safety valve cooker free sample

Our, inventionrelates. to safety valves, and .has particular reference to safety valves for pressure cookers, particularly of.the type used for home cooking, food articles.

Pressure cookers are usually provided with safety valves.. Because of the presence of solid matterin-the food.being cooked, the valves often become clogged and inoperative. To prevent the possibility-.of an explosion, a safety blow-out plug is. also usually, provided, which releases the. steam when. pressure rises above the blow-off: pressure of the.safety valve... Such blow-out plugs have a. disadvantage. in. that- they must be replaced after. each operation; also that their operation results. in a blast of .hot steam upward from the cooker with a resultant danger of scalding attendant"s face and: hands. The same difficulty is often .encountered with the conventional safety valves which exhaust steam directly.upward.

Our. inventionhas. for its object to provide a safety valve for a pressure. cooker which is so constructed that the blow-off steam. escapes in a direction tangential to the cover of the cooker so that the danger of scalding one"s hands or face is. practically, eliminated..

Another object of our invention is to provide a safety valve for a pressure cooker so constructed that it cleans itself when it is operated, by removing any obstructions which may accumulate at the intake of the valve.

Another object of our invention is to provide a safety valve, which can be easily removed for cleaning or replacement but which is provided with a locking mechanism for preventing the valve from working itself loose or from being accidentally removed.

Another object of our.invention is to provide a locking means for our safety valve whereby the valve can be locked in.an open position, when it is desired"to cook at-the atmospheric pressure.

Still.another object of our invention is to provide a supplementary safety, valve constructed ih conjunction with the foregoing safety valve and so arranged that it opens at a pressure substantially higher than, the, blow-off pressure of the main safety valve, being held closed by an adjustable spring and having a relatively large opening whiCh cannot be clogged by food particles.

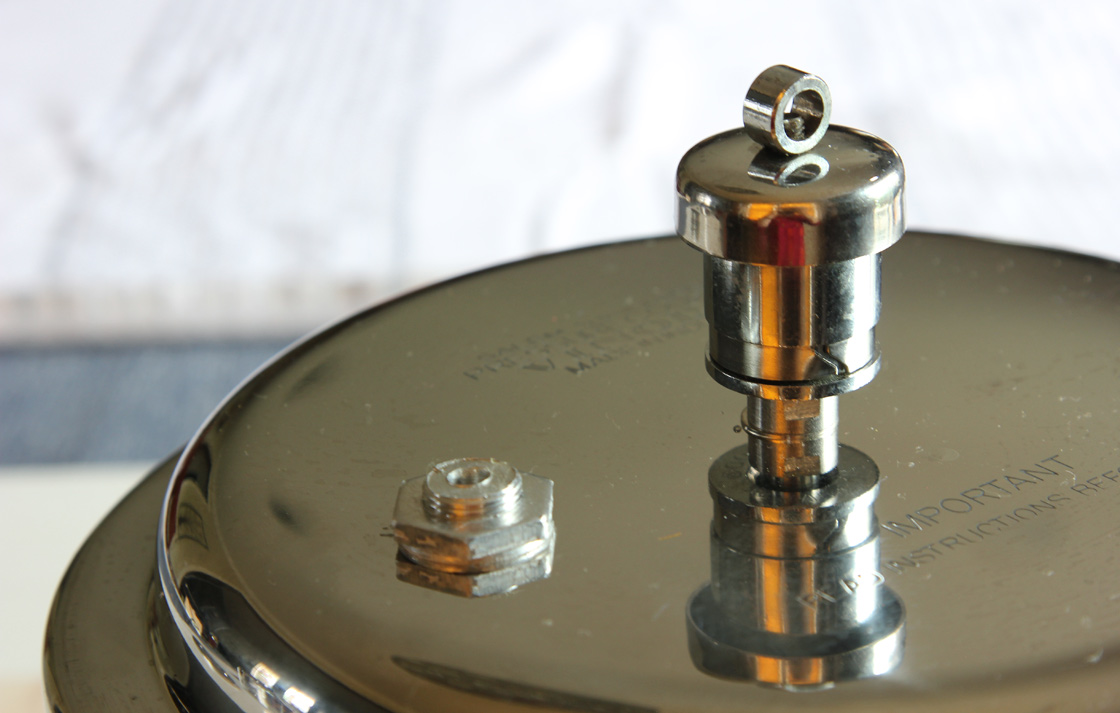

The. foregoing and other objects; features and sdvarntiages" are" more ftlly: described- in the accomanuying,specificatiori andth"dra"wing in which; Fig. 1 is a sectional elevational view of our safety valve in conjunction with supplementary safety valve, the main valve being shown in. an open or inoperative position.

Fig. 2 is a detail view of the removable portion of the valve; Fig. 3 is a top plan view of the valve removable portion; Fig. 4 is a top plan view of the fixed portion !o of the valve; Fig. 5 is a sectional elevational view. of a pressure cooker with our valve shown in. a reduced scale; Fig. 6 is.a sectional elevational view of a simplified valve.

Our safety valve in its form shown in Fig, 1 consists of a disc-shaped base I having a stem or extension 2.threaded at 3 into a convex plate 4. The latter is placed on the outer side of a cover or lid 5 of a pressure cooker 6 as shown in Fig. 5. The cap 4 covers a large opening 10 in the lid 5 and is provided with a gasket: I made of rubber or similar material providing a steamproof seal. The lower end of the extension 2 2 passes through a corresponding opening in a spring plate 12 and is tightened by a nut 131 The plate 12 is curved upward and its ends rest against the under side of the lid 5. By tightening the nut 13. the plate 12 is placed under compression, causing the plate 4 to be tightly pressed against the outer side of the lid 5.

The extension 2 of the base I has a central bore 14 with a tapering valve seat" 1"5 at the lower end of valve 18. The latter has a stem- 9 -passing to the outside of the base I and sliding in a corresponding hole in a cap 20. The latter is threaded at 21 on an upper extension 22 of the base I. The lower portion of the cap is round and is confined within upstanding flange 23- of the base I; A helical spring 25 is placed on-the stem 19 between the valve 18 and the upper portion of the cap 20. The pressure of-the spring 25 determines the vapor pressure in the, cooker at which the valve 18 is raised from its seat I . This pressure can be adjusted by turning the cap 20 to the right or to the left. thereby moving the cap up or down on the threads 21. Each particular position of the cap 20 corresponds to a-definite vapor pressure, which is marked on the cap-by numbers 26:with reference to a stationary mark 27 on the flange 23.

To prevent accidental removal of the- cap 20, it is provided with a locking plunger- 30 slidably fitted in a bore- 31 of the cap and provided with a pin 32 at the bottom engaging- an- arcuate groove 3S in the upper surface of the base I. A stem $3 extends from the plunger and passes through a corresponding hole in the upper clozed end of the bore. A nut 35 is threaded on the upper outer end of the stem 34 and relates the plunger in its place when the cap with the valve is removed from the base I as shown in Fig. 2. A spring 3G on the stem 34 urges the plunger 30 downward. The groove 33 extends through a substantial portion of a circle so as to make it 0 possible to adjust the position of the cap 20 to a desired vapor pressure. The groove 33 also prevents the complete unscrewing of the cap, shoulders 37 at the ends of the groove 33 engaging the pin 32.

The valve 18 is provided with a pin 40 at the lower end, passing with a clearance through the bottom hole 41 in the valve seat. The pin extends beyond the end of the hole 41 so that the pin, when the valve is raised and seated again, will clear the hole 41 from any obstruction or clogging caused by solid food particles.

Blow-off holes 38 extend radially and horizontally through the walls of the extension 2 for releasing the vapors escaping through the valve. The base I has a depending flange 39 at the periphery for breaking the vapor flow from the holes 38 thereby protecting the attendant from the vapor.

For lowering the valve in an open position when it is desired to cook at the atmospheric pressure, a lowering hook 46 is provided at the end of the valve stem 19, one end of the hook rotatively engaging the hole at the stem. By turning the hook in a vertical position as shown in Fig. 1, the valve stem is raised, leaving the valve open. The valve is released when the hook is turned to the side as shown in Fig. 6. " Despite all precautions, however, the valve may be temporarily clogged thereby causing the vapor pressure to rise above the desired value.

To prevent the possibility of an explosion, a second safety feature is provided consisting of the above described cover plate 4 and spring plate or bar 12 to which the lower end of the extension 2 is secured by the nut 13. The tension of the spring plate 12 is so adjusted that the plate will yield when the total vapor pressure on the " cover plate 4 exceeds a predetermined value, usually substantially higher than the corresponding vapor pressure to which the cap 20 was set. Because of the large periphery of the cover plate 4, allowing the vapor to escape in a horizontally o extending stream all along the said periphery, the pressure and the density of the vapor steam are greatly reduced, so that there will be no danger to an attendant of being scalded by the hot vapor.

The cover plate 4 with the spring plate 12 constitutes therefore a second or supplementary safety valve. The blow-off pressure of the second valve can be adjusted by the nut 13. The latter can be locked in an adjusted position by a set screw 43.

A simplified valve is shown in Fig. 6, the second valve being omitted and the extension 44 threaded directly into the cover 45 of the pressure cooker. The body 47 is otherwise made similar to the body 1. The valve can be used with any conventional or other pressure cooker such, for instance, as the cooker 6 with its lid 5. The latter has an inward extending flange 48 with slots 49 which pass over locking lugs 50 extending from the vessel 6. The lid 5 is placed over the edge of the vessel 6 with the slots 49 over the lugs 50 and then the lid 5 is turned by its handle 51 until the fiange portions 48 glide under the lugs 50 until they are stopped by depending stopping lugs 53. A sealing gasket 52 provides an air tight seal for the cooker.

The following is claimed as new: 1. A valve for a pressure cooker comprising a support; a base having an extension; means to mount the extension on said support; a cap threaded on the base; a valve seat in the base; a valve engaging the seat having a stem passing through a hole in the cap; a spring on the stem urging the valve against the seat; the cap being adapted to be manually rotated thereby chang* ing the pressure of the spring on the valve; the base having an arcuate groove with shoulders at its ends; a plunger slidably fitted in the cap; a spring urging the plunger downward for causing the lower end of the plunger to engage the arcuate groove thereby limiting the rotational movement of the cap between the shoulders of the groove; and an exposed head on the plunger adapted to be manually moved upward for releasing the plunger from the groove thereby enabling the cap to be entirely unscrewed from the base.

2. A valve for a pressure cooker comprising a support having an opening therethrough, a base; a convex plate mounted on said support over said opening; means to mount the base on the plate; a valve in the base; an extension on the base passing through the opening; a spring plate resting on the under side of the support over the opening; and means to adjustably secure the lower end of the extension to the spring plate for regulating the pressure at which the convex plate with the base is raised above the support by pressure fluid.

3. A valve for a pressure cooker comprising a support having an opening therethrough, a base; a convex plate mounted on said support over said opening; means to mount the base on the plate; a valve in the base; an adjustable spring for urging said valve closed; an extension on the base passing through the opening; a spring plate resting on the under side of the support over the opening; and means to adjustably secure the lower end of the extension to the spring plate for regulating the pressure at which the convex plate with the base is raised above the support by pressure fluid of the spring plate being adjusted to a higher pressure for closing the convex plate than the closing pressure at which the valve spring is adjusted.

4. A valve for a pressure cooker having a vessel and a lid adapted to be tightly locked in an operative position on the vessel, the lid having an opening; a convex plate placed over the opening; a valve base secured to the convex plate; a valve in the base; a seat for the valve in the base; a spring on the valve urging the valve against the seat; ýmeans to adjust the valve spring pressure for adjusting the pressure of the vapors in.the vessel at which the valve is opened; an extension on the base passing through the opening; a spring plate engaged by the extension, the ends of the spring plate engaging the under side of the lid over the opening; and means to adjust the pressure of the spring plate for regulating the pressure at which the spring plate yields and releases the convex plate to be raised thereby allowing the vapors to escape.

Such a valve assembly is known from German laying-open print DOS No. 2,606,676. The pressure relief means thereof consists of a check valve which also serves as a safety valve. It has a valve housing of a resilient material which is fitted into a hole in the cover in the vicinity of the cooking valve aperture. The closure body is designed as a shaft-shaped valve body, transverses the valve opening and supports two spaced valve disks inside the cover as well as a dome-shaped head outside the cover. The head abuts against the valve opening in the pressureless state. As the pressure builds up in the pressure-cooker, however, the valve body is lifted and the upper valve disk closes off the valve opening internally so that the pressure in the cooker can build up. When the pressure becomes excessive, the upper valve disk can move outwardly through the valve opening of the valve housing. This allows steam to escape through the valve opening. The second valve disk preventing the valve body from being blown off the cooker although it does not obstruct the escape of steam. The cooking valve usually comprises a spring-loaded valve and a displaceable pressure indicator for the cooker which is located therein and is also spring-loaded. The springs press against the interior of a cap which is adapted to be screwed on to the valve housing. In the known valve assembly, the cap of the cooking valve has an asymmetrical design on the underside facing towards the cooker cover. It features a guide bevel at this location which reduces its clearance height. In the normal cooking position, the area with the maximum inner clearance height overlaps or overlies the check valve. When the cap is screwed off, the area with a minimum clearance height comes to lie above the check valve over which it can move without obstruction when the head of the check valve abuts against the outer side of the valve seat in the completely pressureless state. If the check valve has closed due to the internal build-up of pressure in the cooker, ie if the upper valve disk abuts against the valve seat, the guide bevel presses the valve body of the check valve downwardly and steam can escape through the check valve. The pressure in the cooker is relieved, whilst the person using the cooker is warned simultaneously by the sound of the escaping steam not to unscrew the cap any farther. If the valve body has been raised only slightly owing to a slight superpressure in the cooker, eg at the onset of pressure build-up, an additional stop which projects into the clearance height prevents the cap from being rotated any farther.

The known valve assembly is expensive to manufacture, since it requires a valve housing and a valve body for the pressure relief means. These parts are expensive to manufacture and to assemble. The cap of the cooking valve is also expensive to produce owing to its asymmetrical shape, and the dimensions of the guide bevel as well as the region of reduced clearance height must be kept within a narrow tolerance range: the valve body must be pressed downwardly to open the valve on the one hand, although on the othe hand this must not be so far that the valve head closes the opening externally. Another drawback is that when the cap is rotated into the open position, the stop jams the head of the valve body and this cannot return to its original position, even when the cooker is not under pressure, until the cap has been turned back somewhat. When the check valve functions as a safety valve, the valve disk cannot automatically turn back any longer due to the valve opening. The cap cannot be screwed off over the projecting valve body either. This makes it impossible to gain access to the valve body and return it to the normal position. Yet another disadvantage is that the valve body of the check valve can only be cleaned thoroughly--quite essential for proper sealing--if it has been snapped out of the valve disk. Since this is complicated and troublesome, such cleaning is frequently postponed or forgotten completely.

A valve assembly comprising a pressure relief means disposed adjacent to the cooking valve is also known from German utility model No. 7,624,730. The pressure relief means is designed as a safety valve in the form of a check valve. The cap of the cooking valve has indents on the periphery thereof. Both valves are spatially associated with one another such that the valve body can be raised adjacent to such an indent only when the cap is in certain positions. The check valve can be closed and pressure built up in the cooker only in this position. When the valve body is in the raised position, ie when pressure has built up in the cooker, the valve body in turn locks the cap of the cooking valve which cannot be rotated. Hence, the vent opening cannot be opened by adjusting the cap. This known valve assembly, which therefore does not correspond to the preamble of the present invention, is expensive to manufacture due to the design of the check valve. It is also difficult to clean, since the steam is dissipated to one side through a cavity in the cooking valve beneath the cap when the safety valve responds to excessive pressure. These cavities are difficult to reach, even after the cap has been removed. Furthermore, the valve body cannot be turned back into its original position until after the safety valve has responded and the excess pressure has been vented off. Only then can the cap be removed from the cooking valve.

The object of the present invention is to provide a valve assembly according to the preamble of the claim which is economical to manufacture, easy to clean and simple to operate in all modes of operation.

The construction of the closure body as a seal disposed on the cap makes it possible to design the vent opening in the form of a simple hole in the cover without any valve housing. Such a hole can be produced during one and the same operation as the hole for the cooking valve. It is easy to clean. The arrangement of the associated seal in the cap gives rise to a constructional design which is simple and easy to clean. This construction of the pressure relief means is made possible by the recognition that the vent opening need only be open to relieve the pressure. An open valve is unnecessary prior to a pressure build-up, since the air being heated up can escape by way of the conventional sealing rings between the pressure-cooker and the cover until the sealing ring abuts sealingly against the cover and cooker wall due to the build-up of pressure. In the pressure relief means in accordance with the invention, the co-operation of the seal and the vent opening permits steam to escape even when the cap is moved minimally towards the venting position. The pressure in the cooker decreases immediately. Moreover, the co-action of the venting opening and the seal generates a warning sound which warns the cook not to opening the cooking valve while the cooker is still under pressure. If there is no seal in the cap, no pressure will build up in the cooker at all.

The seal can advantageously consist of a material which is so resilient that it sealingly closes the vent opening at normal cooking pressure and permits pressure to be vented should it become eccessive. The pressure relief means thus functions as a safety valve as well.

The annular seal advantageously has an internal diameter which is smaller than the external diameter of the cap section it surrounds. The annular seal is thus seated in the cap region in such a way that it can be neither twisted nor lost. Dirt cannot readily collect between the cap and the annular seal so that the seal does not have to be removed every time the cooker is cleaned.

FIG. 1 indicates the cover 1 of a pressure-cooker. A valve housing 2 is firmly riveted into place in the cover 1. It includes a valve seat 2a against which a valve body 3 is urged by a valve spring 4. This valve spring 4 presses against the inner side of a cap 5 overlying the entire valve assembly and designed as a cap or acorn nut. A pressure indicator 6 is displaceably mounted in the valve body 3. It is pre-biased by a pressure indicator spring 7 which presses against the valve body on the one hand and, on the other hand, against the inside of the cap 5. The cap 5 is adapted to be screwed on to the valve housing by means of a thread 8, thereby determining the tension of the valve and pressure indicator springs.

The cover 1 has a hole 10 in spaced relation from the valve axis and is located between the internal and external diameters of the annular seal. It serves as a vent opening and is closed by the annular seal 9 during cooking.

The afore-described valve assembly functions as follows during cooking: the cap 5 is screwed down to the stop with the inscription "cooking" adjacent to the arrow 12. The valve spring as well as the pressure indicator spring are both pre-biased in this position. The annular seal 9 closes the hole 10. Steam pressure can now build up in the cooker in the known manner once the warm air has escaped between the cooker and the cover as mentioned above. The cooking pressure is chosen by regulating the supply of heat in response to the position of the pressure indicator 6. At the conclusion of cooking, the cap 5 is turned half a turn to the "venting" position. This causes the annular seal to release the hole 10, the steam can escape and the pressure is relieved. The venting is continuous and dependent on the speed of rotation.

If the pressure indicator is not observed during cooking, i.e. if the supply of heat is not turned down at the proper time, thus causing the pressure in the cooker to become excessive, the steam can escape through the hole 10. This gives off a warning whistle and deforms the annular seal 9. Should the generated steam still be excessively high, the valve body 3 is lifted off its seat 2a.

Take another example. You’re a teenager, you’ve had lots of unsettling and unpleasant experiences, and high school is something like hell. Your mind is a very dark and tumultuous place and, without really being able to explain to yourself why, you find that only cutting yourself with a razor blade helps you release that pressure. Probably you don’t exactly call it “pressure”—but if you did, and if you had a way to release that mind pressure in some way other than cutting yourself, can you see that you might gain the same relief in a better way? Cutting yourself is a too-literal safety valve: wouldn’t a figurative safety valve serve you better?

Forget for a moment about the exact content of our thoughts in those three situations—thoughts like, perhaps, “Wow, she is so sexy!”, “I hate my life so much!” or “I think I’ll build a boat by hand and sail around the world!” A cognitive therapist might want to focus on those words; but who will help you focus on the pressure you’re feeling? That must be you. Just as you must install windows in your mind and open them regularly, it is your job to install a safety valve that you know how to operate and that actually releases what for many of us is relentless and often intolerable pressure.

Your mind is a pressure cooker. Therefore you must create a release valve. That release valve might be as simple as creating and using a mantra like “releasing pressure now,” creating and using a more complicated ceremonial safety valve that involves letting the pressure out through your mouth with a “whoosh!”, or creating and using some unique and idiosyncratic strategy that you dream up. If you don’t create this release valve and if you don’t use it regularly, you will live under that pressure and do things to relieve that pressure that you don’t really want do, like betraying your loved ones, cutting yourself, or racing around in existential despair.

I hope that you see clearly what your second task is. Last week I advised you to add windows to your mind and regularly open them. That is your first task. Now I would like you to create a safety valve that allows you to release all that relentless, recurring mind pressure in smart, safe ways. When you can do that releasing you will likely cure your mania, your obsessive-compulsive disorder, your addictive behaviors, and all the other consequences that result from not releasing mind pressure soon enough or well enough. When you begin to do this, you will have taken another step on the path to self-mastery.

WMF pressure cookers are perfect for those who have little time to cook, yet still want healthy, flavorful food. Foods that are pressure cooked offer more nutritional value than those cooked for longer periods using traditional cookware. Foods cooked in a pressure cooker are ready faster, using less liquid. The fact that foods are done in a shorter cooking time means they are less likely to lose their color and flavor, as well as vitamins and nutrients that are evaporated or diluted when cooking for longer periods of time. Pressure cookers reduce cooking time by as much as 70% and cut energy consumption by up to half.

Advantages of WMF pressure cookersSimple operation - Putting on the lid easily, large and good visible cooking indicator with two cooking levels, and 3 different methods of opening the pot after cooking.

Yes. All Buffalo pressure cookers, regardless of size, can be used for canning; however, only the QCP435 commercial model (35 liters / 9 gallons) has an optional pressure gauge that you can order to aid in your canning. Please make sure to follow the USDA’s guidelines for home canning.

What makes our pressure cookers so suitable for canning? Unlike other options on the market, which require frequent replacement of plastic handles, etc., our unibody stainless steel construction ensures exceptional durability. Experience the Buffalo difference with a product that’s designed for lifetime use.

Unlike other pressure cookers, all Buffalo pressure cookers come with at least five standard safety precautions, while certain models have as many as six or seven. The standard features typically include: a safety lock, safety gear, safety valve, vent filter, and pressure release hole. While our pressure cookers are designed with your utmost safety in mind, we do generally suggest following the recommended cooking times provided in our product pages.

It may be caused by leaking due to a loose gasket or loose parts. If you live within the service areas of one of our California stores, please bring your pressure cooker to your local service center for inspection. For all other customers, please contact our customer service team at 888-833-8833 for troubleshooting and further assistance.

It may be caused by leaking due to a loose gasket or loose parts, resulting in there being no pressure inside the pot. If you live within the service areas of one of our California stores, please bring your pressure cooker to your local service center for inspection. For all other customers, please contact our customer service team at 888-833-8833 for troubleshooting and further assistance.

The gasket is made of silicon, the same material used in baby pacifiers. It is non-reactive to food and can withstand heat up to 200 degrees Celsius / 392 degrees Fahrenheit. It should be replaced every 6-12 months. This food-grade material was selected because Buffalo takes health and safety very seriously.

There are numerous types of food that can be cooked with a pressure cooker. For example: beef brisket, pork hock with peanuts, red bean soup, boba balls (for boba tea), etc. Use it to steam rice cakes and turnip cakes, and you can save up to 2/3 of your cooking time! You can also use a pressure cooker for canning. Check out our YouTube channel Pacific Kitchen Life for recipes and tips.

In a fraction of the usual time, prepare healthy, delicious meals with the T-fal Clipso pressure cooker. Compared to standard cooking methods, the pressure cooker reduces cook times by up to 70% for faster results while retaining valuable nutrients and flavor. The cooker"s 6.3-quart capacity makes it easy to create large batches, whether preparing make-ahead meals for the week or cooking for a crowd during the holidays. The pressure cooker’s durable stainless-steel construction ensures optimal cooking and long-lasting performance, and its encapsulated base distributes heat evenly and can be used safely on any cooktop, including induction. Safety features include an innovative one-hand system for risk-free opening and closing, the inability to open when in use and under pressure, a variable steam-release valve for added control, and side handles for secure carrying. The Clipso stainless-steel pressure cooker can go safely in the dishwasher (with gasket and pressure valve removed), and a steam basket and stand are included for multi-level cooking, along with a recipe book with cooking tips.

That ensures that nothing interferes with the lid of the pressure cooker, which is where most of the other safety systems are. Also, check that the primary valve is clean and clear before pressure cooking.

If something were to go side-ways, even before it gets to that point, the pressure cooker itself will detect that the pressure (temperature) inside is too high and turn off the pressure cooker. But, while that’s happening, though, the food inside is still boiling and building pressure so the cooker will release excess pressure from the valve on the lid. And, if the main valve were to be clogged the cooker will release pressure from the lid-lock or secondary valve. If that were to be blocked, the cooker will release pressure from the gasket.

The last safety system of for absent-minded cooks like me. Where at the last minute I realize, “Oh, I need to add some carrots” and try to open the pressure cooker during cooking. Well, the lid locks automatically the minute pressure starts to build. It means that if there is any pressure still inside the cooker, you cannot open the lid. It’s a mechanical system so even if there is no electricity you will still be prevented from opening the lid.

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

Safety valves were first developed for use on steam boilers during the Industrial Revolution. Early boilers operating without them were prone to explosion unless carefully operated.

Vacuum safety valves (or combined pressure/vacuum safety valves) are used to prevent a tank from collapsing while it is being emptied, or when cold rinse water is used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures. When sizing a vacuum safety valve, the calculation method is not defined in any norm, particularly in the hot CIP / cold water scenario, but some manufacturers

The earliest and simplest safety valve was used on a 1679 steam digester and utilized a weight to retain the steam pressure (this design is still commonly used on pressure cookers); however, these were easily tampered with or accidentally released. On the Stockton and Darlington Railway, the safety valve tended to go off when the engine hit a bump in the track. A valve less sensitive to sudden accelerations used a spring to contain the steam pressure, but these (based on a Salter spring balance) could still be screwed down to increase the pressure beyond design limits. This dangerous practice was sometimes used to marginally increase the performance of a steam engine. In 1856, John Ramsbottom invented a tamper-proof spring safety valve that became universal on railways. The Ramsbottom valve consisted of two plug-type valves connected to each other by a spring-laden pivoting arm, with one valve element on either side of the pivot. Any adjustment made to one of valves in an attempt to increase its operating pressure would cause the other valve to be lifted off its seat, regardless of how the adjustment was attempted. The pivot point on the arm was not symmetrically between the valves, so any tightening of the spring would cause one of the valves to lift. Only by removing and disassembling the entire valve assembly could its operating pressure be adjusted, making impromptu "tying down" of the valve by locomotive crews in search of more power impossible. The pivoting arm was commonly extended into a handle shape and fed back into the locomotive cab, allowing crews to "rock" both valves off their seats to confirm they were set and operating correctly.

Safety valves also evolved to protect equipment such as pressure vessels (fired or not) and heat exchangers. The term safety valve should be limited to compressible fluid applications (gas, vapour, or steam).

For liquid-packed vessels, thermal relief valves are generally characterized by the relatively small size of the valve necessary to provide protection from excess pressure caused by thermal expansion. In this case a small valve is adequate because most liquids are nearly incompressible, and so a relatively small amount of fluid discharged through the relief valve will produce a substantial reduction in pressure.

Flow protection is characterized by safety valves that are considerably larger than those mounted for thermal protection. They are generally sized for use in situations where significant quantities of gas or high volumes of liquid must be quickly discharged in order to protect the integrity of the vessel or pipeline. This protection can alternatively be achieved by installing a high integrity pressure protection system (HIPPS).

In the petroleum refining, petrochemical, chemical manufacturing, natural gas processing, power generation, food, drinks, cosmetics and pharmaceuticals industries, the term safety valve is associated with the terms pressure relief valve (PRV), pressure safety valve (PSV) and relief valve.

The generic term is Pressure relief valve (PRV) or pressure safety valve (PSV). PRVs and PSVs are not the same thing, despite what many people think; the difference is that PSVs have a manual lever to open the valve in case of emergency.

Relief valve (RV): an automatic system that is actuated by the static pressure in a liquid-filled vessel. It specifically opens proportionally with increasing pressure

Pilot-operated safety relief valve (POSRV): an automatic system that relieves on remote command from a pilot, to which the static pressure (from equipment to protect) is connected

Low pressure safety valve (LPSV): an automatic system that relieves static pressure on a gas. Used when the difference between the vessel pressure and the ambient atmospheric pressure is small.

Vacuum pressure safety valve (VPSV): an automatic system that relieves static pressure on a gas. Used when the pressure difference between the vessel pressure and the ambient pressure is small, negative and near to atmospheric pressure.

Low and vacuum pressure safety valve (LVPSV): an automatic system that relieves static pressure on a gas. Used when the pressure difference is small, negative or positive and near to atmospheric pressure.

In most countries, industries are legally required to protect pressure vessels and other equipment by using relief valves. Also, in most countries, equipment design codes such as those provided by the ASME, API and other organizations like ISO (ISO 4126) must be complied with. These codes include design standards for relief valves and schedules for periodic inspection and testing after valves have been removed by the company engineer.

Today, the food, drinks, cosmetics, pharmaceuticals and fine chemicals industries call for hygienic safety valves, fully drainable and Cleanable-In-Place. Most are made of stainless steel; the hygienic norms are mainly 3A in the USA and EHEDG in Europe.

The first safety valve was invented by Denis Papin for his steam digester, an early pressure cooker rather than an engine.steelyard" lever a smaller weight was required, also the pressure could easily be regulated by sliding the same weight back and forth along the lever arm. Papin retained the same design for his 1707 steam pump.Greenwich in 1803, one of Trevithick"s high-pressure stationary engines exploded when the boy trained to operate the engine left it to catch eels in the river, without first releasing the safety valve from its working load.

Although the lever safety valve was convenient, it was too sensitive to the motion of a steam locomotive. Early steam locomotives therefore used a simpler arrangement of weights stacked directly upon the valve. This required a smaller valve area, so as to keep the weight manageable, which sometimes proved inadequate to vent the pressure of an unattended boiler, leading to explosions. An even greater hazard was the ease with which such a valve could be tied down, so as to increase the pressure and thus power of the engine, at further risk of explosion.

Although deadweight safety valves had a short lifetime on steam locomotives, they remained in use on stationary boilers for as long as steam power remained.

Weighted valves were sensitive to bouncing from the rough riding of early locomotives. One solution was to use a lightweight spring rather than a weight. This was the invention of Timothy Hackworth on his leaf springs.

These direct-acting spring valves could be adjusted by tightening the nuts retaining the spring. To avoid tampering, they were often shrouded in tall brass casings which also vented the steam away from the locomotive crew.

The Salter coil spring spring balance for weighing, was first made in Britain by around 1770.spring steels to make a powerful but compact spring in one piece. Once again by using the lever mechanism, such a spring balance could be applied to the considerable force of a boiler safety valve.

The spring balance valve also acted as a pressure gauge. This was useful as previous pressure gauges were unwieldy mercury manometers and the Bourdon gauge had yet to be invented.

Paired valves were often adjusted to slightly different pressures too, a small valve as a control measure and the lockable valve made larger and permanently set to a higher pressure, as a safeguard.Sinclair for the Eastern Counties Railway in 1859, had the valve spring with pressure scale behind the dome, facing the cab, and the locked valve ahead of the dome, out of reach of interference.

In 1855, John Ramsbottom, later locomotive superintendent of the LNWR, described a new form of safety valve intended to improve reliability and especially to be tamper-resistant. A pair of plug valves were used, held down by a common spring-loaded lever between them with a single central spring. This lever was characteristically extended rearwards, often reaching into the cab on early locomotives. Rather than discouraging the use of the spring lever by the fireman, Ramsbottom"s valve encouraged this. Rocking the lever freed up the valves alternately and checked that neither was sticking in its seat.

A drawback to the Ramsbottom type was its complexity. Poor maintenance or mis-assembly of the linkage between the spring and the valves could lead to a valve that no longer opened correctly under pressure. The valves could be held against their seats and fail to open or, even worse, to allow the valve to open but insufficiently to vent steam at an adequate rate and so not being an obvious and noticeable fault.Rhymney Railway, even though the boiler was almost new, at only eight months old.

Naylor valves were introduced around 1866. A bellcrank arrangement reduced the strain (percentage extension) of the spring, thus maintaining a more constant force.L&Y & NER.

All of the preceding safety valve designs opened gradually and had a tendency to leak a "feather" of steam as they approached "blowing-off", even though this was below the pressure. When they opened they also did so partially at first and didn"t vent steam quickly until the boiler was well over pressure.

The quick-opening "pop" valve was a solution to this. Their construction was simple: the existing circular plug valve was changed to an inverted "top hat" shape, with an enlarged upper diameter. They fitted into a stepped seat of two matching diameters. When closed, the steam pressure acted only on the crown of the top hat, and was balanced by the spring force. Once the valve opened a little, steam could pass the lower seat and began to act on the larger brim. This greater area overwhelmed the spring force and the valve flew completely open with a "pop". Escaping steam on this larger diameter also held the valve open until pressure had dropped below that at which it originally opened, providing hysteresis.

These valves coincided with a change in firing behaviour. Rather than demonstrating their virility by always showing a feather at the valve, firemen now tried to avoid noisy blowing off, especially around stations or under the large roof of a major station. This was mostly at the behest of stationmasters, but firemen also realised that any blowing off through a pop valve wasted several pounds of boiler pressure; estimated at 20 psi lost and 16 lbs or more of shovelled coal.

Pop valves derived from Adams"s patent design of 1873, with an extended lip. R. L. Ross"s valves were patented in 1902 and 1904. They were more popular in America at first, but widespread from the 1920s on.

Although showy polished brass covers over safety valves had been a feature of steam locomotives since Stephenson"s day, the only railway to maintain this tradition into the era of pop valves was the GWR, with their distinctive tapered brass safety valve bonnets and copper-capped chimneys.

Developments in high-pressure water-tube boilers for marine use placed more demands on safety valves. Valves of greater capacity were required, to vent safely the high steam-generating capacity of these large boilers.Naylor valve) became more critical.distilled feedwater and also a scouring of the valve seats, leading to wear.

High-lift safety valves are direct-loaded spring types, although the spring does not bear directly on the valve, but on a guide-rod valve stem. The valve is beneath the base of the stem, the spring rests on a flange some height above this. The increased space between the valve itself and the spring seat allows the valve to lift higher, further clear of the seat. This gives a steam flow through the valve equivalent to a valve one and a half or twice as large (depending on detail design).

The Cockburn Improved High Lift design has similar features to the Ross pop type. The exhaust steam is partially trapped on its way out and acts on the base of the spring seat, increasing the lift force on the valve and holding the valve further open.

To optimise the flow through a given diameter of valve, the full-bore design is used. This has a servo action, where steam through a narrow control passage is allowed through if it passes a small control valve. This steam is then not exhausted, but is passed to a piston that is used to open the main valve.

There are safety valves known as PSV"s and can be connected to pressure gauges (usually with a 1/2" BSP fitting). These allow a resistance of pressure to be applied to limit the pressure forced on the gauge tube, resulting in prevention of over pressurisation. the matter that has been injected into the gauge, if over pressurised, will be diverted through a pipe in the safety valve, and shall be driven away from the gauge.

There is a wide range of safety valves having many different applications and performance criteria in different areas. In addition, national standards are set for many kinds of safety valves.

Safety valves are required on water heaters, where they prevent disaster in certain configurations in the event that a thermostat should fail. Such a valve is sometimes referred to as a "T&P valve" (Temperature and Pressure valve). There are still occasional, spectacular failures of older water heaters that lack this equipment. Houses can be leveled by the force of the blast.

Pressure cookers are cooking pots with a pressure-proof lid. Cooking at pressure allows the temperature to rise above the normal boiling point of water (100 degrees Celsius at sea level), which speeds up the cooking and makes it more thorough.

Pressure cookers usually have two safety valves to prevent explosions. On older designs, one is a nozzle upon which a weight sits. The other is a sealed rubber grommet which is ejected in a controlled explosion if the first valve gets blocked. On newer generation pressure cookers, if the steam vent gets blocked, a safety spring will eject excess pressure and if that fails, the gasket will expand and release excess pressure downwards between the lid and the pan. Also, newer generation pressure cookers have a safety interlock which locks the lid when internal pressure exceeds atmospheric pressure, to prevent accidents from a sudden release of very hot steam, food and liquid, which would happen if the lid were to be removed when the pan is still slightly pressurised inside (however, the lid will be very hard or impossible to open when the pot is still pressurised).

If old tales of exploding pots have kept you from jumping on the pressure cooker bandwagon, it’s time to reconsider. These days, the best pressure cookers are not only versatile and easy to use, but they’re brimming with safety features — and they’re capable of making great meals faster and easier than ever.

Perfect for busy families or feeding guests without having to spend the whole night in the kitchen, pressure cookers are great for whipping up stews, soups and tough meat cuts as well as whole chickens, rice, beans and more. To determine which popular and highly rated models are best, we put 15 electric and stovetop cookers to the test, using each to make a no-stir risotto, unsoaked beans and a simple beef stew. Here’s what we found.

The creamiest risotto in five minutes? Perfectly cooked beans and oh-so-tender stew meat? Precision cooking, hands-free steam release and a sleek, intuitive display make this pressure cooker worth the price.

With a unique one-handed lid design, durable base and easy-to-grip handles, this stovetop cooker is simple to use and delivers great cooking results for under $100.

It cooks rice — and slow cooks. It can make yogurt — and cook sous vide. With 10 preset functions and app control, the Instant Pot Pro Plus promises to be the holy grail of small kitchen appliances, and delivers on a lot of its promise. First and foremost, though, it’s a great electric pressure cooker, with a simple interface, solid build and useful pressure-release functions that let us easily get great results on all of our test recipes.

The Pro Plus is built using three-ply stainless steel with silicone handles (making it easy to move the cooker to the stovetop or sink or to pour its contents into a bowl or container), and the 6-quart inner pot can be on the stovetop or in the oven for added convenience. An anti-spin feature keeps the pot from rattling around during the cooking process. It comes with a stainless steel steaming rack and extra sealing ring and the cooking pot, rack and lid are all dishwasher-safe. It’s also nice and compact at 13.2-inches long by 13-inches wide by 12.7-inches high and weighs about 20 pounds, so it doesn’t take up too much cabinet or counter space and isn’t a huge chore to lug around.

The Pro Plus only comes in 6-quart size, where some other Instant Pot models are also available in 3- and 8-quart options, which may be a detractor for those feeding large groups or households. It also is not compatible with the brand’s air fryer lids that some may find useful. The one-year limited warranty could be more generous and at $169.95, it’s certainly pricier than the already very capable Instant Pot Duo (see review below). But we think the Pro Plus’s app controls, simple interface, progress status bars and excellent cooking results give it the edge over the other Instant Pot models and make it the best choice overall among the electric pressure cookers we tested.

Instant Pot’s best-selling model comes with seven built-in functions (pressure cook, slow cook, rice cooker, yogurt maker, steamer, saute pan and food warmer), and also features 13 customizable programs. The digital and push-button display is large and easy to read and we appreciated that the lid can be detached for easier cleanup. The stainless steel inner pot can be tossed in the dishwasher and it’s simple to switch between low and high pressure, while a keep warm option and included steam rack offer added convenience.

The Pro Plus upgrade performed better on all three recipes, and has the added benefit of a more streamlined interface, auto steam release and progress indicator. But if you’re just testing out the pressure cooker waters, this is a great option for wading in.

With sleek design and solid performance typical of Breville’s products, we gave the brushed stainless steel Fast Slow Pro high marks for performance and features, which should satisfy advanced pressure cooker aficionados and hands-on cooks. The Breville gives you finer control over pressure (you can adjust in tiny 0.5 psi increments) than the other models we tested. Dual sensors at both the top and bottom of the machine offer even more control when it comes to pressure and temperature, and an auto warm function kicks into gear when it’s done cooking.

And we loved how simple the cooker was to operate. The bright and easy-to-read LCD display and dials allow you to quickly choose from 11 pressure cook settings (vegetables, rice, risotto, soup, stock, beans, poultry, meat, bone-in meat, chili and stew and dessert), from low to high, and you can customize settings as well. We appreciated that the display changes colors denoting whether it’s in pressurize, cook or steam release mode. And the auto altitude adjuster is great for those cooking at higher elevations, since a longer cook time is needed as atmospheric pressure drops the higher you get above sea level.

If you intend to use your electric pressure cooker often, love having the ability to really fine-tune your pressure levels, appreciate the convenience of hands-free steam release and aren’t too worried about a hefty price tag, we think the Breville Fast Slow Pro is a kitchen tool you’ll look forward to putting to work again and again.

If you prefer a simple, straightforward stovetop pressure cooker, the Kuhn Rikon Duromatic looks lovely on the stovetop and does an impressive job cooking food. We tested the 8.5-quart option (Kuhn Rikon offers the Duromatic in a wide range of sizes) and found the two-handle design easy to grab, the pressure indicator simple to read and, while the company doesn’t recommend cleaning the heavy stainless steel pot in the dishwasher, it was no big deal to hand wash it (and we know folks who have tossed their own Kuhn Rikons in the dishwasher for years with no damage).

The T-fal Clipso is a breeze to use. In our tests, the Clipso pressurized very quickly. As with all stovetop models, you bring up the heat to your desired setting, and once steam begins to release through the valve, it’s time to reduce the heat and set your timer. We quickly found the sweet spot and noted that the pot held its pressure nicely throughout the cooking time, with little need for turning the heat up or down.

Like the electric pressure cookers, all the stovetop models performed well in our recipe tests, although some earned more points for better consistency, texture and faster cook time. So while the Kuhn Rikon beat out the T-fal when it came to making beans, risotto and stew, for about $155 less, the T-fal still did an admirable job.

The model comes with a steam basket and tripod and is dishwasher safe when you remove the gasket and pressure valve. It comes with a 10-year warranty against defects or premature deterioration and, for other parts, a one-year warranty is included. And we appreciate the side handles on the pot that allow for easy maneuvering. But what sets the T-fal apart from other models is its unique lid. Designed for one-hand use, the lid clamps down on the pot with jaws that lock into place with the press of a button. Once you’re done cooking and the pressure is released (you can release it by twisting the steam release valve from the cooking icon to the steam icon), the lid opens by pressing the top of a large knob. As a safety feature, the lid will not open until all pressure is released.

The Clipso is only offered in a 6.3-quart capacity, which offers plenty of room to cook for a family of four, and is still compact for storage. For convenience and price, we believe this is a great pressure cooker for beginners and veterans alike.

By trapping steam inside a tightly sealed pot, pressure cookers raise the pressure under which your food cooks (typically to around twice atmospheric pressure), thus raising the boiling point of water and significantly speeding up cooking times.

Simple stovetop cookers use the heat source of your stove and need a bit of attention as you’ll need to adjust your burner to maintain proper pressure, while newer electric versions do the job automatically (and often include functions ranging from air fryer to slow cooker to yogurt maker).

While folk wisdom holds that pressure cookers are dangerous, accidents are in reality rare (and many of those that have been documented have been the result of poor maintenance or misuse). All the pressure cookers we tested come with multiple safety features and lids that lock into place, and are designed so that all pressure must be released before the lid can be removed (with some release techniques, steam is released rather loudly and aggressively and definitely startled us a few times). Some models spit out a bit of moisture as steam condenses, but many of the electric versions include condensation collectors that catch any water before it drips onto your counter.

So, electric or stovetop? Both netted similar cooking results, so it really does come down to personal preference: Do you like your cooking to be hands-on or hands-off? If you want a lot of options (Slow cook! Air fry! Sous vide!) and want to simply add your ingredients and let the machine do the heavy lifting, an electric version is for you. They generally take up more counter space, but if you use your cooker several times a week, you won’t mind and may even save space if it allows you to get rid of your rice cooker, air fryer and crock pot.

We found the stovetop pressure cookers to be simple to use and discovered they come to pressure faster than their electric counterparts. Start on high heat until the desired pressure level is achieved, then simply lower the heat to keep the pressure constant for the duration of your cook time. Of course, you’ll need to keep an eye on your cooker most of the time to be sure the pressure is at the right level.

Our testing pool included 15 pressure cookers in all — nine electric and six stovetop — ranging in price from less than $50 to $330, and in 6- and 8-quart capacities. And while all the models performed well in our recipe tests, which included making unsoaked pinto beans, pea and mushroom risotto and a hearty beef stew, details including construction, interface, ease, cook time and versatility resulted in varied scores. All models were easy to clean, as most pots, inserts and parts are dishwasher safe, although many lids need to be hand-washed fairly rigorously to keep odors from hanging on. And while we didn’t record any particularly bad recipe results, some required more cooking time and some definitely netted better results.

Since many of the electric models are billed as multicookers, we did take versatility into account, noting how many settings, functions and features were available, but looked at these models as pressure cookers first and foremost. We did pay careful attention to ease of setup and use, noted what accessories were included and their usefulness in actual cooking, and looked at the overall quality of the user interface elements of each cooker. By and large, even the electric versions were relatively intuitive to use, but we made sure to note when we had to turn to the instruction manual (and when we needed technical translation!); for stovetop cookers we checked to make sure pressure settings were easy to read, steam valves simple to manipulate, and seals and other moving parts easy to manage.

In the course of our assessment, we paid careful attention to overall design and build quality, examining materials used, noting any unique features such as handle, inner pot and lid design, pressure release valves and gauges and safety enhancements. We checked to see how much storage and counter space the various models took up, and whether they were heavy or light and easy or difficult to handle. And while most of the inner pots and parts of the pressure cookers tested were deemed dishwasher-safe by the manufacturers, we noticed that lids were largely hand-wash only, so we checked to make sure how much elbow grease it took to remove food, and whether our efforts left behind any staining or remaining food odor.

If you love the Instant Pot Duo and also love using an air fryer, this may be just the electric pressure cooker option for you. We found it performed identically to the Duo when it came to pressure-cooking our three recipes, and the interface is also essentially the same as the Duo, though it has four more cooking functions than that model (all 11 include roast, slow cooker, pressure cooker, air fry, saute, sous vide, bake, broil, steam, warm and dehydrate).

However, it’s about twice as heavy as the Duo, and with the air fryer lid (it also comes with a regular lid), it requires a lot of vertical storage and counter space (though not as much as two separate appliances). Included are a broil/dehydrating tray, multi-level air fryer basket, air fryer basket base, protective pad, storage cover and rack. So, if you think an air fryer-pressure cooker combo would save room and you’d use it frequently, this model is certainly worth considering. Otherwise, the Duo will work just fine and the Pro Plus will perform even better.

There was a lot we liked about Cuisinart’s pressure cooker: It has a unique squarish shape, 12 pre-programmed settings, a large and easy-to-read LCD display, both dial and push-button controls and it comes with a handy trivet and stand. The nonstick cooking pot made cleaning a snap and we liked the way the lid locked into place with little effort by simply turning a knob. Cook times were a little longer than for the other machines we tested, but results were good so long as we compensated: we had to cook the beans five minutes longer than the recipe called for, but they turned out nicely with the added time. The risotto had a nice texture after we sauteed it for a few extra minutes to finish the rice and the stew was nice and tender. A big plus for this machine is the steam release button and preheat indicator that allow you to see your cooking progress. We didn’t like that the lid is attached at the back (most of its competitors are attached on the side or lift off completely), because it makes opening the machine a little scary, as any remaining steam is pointed right at your face. The controls were also a bit less intuitive than our winning models.

It takes practically no time to get the Farberware pressure cooker working once you take it from the box: Just a quick wash and a scan of the instruction manual and you’re off. It comes with nine presets (rice, meat, chicken, fish, vegetables, beans/lentils, browning/searing, soups/stews and slow cooking), a straightforward LED display, and includes a cooling stand and plastic measuring cup and spoon. User reviews give it high marks, but we found the risotto to be gummy, the beans to be inconsistent and the stew a bit overly cooked (the veggies were on the mushy side, for example). “I wouldn’t complain if I was served this at a school cafeteria, but would be mad if I got it at a restaurant,” one taster remarked. The machine is stainless steel, though it felt less sturdy than its competitors. We think it’s worth it to spend a little more money to get an Instant Pot Duo.

The Zavor LUX is a high-quality pressure cooker: It is simple to set up, with an intuitive digital LED display, including a super-handy preheating indicator, a lock icon, and screen that changes colors so you know when cooking has started; the LUX also has a custom setting that lets you program your favorite recipes. There are 10 cooking functions (pressure cook high and low, slow cook high and low, steam, saute, sous vide, simmer, yogurt, grains, eggs, dessert, keep warm and time delay) and it comes with a steamer basket and trivet. We liked that the pressure valve includes a clean option that pops the piece out for easy maintenance.

With a whopping 14 programmable cooking functions (pressure cook, steam and crisp, steam and bake, air fry, broil, bake/roast, dehydrate, sear/saute, steam, sous vide, slow cook, yogurt, keep warm and proof), Ninja’s take on the pressure cooker offers a whole lot of versatility. It comes not only with an 8-quart ceramic-coated pot, but also a 5-quart cook and crisp basket for air frying, a reversible rack to double your cooking capacity and more. We thought the “SmartLid Slider” was clever and easy to use: just slide a toggle to Pressure Cooker, Steam Fryer or Air Fryer to unlock different cooking modes and functions on the large, intuitive digital display.

The Foodi performed well on our recipe tests, but not as well as our winners. And while we found it easy to clean, its size was our biggest concern, especially for a device that is meant to replace multiple appliances. The priciest pressure cooker we tested, it was also the biggest. At 15.4-inches long by 14.2-inches wide by 14.25-inches high, it was too big to fit in any of our kitchen cabinets or under our standard-height countertop cabinets for that matter. It’s also really heavy at 25 pounds, making it a pain to haul out of storage if there’s no room for it in your kitchen. For us, the size and price kept it from the winner’s circle, but if you really need all of the functions it offers and have a lot of space, it might be worth a look.

For those looking for a step up from the original Instant Pot Duo, the Pro offers a few more bells and whistles that allow for more precision cooking. Rather than seven functions, the Pro features 10 (pressure cook, slow cook, rice/grain, saute, steam, yogurt, warm, sous vide, sterilizer and canning). It adds twice as many one-touch programs, bringing the number to 28, and the pressure release valve on the lid has a plastic steam diffuser cap that really did result in a quieter release. It has a more advanced interface than the Duo, the display has a cooking progress status bar, and the inner pot has silicone inner pot handles; the steaming rack also has an extra sealing ring. The recipes all turned out well, although not quite as well as our winners. It’s a great pressure cooker, but we prefer the added convenience of the Pro Plus for about $20 more.

With a strong and sturdy stainless steel pot and a lid that easily locks into place, we were big fans of the Vitaquick. For one, its large blue pressure indicator is easy to see, with two white ring markings: one ring means it’s at low (or gentle) pressure, two means it’s at high pressure. Other great features: a removable handle that makes cleaning a snap (remove the gasket in the lid and it’s all dishwasher-

8613371530291

8613371530291