thermal safety valve factory

“Right now, Swagelok is fabricating a differential thermal relief valves (DTRs) system for the company,” says Jones. “Many of the valves that Charbonneau Industries puts together has DTRs on them. Providing these Swagelok Custom Solutions has saved them a lot of time. Their employees no longer have to build these specific assemblies that may take them up to two hours to complete, saving them a significant amount of time per valve.”

In the oil and gas industry, safety is critical. Natural gas runs through miles and miles of pipelines—through cities, along interstates, in houses and everywhere in between. It’s necessary to ensure oil and gas systems are safe and running at all times.

“A lot of our products go into critical applications such as shut-down valves,” Hamilton states. “If these components don’t work when they are supposed to, then that station won’t be able to come offline—potentially impacting the flow down the line.”

“I trust Swagelok because they’re the best,” Curtis Butts, supervisor at Charbonneau Industries states proudly. “I don’t have to question whether or not a Swagelok component is going to work two years, or even ten years, down the road. I’ve seen Swagelok products come back on our actuators and valves that were installed 20 years ago and they’re still holding pressure just fine.”

One of the main causes of pressure increase is thermal expansion from hot temperatures. As the vessels are usually in outdoor ambient conditions, there is a high possibility of this happening especially during the warmer months.

Please note that these relief valves are only designed to handle normal thermal stresses. Further consideration must be made to account for other pressure increase incidents including surges and fires.

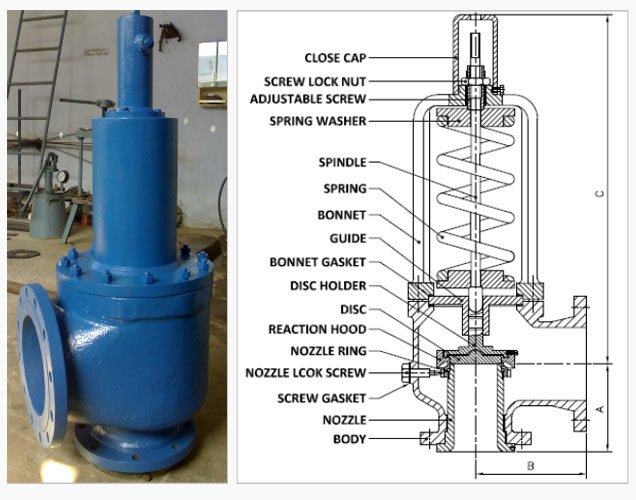

Conventional Safety Relief Valve is used in many industries for protection against high pressure. This valve is used in the gas or liquid industries to control the pressure for high safety standards. Conventional Safety Relief Valve is used for the safety of various pressure devices like a tank, piping, boiler etc. Mainly the Conventional Safety Relief Valve is used to save property and life.

Nivz make Thermal relief valve is being use to relieve the pressure, which is generated by increasing in the liquid volume caused by an increase in temperature. Thermal relief valve also used at Pipe Line, Pressure Vessel or Tanks to relief a pressure which generated by Thermal Expansion. Nivz Valves & Automatino Thermal Relief valves manufacturing range start from ½” (15NB) Size to 2” (50NB) Size.

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Presently we are providing the services from the Ahmedabad, Gujarat to the client situated in the different part of India and also in the different world countries. We are providing complete solution related to the different types of the industrial valve, and also valve customization to the clients.

Safecon Valves Pvt. Ltd. are the pioneers for a wide and comprehensive range for Various types of Industrial and Instrumentation Valves who have been serving to clients in

several countries world wide. We are a long established company producing wide range of manual, automatic, pneumatic, electrical actuated, industrial valves & instrumentation valves, which are precision designed to provide best solutions to industries like Oil and Gas, Refineries, Chemicals, Thermal Power Stations, Textiles, Sugar Breweries & distilleries, Sewage & Water Treatment, Ship yards & Marine Management and others.

We also are dedicated to making our products and manufacturing process environmentally-friendly. We are an ISO 9001:2015 Certified Company who believes in having advanced engineering capabilities and innovation driven focus to continuously expand our offering of Best Quality Industrial and Instrumentation Valves

The Company is established to provide best quality Valves at most competitive price. All Valves are being exported in accordance with internationally accepted standards like API/ASA/ASTM/ANSI/MSS/BS/DIN/JIS/IS specifications. The Product Range includes size range from 1/2" through 16” pressure rating from 150 # through 2500# in almost all Material of Construction.

SAFECON having own Design, Research and Development Division for overall quality goals to achieve and maintain the integrity and conual improvements in design of the valves. Design and Development process are employed at SAFECON to transform customer requirements into Specifications, Product, Process or System by highly expert technical team and give the best solution in order to meet the physical and technical needs of the customer at economical cost.

Stringent Quality checks are carried out at each stage of production to make our Valves operate trouble free for long time results & safe to use under the recommended pressure and temperature conditions. Each Valve is made from finest material & is subject to stringent, rigorous check & inspections at every stage for reliable and dependable valves required for high/low pressure, high/low temperature and for highly corrosive fluids.

Safecon Strictly Follows All National & International Standards And Codes Which are Applicable to Manufacture of Instrumentation Valves. There are.....

... system is subject to a rapid temperature change, the thermal expansion of fluids may potentially cause damage within the system. Thermal relief valves ...

This miniature pressure relief valve is only .187” in diameter and .62” in length. This valve is ideal for both pneumatic and hydraulic pressure relief ...

Pressure Relief Valve Type–SMFN-7000-LP, SMF-7000-MP, SMF-7000-HP & SU-7000This product range is mainly used for Thermal Relief application but thanks to the certified ...

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

1 Piece Ball Valve1 Piece Cast Iron Screwed Ball Valve1 Piece Flanged Ball Valve1 Piece Screwed Ball Valve2 Piece Ball valve2 Piece Cast Steel Ball Valve2 Piece Flanged Ball Valve2 Piece Forged Steel Ball Valve2 Piece Screwed Ball Valve3 Piece Ball Valve3 Piece Cast Iron Ball Valve3 Piece Cast Steel Ball Valve3 Piece Flanged Ball Valve3 Piece Forged Steel Ball Valve3 Piece Reduced Port Ball Valve3 Piece Screwed Ball Valve3 Way Converging and Diverging Control Valve3 Way Plug Valve3 Way Pneumatic Diaphragm Control ValveAir ValveAlloy 20 2 Piece Ball ValveAlloy 20 2 Piece Screwed Ball ValveAlloy 20 3 Piece Ball ValveAlloy 20 3 Piece Screwed Ball ValveAlloy 20 Ball ValveAlloy 20 Dual Plate Lug Type Check ValveAlloy 20 Floating Ball ValveAlloy 20 Swing Check ValveAlloy 20 Trunnion Mounted Ball ValveAlloy 20 ValvesAlloy 20 Wafer Butterfly ValveAlloy Butterfly ValveAlloy Check valveAlloy Dual Plate Wafer Check ValveAlloy Flanged Gate ValveAlloy Flanged Globe ValveAlloy Gate ValveAlloy Gate ValvesAlloy Globe ValvesAlloy Lug Butterfly ValveAlloy Plug ValveAlloy Pressure Seal Globe ValveAluminium Bronze 3 Piece Ball ValveAluminium Bronze Ball ValveAluminium Bronze Butterfly ValveAluminium Bronze Check ValveAluminium Bronze Floating Ball ValveAluminium Bronze Gate ValveAluminium Bronze Lug Butterfly ValveAluminium Bronze Swing Check ValveAluminium Bronze Triple offset Lug Butterfly ValveAluminium Bronze Trunnion Ball ValveAluminium Bronze valvesAluminium Bronze Wafer Butterfly ValveAluminium Dual Plate Wafer Check ValveAluminum Bronze Globe ValveAngle Globe ValveANSI Gate ValveANSI Globe ValveAPI Aluminium Bronze Triple offset Lug Butterfly ValveAPI Gate ValveAPI Globe ValveAustenitic Steel Big Size Ball ValveAustenitic Steel ValvesAWWA Butterfly ValveAWWA Gate ValveAWWA Non Rising Stem Gate ValveAWWA OS&Y Gate ValveAWWA StrainerAWWA Wafer Butterfly ValveAWWA Y StrainerBalancing ValveBall Float Steam TrapBall ValveBellow Seal Globe ValveBi Directional Knife Gate ValveBimetallic Steam TrapBlock and Bleed valveBrass Ball ValveBrass Ball ValvesBrass Check ValvesBrass Flanged Ball ValveBrass Flanged Gate ValveBrass Flanged Globe ValveBrass Gate ValveBrass Gate ValvesBrass Globe ValveBrass Globe ValvesBrass Safety ValveBrass Swing Check ValveBrass ValveBrass Vertical Check ValveBrass Y StrainerBronze Butterfly ValveBronze Check ValveBronze Flanged Gate ValveBronze Flanged Globe ValveBronze Floating Ball ValveBronze Gate ValveBronze Gate ValvesBronze Globe ValveBronze Globe ValvesBronze Swing Check ValveBronze ValveBronze Wafer Butterfly ValveBronze Wafer Check ValveBS Cast Iron Gate valveBS Cast Steel Gate ValveBS Ductile Iron Gate ValveBS Globe ValveBS Non Rising Stem Gate ValveBS NRS Carbon Steel Gate ValveBS NRS Cast Iron Gate ValveBS NRS Ductile Iron Gate ValveBS Rising Stem Gate ValveBS Soft Seat Gate ValveBS Stainless Steel Gate ValveButterfly ValveCarbon Steel Bellow Seal Globe ValveCast Floating Ball ValveCast Iron And Cast Steel Ball ValveCast Iron Diaphragm ValveCasting Trunnion Ball Valvecheck valveConnection Lift Plug ValveControl ValveCryogenic Ball ValveCryogenic Check ValveCryogenic Emergency Cut off ValveCryogenic Gate ValveCryogenic Globe ValveCryogenic Long Stem Globe ValveCryogenic Pneumatic Actuated Globe ValveCryogenic Short Stem Globe ValveCryogenic Steam Jacket Globe ValveCryogenic ValveDiaphragm ValveDIN Globe ValveDIN Non Rising Stem Ductile Iron Gate ValveDIN Non Rising Stem Gate ValveDIN NRS Cast Iron Gate ValveDIN Rising Stem Cast Iron Gate ValveDIN Rising Stem Ductile Iron Gate ValveDIN Rising Stem Gate ValveDIN Soft Seat Gate ValveDirect Acting Pressure Reducing ValveDouble Block and Bleed Ball ValveDouble Disc Gate ValveDouble Eccentric Butterfly ValveDouble Offset Butterfly ValveDouble Orifice Air Release ValveDouble Orifice Kinetic Air ValveDual Plate Lug Check ValveDual Plate Wafer Check ValveDuctile Iron Diaphragm ValveDuplex 1B 3 PC Ball ValveDuplex 3 Piece Ball ValveDuplex Basket StrainerDuplex Butterfly ValveDuplex Check ValveDuplex Dual Plate Lug Type Check ValveDuplex Dual Plate Wafer Check ValveDuplex Floating Ball ValveDuplex Gate ValveDuplex Globe ValveDuplex High Pressure Ball ValveDuplex Lug Type Butterfly ValveDuplex Steel Ball ValveDuplex steel ValveDuplex Swing Check ValveDuplex Top Entry Ball ValveDuplex Trunnion Mounted Ball ValveDuplex Wafer Butterfly ValveEccentric Plug ValveElectric 3 Way Control ValveElectric Actuated 2 Piece Ball ValveElectric Actuated 2 Piece Flanged Ball ValveElectric Actuated 2 Piece Screwed Ball ValveElectric Actuated Ball ValveElectric Actuated Butterfly ValveElectric Actuated Flanged Ball ValveElectric Actuated Floating Forged Ball ValveElectric Actuated Gate ValveElectric Actuated Globe Control ValveElectric Actuated Globe ValveElectric Actuated High Pressure Ball ValvesElectric Actuated High Pressure Direct Mounting Ball ValvesElectric Actuated Lug Butterfly ValveElectric Actuated Metal-Seated Trunnion-Mounted Forged Ball ValveElectric Actuated Three Piece Ball ValveElectric Actuated Three Way Ball ValveElectric Actuated Trunnion-Mounted Casting Ball ValveElectric Actuated ValvesElectric Actuated Wafer Butterfly ValveElectric Cage Type Control ValveElectric Control ValveElectric Double Seat Control ValveElectric O-type Shut-off Control ValveElectric Single Seat Control ValveF22/Alloy Steel Pressure Seal Globe ValveF317L Gate ValveF317L Globe ValveF317L ValvesF321 Gate ValveF321 Globe ValveF321 ValvesF347 3 Piece Ball ValveF347 Ball ValveF347 Butterfly ValveF347 Check ValveF347 Dual Plate Lug Type Check ValveF347 Dual Plate Wafer Check ValveF347 Floating Ball ValveF347 Gate ValveF347 Globe ValveF347 Lug Type Butterfly ValveF347 Swing Check ValveF347 Trunnion Mounted Ball ValveF347 ValvesF347 Wafer Butterfly ValveF44 Gate ValveF44 Globe valvesF44 ValvesF51 Super Duplex Ball ValveF53/F55 Super Duplex Globe ValveFeed Water Control ValveFlanged Butterfly ValveFlanged Knife gate ValveFloat Control ValveFloating Ball ValveFluorine Lined Single Seat Control ValveFoot ValveForged Cryogenic Trunnion Ball ValveForged Floating Ball ValveForged Steel Ball ValveForged Steel Gate ValveForged Steel Globe ValveForged Steel Swing Check ValveForged Trunnion Ball ValveFull Lift Pressure Safety ValveFull Lift Safety ValveFully Welded Ball ValveGate ValveGlobe ValveHastelloy Ball ValveHastelloy C276 2 Piece Flanged Ball ValveHastelloy C276 2 Piece Screwed Ball ValveHastelloy C276 3 Piece Screwed Ball ValveHastelloy C276/B3 3 Piece Ball ValveHastelloy C276/B3 Butterfly ValveHastelloy C276/B3 Dual Plate Lug Type Check ValveHastelloy C276/B3 Dual Plate Wafer Check ValveHastelloy C276/B3 Floating Ball ValveHastelloy C276/B3 Gate ValvesHastelloy C276/B3 Globe ValveHastelloy C276/B3 Lug Butterfly ValveHastelloy C276/B3 Swing Check valveHastelloy C276/B3 Trunnion Mounted Ball ValveHastelloy C276/B3 ValvesHastelloy C276/B3 Wafer Butterfly ValveHastelloy Check ValveHeavy Duty Investment Casting Ball ValveHigh Performance Lug Butterfly ValveHigh Performance Wafer Butterfly ValveIncoloy 2 Piece Ball ValveIncoloy 3 Piece Ball ValveIncoloy Gate ValveIncoloy Globe ValveIncoloy ValvesInconel 2 Piece Ball ValveInconel 3 Piece Ball ValveInconel Ball ValveInconel Butterfly ValveInconel Check ValveInconel Dual Plate Lug Type Check ValveInconel Dual Plate Wafer Check ValveInconel Floating Ball ValveInconel Gate ValveInconel Globe ValveInconel Lug Butterfly ValveInconel safety relief valveInconel Swing Check ValveInconel Trunnion Mounted Ball ValveInconel ValveInconel Wafer Butterfly ValveInverted Bucket Steam TrapInvestment Casting Ball ValveJacketed Ball ValveJacketed Plug ValveKnife Gate ValveLift Check valveLow Lift Pressure Safety ValveLow Lift Safety ValveLubricated Plug valveLug Butterfly ValveMonel 2 Piece Ball ValveMonel 3 Piece Ball ValveMonel 400 2 Piece Flanged Ball ValveMonel 400 ValvesMonel Ball ValveMonel Butterfly ValveMonel Check ValveMonel Dual Plate Lug Check ValveMonel Dual Plate Wafer Check ValveMonel Floating Ball ValveMonel Forged Trunnion Mounted Ball ValveMonel Gate ValveMonel Globe ValveMonel High Pressure Ball ValveMonel Lug Type Butterfly ValveMonel Swing Check ValveMonel Top Entry Ball ValveMonel Trunnion Mounted Ball ValveMonel ValvesMonel Wafer Butterfly ValveNeedle valveNon Slam Swing Check ValveNon-Lubricated Sleeved Plug ValveNon-Rising Stem Gate ValveNon-Slam Swing Check ValveOrbit Plug ValvePilot Operated Pressure Reducing ValvePilot Operated ValvePressure Relief ValvePiston ValvePlug ValvePlunger ValvePneumatic Actuated 2 Piece Ball ValvePneumatic Actuated 2 Piece Flanged Ball ValvePneumatic Actuated Ball ValvePneumatic Actuated Butterfly ValvePneumatic Actuated Flanged Ball ValvePneumatic Actuated Flanged Butterfly ValvePneumatic Actuated Gate ValvePneumatic Actuated Globe type Control ValvePneumatic Actuated Lug Butterfly ValvePneumatic Actuated Three Piece Ball valvePneumatic Actuated Three Way Ball valvePneumatic Actuated Three Way Heavy Duty Ball ValvePneumatic Actuated Two Piece Ball ValvePneumatic Actuated ValvesPneumatic Actuated Wafer Butterfly ValvePneumatic Angle Control ValvePneumatic Angle Seat Control ValvePneumatic Angle Type High Pressure Regulating Control ValvePneumatic Bi Directional Knife Gate valvePneumatic Cage Control ValvePneumatic Control ValvePneumatic Double Seat Control ValvePneumatic Flow Control ValvePneumatic Knife Gate ValvePneumatic Metal Seat Flanged Ball ValvePneumatic Single Seat Globe Control ValvePneumatic Sleeve Type Control ValvePneumatic Three piece Ball ValvePneumatic Three Piece Flanged Ball ValvePneumatic Three Way Ball ValvePneumatic Three Way Flanged Ball ValvePneumatic Trunnion Casting Ball ValvePneumatic Trunnion Forged Ball ValvePneumatic Trunnion Forged Metal Seat Ball ValvePneumatic Unidirectional Knife Gate ValvePressure Reducing ValvePressure Safety ValvePressure Seal Gate ValvePressure Seal Globe ValvePressure Seal Swing Check ValveRotary Airlock ValveSafety ValveSimplex Basket StrainersSingle Orifice Air ValveSingle Plate Wafer Check ValveSlab Gate ValveSlurry Knife Gate ValveSoft Seal Gate ValveSpeciality ValveSS304 Bellow Seal Globe ValveSS316 Bellow Seal Globe ValveSS316L Gate ValveSS316L Lug Butterfly ValveSS316L Wafer Butterfly ValveSteam Pressure Reducing ValveSteam Safety ValveSteam TrapStrainersSuction DiffuserSuper Duplex 2 Piece Ball ValveSuper Duplex 3 Piece Ball ValveSuper Duplex 5A Flanged Gate ValveSuper Duplex 5A Globe ValveSuper Duplex 5A Swing Check ValveSuper Duplex Ball ValveSuper Duplex Butterfly ValveSuper Duplex Check ValveSuper Duplex Dual Plate Lug Type Check ValveSuper Duplex Dual Plate Wafer Check ValveSuper Duplex Floating Ball ValveSuper Duplex Gate ValveSuper Duplex Gate ValvesSuper Duplex Globe ValveSuper Duplex High Pressure Ball ValveSuper Duplex Knife Gate ValveSuper Duplex Lug Butterfly ValveSuper Duplex Pressure Reducing ValveSuper Duplex Top Entry Ball ValveSuper Duplex Trunnion Mounted Ball ValveSuper Duplex ValvesSuper Duplex Wafer Butterfly ValveSurge Anticipator ValveSwing Check ValveThermal Safety ValveThermodynamic Steam TrapThermostatic Steam TrapThree Piece Flanged Ball ValveThree Way Ball ValveThrough Conduit Knife Gate ValveTilting Disc Check ValveTitanium 3 Piece Ball ValveTitanium Ball ValveTitanium Butterfly ValveTitanium Check ValveTitanium Dual Plate Lug Type Check ValveTitanium Dual Plate Wafer Check ValveTitanium Floating Ball ValveTitanium Forged Trunnion Mounted Ball ValveTitanium Gate ValveTitanium Globe ValveTitanium Gr.2 2pc Flanged Ball ValveTitanium Gr.2 3pc Ball ValveTitanium Gr.5 2pc Flanged Ball ValveTitanium Gr.5 3pc Ball ValveTitanium Lug Butterfly ValveTitanium Swing Check ValveTitanium Trunnion Mounted Ball ValveTitanium valvesTitanium Wafer Butterfly ValveTop Entry Ball ValveTriple Duty ValveTriple Eccentric Butterfly ValveTriple Offset Butterfly ValveTrunnion Ball ValveTwin Seal Plug ValveUL/FM Approved ValvesUnidirectional Knife Gate ValveWafer Butterfly ValveWater Pressure Reducing ValveY StrainerY Type Globe ValveZirconium Floating Ball ValveZirconium Gate ValveZirconium Globe ValveZirconium Valves

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

Pressure relief valves are a critical component of fuel, hydraulic, and pneumatic systems in many industries. These valves can serve one of three functions—safety relief, pressure regulation, or protection against thermal expansion. The Lee Company offers a wide range of pressure relief valve configurations designed to ensure that we can offer the right solution for a specific application, helping to guarantee the safety and reliability of your product.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

8613371530291

8613371530291