why is my propane tank leaking from safety valve brands

On hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the protective cap will be removed

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

The following list is a starting point, but you will need to consider everything around you:Open flames: Make sure that there are no open flames, and do not flick any cigarette lighters.

Stir a cup of dishwashing liquid into a cup of warm water and pour into a spray bottle. Then simply spray around the gauges and valves of the propane tank.

After this, slowly open the cylinder valve so that a little gas comes out. If you have sprayed it with soap solution, you will see bubbles at the site of the leak.

After about 15 minutes, spray the solution again on the areas that were leaking before. Slowly turn the cylinder valve to check if there is still a leak.

If your tank is still leaking you are in danger, and need to evacuate the area. It’s important to wait until you are clear of the area and the leak before using a cellphone.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Propane safety is the utmost importance when it comes to propane gas leaks. If you suspect a gas leak in your home or business, stop what you’re doing, leave the area immediately, and call your propane supplier from a safe location immediately to report the leak.

Propane manufacturers add a distinctive skunk or rotten egg smell to propane so you are able to detect right away if there is a leak. Follow our steps below to keep you and your family safe in the event of a propane leak. For information on how to prevent a propane gas tank leak from happening in the first place, we recommend calling a residential propane supply company near you.

The easiest way to detect propane gas leaks is if you smell the bad odor added by the manufacturer. However, people on certain medications or the elderly may not be able to smell propane as well as others. While it’s rare, it may also be possible that the smell added by the manufacturer has dissipated due to rust inside the tank.

Checking for a propane tank leak is easy. Apply soapy water or a special leak detector solution to where the propane tank’s cylinder valve and regulator outlet connect. Next, you’ll need to slowly open the cylinder valve. Bubbles will form if there is a leak.

With any gas leak, there is always the concern that the slightest ignition could start a fire or explosion. Once a gas leak has been confirmed, you’ll need to put out any open flames. Do NOT turn on light switches, household appliances, or even use your phone. The slightest spark could cause an explosion.

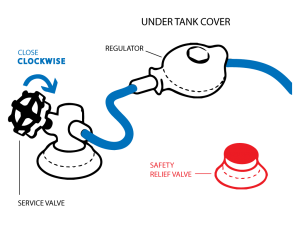

If you are able to, turn the main gas supply valve clockwise to prevent more propane gas from leaking into your home. After, immediately move to a safe location and call your propane supplier.

If you are able, open as many windows as possible as you exit the house. This will help some of the built-up gas escape from your house, reducing risk of fire or explosions. Do not stop to pack any possessions. Inhaling propane gas can make breathing difficult or impossible.

Call 911 or your propane supply company as soon as you and your family are a safe distance away from the home. Your propane supplier and local fire department are able to respond to propane leaks 24/7.

Once you have evacuated the house, do not return until your local fire department has stopped the leak and deemed your home safe to re-enter. Do not be tempted to go back inside the home to get belongings. Breathing in propane gas can be deadly.

Before using any of our propane household appliances, you’ll need to schedule a propane tank inspection to ensure the leak is stopped and fixed so it won’t happen again. To prevent leaks from happening in the first place, we recommend scheduling routine propane gas tank inspections so you and your family can stay safe.

Propane tanks shouldn’t leak over time. Believe it or not, running out of gas in your propane tank can be dangerous. If the propane appliance valve or gas line of a propane tank remains open after the propane supply runs out, a leak may occur when the tank is refilled.

We advise you to leave turning on your propane tank to your propane supply company. While it’s as simple as turning a valve, there can be some significant complications with leaks from the tank to your house.

If your propane tank is leaking at the valve, call your local propane company and tell them that you have discovered a leak in your propane tank. It’s crucial that you don’t try to repair the tank any further yourself and let a professional determine a time to come to your home to do a system check or pick up the tank.

Crystal Flash is a residential propane gas supplier in Michigan that offers propane tank installation and inspection services to keep homeowners safe from gas leaks. For more information on how we protect our customers from gas leaks through propane tank maintenance services, be sure to call any of our Michigan Propane Delivery locations.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pressure relief valves ensure efficiency and safety in many chemical, oil, and gas plants, but they’re susceptible to leaks. If a pressure relief valve is leaking, systems can become overpressurized and even fail, especially if the valve isn’t addressed or repaired quickly.

When you shut down the system, carefully examine the pipelines and the valve itself to determine the cause of the leak. This will help you figure out exactly what you need to do to repair it.

Pressure relief valve leaks usually occur when the valve isn’t properly seated or when the seal is broken or damaged. Leaks can also happen when the pressure relief valve is operating too closely to the set point.

If the valve isn’t completely repaired after your first attempt, you have up to 15 days to perform any additional repairs according to the EPA. If the valve still isn’t fixed, then you can either replace the pressure relief valve or wait until the next shutdown cycle to do more repairs.

When the pressure relief valve has been fixed or replaced, it’s important to take the necessary steps to avoid leaks in the future. To do that, consider implementing a leak detection and repair (LDAR) program for your company.

An LDAR program will help to train workers on everything they need to know about detecting and repairing a leak before system damage can occur. It will also help you monitor valves more efficiently so you can spot leaks faster and spend less money on overall valve repair and maintenance costs.

I"m no expert on flammables, but I"ve grilled a ton in my day on various equipment, and feel I"ve learned a couple things that may help here. However, your mileage may vary, and take this all with a grain of salt.

Depends on what this is. I agree with your read that this likely isn"t your equipment, and is likely something on the tank. If so, it is not known to me, but I have a different approach on tanks than you. More below.

Yes, I think they should do so happily; it leaks gas after all. If they don"t, you should insist (say something about how you were hoping to grill some steaks, not start a house fire).

The only thing I could fathom is if your equipment had some significant downstream pressure, but even if it did, I believe that would cause propane to flow more slowly to your burners, not leak out the back of the tank valve.

This doesn"t sound like a pressure release valve issue to me. If it were, the valve would open when the pressure increased inside the tank (usually a function of tank temperature increase), completely unrelated to when you opened the tank valve.

If I had to guess, I"d say that the bleed screw is not tightened down well. This screw is opened when they fill the tank (allowing the air to escape while LPG is pumped into the tank). When they are done filling the tank, the bleed screw should be tightened, and perhaps that wasn"t done when these tanks were filled. With the tank valve closed, check the bleed valve on the back of the tank valve to ensure it is closed.

Partial Fills. Most all of the tank exchanges only put in about 15# (~3.6 gallons) of propane. Even in warm weather climates you should be able to get 20# (4.7 gallons) of propane into a 20# tank.

Beat-up Tanks. The tanks I see at the exchanges are usually pretty beat-up. This could be part of what you are seeing, tanks with faulty valves (however, I have to believe they do some level of checking before they ship full tanks back to the retail stores, right?).

I have had excellent luck in buying several new, empty tanks (from Home Depot or the like) and having them filled myself (usually at either a U-Haul, AirGas, or gas station). It"s slightly less convenient, but I get a longer effective tank life (usually 33% more gas in my fill vs. exchanged tanks), better value (the gas is cheaper!), and my tanks don"t look nor operate poorly.

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

For example, we have a radiator on the sixth floor, and the elevation is 60 feet high. When you divide the height (60 feet) by 2.3, we get 26.09 pounds. We should add 3 to 4 pounds to that number to allow for better air removal and to limit the chance of the hot water flashing to steam. This takes our normal system pressure to 29-30 psig.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

If the compression tank has an enclosed bladder, check the pressure on the bladder side of the tank. To do this, you have to reduce the system pressure to 0 psig and check the bladder pressure using a tire pressure gauge. The internal pressure should be that same as the system pressure. From above, we know the system pressure is 30 psig.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

Regardless of how new your propane tank is or how often you inspect your propane system, there’s always the possibility that your tank will leak. That’s why everyone in your family needs to know what to do when it happens.

To stop a propane tank from leaking, you should first eliminate all potential igniters to minimize risks. You also need to open the windows to reduce built-up gas. Once it’s safe, you can use soap and water to find the leak. After that, you can tighten the screws and valve to stop the leak.

So, let’s go through all the steps you need to take to quickly and safely deal with it. Stick around because this article will help you gain the vital information that can keep you safe and prevent leaks from happening in the first place.

Disclaimer: propane is extremely flammable and can be dangerous. Always exercise caution and follow the manufacturer’s guidelines when working on your tank. We offer this advice with no guarantee and aren’t responsible for any mishaps!

So, if you suspect that your propane tank is leaking, you have to deal with it with urgency and care. Although it’s not advisable to fix it yourself, it doesn’t mean that you can’t do anything to stop it.

If your propane tank is leaking, you may hear a hissing sound. However, this often means that the leak is substantial, so you’d have to be more careful and act faster.

Manufacturers add an odorant to propane; it’s one of the safety features they have to help you detect a gas leak. It’ll always be a distinct smell, something you don’t normally smell inside a house, like a skunk, rotten egg, or a dead animal.

As soon as you notice any of these things, stop whatever it is you’re doing. Even the slightest spark can cause an explosion, and it won’t wait for you to finish whatever it is you’re doing. So, stop right away and do the following steps:

It’s the first thing you should do to prevent even more damages and make it easier for you to deal with the leak. You can turn off the main gas supply valve by turning the knob clockwise. If you have more than one tank, turn all of them off to minimize the risk.

Before you try anything to stop a propane tank from leaking, you must first look after your safety. So, turn off all potential igniters, including the following:

The biggest risk to any leaking tank is when there’s too much built-up gas inside the house. If the leak is substantial, you won’t be able to do anything because inhaling propane can make it difficult to breathe.

Your propane tank will have enough gas to allow you to find where the leak is coming from, but you’d have to do it as soon as possible. There are two easy ways to find leaks in your propane tank:

Once you have either of these, spray your solution around the gauges and valve of the tank. It should cover the surface to be sure that you’re finding the real problem.

Once you have your solution all over the valve and gauges, slowly open it to release some gas. Bubbles will form on the location where the leak is coming from.

Turn off the cylinder valve to stop the leak, then use a Phillips-head screwdriver to tighten the screws on the face gauge. You may also need to tighten the valve by turning it clockwise. Often, leaks come from loose screws and valves, and tightening them can save you from all the troubles of replacing your propane tank.

Leave the tank for at least 10 minutes, then spray your mixture or solution on the marked areas where the leaks were. Slowly turn on the cylinder valve and see if there are still bubbles forming in those areas.

You’ll need a professional to repair the tank or get a replacement from your dealer. Finally, don’t enter your house until a qualified professional tells you that your house is clear.

There’s very little you can do to prevent propane tanks from leaking because, in most cases, the tank is already faulty when you get it. It could also be because the tank is too old, which poses a greater risk for you.

Rusty tanks can dissipate the odorant that manufacturers add to propane, making it harder for you to detect leaks. So, be sure to check the tank that you’re using and always ask for a replacement if it looks too old.

Overfilled tanks can also be dangerous, especially when they’re in storage. So, as soon as you get a propane tank, be sure to find the tare weight (TW) printed anywhere on the tank. TW is the tank’s weight when empty.

Weigh the tank, then subtract the TW to give you the weight of the propane inside it. If it’s more than what the tank can safely hold, then it’s overweight, and you’d have to release some of it.

Finally, you should get a qualified professional to conduct regular inspection of your propane system. Doing so will help you identify potential issues and ensure that you won’t have leakage problems in the future.

A leaking propane tank is very dangerous, and you have to act as soon as you suspect there’s a leak. Manufacturers add an odorant to propane, making it easier for you to detect leaks and take the necessary steps to keep you and your family safe.

Using a mixture of soap and water, you can easily detect where the leak is coming from, allowing you to stop it. If tightening the screws and valve doesn’t work, it would be best to call a professional to help you repair or replace your propane tank and clear the gas inside your house.

Always keep flammable and combustible materials (e.g., paper, clothing, wood, gasoline, solvents) away from any open flames that originate from your appliances.

Never place your head near or directly over the valves on your storage tank. A sudden release of product from the safety relief valve could result in serious injury.

If you think you smell propane in your home, camper, RV or the area around any gas equipment, or if a gas alarm signals the presence of propane, you should IMMEDIATELY follow these suggestions:

Even if you do not continue to smell propane, do not open or turn on the propane supply valve. Do not re-enter the building, vehicle or area. Let a qualified propane service technician and/or emergency personnel check for escaped propane.

Have a properly trained propane service technician repair the leak. The propane service technician or emergency responder needs to determine that the leak situation has been fully resolved. The propane service technician should check all of your gas appliances and re-light any appliance pilots.

All lines not attached to appliances must be closed and terminated with threaded caps or plugs. If you have any questions, please call your propane supplier.

Propane expands when heated. That increases the pressure in the tank. Above a certain pressure, the relief valve opens to release a small amount of vapor. That release keeps the pressure from building up too much inside the tank. Once excess pressure has been released, the relief valve closes automatically.

It’s important to keep your tank painted with a white, aluminum or other reflective color. A rusty, unpainted or dark-colored tank may cause pressure build-up resulting in a safety relief valve discharge.

All appliances should be installed and repaired only by qualified technicians. Improper ventilation can starve the combustion process in the appliance and create a situation that could produce toxic carbon monoxide gas. Carbon monoxide is an odorless and colorless gas that, in sufficient amounts, may be deadly to humans. Usually, headaches and/or flu-like systems are initial signs of carbon monoxide poisoning. If you suspect that any of your appliances have been improperly vented, you should discontinue using them and contact your propane supplier or local fire department immediately for an inspection.

An appliance gas control is a precision mechanism that may malfunction if it is exposed to water from flooding, storms, or any other damaging environments. A flooded gas control must be replaced by a qualified gas appliance technician. Damaged gas control valves must be replaced.

If you continue to smell gas, even after lighting a pilot, turn off the gas valve immediately upstream of the appliance to stop the flow of gas. Contact your propane supplier immediately to investigate the situation.

If an appliance or any other component of your propane system has been tagged “out-of-service,” do not attempt to enable it. The tag indicates a serious unsafe condition.

Ask your propane supplier to conduct a regular gas safety check to inspect your system for leaks and ensure it meets all applicable safety standards. The technician will also check your tank, piping, regulators, gauges, connectors, valves, vents, thermostats, pilots, burners and appliance controls to make sure they are in good working condition.

Do not use a propane gas cylinder if it shows signs of external damage, such as dents, gouges, bulges, fire damage, corrosion, leakage or excessive rust.

To see how much propane is left in your cylinder, run a wet finger down the side. The wet streak will evaporate faster over the empty part of the cylinder.

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

For example, we have a radiator on the sixth floor, and the elevation is 60 feet high. When you divide the height (60 feet) by 2.3, we get 26.09 pounds. We should add 3 to 4 pounds to that number to allow for better air removal and to limit the chance of the hot water flashing to steam. This takes our normal system pressure to 29-30 psig.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

If the compression tank has an enclosed bladder, check the pressure on the bladder side of the tank. To do this, you have to reduce the system pressure to 0 psig and check the bladder pressure using a tire pressure gauge. The internal pressure should be that same as the system pressure. From above, we know the system pressure is 30 psig.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Houses or buildings utilizing gas energy require a gas piping system to power heaters, ovens, and other heating appliances. One of the most important elements of a gas piping system is the propane service valve, which controls propane gas flow in and out of a building. While there may be many other valves within gas plumbing, this valve functions as an on/off switch and serves as the main point of control for cutting off or allowing for the flow of gas into a piping system.

Propane valves are simply used to turn gas on or off. Similar to that of a water faucet, propane valves consist of a handwheel that controls propane gas flow when turned. When the wheel is turned, a stem and seat mechanism located within the valve opens or closes to prevent or allow gas flow from the tank.

Using propane gas requires an LP gas regulator, which decreases the amount of pressure released into the gas line, keeping it at an acceptable and safe level while still meeting the needs of the application.

There are multiple different valves in any propane system, each of which has a particular job. At IPS Equipment, we provide some of the most common types of valves for propane systems, including:

A pressure or safety relief valve is a safety mechanism that every propane system needs. It allows excess pressure in the tank to be slowly and safely released. Without this valve, pressure can build up and cause the tank to crack or rupture.

The relief valve has a pressurized spring. If the pressure levels within the tank grow too high, the spring forces the valve open just enough to return the pressure levels to acceptable levels. Once the pressure decreases, the spring relaxes, and the valve automatically closes.

This valve is where gas delivery personnel add new gas to a propane tank. Propane delivery trucks have hoses that can be attached to the filler valve so propane can be pumped into the tank. This valve is also pressure-activated, and it opens automatically in response to the pressure in the hose.

Filler valves have gaskets that operators can push the hose end against to avoid propane leaks. They also only allow for unidirectional fluid movement, meaning that once the tank is full, there is no risk of propane escaping when the hose is withdrawn.

This shut-off valve prevents gas from entering the building and any attached appliances. You can use this central point of control like an on/off switch to completely halt the path of gas in the system.

This valve is also called a vapor return valve or vapor eliminator valve. It ensures that propane is delivered at the proper pressure levels from the propane delivery truck to a personal tank and returns any excess propane back to the delivery truck. This is similar to a safety valve, except the vapor equalizing valve ensures the propane is delivered at proper pressures for optimum use, not safety. This is especially crucial during hot weather or in warm environments, as that can increase the pressure.

This specialized valve is meant for use by propane companies only. It allows operators with the proper tools to drain liquid propane from the tank. Propane tanks must be drained to <5% capacity levels before they can legally be moved.

IPS Equipment specializes in supplying propane marketers with reliable valves, fittings, regulators, and more for propane systems. Contact us today to learn more about our comprehensive products or services, or browse through our catalog to start your order.

It’s never a good sign when you find water on the floor around your water heater. But before you panic, it’s important to figure out where it’s coming from.

Upon further investigation, if you find the water is being discharged from a small tube that comes out of the top or side of the unit, runs down the side of the tank, and ends near the ground, then the source is likely the temperature pressure relief valve, or relief valve, for short.

The relief valve is an important safety feature on the water heater. If the water inside the unit gets too hot (usually above 210 degrees) or pressure builds up too high (above 150 psi), the water heater can become damaged or even explore.

A good solution to this risk is the relief valve. If at any point the temperature or pressure reaches an unsafe level, the water heater triggers the relief valve to open and release water out of the tank until the temperature and pressure return to normal.

Both circumstances should be taken very seriously. If the relief valve is needed frequently, that means there’s an issue with your water heater that is causing unsafe temperatures or pressure.

On the other hand, if the relief valve is stuck or has another problem, it needs to be fixed or replaced right away so it can do its job properly when necessary.

If water is coming out of the relief valve of your water heater, don’t ignore it. Bring in the expert team at Pratt Plumbing to inspect your water heater to make sure you don’t have a potentially dangerous situation in your home. To schedule an appointment, call (806) 373-7866 today.

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

I"m no expert on flammables, but I"ve grilled a ton in my day on various equipment, and feel I"ve learned a couple things that may help here. However, your mileage may vary, and take this all with a grain of salt.

Depends on what this is. I agree with your read that this likely isn"t your equipment, and is likely something on the tank. If so, it is not known to me, but I have a different approach on tanks than you. More below.

Yes, I think they should do so happily; it leaks gas after all. If they don"t, you should insist (say something about how you were hoping to grill some steaks, not start a house fire).

The only thing I could fathom is if your equipment had some significant downstream pressure, but even if it did, I believe that would cause propane to flow more slowly to your burners, not leak out the back of the tank valve.

This doesn"t sound like a pressure release valve issue to me. If it were, the valve would open when the pressure increased inside the tank (usually a function of tank temperature increase), completely unrelated to when you opened the tank valve.

If I had to guess, I"d say that the bleed screw is not tightened down well. This screw is opened when they fill the tank (allowing the air to escape while LPG is pumped into the tank). When they are done filling the tank, the bleed screw should be tightened, and perhaps that wasn"t done when these tanks were filled. With the tank valve closed, check the bleed valve on the back of the tank valve to ensure it is closed.

Partial Fills. Most all of the tank exchanges only put in about 15# (~3.6 gallons) of propane. Even in warm weather climates you should be able to get 20# (4.7 gallons) of propane into a 20# tank.

Beat-up Tanks. The tanks I see at the exchanges are usually pretty beat-up. This could be part of what you are seeing, tanks with faulty valves (however, I have to believe they do some level of checking before they ship full tanks back to the retail stores, right?).

I have had excellent luck in buying several new, empty tanks (from Home Depot or the like) and having them filled myself (usually at either a U-Haul, AirGas, or gas station). It"s slightly less convenient, but I get a longer effective tank life (usually 33% more gas in my fill vs. exchanged tanks), better value (the gas is cheaper!), and my tanks don"t look nor operate poorly.

Water heaters come equipped with a temperature and pressure relief valve, also known as a TPRV. This valve allows water or steam to escape from the water heater if the temperature or pressure gets too high. This prevents a water heater from exploding or turning into a missile.

When a TPRV at a water heater leaks, it’s usually a simple fix; just replace the valve. These valves cost less than $15 and replacing the valve is a basic job. There are plenty of videos on YouTube showing how to do this, and the whole project probably won’t take more than fifteen minutes.

If you replace a TPRV and it starts leaking again, it probably means the valve is doing its job; it’s relieving excess pressure. When this happens, the fix gets a little bit more involved, and some troubleshooting is in order.

The TPRV on a water heater is set to discharge at 150 PSI or 210° Fahrenheit. These numbers will be printed right on the valve, or on a tag attached to the valve. See below.

If a pressure relief valve for a boiler is accidentally installed on a water heater, it will leak like crazy from the start. These valves may look identical, but they’re set to go off at 30 psi, not 150 psi.

The easiest way to do this is to get a gauge with a garden hose thread, connect it to an outside garden hose faucet, and open up the faucet. If that’s not an option, you can also use the hot or cold spigot for a washing machine. You should expect the pressure to be somewhere in the 40 – 80 PSI range with no other water running. If the pressure is over 80 PSI, it should be corrected. That’s too high for your system. The solution is to have a pressure regulator installed. Get a plumber to do that, as they’ll need to install an expansion tank at the same time. I’ll come back to those in a minute.

If the pressure is within the acceptable range, you probably have an intermittent problem with excessive pressure that can be easily re-created. Go run a bunch of hot water at your plumbing fixtures until you’ve exhausted the hot water supply on your water heater, and keep running the water for another few minutes. If you have several fixtures open, this should only take about ten to fifteen minutes. Now stop running water at all of your fixtures and wait.

You’ve just replaced the hot water in your water heater with cold water, which will cause your water heater to run for a while. This will cause the water to expand significantly until the water heater thermostat is satisfied. That might take about an hour or two. In most situations, this water will expand back out through the cold water inlet, all the way back to the water supply coming into the house. The municipal water supply for the house acts as a gigantic expansion tank… and nobody notices. This is illustrated in the diagram below.

Your pressure gauge shouldn’t change a bit while this happens. If the pressure increases with this test, however, you’ve made an important discovery. You have a closed system!

A closed system exists when water can’t leave your house. One way for this to happen is to have a check valve installed on the water supply coming into the home. I don’t see a lot of these in Minnesota, but I do see them periodically.

The other way to create a closed system is to have a pressure regulator installed that contains a built-in check valve. With either of these installed, water can’t leave the house. When water expands and can’t go anywhere, pressure in the system increases. Watch your pressure gauge to verify this. Once the pressure gets to 150 PSI, the TPRV should do its job and leak.

When a closed system exists on the water distribution piping in a home, an expansion tank needs to be installed somewhere on the plumbing system. This is a simple and straightforward fix; an expansion tank will give the water somewhere to go when it expands, and the TPRV on the water heater will stop causing problems.

Expansion tanks are required when a closed system exists, both by water heater manufacturers and by plumbing codes. The Minnesota State Plumbing Code requires an expansion tank when a pressure regulator is installed (608.2):

An approved expansion tank shall be installed in the cold water distribution piping downstream of each such regulator to prevent excessive pressure from developing due to thermal expansion and to maintain the pressure setting of the regulator.

A water system provided with a check valve, backflow preventer, or other normally closed device that prevents dissipation of building pressure back into the water main shall be provided with an approved, listed, and adequately sized expansion tank or other approved device having a similar function to control thermal expansion.

If an expansion tank is already installed and there is still a problem with excessive pressure, you have a problem with the expansion tank. I’ll talk about expansion tanks in next week’s blog post.

8613371530291

8613371530291