safety valve air brakes manufacturer

Valves direct the flow and release of air throughout an air brake system … a big job for the network of compact components located on an 80,000 pound vehicle. But when it comes to product performance and support, Bendix valves have set the standard for everyone else.

If you want to maintain performance, reliability, and even safety, go with the best, stay with the best… genuine Bendix. Why take a chance with anything less?

Genuine Bendix valves – whether new or remanufactured – reflect today’s highest engineering standards and comply with all federal safety regulations. In fact, genuine Bendix is the industry standard valve system chosen by leading OE manufacturers throughout North America.

Commercial vehicles are becoming more sophisticated and compressed air requirements are increasing daily. That’s why we’re always hard at work developing and testing the next generation of valves and control system components designed to enhance and improve vehicle performance. With highly sophisticated R&D activities and up-to-date expertise from around the globe, we continue to ensure each new design meets and exceeds your needs.

There is no application guide that tells us what air brake valves the manufacturer used on your truck or trailer. The onlypeople who can tell you what valve the vehicle manufacturer used based on a VIN are the vehicle dealers. With that said,there are other ways to determine which valve you need. You may find a label or a metal tag on the valve that has theOEM part number printed on it. Sometimes, the number is stamped right on the valve body. Raised casting numbers are usuallyno help at all. You"re looking for stamped numbers here.

If you can"t find any numbers, you can look for a match based on the pictures we provide here on AnythingTruck.com. This iseasiest if you know at least what type of valve you"re working with. Is it a relay valve or push-pull valve? If you have noidea what kind of brake valve you"re replacing, you will probably benefit from looking over the Bendix Air Brake Handbook.

We try to provide a comprehensive cross reference lists for each air brake valve we offer here, but there are always OE numberswe haven"t learned about yet. The list of pages below contains useful part number references from OE valve manufacturers. Youcan try your part number at the sites listed or just give us a call or drop us an email for help.Bendix Part Number SearchUse this if you have a Bendix part number and want to find their current number.

Determine the port(s) improperly emitting air pressure and perform the following service checks:Exhaust port leakage at rest - Disconnect the delivery lines. If the leak stops,inspect the device at the other end of the delivery line for leakage. If the leakagecontinues, inspect and repair or replace the leaking valve.

Always blow out all attaching lines and reservoirs when installing a replacement valve to purge any contamination from the system. Avoid using thread sealant or tape as excess material can itself contaminate the air device.

The most common cause of governor failure is contamination. Blow out all attachinglines, hoses, etc when replacing a governor. Make sure the reservoir pressure sensingline is routed from the reservoir so that no contamination may enter the line and passinto the governor. A replacement D-2 air governor can be found here.

Compressors that are passing excessive oil as evidenced by the presence ofoil at valve exhaust ports or seeping from air inlets is usually a result of:Restricted air intake - Check the compressor air filter and replace as necessary.Check the compressor air intake hose for kinks, excessive bends, and a minimum ID of 5/8".

Some browsers have a " Do Not Track" feature that lets you tell websites that you do not want to have your online activities tracked. These features are not yet uniform. Although we do not at this time honor “ Do Not Track” signals from a web site browser, we offer you a choice about whether to accept cookies from our website, and you may refuse, or later delete, cookies. Please refer to your browser’s Help instructions to learn more about cookies and other technologies and how to manage their use. If you elect to refuse or delete cookies, you will need to repeat this process each time you use a different computer or change browsers. If you choose to decline cookies, some of your online functionality may be impaired.

In addition, we may disclose information collected from and about you as follows: (1) you expressly request or authorize us to do so ; (2) we believe the information is needed to comply with the law (for example, to comply with a search warrant, subpoena or court order), respond to a government request, enforce an agreement we have with you, or to protect our rights, property or safety, or the rights, property or safety of our employees or others ; (3) the information is provided to our agents, third parties or service providers who perform functions on our behalf ; (4) to address emergencies or acts of God ; (5) in anticipation of and in the course of an actual or potential sale, reorganization, consolidation, merger, or amalgamation of all or part of our business or operations in which case your information may be provided to the purchaser or resulting entity ; or (6) to address disputes, claims, or to persons holding a legal or beneficial interest.

Under California Civil Code Section 1789.3, California users of the Services are entitled to the following specific consumer rights notice: The Complaint Assistance Unit of the Division of Consumer Services of the California Department of Consumer Affairs may be contacted in writing at 1625 North Market Blvd., Suite N 112, Sacramento CA 95834, or by telephone at (916) 445-1254 or (800) 952-5210.

As well, the compressor in the system is capable of pumping air pressure to 500 psi (3450kPa), which poses danger to both the driver and others around the vehicle.

The driver of a commercial vehicle must know that the safety valve makes the sound of a machine gun when it releases excess air pressure from the system.

Restore the like-new performance of your alcohol evaporator with a high-quality Haldex evaporator safety valve. Engineered by a brand with over 100 years of engineering expertise, this product is manufactured to meet or exceed OEM specifications in function, form, and fit.

The Newstar air brake safety valve is designed to prevent the air brake reservoir from bursting from overpressure. Its design and engineering matches original equipment specifications.

Ensure optimum safety for a vehicle and its passengers with the aid of impeccable, robust and premium air brake safety valve at Alibaba.com. These incredible brakes are sturdy in nature and are produced by improvising the latest technological inventions to ensure flawless performance. The air brake safety valve collections on the site are not just ideal for enhancing the safety standards of vehicle riding but also help in gripping the road firmly when used for ceasing movements. These air brake safety valve are sold by reliable and trusted sellers who are known to manufacture or supply brilliant products with outstanding after-sales services.

Brakes are an important part of any vehicle and nothing could be better for a vehicle other than the superior air brake safety valve at the site that come with enhanced braking systems capable of stopping the vehicle smoothly anytime and at any condition. These products on the site are equipped with all the latest features that aid in enhancing the performance and also last for a long time without compromising on the quality. Some of the air brake safety valve are equipped with hemispherical plugs that can ensure a smooth start for the engine and also help in maintaining the stability and reliability of the engines. These air brake safety valve are ideal for all types of vehicle models and are highly temperature resistant as well.

Alibaba.com brings the latest air brake safety valve for vehicles in distinct capacities, features and material qualities depending on a user"s requirements. These air brake safety valve are available in metal versions and ceramic versions depending on the models and are perfect for heavy-duty uses. The air brake safety valve and brake pads of these braking systems are sustainable and are wear-resistant with the efficacy of sudden braking in critical terrains without the chance of any mishaps.

Grab these products at Alibaba.com from the broad ranges of air brake safety valve that can fit into one"s budget and other requirements. These products are customizable in accordance with vehicle requirements and are available as OEM orders. After-sales services that may include servicing, maintenance are also offered on plenty of the products available here.

All product codes and part numbers displayed within this website are for cross reference purposes only. Where vehicle manufacturers are mentioned in association with any part numbers, this is purely an indication of the suitability of the part for that type of vehicle. No inference, insinuation or implication is intended as regards the origin or manufacture of any parts promoted, advertised or sold by FGH Air Brake Ltd.

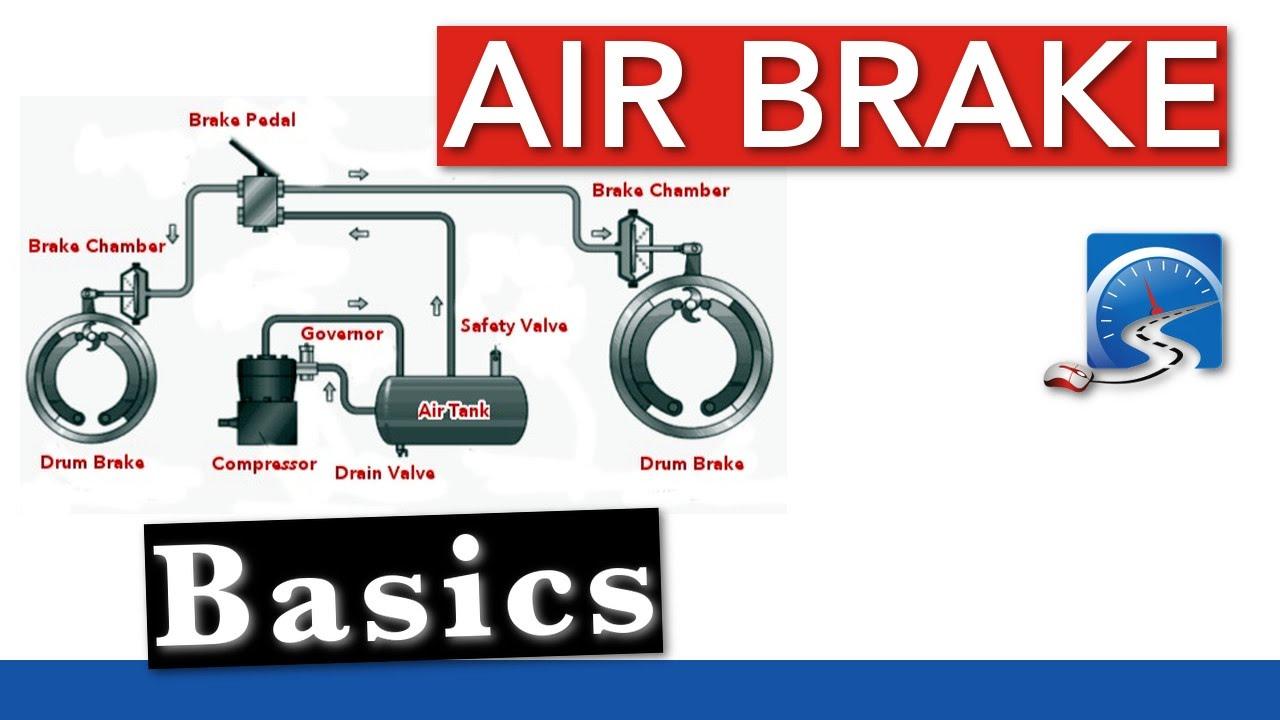

These subsystems are integrated into a complex web of checks and balances as shown in Figure 2-2, in which compressed air stops the vehicle. As a guard against over-pressurization, the reservoir has a high pressure relief valve called a pop-off valve that opens and releases air pressure if it was to ever reach 150 psi. If the governor is working properly, pressure will never rise enough in the system for this safety valve to blow. The one-way check-valve is one of many found in the system which allows air to flow in only one direction. This is a safety feature. In case a leak occurs, the entire air system would not be depleted.

The pressurized air leaving the compressor is approximately 300 °F and contains water and oil vapor which must be removed. If water vapor and impurities continued through the system, they could damage vital components, most importantly the valves. The air valves contain rubber o-rings that can be damaged by the acid in the oil. Impurities can cause the valves to stick and in cold weather ice can form from the water vapor and block the air flow through the hoses.

To avoid these potential problems, water and oil are removed from the air by the air dryer as shown in Figure 2-4. The air dryer is installed between the compressor and the wet tank. The dryer is usually mounted on the frame rail of the tractor. The condensation type air dryer operates by accepting the hot air from the compressor and cooling it, allowing the water and other impurities to condense. The condensate is expelled out the purge valve whenever the air compressor unloads. In cold climates, the air dryer has an internal heater to prevent the purge valve from freezing. The air leaving the dryer is free of most of the impurities that can affect the brake system.

Most modern trucks use a desiccant air dryer.In this air dryer, the water is stripped from the air by running it through a bed of beads called the desiccant. The beads attract moisture to their surfaces and hold it there. The process called regeneration removes the moisture from the desiccant by a blast of dry air from the air tank whenever the governor opens the unloader valve. Regeneration dries thousands of desiccant beads in about 2 seconds. The water from the beads drops into a holding tank and is vented to the atmosphere through the purge valve when the air compressor unloads.

As discussed above, the air leaving the air compressor is hot, and as it cools the water vapor condenses. Should this vapor find its wayinto the brake lines of valves, the brake system could be rendered inoperative

An installation option to prevent this is an alcohol evaporator.An alcohol reservoir is attached to the air compressor so that a small amount of alcohol vapor mixes with the compressed air. The water that eventually condenses out contains a small amount of alcohol which lowers the freezing point of the water, thereby preventing icing in the air lines and at the valves. Of course, this only works if the driver remembers to refill the reservoir before the water freezes. Due to improvements in air dryers, alcohol evaporators are quickly becoming obsolete.

The compressed air exits the air lifter and enters the first air tank which is called the wet tank because additional water vapor condenses on the cool tank walls.

At least once a day the wet tank should be drained by manually opening the valve on the bottom of the tank. Air dryers do not eliminate the need to drain the wet tank.

Upon leaving the wet tank, the pressurized air divides into two separate lines, each leading to a reservoir tank (dry tank). One line leads to the rear axle reservoir, which powers the rear tractor brakes. The other leads to the front axle reservoir, which powers the front axle tractor brakes and all air operated equipment, such as the windshield wipers, gauges and horn.

These dry tanks, shown in Figure 2-5, function as storage units for the compressed air, and similar to the wet tank, have drain valves on the bottom for drainage of any oil or moisture that escaped the wet tank . These air tanks are protected by one way check valves which allow air to flow only into the tank, but never back out. This not only prevents the backwash of impurities, but also protects against air pressure loss within the system.

As a historical note, when air brake systems began to be used, there was only one wet lank and one dry tank. A second dry tank originated as an optional feature called a California tank because of a law originating in that state. This law required a backup air tank if the primary tank failed.

Eventually air brake manufacturers made the secondary tank a standard component and brake systems evolved into today’s three -tank system. To maximize available space, some tractors have multiple compartments within a single tank. One large tank is separated into smaller sections by baffles or dividers. Each section then functions as an individual tank. The two reservoir tanks form the basis of what is known as the dual circuit brakesystem by which modern trucks operate.

If a failure occurs in either of the reservoir tanks, a double check valve positioned between them seals off the failed tank and its air line, thus preventing the air supply of the intact tank from being depleted and preserving the remaining air pressure for use by the operational tank.

The Federal Motor Vehicle Safety Standard 121 has required the dual circuit system for all vehicles that use air brakes that have been built since 1975.

It’s impossible to fix something without understanding how it’s supposed to work. Brake system repair decisions can be difficult to make, and costly to execute, without a basic understanding of system components and their operation.

The following discussion details the operation of a typical S-cam air brake system on a single-axle tractor and trailer (see diagrams). Systems vary somewhat, depending on the manufacturer and on optional equipment and configuration, but all can be thought of as comprising three sub-systems.

The supply system, as the name implies, supplies pressurized air – the energy source for any air brake system. The key player in this sub-system is an engine-driven air compressor (1). A governor (2), which may be integrated with the compressor, controls the compressor’s output by unloading or cycling it. Pressure is generally maintained at 100 to 120 psi, and is monitored by the driver by means of dash-mounted pressure gauges (3). A low-pressure switch (4) senses system pressure and sends an electrical signal to a dash light or buzzer to alert the driver when air pressure falls below 60 psi.

Reservoirs, three per tractor and, usually, two per trailer, store the compressed air until it is needed to actuate the brakes. Check valves (5) prevent pressurized air in the primary and secondary reservoirs from passing back through the compressor while it is not running. A safety or “pop-off” valve (6) is usually installed in the reservoir closest to the compressor. In the event of over-pressurization, the safety valve allows air to escape, preventing damage to air lines, reservoirs and other components.

The reservoir closest to the compressor is often referred to as a wet tank, because that is where atmospheric moisture – the No. 1 enemy of air brake systems – condenses in the greatest quantities. Reservoirs are equipped with drain valves (7) so water can periodically be eliminated. These can be manually or automatically operated. Alcohol is sometimes introduced into air systems operating in cold climates to prevent water from freezing and plugging air lines.

An air dryer (8) is a device that condenses and eliminates most of the water from an air system. An air dryer is a canister that usually contains a bed of desiccant material. As air passes through, the material captures moisture and blow-by from the compressor.

The control system consists of a series of pneumatic valves that direct air and control pressure to appropriate components. Although discussed here individually, different valves are often combined in a common housing.

The main valve is the dual-control foot valve (9), so called because it is actually two valves that operate simultaneously, in response to input from the driver’s foot at the brake pedal.

Two valves are necessary because, after the wet tank output, the system splits into two separate brake circuits. Air downstream of the wet tank is divided between primary and secondary reservoirs. The split system ensures that, in the event of a failure, the entire system will not become inoperative, and the truck can be brought to a controlled stop.

When the brake pedal is depressed, air flows from the primary reservoir and through the primary portion of the dual-control foot valve to actuate the rear axle brakes. Meanwhile, air flows from the secondary reservoir, through the secondary portion of the dual-control foot valve, to actuate the front axle brakes. A two-way check valve (10) senses primary and secondary supply pressure, and allows the dominant pressure to actuate the trailer brakes. Primary air can also be manually supplied to the trailer by means of a hand valve, (11) usually located on or near the steering column.

Relay valves (13) are used on trailers and on the rear axles of long-wheel-based tractors to minimize delays of brake application due to length of plumbing. These valves are directly supplied with unmodulated air pressure, and use air from the dual-control foot valve or manual trailer valve as a signal to quickly direct air to the brakes they serve.

Relay valves come in a variety of “crack” pressures. Crack pressure is the air pressure value required at the input from the foot valve before the relay valve will send air pressure to the brakes controlled by that valve. Crack pressure is an important element of brake timing and balance, and is determined – axle by axle – by how heavily loaded the axle served by a valve is, how big its brakes are, and how aggressive the linings are on those brakes.

A valve that cracks at too low a pressure for a given axle can cause premature application, wheel lockup and trailer pushing, if the affected axle is on the tractor. Too high a crack pressure can cause delayed application, insufficient braking and trailer pushing, if the affected axle is on the trailer.

After a stop, when the driver lifts his foot from the brake pedal, a quick release valve (14) allows brake actuation air to be quickly exhausted near the brakes it serves, rather than having to travel back through the supply line, thus speeding brake release time.

Dash-mounted valves (15 and 16) control air pressure to the parking brakes. In most cases, these are spring brakes, so called because when no pressure is supplied, the brakes are applied by means of a spring. Air pressure, when applied, overcomes spring force and releases the brakes. More on that a little later.

A tractor protection valve (17) senses pressure in one or both lines that carry air to the trailer. These lines are connected to the trailer by means of quick-connect air fittings called gladhands. When there is no pressure in the line(s) – due to trailer breakaway or a gross air leak in the trailer circuit – the valve closes to maintain air pressure in the tractor circuit. In everyday use, the valve also works in conjunction with the dash-mounted trailer parking brake valve (16), to shut off air to the trailer circuit before disconnecting tractor from trailer.

The spring brake (or multi-function) valve (18) limits the air pressure used to keep the trailer parking brakes off and, by means of an integral check valve, isolates a failed reservoir, which would otherwise cause the parking brakes to be automatically applied.

Foundation brakes are where properly supplied and controlled air is used to stop a vehicle. When the brake pedal is depressed, air pressure is directed to brake chambers (19) at each wheel end. Brake chambers consist of a pressure housing, diaphragm and pushrod. As air pressure is exerted on the diaphragm, the pushrod on the other side of the diaphragm is extended. The force the pushrod exerts is the product of the amount of air pressure applied in psi, and the area of the diaphragm in square inches. For example, 60 psi, applied to a chamber with a 16-square-inch diaphragm would create a force at the pushrod of 960 pounds. A 60-psi application to a chamber with a 30-square-inch diaphragm would yield 1,800 pounds of pushrod force. Improperly matched brake chambers, therefore, can cause severe brake balance problems.

The shaft, in turn, is connected to an S-shaped cam between the brake shoes. As the shaft rotates, so does the cam. The brake shoes are forced apart and against the brake drum, creating the friction needed to slow the vehicle. The amount of friction produced is determined, in part, by the size of the brakes, the coefficient of friction (aggressiveness) of the brake lining material, and the mass and heat-rejection potential of the drum.

The slack adjuster is equipped with an adjusting mechanism to compensate for brake lining wear. If this were not so, the pushrod would be required to extend farther and farther as brake lining wear progressed. It wouldn’t take long before the pushrod would not be able to extend far enough to apply the brakes. Modern brake adjusters accomplish this automatically.

The brake adjuster’s length and the brake chamber’s size are two variables commonly altered to meet braking requirements. The product of these two values is expressed as the “AL factor.” This factor, when multiplied by 60 psi air pressure, is the industry standard for braking calculations.

In addition to applying the service brakes used in everyday driving, the brake chambers on the rear tractor axles and on the trailer axles apply the parking brakes. These brake chambers, (spring brakes), incorporate a second chamber, containing a second diaphragm and a powerful spring.

When the vehicle is in use, the dash-mounted parking brake valves are in the “run” (pushed-in) position. This supplies air pressure to the spring chamber, on the side of the diaphragm opposite the spring. Air pressure acting on the diaphragm compresses the spring, and the parking brakes are held off. This does not affect the operation of the service brakes.

When the vehicle is parked, the dash valves are pulled out. This exhausts spring brake hold-off air, allowing the spring to apply the parking brakes. In the event of a loss of system pressure, hold-off air pressure is overcome by the parking brake spring, and the brakes are automatically applied to provide emergency stopping.

Per federal regulations, the parking brakes must be able to hold a vehicle, loaded to its gross weight rating, stationary on a smooth, dry, concrete roadway, facing uphill or downhill, on a 20 percent grade.

We hope that this overview of air brake basics helped clarify your understanding and provide a grounding for dealing with more complex braking topics to be covered in future issues of CCJ.

8613371530291

8613371530291