have been dislocated by a two-month-old natural gas storage well leak in the northwest end of the Los Angeles San Fernando Valley (see Daily GPI, Nov. 19).

State and Southern California Gas Co. officials contacted by NGI Monday refused to talk about the valve, saying that the well was in full compliance with state safety requirements on Oct. 23 when the leak was discovered in the Standard Sesnon 25, or SS25 well. Officials in the Department of Conservation’s (DOC) Division of Oil, Gas and Geothermal Resources (DOGGR) said rules and safety inspections for underground gas storage facilities are likely to change in the future.

Both the Sempra Energy gas utility and the state have confirmed that SS25 has no subsurface valve. Attorneys for residents of the Porter Ranch development near the Aliso Canyon storage facility allege that the presence of a valve might not have prevented the leak, but it could have stopped fumes from the odorized gas from flowing to the community (see Daily GPI, Dec. 23, 2015).

In an amended filing against SoCalGas last Tuesday, attorneys allege that SoCalGas removed a subsurface valve at the 8,500-foot base of the leaking well back in 1979 and never replaced it. The company did not respond to this allegation, only saying that DOGGR has indicated “that well SS25 was in full compliance with its regulations at the time of the leak, and SoCalGas shares this view, and [we] will continue to cooperate with DOGGR as its compliance investigation continues.”

A SoCalGas spokesperson further confirmed that the leaking well “does not have a subsurface safety valve,” adding that DOGGR regulations do not require “these types of valves to be installed in wells such as SS25.”

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

Oil and Gas industry is one of the largest core industries of the world both in terms of size of operation and revenue. However, as the industry primarily deals with production, refining and transportation of hydrocarbons, which are highly volatile and combustible in nature, the risks involved are extremely high. There is a constant threat to worker’s life as well as the work space environment on a whole. Therefore, it is absolutely essential to develop and integrate technologies into the system which act as fail-safe and safety mechanism to prevent any disaster from happening or to minimize its spread and effect. Subsurface safety valves are one such technology implemented for the same in the upstream industry.

A subsurface safety valve or downhole safety valve is a component installed in the oil and gas well, which acts as a fail-safe mechanism. It aims at preventing uncontrolled and sudden release of reservoir fluids, in case of a disaster or mishap by implementing emergency closure mechanism. Because of its importance, it is almost always installed and is a vital component of the completion operation.

Tremendous growth in exploration and production activities across the globe along with growing emphasis on health and safety marks growth of the Subsurface Safety Valves EquipmentMarket. The Market had an estimated worth of xx Billion dollars in 2016, and is growing at a steady rate of xx% every year. Our extensive and in-depth analysis concludes that the market is booming and suggests that it will eventually reach an approximated net worth of xx billion dollars by 2026.

Principle of working:A subsurface safety valve is generally a one-directional (uni-directional) flapper type of valve which is directed in such a way that when pressure is applied from an upward direction, the flapper opens in downward direction (It moves towards downward direction). This ensures the closure of a safety valve even if a high pressure is applied by well fluids from downward direction, thus making the tool fail-safe and a method to isolate the well bore.

Surface controlled subsurface safety valves: They are controlled by the action of hydraulic pressure provided through a capillary control line which is connected to a surface control panel. The valves are normally closed (fail-safe) and require a constant pressure supply to be opened.

Subsurface controlled subsurface safety valves (Storm chokes): They are installed in standard profile nipples in the tubing string, just below the surface tubing hanger and are retrieved by the help of wire line. It is activated by a change in operating conditions.

Comprehensive analysis of subsurface safety valves systems along with technology, equipment, advancements, procedures, services etc. is provided in the report.

The primary driver of the market is the concurrent oil price which significantly drives the costs of services and equipments. The market is also driven by advancements in drilling operations scenario like exploitation of unconventional reservoirs, growing health and safety concerns, needs to improve well control etc. As implementation of Sub-surface safety measures is an absolute necessary, the equipments’ market does not face any significant threats. Lower oil prices will reduce the E&P activities and hence can somewhat affect the market. Also, development of newer control methods, high costs of maintenance, regular work over requirements etc. may pose a challenge for the market. However, continuous research and development in the field and inclusion of advanced automation has made the technology more efficient and effective and therefore, there is a scope of tremendous growth.

Factory of Safety Shut-off Valve Ssv Unit Price: US$ / Piece Min. Order: 1 Piece Add to Inquiry Basket Factory of DN25 DN50 Ssv Valve Factory of DN25 DN50 Ssv Valve Unit Price: US$ / Piece Min. Order: 1 Piece Add to Inquiry Basket China Supplier Ssv Safety Shut Valve Class 600 China Supplier Ssv Safety Shut Valve Class 600 j5qnlUFeHzTb The hydraulic self-contained safety system (HSCSS) is a highly reliable control system for shutdown valves (SDV) or surface safety valves (SSV). The low-cost HSCSS is designed specifically for remote locations where external power sources are not available. YsNgX7MQsT1k API 6A High Pressure Actuated Surface Safety Valve (SSV) 1-13/16" to 7-1/16" Pressure 2000PSI to 2000PSI Actuated Safety Valves (SSV) & Controls MODEL S200 HYDRAULIC GATE VALVE 4.1/16" 10K, FLS TYPE., FLANGED, API 6A, PSL3 PR2 U DD/EE h6BUVQ6QzNP2 Surface Safety Valve 3-1/16" 10k, with Hydraulic Fail Safe, Sour Service, Find Details about Ssv, Surface Safety Valve from Surface Safety Valve 3-1/16" 10k, with Hydraulic Fail Safe, Sour Service - Vigor Mework Petro-Industries Limi: 10000psi. Transport Package: Std. Specification: API6A, Origin: P. R. C jM5eo33mdqMo

8613371530291

8613371530291