fire safety valve for oxygen manufacturer

All DirectHomeMedical offers online support through our website, live chat and toll free support during normal business hours, and email support 24-hours a day. Please contact us if you have any questions about our services or the products we sell. DirectHomeMedical.com is authorized and approved, by the manufacturers we represent, to sell and ship products to end-users residing in the United States, not to other third parties or businesses. A prescription is required for the purchase of certain products on this site. All products offered are sourced directly from the original equipment manufacturers or their representatives. PROPOSITION 65 WARNING: Some products on this site may contain a chemical known to the State of California to cause cancer, birth defects or other reproductive harm. COPYRIGHTS: Selected product images and descriptions used throughout this site are used with the permission of the copyright holders. All ResMed Product Images © ResMed. All Philips Respironics Product Images © Philips Respironics. All Fisher & Paykel Healthcare Product Images © Fisher & Paykel Healthcare. Site Design & Content Copyright © 2004-2018 DirectHomeMedical. Respironics recommends that new patients purchase their devices, masks and initial accessories from a homecare company that can provide an individualized patient equipment set-up, clinical and after-sale support, and a program to assist patients with therapy success. All products and services advertised on this site are provided by DirectHomeMedical.com or its designates. DirectHomeMedical occasionally offers discounts via coupon code. Coupon codes cannot be combined and there is a limit of one coupon per order. DISCLAIMER: Information on this website is informational only and should not replace the advice of a physician.

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

An increased risk of fire is an unfortunate and all too common problem associated with oxygen therapy. Firesafe™ devices help reduce this risk by isolating the oxygen flow and extinguishing a fire tracking back along the oxygen delivery tubing.

Firesafe™ devices can be installed directly in the oxygen delivery circuit and at the interface with the oxygen supply equipment, providing the following benefits:

The Firesafe™ MKII Cannula Valve acts like a thermal fuse protecting both patient and oxygen source from propagating fire. To prevent incorrect installation, the valve is bi-directional, allowing it to be fitted in either direction.

The Sunset Healthcare OxySafe Firesafe Cannula Valve Helps protect against oxygen tubing fires using a thermal fuse designed to stop the flow of gas in the event that the downstream oxygen tubing is ignited. Thereby, the product helps to improve patient safety by tremendously reducing the impact of oxygen-aided fires with the Firesafe Cannula Valve.

Install two OxySafe valves per patient, one as close to the patient as possible and one as close to the oxygen source as possible. This way, both the patient and the source of oxygen are protected, minimizing risk of a disastrous fire. When installing the OxySafe close to the patient, we recommend using a cannula without a built-in supply tube so the valve can be as close to the patient as possible.

Manufacturer of oxygen valves. Oxygen clean valves are available in 2-way or 3-way, normally-closed or fully ported configurations. They supply safety of operation in oxygen applications with quick response, low power consumption, long life, & unlimited flexibility in design. The valves are ultrasonically cleaned, assembled, inspected & tested in an enclosed controlled area with a state-of-the-art positive pressure HEPA filtration system.

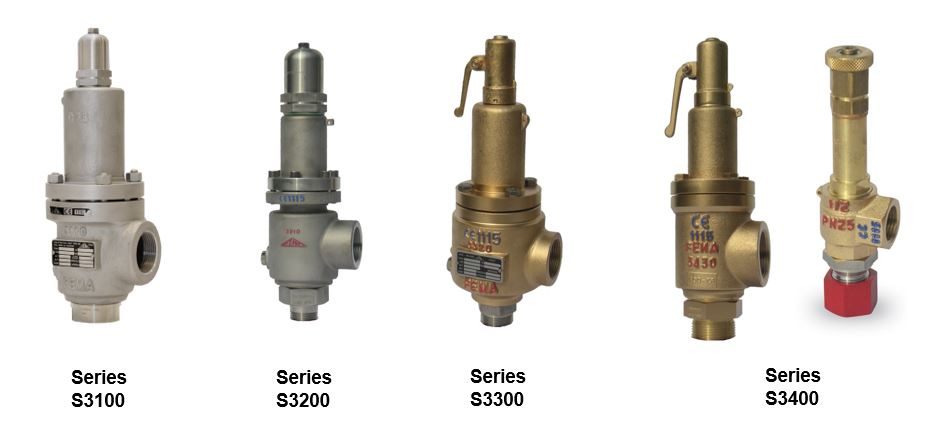

Manufacturer & custom manufacturer of valves including oxygen valves, air line valves, air compressor valves, & air pressure control valves. Pipe size ranges from 1/2 in. to 3 in. Pressure ranges from 150 psi to 300 psi . Maximum fluid temperature is 400 degrees F. Available in bronze & stainless steel. Suitable to control the flow of steam, corrosive fluids, deionized water, condensate, ammonia, vegetable oils, fuel oils, cryogenics, & flammable liquids.

ISO 9001:2015 certified. manufacturer and designer of valves including liquid oxygen valves. Flange, lined pipe, sanitary, union, straight sided and glass pipe insert, sanitary cartridge, low and high pressure, socket weld, connector, bushing, horizontal, vertical flanged, miniature and tubing valves are also available. Materials include carbon and stainless steel, high and non-ferrous alloys and titanium and nickel alloys. Meets NACE standards. CE certified. Made in the USA.

Manufacturer of air diaphragm valves. Various materials include cast iron, ductile iron, stainless steel, PVC, bronze and aluminum. Petroleum, chemical, water treatment, filtration, foods, beverage, pharmaceuticals, utilities and other industries served. Meets ASTM standards. On-time shipment.

Distributor of oxygen valves. Check valves, solenoid valves, ball valves, cryogenic valves, relief valves, needle valves, plug valves, actuated valves, diaphragm valves, pressure regulators, cylinder regulators, back pressure regulators, control valves, & tube fittings. Markets served include industrial gas, chemical, medical, power, marine, oil & gas processing.

Manufacturer of standard and custom oxygen gas check valves. Available in 12 mm dia. nominal bore, 6,090 psi operating pressure and 41 to 140 degrees F operating temperature. Features include wear and corrosion resistance, male thread inlets, outlets and EPDM sealing. Also suitable for mounting into gas mixing plants and vacuum applications. CE certified.

Manufacturer of process equipment including valves suitable for controlling pressure. Types of valves include air & hand operated, air pressure control, back pressure, bleed, check, drain, hydraulic flow control, pneumatic, relief, sequencing, two, three & four way & unloading valves. Specifications of valves include 6,000 psi pressure rating & 1/4 in. & 1/2 in. pipe sizes. Valves are available with anodized aluminum bodies, brass & stainless steel internals & Viton® & KEL-F seals.

Distributor of ammonia and oxygen ball valves made from alloy 20, bronze, ductile iron, Hastelloy®, carbon steel, stainless steel, titanium and PVC. Features vary depending upon model, including stem seal design, conventional floating or ceramic balls, PEEK seats/seals and corrosion, impact and high thermal shock resistant balls. Bonnet options such as extended and bellows stems provided. Automation services and stock items available.

Stocking distributor of valves available in forged steel, cast steel, chrome molly, Monel®, Hastelloy® B & C, cast iron, ductile iron, bronze, brass & PVC. Electric, hydraulic & pneumatic actuations. Modifications include flange ups, conversions, coatings, hydro testing, packing changes & trim changes.

Distributor of valves for medical and gas distribution industries. Ball, shut-off, check, zone, selector and gate valves are available. Replacement tilt valves for helium are also offered. Compatible with gas and oxygen. Features of ball valves include three-piece or full port design, quarter-turn, threaded and blowout proof steams.

Distributor of safety, pressure reducing, and relief valve products for industrial and commercial applications, including steam, air, liquid, cryogenics, and non-hazardous gases. Safety and relief valve products range in size from 1/4 inch NPT through 6 inch flange and are suitable for services ranging from cryogenic to 850 degrees F at set pressures ranging from vacuum to 6,500 psig. Available in a wide range of materials including brass, bronze, carbon steel, stainless steel, cast iron, and aluminum.

Distributor of interior, airframe, cockpit and engine parts for the aircraft industry. Parts such as latches, filters, actuators, dampers, clamps, sensors, connectors, contacts, valves, relays, heaters, cables, switches, insulation blankets, displays, headsets, seats, indicators and exterior lights are available. Bin management, custom kitting, vendor consolidation, stocking solutions, consignment programs and supply chain management also provided. Capabilities include waterjet machining, horizontal and vertical CNC multi-axis machining, high speed machining and large-part precision machining, CNC knife cutting, bonding, milling and turning. 24/7/365 AOG support services are offered.

Manufacturer and distributor of metal-seated valves for oxygen processing applications. Features include fire resistant all-metal construction, seat overlays, resilient metal seal ring and spiral wound gaskets. Specifications include operating temperatures ranging from -254 degrees C to 800 degrees C and pressure up to 160 bar. Used to withstand high pressure loads and wear. Meet ASME standards.

Anderson Greenwood, Cash Valve, Clarkson, Crosby, FCT, Fasani, Hancock, K-Ball, KTM, Kunkle, Neotecha, Raimondi, Sapag, Sempell, Vanessa, Varec, Vonk, Yarway

Manufacturer of standard and custom oxygen service floating and trunnion ball valves. Available in a variety of sizes. Cryogenic and high temperature metal seated configurations are also offered. Features vary depending upon model and include double blocks, bleed design, renewable seats and extended bonnets. Serves oil and natural gas, power, chemical, refineries, petrochemical and piping plants industries. CE certified.

Manufacturer of oxygen valves made from chrome plated brass. Available in 9/16 in. sizes and maximum operating pressure up to 200 psi. Meets AWS standards. FDA approved.

Manufacturer of standard and custom non-rotating oxygen valves made from Monel® and 316 stainless steel. Available with operating pressure up to 6,000 psig at 70 degrees F and -20 degrees F to +250 degrees F operating temperature. RoHS and REACH compliant. Meets ASME and ASTM standards. CSA approved.

Distributor of oxygen butterfly valves. Available with stainless steel rings and plates. Various capabilities include cutting, threading, grooving, bending, coiling and welding. Stock items available.

Distributor of valves. Types include operating, oxygen, butterfly, sampling, sluice and knife gates, and regulating valves. Industries served include petrochemical, biotechnical, wastewater, pharmaceutical, medical, commercial, food & beverage, and OEM.

Custom manufacturer of air drain, ball, bleed, butterfly, check, gate, swing and globe valves. Made from brass, bronze alloys, carbon steel and stainless steel materials. Available in flange bolt, NPT, solder or sweat end port connections with PEEK and PTFE seat materials. Suitable for hydrazine, liquid oxygen, methyl bromide, slurry, sulfuric acid, vapor and wastewater media. Prototype to high volume production available. Secondary services such as inspection, repair and testing are also offered. Serves the aerospace, automotive, medical, mining, marine, military, petrochemical and transportation industries. Blanket orders are accepted. Rush and emergency services are offered.

Manufacturer of standard and custom oxygen valves. Features vary according to model, and can include redundant construction, welded structure, regulation accuracy within +/-2.5%, integrated filter, and more. Manufacturing capabilities include machining, assembly, and testing. Materials worked with include titanium, Inconel®, aluminum, Monel®, stainless steel, and more. Engineering focuses include cryogenics, hypergolics, hydraulics, electromagnetics, pneumatics, piezoelectric, and more. Services include design and solid modeling. Analysis services include finite element, stress, thermal, vibration, computational fluid dynamics, electromagnetism, math, fracture, thermal stress, and more.

ISO 9001:2015 certified. Manufacturer of standard and custom high pressure, cryogenic and bronze ball valves for ammonia, oxygen, hydrogen, methane, nitrogen, fluorine and LNG. Features vary depending upon model, including direct mounting pads, anti-static devices and screwed, socket weld and raised flange ends. Meets ASTM, ANSI, API and ASME standards. RoHS and REACH compliant. FDA, FM and NSF approved. UL listed.

ISO 9001:2008 certified manufacturer & distributor of valves including gas valves. Features of gas valves include adjustable pressure gauge from 0.2 Mpa to 0.5 MPa, inlet pressure from 5/8 - 18 UNF to 1/2 - 20 UNF, flow rate up to 15 L/m & operating temperature form 0 degree F to 40 degree F. Valves available in brass & aluminum bodies. Can be used for gases including N2, Ar, CO2, N20, He, air & gas mixtures.

Custom manufacturer of cam operated butterfly valves. Features include bubble tight closure, transition and rotary motion. Suitable for managing high pressure cryogenic fluids such as liquified natural gas, methane, oxygen, hydrogen and nitrogen. Secondary services such as design, engineering, rapid prototyping, testing and fabrication are also offered. Serves aerospace, chemical, petrochemical, mobile pipeline, OEM and air separation industries. ITAR registered.

Custom manufacturer of electromechanical and electromagnetic products. Vacuum or bi-stable isolation, mist dispenser, miniature carbon dioxide, rectified electromagnetic and two-way compact solenoid valves are offered. Ether injection, door latch, linear sorting, paintball marker, elevator, oscillating and rotary solenoids are available. Pivot or dual solenoid valve actuators, encapsulated or dual wind sensor coils, holding magnets, buzzers, vibrators and milking pulsators are also sold. Serves the transportation, appliance, agricultural, medical device, industrial process control, office, food service, sports recreation, HVAC, health and beauty, pharmaceutical, and postal sorting industries.

Manufacturer of standard & custom oxygen valves & liquid oxygen valves. Cryogenic 3 piece valves, cryogenic control valves, cryogenic diverter valves, cryogenic flanged valves, flanged full port ball valves & oxygen service ball valves are available.

The sealing materials must be carefully selected when manufacturing oxygen valves. The sealing materials used at Hartmann have all been approved by the German Federal Office for Materials Research (BAM) in regard to oxygen burnout safety for the related pressure and temperature range.

Already natural grease like from our hands may be sufficient to cause ignition of materials in oxygen environment. Therefore, we have strict rules for the production of the valves, which are fixed in our oxygen work instruction, such as ultrasonic cleaning and the assembly and testing of the fittings in a separate oxygen room. In addition, only special lubricants suitable for oxygen are used in very small amounts during assembly, and the leak test that follows is carried out exclusively with gas. After successful testing, the oxygen ball valves will be packed in welded foil and separately marked to indicate that they are free of oil and grease.

Fusible link valves are designed to automatically shut off any gas or liquid in the pipeline when the fire is present. This ensures that fires don’t spread and offers better performance than standard shut-off valves.Heat-sensitive elements will shrink and cause the fusible top work assembly to open, cut off fluid flow through a pipe, and prevent fuel leakage.

The fusible link serves as a pressure release and shutoff valve used to prevent the overpressurization of equipment and/or piping systems. It allows pressurized fluid to discharge through a pipe into the atmosphere or into another section of piping.

A fire-safety valve with a fusible link is an important safety device in the event of a fire on naval vessels, as a fire extinguisher is not sufficient on its own to prevent the risk of explosion from overheating oil tanks.

Contact us today if you would like more information about our fire-safety valves with fusible links! We offer competitive pricing and excellent customer service! You can get fusible link valves from THINKTANK, and build your own brand.

This control valve is used in control circuits for neutral and aggressive media in the chemicals, process engineering and plant construction industries. Positioners (pneumatic or electro-pneumatic) are used for precise ...

The combination of the sliding gate valve with piston actuator and integrated positioner offers a compact valve assembly, chracterized by a high control quality and control dynamics. Due to the direct ...

This control valve, with NAMUR interface for universal positioner assembly, is suitable for a wide range of industrial applications. Media such as steam, liquids, gases, etc. are easy to handle. This valve ...

... customization of the valve flow characteristic allowing users to "shape" valve response to their needs. This feature makes it an ideal solution for parallel valve positioning systems ...

The Worcester C4, C44, C51 is a 3-piece and flange cryogenic ball valve specifically designed for use on liquid gases such as nitrogen and oxygen. It offers high-performance, shutoff valves ...

... eccentric butterfly valve Elara is available in forged or cast executions and different body, disc and seat materials. Application fields cover power generation, district cooling and heating as well as chemical processes ...

Series FNV Needle Valves feature a forged body, integral bonnet design with PTFE and metallic wafer stem packing. This provides leak-tite service from vacuum to the maximum operating pressure. Series FNV are available ...

... -OFF valve for: chemical products, for water and pneumatic installations, gas, water, vacuum. For steam applications, working pressures may be reduced and special seals required.

... our portfolio by adding our long term proven series 984 in a special prepared version for oxygen. These valves will be equipped with suitable grease for oxygen and sealed in single plastic ...

These cryogenic globe valves have a pneumatic actuator at PN 50. They have a bronze body and stainless steel topwork, with internal parts made from bronze. The actuator can be spring closed, air opened or on the contrary. ...

The SIRAL"s V 3000 series degreased valves are used for oxygen applications, with connections from ¼” to 2”, and FF threads according to the ISO 7/1. They can operate on pressures from PN 16 to PN 63, ...

... butterfly valve with a one piece body and an eccentric soft seat. It is specially designed for industrial gas applications featuring long-lasting tight shut-off capability, excellent flow characteristics and long service ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale oxygen safety valve on Alibaba.com. When you search for oxygen safety valve and related items, you will be able to find many types of oxygen safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of oxygen safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Keep oxygen cylinders and vessels in a well-ventilated area (not in closets, behind curtains, or other confined space). The small amount of oxygen gas that is continually vented from these units can accumulate in a confined space and become a fire hazard.

Oxygen cylinders and vessels must remain upright at all times. Never tip an oxygen cylinder or vessel on its side or try to roll it to a new location.

Always operate oxygen cylinder or container valves slowly. Abrupt starting and stopping of oxygen flow may ignite any contaminant that might be in the system.

Keep all grease, oil and petroleum products (even small amounts) and flammable materials away from your oxygen equipment. Some organic materials can react violently with oxygen if ignited by a hot spark.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

An oxygen firebreak, also known as a fire stop valve or fire safety valve, is a thermal fuse designed to extinguish a fire in the delivery tube being used by a patient on oxygen therapy and stop the flow of oxygen if the tube is accidentally ignited. Oxygen firebreaks are fitted into the oxygen delivery tubing close to the patient, typically around the patient"s sternum where the two nasal cannula tubes join and connect to the delivery tubing.

Oxygen is not flammable, but when it is present in increased concentrations it will enable fires to start much more easily. Once a fire has started, if supplemental oxygen is present it will burn more fiercely, based on the principle of the fire triangle. Materials that do not burn in ambient air may burn when there is a greater concentration of oxygen present than there is in air.

Once a fire has started in the patient"s nasal cannula it will track back towards the oxygen source and if not stopped may lead to a ‘whole house’ fire. Whole house fires are directly correlated with single or even multiple deaths. According to the US National Fire Protection Association (NFPA), 25% of oxygen fires get beyond the immediate surrounding area to become ‘whole house’ fires.

While an oxygen firebreak / thermal fuse cannot stop the initial ignition, it can limit the potential for whole house fires, more serious injury and death. Firebreaks / thermal fuses can also buy more time for a patient and other individuals in the building to escape, and limit the material cost of fire damage.

A study, The prevalence and impact of home oxygen fires in the USA, published in September 2019, analysed media reports of home oxygen fire incidents between December 2017 and August 2019. The report found 311 incidents, resulting in 164 deaths, equivalent to one patient death every four days. It also found that a third of reported incidents referenced exploding cylinders, posing a significant risk to third parties, including emergency services. The estimates that there are between 100 and 150 deaths every year from home oxygen fires in the US, describing it as a ‘material health issue’.

Further research published in November 2021 confirmed that home oxygen fires remain a material public health challenge. The study, Firebreaks: a risk-based approach to safer home oxygen delivery examined media reports of home oxygen fire incidents between August 2019 and July 2021. 256 incidents and 152 deaths were recorded in this 23-month period, equating to a death every four days, consistent with the previous research. Over the total study period of 3.5 years, there were 567 fires involving home oxygen and 316 deaths, including two firefighters who lost their lives. The new report also examines the significant impact of burns resulting from home oxygen fires, drawing on a study by Wake Forest Baptist Medical Center in 2020 which found home oxygen fires cause at least 1,000 burn injuries per year.

In 2008 the NFPA published a report suggesting that there are 46 deaths each year in the US from 182 fires. The report also stated that US hospital emergency rooms deal with an average 1,190 cases of burns each year as a result of home oxygen fires. However, the NFPA describes these statistics as "likely underestimates".

Further analysis by Marty Ahrens on behalf of the NFPA in 2017 recorded a likely average annual death rate for home fires involving oxygen administration equipment of 70 people (or 3% or all home fire deaths), based upon figures between 2011 and 2015. The report also suggested that these fires or burns are becoming more common.

The United States Fire Administration (USFA) said in a 2015 report that "While no one factor is solely responsible for the increased fire risk to older adults receiving home health care, smoking in the presence of oxygen is recognized as one important problem."

A study of home oxygen therapy patients in the Veterans Health Administration between 2009 and 2015 examined 123 cases of reported adverse events related to flash burns. It found that 100 cases (81%) resulted in injury, and 23 (19%) resulted in death. Although 89% of veterans claimed to have quit smoking, 92% of burns occurred as a result of smoking.

In July 2022, the International Association of Fire Chiefs (IAFC) adopted a position statement on home oxygen fire safety that recommended the use of firebreaks.

Not all European countries monitor data on the number of fires that occur as a result of home oxygen. Despite a European Union Medical Device Directive requiring incidents to be reported to national vigilance authorities, there is often inadequate coordination to publish the information centrally.Bundesinstitut fur Arzneimittel und Medizinprodukte, BfArM) it is likely that such incidents are grossly under-reported.

A white paper report, published by BPR Medical in April 2022, found that 23 deaths from home oxygen fire incidents in France and Italy, had been reported by the media between 2017 and 2021. By contrast, data from the European Industrial Gases Association (EIGA), reports home oxygen fires caused 15 fatalities between 2013 and 2017 across 16 countries, suggesting significant under-reporting of the issue.

In England and Wales, central reporting of adverse incidents is a requirement of the NHS Service Specification for Home Oxygen. After firebreaks became mandatory in 2006, the average number of deaths by fire was 0.36 per thousand patients per year. In the US, where firebreaks were not required, almost twice as many patients (0.62 patients per thousand) died.

In 2018, a freedom of information request to all clinical commissioning groups in England (where firebreaks are mandatory) revealed that during the five years between 2013 and 2017 inclusive, 63 serious incidents involving oxygen fires were recorded and just one fatality. 73% of CCGs, representing 71% of patients in England, responded to the request. When the results are extrapolated to cover the whole patient population of 81,000, the figures are 89 incidents and 1.4 deaths.

78-year-old famous Italian artist Luciano Ventrone died in his house in Collelongo due to an oxygen tank explosion. The man was under oxygen therapy due to respiratory problems, and his attempt to light up a cigarette caused the oxygen tank to explode.

Rober F. Wiglesworth (60-years-old) died after suffering burn injuries that stemmed from smoking a cigarette while being on oxygen. The Lehigh County coroner says that Wiglesworth died after receiving 2nd-degree burns and complications from obstructive pulmonary disease (COPD) one week earlier.

Floyd E. Shoop (68-years-old) died following an apartment fire in Vancouver. The fire department responded to the fire, and Shoop was found dead in his bedroom where the fire originated. Officials state that Shoop was a smoker and was on medical oxygen. Another person suffered from smoke inhalation and was hospitalised. Two cats were killed. The fire caused an estimated $203,000 in damage.

75-year-old Michael Richard Praglowski died in a house fire. Crews were called and discovered Praglowski unconscious inside a second floor bedroom. Praglowski later passed away in hospital. Investigators believe the fire was accidental and was caused when Praglowski was smoking while hooked up to an oxygen tank.

Bernardine Crittenden (85-years-old) died in a house fire in Wellington caused by her smoking a cigarette while being on oxygen. The fire caused roughly $50,000 in damage. By the time firefighters arrived, the fire had “burned itself out after causing considerable fire damage to the living room”. The woman was found dead.

A 87 year-old woman was severely injured in a fire that occurred at a care-home in Giromagny. The woman attempted to light a cigarette up while being on oxygen, which resulted in big flames burning her severely on the face and hands. She was rushed to hospital. This incident occurred under a week after an appointment with an oxygen-safety company was cancelled, raising concerns amongst family members of residents.

Two people were killed and six injured in an apartment complex fire, 48 year old Andrew Thornburg and 56 year old Richard Wilkinson. A number of senior citizens live in the apartments many of whom use walkers and wheelchairs making the task of evacuating the residents harder for fire crews. The fire is believed to have been caused by "smoking materials", with many of the residents understood to be home oxygen users."

43 year-old firefighter David Fischer was killed when a propane tank exploded during a fire. Home oxygen patient Raymond Joseph Bachmeier (82) was also killed in the incident. Authorities said that the fire was caused by "a cigarette being smoked in bed while on oxygen."

54-year-old Caroline Murphy died as a result of health complications from burns suffered in her home when her home oxygen equipment caught fire while she was using an e-cigarette.

A woman died in a fire which started while she was smoking and simultaneously using her oxygen cylinder. Her husband also died trying to escape the blaze.

A 60-year-old wheelchair-using patient, described as a "big smoker", died when his liquid oxygen dewar exploded following a nighttime fire in his apartment. His wife also suffered injuries.

A patient died and an apartment was destroyed after medical oxygen cylinders exploded, leading to a fire. Fifteen other residents had to be relocated after the incident.

Patient Jackie Hisle Jr. was sentenced to ten years’ imprisonment on three counts of manslaughter after an incident in which his son, Donald Hisle, and two other residents were killed and six others were injured. Mr Hisle Jr. was smoking while using an oxygen concentrator, despite warnings.

A jury awarded $2.5 million in damages against Apria Healthcare after the death of 72-year-old Jimmy Kelley from Knox County. The award was reduced to $1.275 million after the jury found Kelley to be partly responsible. Mr Kelley, a smoker, also used a space heater in a camper van where oxygen cylinders were stored.

Before placing a new concentrator on the market, all oxygen concentrator manufacturers need to make a 510(k) premarket submission to the US Food and Drug Administration (FDA).

If the manufacturer chose to apply ISO 80601-2-69:2014 to demonstrate the safety of the new device, the fire safety elements of the standard, including ‘a means to extinguish a tubing fire and isolate the oxygen flow’ are a requirement. Approval to market the product would then be based upon compliance to the standard.

In March, 2018, the US Veterans Health Administration issued a Patient Safety Alert mandating the use of thermal fuses in all its patients" home oxygen installations, unless there is a clinical reason for not doing so. The Patient Safety Alert applies to all patients, not just those deemed to be at "high risk". It requires two thermal fuses to be fitted per patient installation, and any unidirectional thermal fuses must be replaced with bidirectional versions at the next scheduled visit (unless the unidirectional thermal fuse is designed so it cannot be fitted in the wrong direction).

In January 2020, in coordination with Fire Departments around the state and other agencies, the Wyoming State Fire Marshals Office launched the statewide community risk 307 CRR initiative.

In March 2022, the American Burn Association (ABA) agreed a position statement on home oxygen burn prevention supporting the use of bidirectional thermal fuses in oxygen tubing.

In July 2022, the International Association of Fire Chiefs (IAFC) adopted a position statement on home oxygen fire safety that recommended the use of firebreaks.

All economic operators in the EU, including home oxygen service providers, must comply with the Medical Device Directive (93/42/EEC) or the Medical Device Regulation (2017/745).

The instructions for use for an oxygen concentrator placed on the EU single market must include an instruction to the effect that a firebreak shall be fitted close to the patient to stop the flow of oxygen in the event of a fire. By including this statement the oxygen concentrator manufacturer is complying with the harmonised EN ISO type standard for oxygen concentrators EN ISO 8359:2009+A1:2012, which provides the manufacturer with an immediate presumption of conformity to the Essential Requirements of the Medical Devices Directive and allows them to properly apply the CE mark. Since January 2015 all instructions for use provided with oxygen concentrators placed on the European market will include this statement.

The applied CE mark is reliant on the home oxygen service provider following this instruction and fitting a firebreak. If the firebreak is not fitted, then the Essential Requirements for performance and safety are not met and the CE mark is no longer valid. It also means that the home oxygen service provider"s status, within the framework under which the single market for medical devices operates, changes from ‘distributor’ to ‘manufacturer’. This has significant regulatory implications.

The EU Medical Devices Directive also requires that economic operators adopt solutions that ‘reduce risk as far as possible’ in line with the ‘state of the art’. The fitting of firebreaks is therefore a requirement irrespective of the oxygen source, including oxygen concentrators, liquid oxygen dewars or gas cylinders.

Statistics from the European Industrial Gases Association (EIGA) suggest that home oxygen fires caused 15 deaths between 2013 and 2017 in 16 EU countries. However media analysis across another five-year period (2017-2021), published in a white paper by BPR Medical,

The report calls for Competent Authorities in Europe to address home oxygen fire reporting procedures and the implementation of existing patient safety regulations.

An additional legal requirement applies in the UK, where the fitting of firebreaks has been mandatory under the service specification of the home oxygen service

In 2011, the German Federal Institute for Drugs and Medical Devices recommended ‘corrective actions to prevent fires in oxygen concentrators’. It issued a notice stating that from July 1, 2012 all devices should be equipped with installations for stopping encroachment of the fire into the device, and interruption of the delivery of oxygen in the accessory as close to the patient as possible, in case of ignition. Manufacturers were also required to offer retrospective refitting for devices placed on the market before July 1, 2012.

The safety requirements for oxygen concentrators are governed by the amended standard ISO 8359:1996+A1:2012. The US FDA recognized the standard from January 2014. In January 2015, it was superseded by ISO 80601-2-69:2014. Health Canada, which is responsible for national public health, still recognizes the standard.

All of the 28 CEN (European Committee for Standardization) national standardization bodies (NSBs) have published EN ISO 8359:2009+A1:2012 as national standards. In Europe EN ISO 8359:2009+A1:2012 has harmonized standard status, which triggers ‘presumption of conformity’.

Included in ISO 80601-2-69:2014 are specific requirements that serve to mitigate the risk of fire related to oxygen therapy. The requirements state that the following should be provided:

A means to extinguish a tubing fire and isolate the oxygen flow in the accessories (nasal cannula and tubing or mask and tubing). The standard states that this should be fitted close to the patient.

A means to prevent the fire spreading into the oxygen concentrator outlet. The standard states that the means can also stop the flow of oxygen although it is not required to do so. It also specifies that if a bubble humidifier is fitted to the concentrator, that the means must also protect the bubble humidifier.

Wolff, B. K.; et al. (July 11, 2016). "Flash Burns While on Home Oxygen Therapy: Tracking Trends and Identifying Areas for Improvement". American Journal of Medical Quality. 32 (4): 445–452. doi:10.1177/1062860616658343. PMID 27401082.

Wolff, B. K.; et al. (July 11, 2016). "Flash Burns While on Home Oxygen Therapy: Tracking Trends and Identifying Areas for Improvement". American Journal of Medical Quality. 32 (4): 445–452. doi:10.1177/1062860616658343. PMID 27401082.

Wolff, B. K.; et al. (July 11, 2016). "Flash Burns While on Home Oxygen Therapy: Tracking Trends and Identifying Areas for Improvement". American Journal of Medical Quality. 32 (4): 445–452. doi:10.1177/1062860616658343. PMID 27401082.

Technical specifications for oxygen concentrators (PDF). World Health Organization. 2016-10-25. p. 27. ISBN 978 92 4 150988 6. Retrieved 15 October 2017.

Oxygen pressure relief valves are pressure-reducing devices used in compressed air gas systems. By opening proportionally to pressure increases, pressure relief valves are used to ensure outlet pressure remains stable when the inlet pressure and outlet flow change. Let’s learn more about the use of oxygen pressure relief valves, including specifications of pressure relief valves, installing the, cautions when using the pressure relief valves, and more.

Pressure relief valves open at a pre-designated pressure to release fluid or gas until the pressure drops back down to a standard level. Most safety relief valves operate using a spring-loaded poppet that applies an opposite force to the system’s upstream pressure. Once the force of the upstream pressure exceeds the force of the spring, the poppet opens the valve seat, and fluids or gases may pass through. Once the upstream pressure falls below the power of the spring, the poppet will close back up.

During operation, the pressure relief valve should remain closed and only open once the system’s pressure reaches a preset level. Another key factor is that the valve should open wider as excess pressure increases. Once the pressure is sufficiently relieved and falls a few psi below a standard level, the valve should reseal itself.

Because of the diverse demands of various industrial processes, there are many different pressure relief valve models in existence, and they have a lot of different specifications. There are four key specifications used to identify various safety relief valves:

Some gases, such as nitrogen, air, argon, and other permanent gases, can use oxygen pressure relief valves. Some other gases, such as ammonia and other corrosive gases, need to use a dedicated pressure relief valve. These dedicated pressure relief valves and cylinders often use special connection ports. For example, hydrogen and propane both use left teeth thread, also known as a reverse thread.

When installing a pressure relief valve, make sure the connection specification is consistent with the connector of the cylinder and system. Both pressure relief valves and cylinders use hemispherical connections, which can be dovetailed by tightening the nut. When in use, two hemispherical surfaces should be kept smooth to ensure an airtight effect. Before installation, remove any dust using high-pressure gas. If necessary, you can use PTFE and other materials for gaskets.

Once done working, always discharge the remnant gas inside the pressure relief valve and loosen the regulating stem to avoid deforming the elastic components from long-term pressure.

As a sanitary valves manufacturer, people often ask us, “How long does a pressure relief valve last?” We always recommend checking for and following any replacement life cycle specified by the manufacturer. If there is no specific date, you should replace most pressure relief valves five years (or sooner) after its manufacture date. This is only a general recommendation, and the replacement cycle can vary greatly depending on which valve you have.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291