why is my propane tank leaking from safety valve factory

Valve leakage is a common but troublesome occurrence in industrial facilities. While some valves are expected to have a certain level of leakage, especially as they begin to reach nameplate set pressure, other valve leakage is problematic and can even be dangerous for your facility. If you suspect valve leakage, here are a few reasons why your safety or pressure relief valve may be leaking, how to test the valve, and how to troubleshoot a valve you’ve confirmed is leaking. Four common reasons a pressure relief valve might be leaking include:

Pressure relief and safety relief valves will leak if the valve isn’t fully closed. This is a common problem in industrial settings where environments are often dusty or dirty. If there is any debris in the valve, it can obstruct the valve from fully closing, causing it to leak.

Pressure relief valves age and can begin to deteriorate, especially in factories and facilities where they encounter extreme temperatures and a great deal of wear. Over time, valves can become damaged, which affects their ability to close properly. If there is any damage or excessive wear to the valve seat or seal, leakage is likely.

Another common cause of safety relief valve leakage is when the valve is the wrong size for the project. Whether it’s a loose fit or the wrong fit entirely, a poorly fitting valve won’t be able to function properly, and will often leak.

If you suspect a leaking safety relief valve, or if you would like to complete regular maintenance to prevent valve leakage in the first place, it’s good to know that it is possible to test for a leaking valve. Known as a seat tightness or leakage test, these tests maintain the pressure relief valve’s inlet pressure at a certain percentage of the valve’s set pressure, so the valve technician can assess the valve’s condition.

The AccuTEST inline valve testing system offers a unique feature — the Lift and Hold test — specifically designed to test for leakage. The system performs an automated leakage test according to the operator’s requirements. The operator sets the percent of set pressure and the duration of the test. When the operator starts the test, the AccuTEST system takes over, holding the valve at the appointed percentage of set pressure for the specified duration. While the system holds the valve at pressure, the operator is able to count any bubbles in the valve to assess its condition and determine whether the valve is leaking or not.

When you have confirmed the source of the leak, you can assess whether the valve could be repaired, or if it should be completely replaced. For example, if the valve is the wrong size or if the valve is damaged, it’s best to replace it. If the valve can be cleaned and adjusted to function properly, then repair may be an option.

Once your leaking safety relief valve has been repaired or replaced and is functioning as it should, it’s important to consider implementing regular maintenance and testing. Leaking pressure relief valves can present serious complications for the functionality of your facility. Implementing a regular maintenance and pressure relief valve testing schedule can help you stay in front of concerns like this, ensuring your facility is running efficiently, and at pressure, at all times.

If you are concerned about a leaking safety or pressure relief valve, or are seeking inline valve testing equipment that is capable of performing seat tightness or leakage tests, you might be interested in AccuTEST’s equipment. With exclusive Lift and Hold testing capabilities, AccuTEST inline pressure relief valve testing equipment offers the functionality you need. See how our equipment works in real-time — schedule a live webinar demo today.

On hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the protective cap will be removed

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

If the propane tank on your RV is leaking after a refill, then you have a serious problem on your hands. Of course, leaking propane can be extremely dangerous. So, why is your propane tank leaking after a refill?

The common reasons for a propane tank leaking are due to an open bleeder valve, an open relief valve, or a faulty valve system. We are also going to address the issue of a cracked propane tank. Although very unlikely, they can sometimes suffer serious physical damage.

Yes, absolutely is a leaking propane tank dangerous, and extremely so. Propane is flammable, which is why it is used for heating and cooking. If propane is leaking out of the tank, and it comes in contact with an open flame or spark, it’s going to cause a serious explosion.

It’s going to ignite the gas that is leaking out, and this flame will travel all the way back into the tank, and either just catch fire, or explode. There is also the fact that if it is in an enclosed space, inhaling propane is also very dangerous.

Although propane in itself is technically not toxic, it will displace the oxygen in the air. This means that if you breathe in too much propane, you won’t get enough oxygen, and can effectively suffocate to death.

One of the most common causes of a propane tank leaking after refilling is if the bleeder valve is open. Bleed valves are a special type of manually operated valve designed for bleeding liquids or gases out of a system.

It could also be the case that even if the bleeder valve is not open, the coil that it uses can be clogged with debris. This can then result in your propane tank leaking, specifically if the tank has too much propane in it. A good thing is that this is a very easy problem to solve.

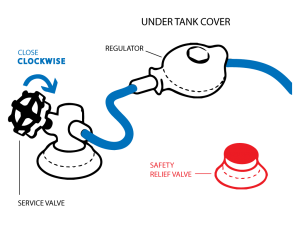

The solution to a bleeder valve being open is simply to close it. All you have to do is to close the bleeder valve. You simply have to rotate the valve clockwise. Generally speaking, you are going to need to use a screwdriver, and you will need to turn the valve in a clockwise direction to close it.

The next reason why your propane tank might leak after a refill is if the relief valve is open. As the name implies, the relief valve is designed to help relieve pressure in the tank if there is too much of it.

Therefore, if it is hot outside, this relief valve may open up to allow pressure to get out of the tank. If the relief valve is slightly open, it will cause propane to leak out of the tank. Moreover, if the whole valve opens up, this can actually be quite dangerous.

the solution to a relief valve being open is actually quite simple, but you don’t actually want to touch the valve. This valve opens up all on its own in order to relieve pressure, and it should close on its own too.

If you tap or touch the valve in any way, or try to manipulate it, you may actually cause it to open up more, which is of course the opposite of what you are looking to achieve.

To solve this problem, you actually want to cool the tank down, which you can do by spraying it with some cool water or submerging it in a cold bath. This will relieve pressure on the tank and will cause the valve to close on its own.

However, if this does not work, then either this is not the issue or the relief valve is damaged to the point where you will just need to replace the propane tank.

The valve stem, or in other words the area where you connect the inlet tube to refill it with propane might be completely damaged or leaking. This is a huge problem because propane leaking out of the main stem can easily catch fire.

The solution to this issue is a little more complex because you will need to replace the entire tank valve stem system to prevent further damage and to prevent explosions from occurring.

Before you try to replace the valve, however, you need to ensure that the propane tank is 100% empty. Once the tank is 100% empty, you want to close the valve by turning the handle clockwise.

You now need to take out the leaking valve. You’re going to use a heat gun to soften up the weld that is holding together the cylinder and the gas valve.

Once this has been done, you want to open the nozzle of the tank to allow the regulator to come down to regular atmospheric pressure. You want to hold the tank very tightly while doing this.

You now need to attach the new valve and make sure that it comes complete with an overfilling prevention device inside of it. You’re going to attach the valve by threading it into the bung of the cylinder, and then tighten it using your pipe wrench.

If the actual propane cylinder itself is cracked or damaged in any way, and this is what’s causing the leak, then your only option is going to be to get a new propane tank.

If you need to replace the valve system on your propane tank, you do need to empty it first. To empty a leaking propane tank, you first want to disconnect it, and then take it to an open area.

The propane that is escaping is causing the hissing sound. Moreover, if the pressure within the propane cylinder gets to the same amount of pressure as the spring that is used to keep the relief valve shut, then the safety relief valve will open.

In other words, if your new propane tank is hissing, it is an issue with the safety relief valve. Refer to the above sections in order to fix a propane tank with an open relief valve.

When there is too much pressure inside a propane tank, the safety relief valve will open up to allow that extra pressure to escape. This is completely normal.

Propane is an extremely flammable gas, and yes, it can explode. If there is any kind of open flame or spark that the leaking propane comes into contact with, the result will be a massive explosion.

As you can see, there are a few reasons why a propane tank might leak after a refill. However, all of these issues are pretty serious, because you obviously don’t want propane leaking out.

Therefore, you want to take all of the necessary steps to remedy the issue as quickly as possible. If the propane tank cannot be fixed, you have to get a new one. Propane is just way too dangerous to take any chances with.

My name is Madeline Cooper, and I have now been living and traveling across the states in my RV for the past 8 years. It has been such an amazing experience, and I have learned so much along the way.

Through this blog, I want to share all of my hints and tips, along with reviews of the best RVing accessories. I hope this blog will help others with their RV trips, and make traveling easier for you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Propane tanks contain liquefied propane that is produced by refining natural gas and crude oil. People usually use it as an alternative source of energy. These are useful when you have no access to electricity, coal, or gas.

Another thing to note about propane tanks is that they are quite cheap when compared to electricity. These tanks can be found in various sizes for containing high pressure propane. The tanks are usually designed in such a way that the tank is first installed at the buyer’s location. Afterwards the tank is filled up on-site.

The price for these is almost half of the cost when compared to using electricity for providing power. People use these in various situations which range from using these to provide themselves with a fire while cooking to even using them at your house toheat up water. Aside from this it is also used for pool heaters, patio heaters, BBQ fuel, and backup generators.

It is also important to understand why propane is so commonly used for all these purposes. It has high energy density and it is extremely portable. Due to these reasons, the cost of using propane is much lower than other forms of energy. Propane does not need too much pressure to be converted into liquid so that saves up on costs too.

Installation of a propane tank is not that difficult. It is mostly handled by the company that you will hire. The most important thing to note is that whenever you store any form of fuel, you need to have certain security precautions in place.

Even though these tanks are a blessing, sometimes the valve stem on your propane tank might start leaking. This can be really dangerous and should be taken care of as soon as possible. Due to this reason, we have compiled a list of possible issues that can occur with your propane tank and how to best solve them as soon as possible.

Valve stem leaking is quite a common issue with those propane tanks that are a bit older. The most probable reason for this leak can be that your propane tank is damaged. Most stores and exchanges that provide people with LPG tanks have hundreds of tanks lying around.

These sometimes get damaged while the store is refilling them. Too many hard bumps into any other tanks during the refilling or transportation process can cause slight damage to these tanks which can be sufficient for propane to start leaking bit by bit.

The tank that you received might have become damaged similarly and that is why it might be leaking. The best option for you is to return to the store you bought this tank from. You should tell them about your problem and allow them to recheck the tank themselves.

If the tank is indeed leaking and you just purchased it from them or got refilled shortlybefore then it is highly likely that they will give you an exchange or return.

Although this rarely happens in any situation, there might be a problem with the equipment that you are using with your propane tank. If the pressure coming from your equipment is really low then the gas will flow slowly to the burners. In most cases, this results in a low flame and no other problem.

However, it might be possible that this is causing a gas leak from the back of the tank’s valve. Make sure to take a closer look at all your equipmentand fix anything that might be wrong with it.

Just like it is being repeatedly stressed upon, propane gas leaks should not be taken lightly, if you feel that you are not skilled enough to tamper with the equipment then it is better that you call an expert. This should help you in stopping any additional gas from leaking out of the tank.

Another reason for the gas to leak out from the propane tank can be that the pressure release on the tank is causing this problem. This usually happens when the temperature of the tank is increased and it starts to build up pressure inside.

This pushes the gas out of the valves that are present in the tank. Take a look at your valve while using the tank. If it opens while you are using it then it means that your tank is building up pressure inside. Get the pressure release valve replaced or replace it on your own to fix this problem.

You should not tamper with the valves if you do not have the required expertise. It is always better to take the help of an expert who has done such work before.

This can mostly happen in those cases when the tank went empty and someone left the valve open while checking it out. The next time when the tank is filled, the valve can keep leaking out the gas until someone does not notice the gas odor. This is an extremely dangerous thing to happen as even the slightest bit of propane gas leak can cause a major explosion.

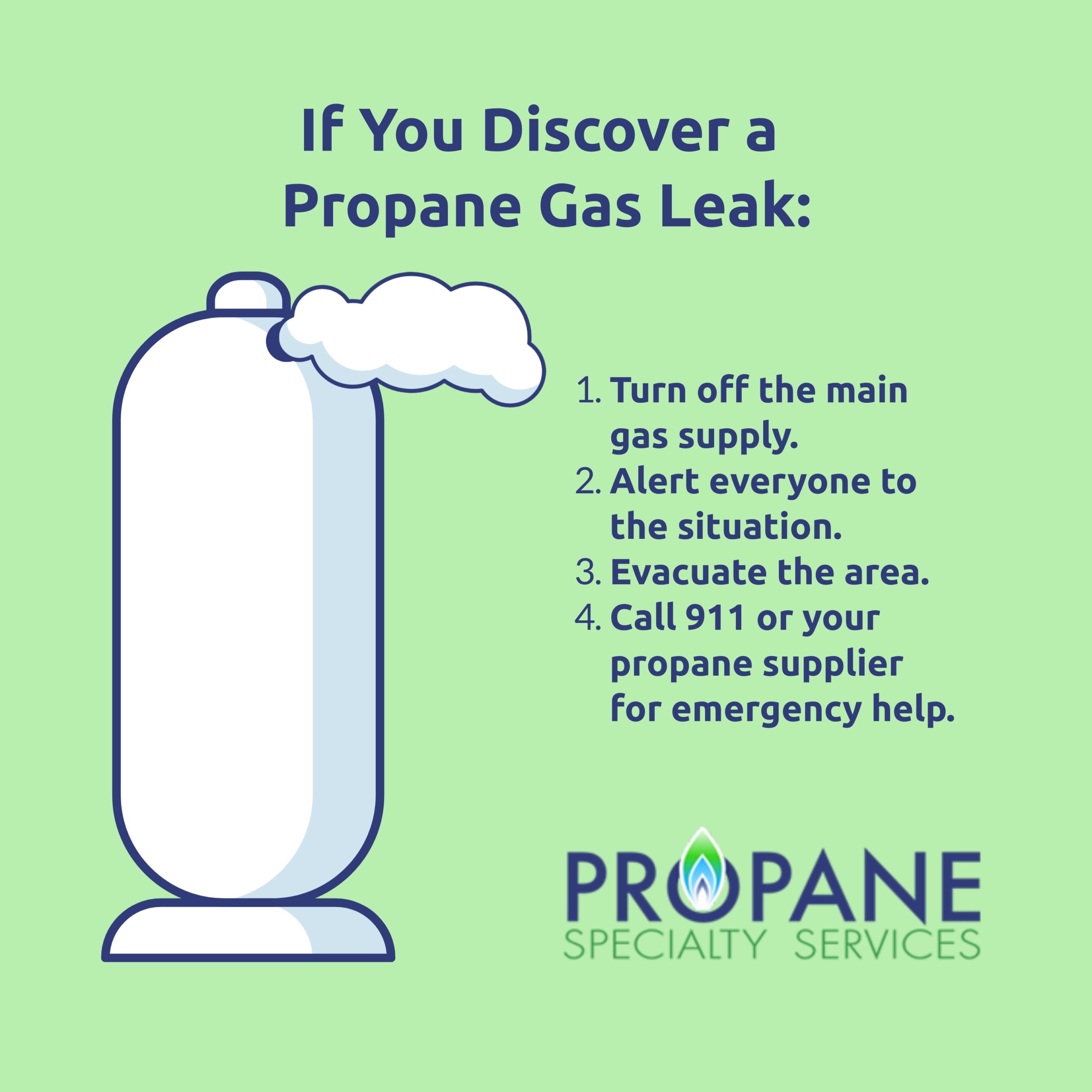

Since it is a well-known fact that a propane gas leak can actually cause massive explosions, there are certain steps that you should take if you are the one who has discovered a leak.

Immediately make sure that the risk for a fire explosion is reduced. This means that you have to ascertain that nobody in the vicinity lights up a cigarette or a match. It can quickly cause a massive fire explosion.

Propane safety is the utmost importance when it comes to propane gas leaks. If you suspect a gas leak in your home or business, stop what you’re doing, leave the area immediately, and call your propane supplier from a safe location immediately to report the leak.

Propane manufacturers add a distinctive skunk or rotten egg smell to propane so you are able to detect right away if there is a leak. Follow our steps below to keep you and your family safe in the event of a propane leak. For information on how to prevent a propane gas tank leak from happening in the first place, we recommend calling a residential propane supply company near you.

The easiest way to detect propane gas leaks is if you smell the bad odor added by the manufacturer. However, people on certain medications or the elderly may not be able to smell propane as well as others. While it’s rare, it may also be possible that the smell added by the manufacturer has dissipated due to rust inside the tank.

Checking for a propane tank leak is easy. Apply soapy water or a special leak detector solution to where the propane tank’s cylinder valve and regulator outlet connect. Next, you’ll need to slowly open the cylinder valve. Bubbles will form if there is a leak.

With any gas leak, there is always the concern that the slightest ignition could start a fire or explosion. Once a gas leak has been confirmed, you’ll need to put out any open flames. Do NOT turn on light switches, household appliances, or even use your phone. The slightest spark could cause an explosion.

If you are able to, turn the main gas supply valve clockwise to prevent more propane gas from leaking into your home. After, immediately move to a safe location and call your propane supplier.

If you are able, open as many windows as possible as you exit the house. This will help some of the built-up gas escape from your house, reducing risk of fire or explosions. Do not stop to pack any possessions. Inhaling propane gas can make breathing difficult or impossible.

Call 911 or your propane supply company as soon as you and your family are a safe distance away from the home. Your propane supplier and local fire department are able to respond to propane leaks 24/7.

Once you have evacuated the house, do not return until your local fire department has stopped the leak and deemed your home safe to re-enter. Do not be tempted to go back inside the home to get belongings. Breathing in propane gas can be deadly.

Before using any of our propane household appliances, you’ll need to schedule a propane tank inspection to ensure the leak is stopped and fixed so it won’t happen again. To prevent leaks from happening in the first place, we recommend scheduling routine propane gas tank inspections so you and your family can stay safe.

Propane tanks shouldn’t leak over time. Believe it or not, running out of gas in your propane tank can be dangerous. If the propane appliance valve or gas line of a propane tank remains open after the propane supply runs out, a leak may occur when the tank is refilled.

We advise you to leave turning on your propane tank to your propane supply company. While it’s as simple as turning a valve, there can be some significant complications with leaks from the tank to your house.

If your propane tank is leaking at the valve, call your local propane company and tell them that you have discovered a leak in your propane tank. It’s crucial that you don’t try to repair the tank any further yourself and let a professional determine a time to come to your home to do a system check or pick up the tank.

Crystal Flash is a residential propane gas supplier in Michigan that offers propane tank installation and inspection services to keep homeowners safe from gas leaks. For more information on how we protect our customers from gas leaks through propane tank maintenance services, be sure to call any of our Michigan Propane Delivery locations.

I"m no expert on flammables, but I"ve grilled a ton in my day on various equipment, and feel I"ve learned a couple things that may help here. However, your mileage may vary, and take this all with a grain of salt.

Depends on what this is. I agree with your read that this likely isn"t your equipment, and is likely something on the tank. If so, it is not known to me, but I have a different approach on tanks than you. More below.

Yes, I think they should do so happily; it leaks gas after all. If they don"t, you should insist (say something about how you were hoping to grill some steaks, not start a house fire).

The only thing I could fathom is if your equipment had some significant downstream pressure, but even if it did, I believe that would cause propane to flow more slowly to your burners, not leak out the back of the tank valve.

This doesn"t sound like a pressure release valve issue to me. If it were, the valve would open when the pressure increased inside the tank (usually a function of tank temperature increase), completely unrelated to when you opened the tank valve.

If I had to guess, I"d say that the bleed screw is not tightened down well. This screw is opened when they fill the tank (allowing the air to escape while LPG is pumped into the tank). When they are done filling the tank, the bleed screw should be tightened, and perhaps that wasn"t done when these tanks were filled. With the tank valve closed, check the bleed valve on the back of the tank valve to ensure it is closed.

Partial Fills. Most all of the tank exchanges only put in about 15# (~3.6 gallons) of propane. Even in warm weather climates you should be able to get 20# (4.7 gallons) of propane into a 20# tank.

Beat-up Tanks. The tanks I see at the exchanges are usually pretty beat-up. This could be part of what you are seeing, tanks with faulty valves (however, I have to believe they do some level of checking before they ship full tanks back to the retail stores, right?).

I have had excellent luck in buying several new, empty tanks (from Home Depot or the like) and having them filled myself (usually at either a U-Haul, AirGas, or gas station). It"s slightly less convenient, but I get a longer effective tank life (usually 33% more gas in my fill vs. exchanged tanks), better value (the gas is cheaper!), and my tanks don"t look nor operate poorly.

First of all, check if it’s actually a leak in the propane tank and move ahead according to the result. Maybe it’s a bleeder valve or a relief valve that’s open. Moreover, it could even be a damaged valve stem that’s causing the leak. Well, then you’ll need to change it.

Propane tanks are the cylinders that store propane fuel for heating and cooking. Handling it with care is necessary because it can be harmful otherwise. It is quite easy for a propane tank to be leaked or damaged. This in turn can lead to further accidents.

As soon as you sense a burning smell or a hissing noise, check for a leak near the propane tank valve. It’s vital to determine the leak and fix it right away for safety purposes.

Step 2:Add in 1 cup of liquid soap and 1 cup of warm water. Mix it and pour it into a spray bottle. Use this solution to spray onto the valve and gauge of the tank. Use quite a generous amount of the mixture on it.

Step 3:At this point, look for signs of leakage. Look for bubbles where you’ve sprayed the solution. If you see smaller bubbles, it indicates a small leak. But if you see larger bubbles of a good amount, you know the leak is pretty big.

Now there are a few causes behind a leaked propane tank valve stem leaking. Identifying the problem will be easier if you’re done checking for the leak.

The bleeder valve also known as the fixed level gauge is usually opened when the tank is filled with propane. An open bleeder valve can cause a leak in the propane tank.

Moreover, even if the bleeder valve isn’t open, its coil might be clogged with debris. This results in the propane tank leaking. Especially when the tank is overflowing with propane.

This is not a big deal and can be fixed immediately. Just turn off the bleeder valve. You can do it by rotating the valve clockwise. This will close it and stop the flow of gas.

The relief valve in the propane tank is designed to relieve the pressure of the tank. This means, during hot and humid weather, the relief valve slightly opens up to allow excess pressure to vent.

Now the solution here is to not touch the valve. The valve opens on its own and will close too. But tapping the valve or touching it may help it open completely. And we don’t want that.

To fix the situation, let the tank cool down. You can cool it down by spraying water coming from the garden hose. Just spray it all over the surface of the tank. This will allow the relief valve to close gently on its own.

Now the propane tank valve may be completely leaked or damaged. Hence releasing the propane gas. This can be seriously harmful because it can catch fire easily.

If you detect a leaking propane tank valve stem, you’ll need to replace the entire tank valve to prevent further damage. For replacing the valve, here’s what you’ll need-

To replace the tank valve, you’ll need to ensure that the cylinder is completely empty. Close the valve by turning the handle clockwise after your tank is emptied.

Now to take the leaked valve out, use a heat gun to soften the weld between the gas valve and the cylinder. At this point, open the tank nozzle to allow the tank regulator to style down to regular atmospheric pressure. Make sure to hold the tank still while you do this.

Now you need to attach the new valve. Make sure to include an overfilling prevention device (OPD) within the valve. You can attach the valve by threading it to the cylinder’s bung. Now tighten the attachment using a pipe wrench.

Answer: Refilling a propane tank is a wiser decision to make. It saves a lot of money and time as you don’t have to go through the hassle of replacing the entire tank.

Answer: A small amount of leak in the propane tank isn’t a big deal. But if the leak builds up over time, it can badly affect your health. As it can lead to hypoxia and carbon monoxide poisoning.

Apropane tank valve stem leakingcan call for severe accidents if actions aren’t taken immediately. Hence, it’s crucial to identify the leak’s location so you can fix it.

One thing you should pay attention to is the propane tank’s safety relief valve. All propane tanks, including the cylinders you use for your BBQ grill, are required by law to have pressure relief devices to allow for the release of excess pressure in the tank.

A spring keeps the safety relief valve closed as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear pop if that occurs.

Your propane tank needs to have room for the propane inside it to expand. That is why your propane tank is filled to 80% of its capacity. The 20% of the tank that is empty space allows the propane to safely expand.

That expansion is why propane tanks are white or beige. Light colors reflect heat to minimize expansion. Dark colors retain heat and can cause the propane inside your tank to expand to dangerous levels. So, even if your propane tank doesn’t go with the color of your siding, leave it alone.

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

For example, we have a radiator on the sixth floor, and the elevation is 60 feet high. When you divide the height (60 feet) by 2.3, we get 26.09 pounds. We should add 3 to 4 pounds to that number to allow for better air removal and to limit the chance of the hot water flashing to steam. This takes our normal system pressure to 29-30 psig.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

If the compression tank has an enclosed bladder, check the pressure on the bladder side of the tank. To do this, you have to reduce the system pressure to 0 psig and check the bladder pressure using a tire pressure gauge. The internal pressure should be that same as the system pressure. From above, we know the system pressure is 30 psig.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

Pressure relief valves ensure efficiency and safety in many chemical, oil, and gas plants, but they’re susceptible to leaks. If a pressure relief valve is leaking, systems can become overpressurized and even fail, especially if the valve isn’t addressed or repaired quickly.

When you shut down the system, carefully examine the pipelines and the valve itself to determine the cause of the leak. This will help you figure out exactly what you need to do to repair it.

Pressure relief valve leaks usually occur when the valve isn’t properly seated or when the seal is broken or damaged. Leaks can also happen when the pressure relief valve is operating too closely to the set point.

If the valve isn’t completely repaired after your first attempt, you have up to 15 days to perform any additional repairs according to the EPA. If the valve still isn’t fixed, then you can either replace the pressure relief valve or wait until the next shutdown cycle to do more repairs.

When the pressure relief valve has been fixed or replaced, it’s important to take the necessary steps to avoid leaks in the future. To do that, consider implementing a leak detection and repair (LDAR) program for your company.

An LDAR program will help to train workers on everything they need to know about detecting and repairing a leak before system damage can occur. It will also help you monitor valves more efficiently so you can spot leaks faster and spend less money on overall valve repair and maintenance costs.

Have you experienced a propane leak before? Like any other flammable gas, propane fuel must be properly handled in all environments. Whether you’re using it to power industrial equipment or transport large tanks, understanding the risks of propane leaks and ensuring the correct monitoring equipment is in place is vital for the safety of your team.

If you regularly work with liquefied petroleum gas or propane, your facility assumedly has gas detection equipment installed to maintain optimal gas levels. If your monitor were to malfunction, however, it’s important to know the steps to take if a propane leak were to occur.

In its organic form, liquefied petroleum gas is nontoxic, colorless, and odorless. To help customers and operators to safely handle propane gas, an odorant is added so that it smells like rotten eggs. While simply smelling propane is often how propane leaks are discovered, your sense of smell isn’t the most reliable source.

You can also check your propane tank on a regular basis by applying soapy water or specialized leak detector solution to the tank’s cylinder gas supply valve or regular outlet connection. If bubbles form when you slowly open the cylinder valve, there’s a probable chance that you could have a propane leak.

Pro Tip: If you have an extensive LPG system, having a reliable gas detection system is key to ensure that you have 24/7 monitoring of your environment.

When you discover a leak, it’s important to respond quickly and appropriately to reduce chances of fire or sudden explosion. If you have access to the main gas supply, be sure to turn it off immediately to prevent any more propane gas from leaking.

After, make sure that every person in and around your facility is alerted and given the opportunity to evacuate safely. Once you’ve left the area and are a safe distance from the gas leak, call 911 or your propane supply company to report the leak and to get emergency assistance.

Safety prevention is a top priority for every facility, especially when using flammable materials such as liquefied petroleum gas. One of the best ways to guard against propane leaks is by committing toroutine equipment maintenance. By performing a system check and ensuring that you have the latest connectors and gas lines, you can greatly reduce the likelihood of a propane leak in your building or area.

Additionally, be sure that your facility has a propane gas detector configured to sound an alarm when an unsafe concentration level of propane is found. These precautions along regular team safety meetings will ensure that your business will be adequately prepared when faced with a propane gas leak.

Regardless of the type ofLPG systemyou have installed, having the right safety measures is key to handling propane leaks. Your business’s success and the health of your workers depends on having the best training and detection equipment necessary to handle any leak or malfunction.

It is afternoon and the outside temperature is 104 degrees Fahrenheit. You arrive at a hardware store and safely park on the side of the structure where you can see the consumer propane storage and the loading dock area.

After contact with the RP you discover a single cylinder used to power their forklift is leaking from one of the ports on the top. The tank has been removed to a fresh air environment away from ignition sources prior to arrival. The area is surveyed with a gas monitor and is clear. There are no ignition sources.

You start to think, PV=nRT, and wow it is hot, the relief valve is doing it’s job, lets put this thing in the shade (in a safe ventilated environment clear from an ignition source) and observe. Does the Ideal Gas law apply to a cylinder which may have liquid and gas present? It is hot, any gas portion should expand..makes sense.

Upon further discussion with RP the tank was actually discovered indoors, where the temperature is NOT hot. The tank was noticed from the smell as well as the hissing sound from a port on the top. The valve on the top was closed, although noticeably worn. While the slowly leaking tank rested in the shade in a safe environment we had a few moments to think this out further.

Burn Off? – This method is done in some jurisdictions and can be a safe option. Check the link if below does not play and see how teams in Florida rendered a tank safe with a well done burn off operation. This option requires the right location, equipment, and regulatory permissions.

Plug? – The leak appeared to be from the relief valve which may just be doing its’ job, and to plug would interfere with that function. For this to be done safely the plug would also need to have a relief valve. This was also not an option. Here is a good reason why not, according to propane101.com

Pictured is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of “repairing” the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with the safety relief valve.

Let it vent? – How long will this take? Heck can we just fire up the grill and have a cook out… We are good now with any ‘plume’ issues but the more time this leaks in this location, the more chance for problems downwind.

Where is it from? Well there was not an immediate ‘vendor’ to contact as the hardware store received new tanks with their other inventory as they needed the tanks. They were a busy facility and went through several tanks in a month but they were not from a ‘propane’ vendor.

What about this tank again? As the ‘active’ facility part had us fooled (all the other cylinders looked pretty new). Upon further inspection the tank was dated 1987! With no marking newer (indicating it was never serviced) this tank was well over the 12 year mark and this valve was likely not working as it was supposed to, it was malfunctioning. Heck it was due for service last century!

We verified the malfunction by venting the air pressure valve at the top to relieve some extra pressure. Use the correct PPE, the release can become very cold. This combined with the cooling measures, should cause a normally functioning relief valve to reset. Nope. Old tank, bad valve.

In the meantime the RP contacted a local propane facility (at our suggestion) who was able to roll out and assist. The field tech was able safely secure and transport the tank to their nearby facility for transfer. Â As our options were running out this was much better for everyones safety as well as the business since the tank remained product and not hazardous waste. Â It helps that we have a good relationship with local ‘experts’ which in this case was a propane provider.

All propane tanks and cylinders must be inspected and re-qualified within 12 years of the date they were manufactured, and again every five, seven or 12 years after the initial re-qualification date. Â It is up to the owner of the propane tank to keep track of the tank’s re-qualification date

Our goal is to raise awareness, share some incidents, and prompt questions and inspire some drill related to every day incidents. Check out our facebook page and comment if you have war stories, comments, training ideas -“Train as if you life depends on it….”HMN Staff

Most conventional tank valves are not field-repairable. But with RegO, you’re ready to go when you roll up. Our innovations in propane tank valves include our patented RegO MultiBonnet®, the industry’s only field-repairable tank valves that provides users easy access to repair the valve stem packing without disruption of service and without the added cost of evacuating the tank. Jobs that used to take hours now take minutes.

In addition, RegO’s UL-listed, factory installed and tested Presto-Tap® tank fittings provide a quick and easy method of performing a system leak test, saving users time and money, while reducing fugitive emissions by up to 90%.

RegO MultiValves contain UL-listed, factory installed and tested Presto-Tap fitting that provides a quick and easy, cost-effective method of performing a system leak test that saves you time and money while reducing emissions by up to 90%

Combines low emission double back check filler valve, vapor equalizing valve, pressure relief valve, MultiBonnet service valve, fixed liquid level gauge, “junior” sized float gauge flange opening and factory installed and tested Presto-Tap.

These compact MultiValves are especially suited for vapor withdrawal of ASME containers where compact groupings of components are necessary. Separate filler valves andpressure relief valves are required.

Designed for vapor withdrawal service on ASME and DOT containers or in fuel line applications. Since none of these valves have an integral pressure relief valve, they may only be used as an accessory valve on containers that have an independent pressure relief valve sufficient for that container’s capacity.

These MultiValves permit vapor withdrawal from ASME containers up to 50 sq. ft. surface area and DOT containers up to 420lb propane capacity. They allow on-site cylinder filling without interrupting gas service.

Combines high capacity double back check filler valve, MultiBonnet service valve, fixed liquid level gauge, pressure relief valve and factory installed and tested Presto-Tap.

The RegO Presto-Tap Universal Service Tech Kit has all the diagnostic tools needed to perform system leak testing at any point of the propane system all in one easy-to-carry bag.

Always keep flammable and combustible materials (e.g., paper, clothing, wood, gasoline, solvents) away from any open flames that originate from your appliances.

Never place your head near or directly over the valves on your storage tank. A sudden release of product from the safety relief valve could result in serious injury.

If you think you smell propane in your home, camper, RV or the area around any gas equipment, or if a gas alarm signals the presence of propane, you should IMMEDIATELY follow these suggestions:

Even if you do not continue to smell propane, do not open or turn on the propane supply valve. Do not re-enter the building, vehicle or area. Let a qualified propane service technician and/or emergency personnel check for escaped propane.

Have a properly trained propane service technician repair the leak. The propane service technician or emergency responder needs to determine that the leak situation has been fully resolved. The propane service technician should check all of your gas appliances and re-light any appliance pilots.

All lines not attached to appliances must be closed and terminated with threaded caps or plugs. If you have any questions, please call your propane supplier.

Propane expands when heated. That increases the pressure in the tank. Above a certain pressure, the relief valve opens to release a small amount of vapor. That release keeps the pressure from building up too much inside the tank. Once excess pressure has been released, the relief valve closes automatically.

It’s important to keep your tank painted with a white, aluminum or other reflective color. A rusty, unpainted or dark-colored tank may cause pressure build-up resulting in a safety relief valve discharge.

All appliances should be installed and repaired only by qualified technicians. Improper ventilation can starve the combustion process in the appliance and create a situation that could produce toxic carbon monoxide gas. Carbon monoxide is an odorless and colorless gas that, in sufficient amounts, may be deadly to humans. Usually, headaches and/or flu-like systems are initial signs of carbon monoxide poisoning. If you suspect that any of your appliances have been improperly vented, you should discontinue using them and contact your propane supplier or local fire department immediately for an inspection.

An appliance gas control is a precision mechanism that may malfunction if it is exposed to water from flooding, storms, or any other damaging environments. A flooded gas control must be replaced by a qualified gas appliance technician. Damaged gas control valves must be replaced.

If you continue to smell gas, even after lighting a pilot, turn off the gas valve immediately upstream of the appliance to stop the flow of gas. Contact your propane supplier immediately to investigate the situation.

If an appliance or any other component of your propane system has been tagged “out-of-service,” do not attempt to enable it. The tag indicates a serious unsafe condition.

Ask your propane supplier to conduct a regular gas safety check to inspect your system for leaks and ensure it meets all applicable safety standards. The technician will also check your tank, piping, regulators, gauges, connectors, valves, vents, thermostats, pilots, burners and appliance controls to make sure they are in good working condition.

Do not use a propane gas cylinder if it shows signs of external damage, such as dents, gouges, bulges, fire damage, corrosion, leakage or excessive rust.

To see how much propane is left in your cylinder, run a wet finger down the side. The wet streak will evaporate faster over the empty part of the cylinder.

8613371530291

8613371530291