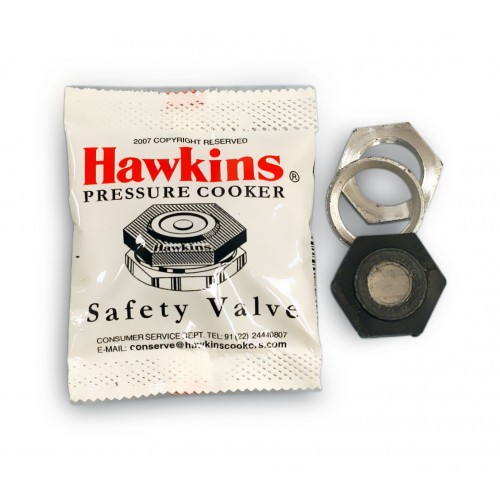

hawkins safety valve free sample

Today, most pressure cookers are variations on the first-generation cookers, with the addition of new safety features such as a mechanism that prevents the cooker from being opened until it is entirely depressurized.

These include an electric heat source that is automatically regulated to maintain the operating temperature and pressure. They also include a spring-loaded valve (as described above) and are typically non venting during cooking.

In a sealed pressure cooker the volume and amount of steam is fixed, so the temperature can be controlled either directly or by setting the pressure (such as with a pressure release valve).

Pressure cookers employ one or more regulators to control the pressure/temperature. All types have a calibrated pressure relief valve, as well as one or more emergency valves.

With the simplest types, once the desired pressure is reached, the valve opens, and steam escapes cooling the vessel and limiting the temperature. More advanced stovetop models have pressure indicators that permit the user to adjust the heat to prevent the steam from escaping. Third generation types automatically measure the state of the vessel and control the power so as to not release steam in operation.

Pressure cookers are available in different capacities for cooking larger or smaller amounts, with 6 litres" capacity being common. The maximum capacity of food is less than the advertised capacity because pressure cookers can only be filled up to 2/3 full, depending on ingredients and liquid (see Safety features section).

A gasket or sealing ring, made from either rubber or silicone, forms a gas-tight seal that does not allow air or steam to escape between the lid and pan. Normally, the only way steam can escape is through a regulator on the lid while the cooker is pressurized. If the regulator becomes blocked, a safety valve provides a backup escape route for steam.

Early pressure cookers equipped with only a primary safety valve risked explosion from food blocking the release valve. On modern pressure cookers, food residues blocking the steam vent or the liquid boiling dry will trigger additional safety devices. Modern pressure cookers sold from reputable manufacturers have sufficient safety features to prevent the pressure cooker itself from exploding. When excess pressure is released by a safety mechanism, debris of food being cooked may also be ejected with the steam, which is loud and forceful. This can be avoided if the pressure cooker is regularly cleaned and maintained in accordance with the manufacturer"s instructions and never overfilled with food and/or liquid.

Modern pressure cookers typically have two or three redundant safety valves and additional safety features, such as an interlock lid that prevents the user from opening the lid when the internal pressure exceeds atmospheric pressure, preventing accidents from a sudden release of hot liquid, steam and food. If safety mechanisms are not correctly in place, the cooker will not pressurize the contents. Pressure cookers should be operated only after reading the instruction manual, to ensure correct usage. Pressure cooker failure is dangerous: a large quantity of scalding steam and water will be forcefully ejected and if the lid separates it may be propelled with considerable force. Some cookers with an internally fitted lid may be particularly dangerous upon failure as the lid fits tighter with increasing pressure, preventing the lid from deforming and venting around the edges. Due to these dangers pressure cookers are generally over-engineered in a safety regard and some countries even have regulations to prevent the sale of non-compliant cookers.

For first generation pressure cookers with a weighted valve or "jiggler", the primary safety valve or regulator is usually a weighted stopper, commonly called "the rocker" or "vent weight". This weighted stopper is lifted by the steam pressure, allowing excess pressure to be released. There is a backup pressure release mechanism that releases pressure quickly if the primary pressure release mechanism fails (e.g., food jams the steam discharge path). One such method is a hole in the lid that is blocked by a low melting point alloy plug and another is a rubber grommet with a metal insert at the center. At a sufficiently high pressure, the grommet will distort and the insert will blow out of its mounting hole to release pressure. If the pressure continues to increase, the grommet itself will blow out to release pressure. These safety devices usually require replacement when activated by excess pressure. Newer pressure cookers may have a self-resettable spring device, fixed onto the lid, that releases excess pressure.

On second generation pressure cookers, a common safety feature is the gasket, which expands to release excess pressure downward between the lid and the pot. This release of excess pressure is forceful and sufficient to extinguish the flame of a gas stove.

The recommended maximum fill levels of food/liquid avoids blockage of the steam valve or developing excess pressure: two-thirds full with solid food, half full for liquids and foods that foam and froth (e.g., rice, pasta; adding a tablespoon of cooking oil minimizes foaming),pulses (e.g., lentils).

With first generation designs, the pressure regulator weight begins levitating above its nozzle, allowing excess steam to escape. In second generation pressure cookers, either a relief valve subsequently opens, releasing steam to prevent the pressure from rising any further or a rod rises with markers to indicate the pressure level, without constantly venting steam. At this stage, the heat source is reduced to the lowest possible heat that still maintains pressure, as extra heat wastes energy and increases liquid loss. In third generation pressure cookers, the device will detect the vessel has reached the required cooking temperature/pressure and will maintain it for the programmed time, generally without further loss of steam.

This method is sometimes called a quick release, not to be confused with the cold water release (mentioned below). It involves the quick release of vapor by gradually lifting (or removing) the valve, pushing a button, or turning a dial. It is most suitable to interrupt cooking to add food that cooks faster than what is already in the cooker. For example, since meat takes longer to cook than vegetables, it is necessary to add vegetables to stew later so that it will cook only for the last few minutes. Unlike the cold water release method, this release method does not cool down the pressure cooker. Releasing the steam with care avoids the risk of being scalded by the rapid release of hot steam. This release method is not suitable for foods that foam and froth while cooking; the hot contents might spray outwards due to the pressure released from the steam vent. Pressure cookers should be operated with caution when releasing vapour through the valve, especially while cooking foamy foods and liquids (lentils, beans, grains, milk, gravy, etc.)

The cold water release method involves using slow running cold tap water, over the edge of the pressure cooker lid, being careful to avoid the steam vent or any other valves or outlets, and never immersing the pressure cooker under water, otherwise steam can be ejected from under the lid, which could cause scalding injury to the user; also the pressure cooker lid can be permanently damaged by an internal vacuum if water gets sucked into the pressure cooker, since the incoming water blocks the inrush of air.

Safety is our #1 priority at Hawkins County Gas. We strive to make our customers feel comfortable and safe at all times. In the event of an emergency, call our 24-hour emergency line at (423) 272-8841 or (423) 357-8585. If your call is not answered please dial 911 and report your emergency.

The installation of natural gas or propane appliances inside bathrooms comes with many code restrictions to ensure safety. For example, an unvented heater installed in a bathroom must be wall-mounted and cannot exceed 6,000 BTUH. There are other restrictions like this, so please contact us with your questions or concerns.

The installation of natural gas or propane appliances inside bedrooms comes with many code restrictions to ensure safety. For example, an unvented heater installed in a bedroom must be wall-mounted and cannot exceed 10,000 BTUH. There are other restrictions like this, so please contact us with your questions or concerns.

Natural gas and propane appliances need proper air flow to operate correctly. Each appliance is labeled with the necessary clearances to insure proper air flow. Clearances around each appliance, vent, exhaust, combustion and/or make-up air system MUST BE maintained for safety reasons.

Installing natural gas or propane appliances in garages comes with various code restrictions that must be followed to ensure safety. For example, unless an appliance is listed as flammable vapor ignition resistant, it must be installed so that the source of ignition is at least eighteen inches (18") above the level of the garage floor. This reduces the risk of gasoline or other flammable vapors from being ignited by the main burner or pilot flame.

Each water heater is equipped with a temperature and pressure relief valve, sometimes referred to as a "T & P Valve" or a "pop-off". These valves are designed to relive any over-pressure in the tank in the event of a malfunction. It the "T & P Valve" is leaking, it should be inspected by a trained professional because it may be an indicator of a larger problem. Water heater "T & P Valves" SHOULD NEVER BE REMOVED AND PLUGGED as this can lead to dangerous over-pressure of the water heater.

In our SPM, the capture, wash, and release processes are all carried out in the incubation reservoirs. By only transporting liquids to/from the incubation reservoirs in the microchannels, we avoid the problems of trapping and losing beads in microchannels or microvalves and microchannel obstruction. In the incubation reservoirs, metered air bubbles are used to keep the beads in suspension and thereby enhance the rate and efficiency of target capture. The air pumping volume per stroke is controlled by the size of the microvalves and the air pumping rate is controlled by the solenoid valve timing. The current microvalve size is ~0.47 μL and volumetric flow rate is set at ~1.5 μL air/s. These parameters are easily adjusted to satisfy different mixing needs. Uniform mixing of magnetic beads and nucleic acids is achieved by pumping air bubbles for 30 seconds every 10 minutes. By regulating the air flow with microvalves to produce bubbles with a diameter less than 1mm, the air pumping volume and timing is precisely controlled avoiding reagent blowout.

Although other methods such as an acoustic mixer (Frommelt et al. 2008), electrophoresis mixer (Fang et al. 2015), microfabricated conductors (Suzuki et al. 2004), motor controlled rotational magnets (Jackson et al. 2016), and an on-chip centrifuge (Strohmeier et al. 2015) have been introduced to enhance the mixing of magnetic beads and nucleic acids, they all increase the instrument size/weight, fabrication costs, power consumption, and operation complexity which is not desired for resource-limited settings. In our case, since the air bubbles are injected through pneumatically actuated microvalves, the solenoid valves used for fluid control also conveniently produce the bubbles. In addition, since the air bubbles are pumped into the incubation reservoirs from common channels, additional layers and chambers to diffuse air bubbles for enhanced mixing are not needed (Lin et al. 2014).

Exploiting these advances, we developed an efficient multiplexed on-chip sample preparation and sensing technique for Ebola virus diagnosis. With the metered air bubble mixing and thermally stable pull-down beads, we improved the capture efficiency by 2 orders of magnitude compared to our previous on-chip experiments using in-valve target capture and streptavidin beads (Cai et al. 2015). The sample preparation process is automated and exhibits the same capture efficiency as manual off-chip processing. Combined with amplification-free counting of single molecules using the ARROW chip, we achieved a limit of detection of 0.21 pfu/mL using 3X on-chip concentration with only 40 minutes incubation time. Although same detection limit was reported using in-valve target capture and streptavidin beads, it requires nearly 500X preconcentration and more than 8 hours incubation time (Cai et al. 2015). In addition, using the new on-chip concentration protocol (80X), we push the detection limit to 0.021 pfu/mL which is one order of magnitude higher than previous results. This approach shows great sensitivity, specificity, and a wide dynamic range required for a practical clinical assay and has a similar sensitivity as PCR (Trombley et al. 2010).

Tani-Logics Uk eBay Listing Template Welcome to the Home of Hawkins Pressure Cookers MENU Home New Arrivals Ending Soon Feedback Contact Us Home New Arrivals Ending Soon Feedback Contact Us Fast & Free Delivery Same Day Dispatch Best Price Guarantee Buy with 100% Confidence Categories Pressure Cookers Cookware Glues & Adhesives Health & Beauty Perfume Oils Natural Soaps DIY & Tools Browse More Useful Link View Store Add to Favourites Ask Question View Feedback Why Choose Us ? 12 Litre Hawkins Cl

Your pressure cooker and dinner can be ruined with too much food or too little liquid. Too much food could block the pressure valve while too little liquid can permanently damage the cooker’s metal, bakelite and silicone fittings. Here’s everything you need to know to keep your pressure cooker on the level and dinner coming.

Max 1/2 Full for Beans, Rice, Grains, Dehydrated Foods and Fruit – These foods either expand during cooking or generate lots of foam (or both). Beans can swell to twice their size during cooking and some grains, even more. They also generate lots of foam and bubbles – which climb up the sides of the cooker to spray out of the valves – plugging them up. This class of ingredients should also be opened using Natural Release method – which avoids the foamy starchy, bubbly, goo from spraying out of the valve during the pressure release, too.

A pressure cooker’s maximum capacity is, in fact, a safety feature. In order for a pressure cooker to receive UL rating, their manual must contain text to this effect.

Pressure cooker maximum capacities apply to all pressure cookers types (electric, jiggler, weight-modified and spring valves), shapes (pressure pans, stock pot- and braiser-type cookers), sizes (from 1 to 12L) and origins (Europe, Asia, America). That’s because all pressure cookers have valves and safety mechanisms placed in the lid.

The maximum capacity recommendations are in place to ensure neither food nor cooking liquid interfere with, or trigger, the safety systems located in the lid. The NUMBER ONE REASON for pressure cooker mishaps usually involves someone not familiar with pressure cooking filling the cooker beyond the cooker’s recommended maximum capacity – ultimately blocking the pressure release valve.

A larger pressure cooker will need more steam to pressurize and will also need more liquid to boil and generate that steam. Some pressure valves vent by function or design. While a spring valve releases little or no steam to keep a cooker at pressure, instead, a weight-modified or jiggler-type valvemust release pressure and steam rhythmically to maintain a set pressure. The extra venting means that a longer cooking time will evaporate more liquid, and the cooker will require more to keep it from running dry.

You can reach your pressure cooker’s minimum liquid requirement with stock, fruit juice, a little wine or beer – but not hard liquor (large quantities of alcohol will evaporate through the valve and the vapor will ignite).

A steel tank contains air at a pressure of 15 bar at 20°C. The tank is provided with a safety valve which can withstand a pressure of 35 bar. Calculate the temperature to which the tank can be safely heated

8613371530291

8613371530291