pressure cooker steam coming out of safety valve price

Pressure cookers have become commonplace in modern households, and their improved safety features have made them twice as popular. In the past, pressure cookers earned a dark reputation for explosions, but today, most pressure cookers have a minimum of 10 or more safety features.

That said, when the pressure cooker safety pressure valve starts leaking, you should know the cause because pressure cookers must release steam to stay safe.

You find many pressure cooker safety valves on top of the lid near the handle, but this depends on the type. If you see a leak from here while pressure cooking, that doesn’t always mean danger.

The safety valve releases the steam to lower the pressure to safer levels and regulate the pressure. The newer models, like the electric pressure cooker, even release the steam using a computer chip. A pressure cooker model like this will release light vapors or condensation from the safety valve, which doesn’t pose a danger.

Important to note: The safety valve leaking doesn’t pose a danger as long as the pressure cooker continues to build to the desired PSI. Once you reach your desired PSI, the safety valve should stop leaking altogether. If it continues to leak, that indicates pressure control failure.

Pressure cookers will open the safety valves enough to release the pressure cooker steam building in the pot. This causes a hissing sound or rattling sound. Don’t feel intimidated that is normal. If you wanted a quieter pressure cooker, electric pressure cookers don’t make as much noise.

You must maintain consistent pressure to ensure that the pressure cooker will cook the food all the way through. Safety valves can be bought and replaced if you have a broken one. However, buy a quality safety valve from any of the reputable brands to ensure the quality.

Manufacturers made safety valves to protect consumers from exploding pressure cookers. If you have a defective safety valve that doesn’t leak, you could use it. You could use it, but you wouldn’t be wise to do it. Don’t do this.

Safety valves let out the dangerous excessive steam. When they leak, they let out steam unnecessarily, and the pressure cooker won’t cook the food. On the other hand, when defective and closed, you have a higher risk of it exploding. Never use a pressure cooker that has either a leaking valve or a defective valve.

You don’t want to see steam exiting the safety valve because the leaking from high pressure can put you in a dangerous situation. The escaping steam can cause second and third-degree burns if exposed to the skin. If you notice a leak, immediately turn off your pressure cooker from the heat source and release the steam. Even smaller leaks pose a danger.

Steam exits from the safety valve of your pressure cooker because of a broken disc, or rubber gasket, on the inside. Because of this, it releases too much steam and the vessel never boils. If you have damage to the valve, you will see a hole in the valve.

Warning: Working on the safety valve yourself does pose a small level of danger. Do this at your own risk. If you don’t want the risk, then take it to an authorized service center. A utensil repair professional can also repair this, but it depends on how much damage was done to the pressure cooker.

Buying a low-quality pressure cooker could be the cause of why these products don’t last long. They have a proneness to issues. You should also clean and maintain your pressure cooker after each use because it can begin to leak if not cleaned properly.

As we said, you can use two methods to replace the safety valve if you have a leak: You can replace it from the inside of the lid, or you can replace it from the outside of the lid. Before attempting either consult your user manual.

To replace the safety valve from the outside, you will use a screwdriver on the outside to turn the screw, while you hold the screw and keep it from twisting on the inside. Once it releases, use a cotton swab to clean the inside of the hole.

Check for surface damage as well to make sure that you don’t have structural problems. Examine the o-ring as well to make sure that it doesn’t have defects. Replace the safety valve with the new one and tighten it up.

From the inside, you will use a wrench to unscrew the safety, while the screwdriver will hold the screw in place. Once you have released it, do the same thing as you did with the first method. Replace the safety valve and tighten it back up.

While you can replace them via the DIY method, don’t try to fix a broken safety valve. The replacement parts only cost between $2 to $17 to replace a safety valve. Buy from a genuine brand because it guarantees that you fix the problem.

Considering the cheap cost, you may want to buy a spare because you can replace it at a moment’s notice. When the pressure reaches a dangerous level, the safety valve acts as the canary in the coal mine. This blows out before it explodes. The safety valve attempts to bring the pressure back down to a normal level.

Never use a damaged valve because it doesn’t provide the same level of protection. You may experience similar problems as before like the valve leaking, or the valve shutting down altogether. Both scenarios put you in a dangerous situation.

The safety valve leaking poses a danger at the first sign of damage. With that in mind, a leak only gives you one example of what can happen to them. You should replace the safety valve whenever it becomes cracked or brittle. As soon as you see the damage, replace it.

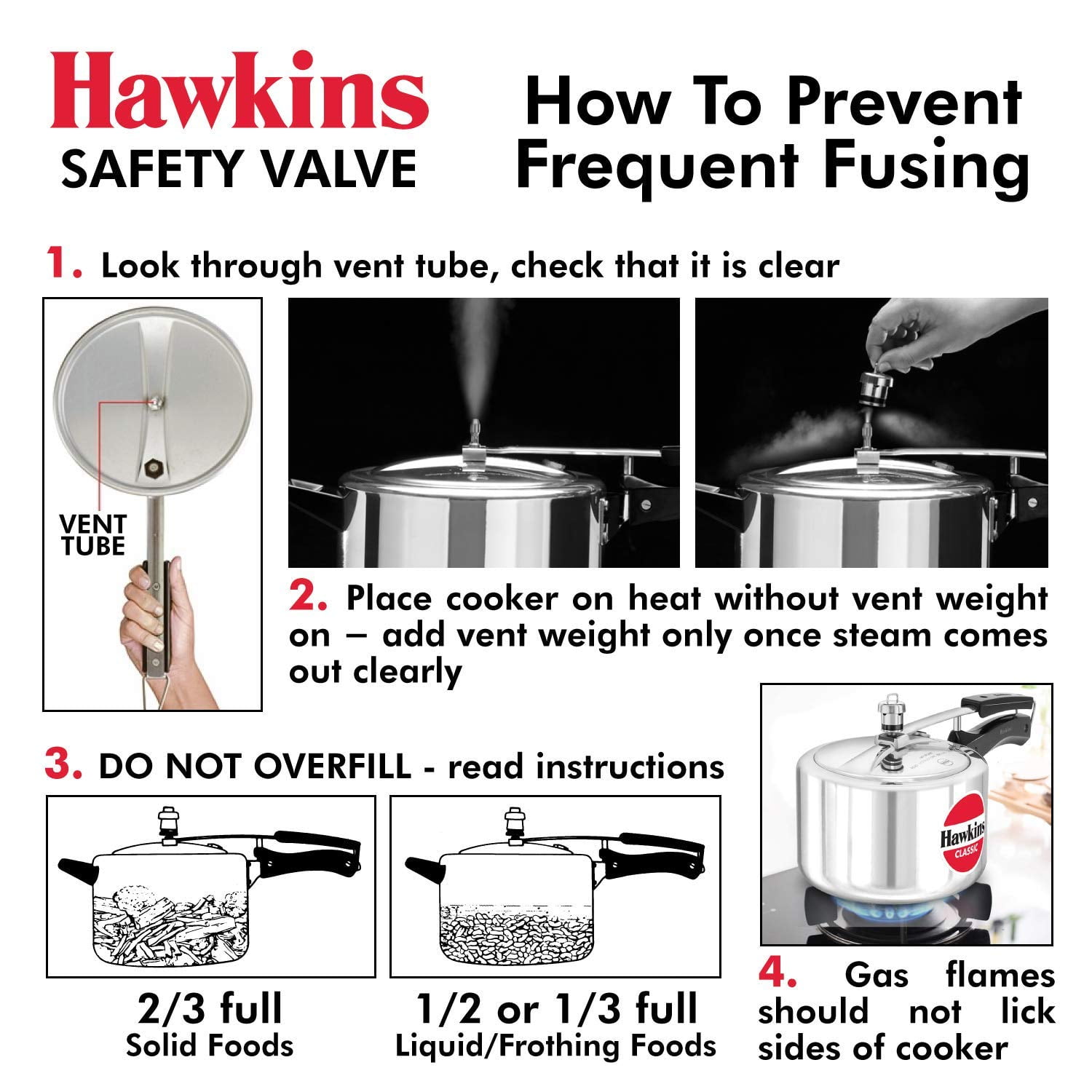

Inspect the safety valve for signs of wear before each use. Another reason that manufacturers say to only fill the pressure cooker two-thirds full is that it ensures that the food doesn’t block the safety valve. The pressure cooker will build a dangerous level of pressure if that happens.

Let’s say that the food blocked the pressure release valve. The safety valve may melt to release the steam. That becomes the last stop before the pressure cooker explodes. The valve helps to maintain the pressure levels. While you have other safety features, this component especially protects you.

Thorough cleaning after using your pressure cooker will go a long way to helping it stay in tip-top condition. Handwash the pressure cooker lid with soap and warm water. Never put a pressure cooker in the dishwasher because this can be hard on the more sensitive components like the gaskets and rubber ring or seal.

A leaking safety valve doesn’t always mean danger, but look for the cause if it continues after you reach the desired PSI. Some steam leaking is normal, but you shouldn’t see an excessive amount of it leaking. That indicates that your pressure cooker has too much pressure.

Never try to repair a damaged safety valve. You can simply replace them, but if you don’t feel comfortable doing it yourself, hire a professional. Always pay attention to leaks because they can stop your pressure cooker from building pressure.

Seeing steam coming out of your pressure cooker may be scary, and you may be wondering if this is a normal thing. You may have heard stories about pressure cookers exploding and wonder if they are dangerous. We are here to explain how it all works and hopefully set your mind at ease.

Firstly, it is normal for the pressure cooker to release steam out of the safety valve on the lid. However, it is not normal for it to leak steam from anywhere else, such as the edges of the lid.

An electric pressure cooker will take around 5-15 minutes to get up to pressure before cooking the food. Factors affecting the pressurization time include how full the pot is and how cold the ingredients are.

Once the pot reaches the required pressure, the float valve will come up, the pressure cooker will beep once, and the cooking time will begin to count down.

At this time, you may notice hissing sounds and some steam coming out of the steam release valve or float valve hole on the lid while the pressure builds – this is entirely normal.

Some Instant Pot models automatically set the pressure valve to “Sealing” when they close, while some need to be set manually. If you forget to set the pressure valve to “Sealing,” you will continue to see steam coming from the pressure valve and possibly from under the edges of the lid as well.

If there is still steam coming out after the pot has come to pressure, or if the pot just won’t come to pressure at all and you’re sure the pressure valve is set to “Sealing,” then this is not normal. It may mean that your seal is either missing or has not been seated correctly around the rim of the lid.

The first thing to do is make sure that the silicone seal inside the edge of the pot is there. It is easy to forget to put it back after washing it. However, putting on a lid without replacing the seal is something that most pressure cooker owners do at some point, so don’t feel foolish!

The second thing to do is check that the sealing ring is evenly seated under the wire around the edge of the lid. An unevenly installed seal can create a partial seal that allows steam to leak out from the edges of the lid. This can happen even when the pot is pressurized and is not supposed to happen.

If you continue to have the same problem even after reseating the ring, then your ring may be damaged, and you probably need a new ring. Alternatively, you may be trying to use an off-brand ring that isn’t right for your pressure cooker.

Generally speaking, if you catch the problem in time, you can continue cooking after you’ve fixed the sealing issue. After replacing or reseating the seal, put the lid back on and resume the cooking cycle where you left off.

If you didn’t catch this problem early on, you might have lost a lot of the liquid in your pot as the steam escaped. If you’re cooking something with a lot of liquid, such as soup, this probably won’t be a problem, but if you’re cooking a low-liquid meal, you will need to replace that liquid before you resume cooking.

Keep in mind that the pressure cooker relies on a lot of pressure to cook your food. All pressure cookers are made to vent the excess pressure in steam to prevent too great a build-up. So, venting steam is normal.

As pressure builds up inside the pressure cooker, the safety valves will start operating, and they will release the unnecessary steam that has formed inside the unit as it heats the liquid inside. You will see the steam come out as that happens, and a hissing sound will accompany this.

When the steam build-up reaches a certain point, some of that steam needs to come out to eliminate any dangerous high-pressure situations. That means that the pressure cooker has reached the desired pressure level, and any steam released is an excess and not something needed for the cooking process.

However, you shouldn’t think that the pressure cooker steam coming out of the safety valve signifies that your food is ready. It simply shows that the cooking process reached a point where too much steam was inside the pot. The food will only be ready once the set time has elapsed.

Usually, a pressure cooker releases steam out of its safety valve when the contents reach around 250 degrees Fahrenheit. Normally, the cooking temperature stays under 212 degrees, but we see some pressure releasing via the safety valve when it goes past that.

You do not need to do anything because the steam will be released gradually by the unit itself. Every pressure cooker is created with the idea of being as hands-off as possible, so once you have set the cooking time and mode, you can leave it to do its thing.

All you have to do is to double-check the valves and seal as we detailed above and ensure that they are working correctly before you start cooking. This way, the pressure cooker will use those safety valves automatically and release pressure as needed.

While that hiss might scare you at times, it’s normal and a part of the pressure-cooking process! So be safe, and we hope you enjoy using your pressure cooker.

The safety valve inside a pressure cooker is a safety backup mechanism that comes into effect when the pressure inside the cooker turns uncontrollably high and finds no path to escape.

To release steam, the cooker has pressure regulating valves that Jiggle or extend outwards with the help of spring. Some release steam with the help of a computer chip!

If for any reason, the pressure regulating valve fails to release steam, the excessive pressure causes the safety valve to open up and release steam in a controlled way.

The other valve is located a little away from the pressure regulating valve. It is screwed on the lid of the cooker and is made up of synthetic rubbers like neoprene or hardened Viton.

If you see pressure steam coming out of the safety valve, it does not signify danger. It only points to some possible dysfunctions that need to be taken care of.

Damaged Gasket. A gasket is a rubber ring that helps to seal the cooker. A damaged or uneven placement of the gasket could lead compromise the seal of the cooker leading to pressure escaping from the safety valve.

Cheap quality pressure cookers made from an unknown brand are a safety hazard as they compromise on health and protection of the consumer. Low-quality safety valves malfunction easily causing steam to escape.

If the quantity of food and water is too less and water boils away, it can result in a burnt and empty cooker. Since the temperature and time duration is not controlled, the temperature inside the cooker becomes excessively high quickly leading to the safety valve breaking down.

If the pressure cooker is placed on a large flame, the flame starts licking the side walls leading to excessive temperature building and safety valve destruction

If the pressure cooker is not regularly cleaned and maintained, it can clog the pressure regulating valve forcing the safety valve to emit steam out of the cooker.

Some models come with a sealing feature that needs to be set manually. Forgetting to turn them on can cause the steam to escape from the safety valve.

For traditional pressure cookers, failure to manually adjust the temperature and pressure causes excessive pressure build-ups causing the safety valve to break or melt.

You can replace the safety valve from the outside by holding firmly the inside part so it doesn’t move. Use a screwdriver to rotate and twist the screw on the outside until it comes off.

Always buy from trusted brands as they ensure quality checks when it comes to material and usage. No amount of budgeting should compromise your safety and good health.

Make sure the rubber rings and the lid of the cooker are closed properly and in correct alignment. If the rubber ring has become loose, it is best to replace it.

Follow the tips above to avoid steam coming out from your safety valve. If, despite all precautions, the safety valve opens up, replace it with a new one.

General wear and tear are bound to happen in any cooking vessel over the years so don’t worry about it much. Fix the cause and all the best cooking scrumptious and healthy food!

Pressure cooking is a wonderful way to prepare food that cooks thoroughly and quickly at a high temperature. Some are worried about the dangers of using a pressure cooker, so it is helpful to find out how to check your pressure cooker safety valve for safe operation.

For those worried that a pressure cooker might explode, the safety valve is the design feature that prevents this from happening. If the cooker has a safety valve, you can see it installed on the cooker’s lid.

A pressure cooker is designed to trap the steam inside to increase the pressure. However, too much pressure is not safe. The valve must release pressure if it gets too high.

The blog of pressure cooking today has many recipes that are delicious. There are 25 recipes for pasta so you can try a new one every day for nearly a month.

There is a weight inside many of the safety valves that is lifted by the internal steam pressure when it reaches a certain amount. When the pressure lifts the weight inside the valve, this allows some steam to escape.

Jeffrey Eisner who says “he is a nice Jewish boy from Long Island.” He started with pressure cooking by making a simple mac and cheese dish with a recipe that he shared on YouTube. The video was an immediate success and led to his making new recipes for pressure cooking.

In a sealed cooker, as the pressure builds up, the boiling point of water rises. This phenomenon is the cause of the increased heat that cooks the food more thoroughly and faster.

The science that explains this is fascinating. The normal boiling point of water under standard atmospheric pressure of 15 pounds per square inch (psi) is 212°F (100°C). In a pressure cooker, the atmospheric pressure doubles from 15 psi to 30 psi. This added pressure raises the boiling point of water from 212°F (100°C) to 250°F (121°C).

If you see steam escaping from the safely valve do not worry. The steam escaping from the safety valve is its normal function, which means the valve is working properly.

If the internal pressure within the cooker gets high enough, this lifts a weight in the safety valve that allows steam to escape. The escaping vapor lowers the pressure. You can hear the steam escaping, making a whistling sound, or rattling the valve.

The first pressure cooking devices were used in the 17th century. They were useful to remove fat and collagen from bones so that the bones could then be ground down to make a pure bone meal.

The inventor of the device, Denis Papin, called it a “steam digester” or “bone digester.” His invention was the precursor to both pressure cookers and the steam engine. Surprisingly, the early designs did not have any safety features, and this caused some of the first ones to explode while being used.

The legacy of those early pressure-cooking devices may be why some still fear this problem even today. Papin, to his credit, came up with a design improvement that is what we call a safety valve to avoid the dangers of these explosions.

By the 1930s, the modern pressure cooker design became useful in a home kitchen. The Flex-Seal Speed Cooker, invented by Alfred Vischer, came out in 1938.

These home cookers became even more popular in 1939 with the release of the design by the National Pressure Cooker Company (now called National Presto Industries), which is still manufacturing these cookers today.

The first-generation cookers had a safety valve that worked with a weight. When the internal pressure rises high enough to lift the weight, some steam escapes, and the valve makes a distinctive rattling sound.

Second-generation cookers use a spring-loaded valve that makes less noise and is adjustable for pressure sensitivity by using a dial, which is on the cooker.

Third-generation models are the most recent versions. They use an electric heating source that is regulated by the internal pressure. These devices do not need a safety valve because the heat source automatically shuts off before the pressure gets too high.

Suppose you are thinking about getting a new cooker. In that case, there is another device that you might consider called a food dehydrator, which I describe in the article entitled, “How Much Electricity Does a Dehydrator Use?” here.

For the styles of cookers with a safety valve, it may not be obvious when the valve is not working if it is blocked. You may notice the lack of steam while the cooker is heated. The valve could rarely be blocked, but if not cleaned properly, it is possible.

Alternatively, the valve may be broken, missing, or the pot may not seal properly. These problems might allow too much steam to escape. This leakage may cause the cooker not to heat up properly and not allow the internal pressure to build up to the proper level.

One of the signs of a problem with a lack of pressure is that the food takes much longer to cook than you normally expect when using a cooker of this type.

One tip in the video is not to open the cooker after finishing cooking and take the lid to run it under cold water. This sudden temperature change can make the safety valve work less well and may cause the need to change the valve more frequently.

If you use a cooker that needs a valve to work properly and the valve is broken or missing, you can replace it with a new valve. Be sure to get the manufacturer’s specifications to ensure you use the correct replacement part.

Some of these problems include the ventilation knob being open or not enough liquid is in the cooker (requires at least one cup). Another cause is the sealing ring is missing, damaged, covered with food particles, or not in the proper position.

The video narrator shows how she cleans her float valve for her instant pot that she uses as a cooker. If you use too little liquid or too much, the cooker may not pressurize.

For the type with screws, hold the valve from the bottom of the lid with the pliers and use the screwdriver to remove the screws from the top to remove the broken part. Replace it with the new one and tighten the screws that hold it in place by holding it with the pliers from the bottom of the lid again and tightening the screws from the top.

For the type with a nut, use the wrench to loosen it for removal and perhaps a socket when you put on the new valve to tighten it with enough torque to hold it securely in the proper position.

Modern pressure cookers that are in good repair are quite safe. The one caution to remember is not to overfill the cooker so that the food might block the safety valve. This overfilling with food would be very difficult to do and not something to worry about for normal use.

Be careful where you keep your cooker on the countertop because it is important to know how hot a stovetop can get. Even when turned off, a stovetop may still be very hot, which I discuss in this article.

Now you know everything you need to know about a pressure cooker safety valve. You know what they do, how they work, and how to replace one if it needs repair. Enjoy your pressure-cooking recipes without worrying about the safety valve.

If having a safety valve on your cooker still bothers you, consider buying an electric cooker without a valve that instead has a built-in safety feature that automatically shuts off power if the pressure gets too high.

Pressure cookers have become commonplace in modern households, and their improved safety features have made them twice as popular. In the past, pressure cookers earned a dark reputation for explosions, but today, most pressure cookers have a minimum of 10 or more safety features.

That said, when the pressure cooker safety pressure valve starts leaking, you should know the cause because pressure cookers must release steam to stay safe.

You find many pressure cooker safety valves on top of the lid near the handle, but this depends on the type. If you see a leak from here while pressure cooking, that doesn’t always mean danger.

The safety valve releases the steam to lower the pressure to safer levels and regulate the pressure. The newer models, like the electric pressure cooker, even release the steam using a computer chip. A pressure cooker model like this will release light vapors or condensation from the safety valve, which doesn’t pose a danger.

Important to note: The safety valve leaking doesn’t pose a danger as long as the pressure cooker continues to build to the desired PSI. Once you reach your desired PSI, the safety valve should stop leaking altogether. If it continues to leak, that indicates pressure control failure.

Pressure cookers will open the safety valves enough to release the pressure cooker steam building in the pot. This causes a hissing sound or rattling sound. Don’t feel intimidated that is normal. If you wanted a quieter pressure cooker, electric pressure cookers don’t make as much noise.

You must maintain consistent pressure to ensure that the pressure cooker will cook the food all the way through. Safety valves can be bought and replaced if you have a broken one. However, buy a quality safety valve from any of the reputable brands to ensure the quality.

Manufacturers made safety valves to protect consumers from exploding pressure cookers. If you have a defective safety valve that doesn’t leak, you could use it. You could use it, but you wouldn’t be wise to do it. Don’t do this.

Safety valves let out the dangerous excessive steam. When they leak, they let out steam unnecessarily, and the pressure cooker won’t cook the food. On the other hand, when defective and closed, you have a higher risk of it exploding. Never use a pressure cooker that has either a leaking valve or a defective valve.

You don’t want to see steam exiting the safety valve because the leaking from high pressure can put you in a dangerous situation. The escaping steam can cause second and third-degree burns if exposed to the skin. If you notice a leak, immediately turn off your pressure cooker from the heat source and release the steam. Even smaller leaks pose a danger.

Steam exits from the safety valve of your pressure cooker because of a broken disc, or rubber gasket, on the inside. Because of this, it releases too much steam and the vessel never boils. If you have damage to the valve, you will see a hole in the valve.

Warning: Working on the safety valve yourself does pose a small level of danger. Do this at your own risk. If you don’t want the risk, then take it to an authorized service center. A utensil repair professional can also repair this, but it depends on how much damage was done to the pressure cooker.

Buying a low-quality pressure cooker could be the cause of why these products don’t last long. They have a proneness to issues. You should also clean and maintain your pressure cooker after each use because it can begin to leak if not cleaned properly.

As we said, you can use two methods to replace the safety valve if you have a leak: You can replace it from the inside of the lid, or you can replace it from the outside of the lid. Before attempting either consult your user manual.

To replace the safety valve from the outside, you will use a screwdriver on the outside to turn the screw, while you hold the screw and keep it from twisting on the inside. Once it releases, use a cotton swab to clean the inside of the hole.

Check for surface damage as well to make sure that you don’t have structural problems. Examine the o-ring as well to make sure that it doesn’t have defects. Replace the safety valve with the new one and tighten it up.

From the inside, you will use a wrench to unscrew the safety, while the screwdriver will hold the screw in place. Once you have released it, do the same thing as you did with the first method. Replace the safety valve and tighten it back up.

While you can replace them via the DIY method, don’t try to fix a broken safety valve. The replacement parts only cost between $2 to $17 to replace a safety valve. Buy from a genuine brand because it guarantees that you fix the problem.

Considering the cheap cost, you may want to buy a spare because you can replace it at a moment’s notice. When the pressure reaches a dangerous level, the safety valve acts as the canary in the coal mine. This blows out before it explodes. The safety valve attempts to bring the pressure back down to a normal level.

Never use a damaged valve because it doesn’t provide the same level of protection. You may experience similar problems as before like the valve leaking, or the valve shutting down altogether. Both scenarios put you in a dangerous situation.

The safety valve leaking poses a danger at the first sign of damage. With that in mind, a leak only gives you one example of what can happen to them. You should replace the safety valve whenever it becomes cracked or brittle. As soon as you see the damage, replace it.

Inspect the safety valve for signs of wear before each use. Another reason that manufacturers say to only fill the pressure cooker two-thirds full is that it ensures that the food doesn’t block the safety valve. The pressure cooker will build a dangerous level of pressure if that happens.

Let’s say that the food blocked the pressure release valve. The safety valve may melt to release the steam. That becomes the last stop before the pressure cooker explodes. The valve helps to maintain the pressure levels. While you have other safety features, this component especially protects you.

Thorough cleaning after using your pressure cooker will go a long way to helping it stay in tip-top condition. Handwash the pressure cooker lid with soap and warm water. Never put a pressure cooker in the dishwasher because this can be hard on the more sensitive components like the gaskets and rubber ring or seal.

A leaking safety valve doesn’t always mean danger, but look for the cause if it continues after you reach the desired PSI. Some steam leaking is normal, but you shouldn’t see an excessive amount of it leaking. That indicates that your pressure cooker has too much pressure.

Never try to repair a damaged safety valve. You can simply replace them, but if you don’t feel comfortable doing it yourself, hire a professional. Always pay attention to leaks because they can stop your pressure cooker from building pressure.

Although it’s quite normal to see a small amount of steam releasing from this opening, there is a possibility that you might not have placed the whistle correctly on the lid.

You should always place the cooker on a flat surface, including when you’re cooking it on the flame. If it’s tilted on one side, it may leak steam from the pot.

It is important to remember that the leakage of the safety valve isn’t any danger so long it continues to increase until it reaches that desired PSI. Once you’ve reached the desired PSI, it should cease completely leaking. If it persists in leaking, it is a sign of a failure in the pressure control.Make sure to check these things as this may fix it:Handle correctly seated and do not sit in the position that vents.

Slowly tighten them, and then check to see if this solves the problem.Safety Valves: What You Need to KnowPressure cookers can allow the safety valves to open enough to let the steam build-up within the cooker. The result is a hissing or a rattling sound. Do not be afraid, it’s normal. You’re looking for an easier pressure cooker with quieter electric pressure cookers that do not create as much noise.It is essential to maintain a consistent pressure level so that the cooker will cook your food throughout. Safety valves can be purchased and repaired if you’ve got broken bones. But, make sure you buy a high-quality safety valve from one of the well-known brands to ensure high quality.The Purpose of Safety ValvesManufacturers designed security valves to safeguard the consumers from explosions in pressure cookers. If you’ve got a deficient safety valve that isn’t leaky, then you can use it.

You can make use of it, but it’s not advisable to try it. Avoid this. Safety valves release risky excessive steam. If they leak, they release unnecessary moisture, so the cooker will not make the dish cook. However, if the valve is defective and shut, there is the chance of being ablaze. Don’t make use of a pressure cooker that is leaking or a damaged valve.The potential injuries that could result from an explosion of a pressure cooker could cause:Blindness

DeathHow Do You Handle Steam Coming out of the Safety Valve?You shouldn’t see steam escape from the safety valve since the leak can cause you to be in a dangerous situation. The steam that escapes can cause third and second-degree burns when exposed to the skin. If you detect an issue, you must immediately switch the cooking pressure away from its heat source and let out the steam. Even more minor leaks pose a danger.Why Does Steam Come out of the Safety Valve?Steam is released through the safety valve in the pressure cooker due to a damaged disc inside. That is why the valve produces too much steam, and the pressure cooker does not boil. If there is damage to the valve, you’ll find a hole within the valve.

Avert: Working on the safety valve by yourself can pose some risks. You are doing it at your discretion. If you aren’t willing to take the risk, take it to a licensed service center. An expert in repairing utensils could repair the problem, but it will depend on the amount of damage done to the pressure cooker.There are a few possible reasons for the reason why steam may flow out of the valve that is used to protect you, for instance:Too old for a pressure cookeing

The absence of regular maintenanceThe purchase of a poor quality pressure cooker may cause cookers don’t last for long. They are prone to problems. Also, you should keep clean the pressure cooker after every use since it may start to leak if it is not maintained correctly.How to Replace the Safety ValveIf pressure cooker steam coming out of safety valve. We’ve said that you have two options to repair the safety valve if there’s a leak. You can replace it on the interior of the lid or return it to the exterior part of the lid.

To replace the valve on the outside, employ a screwdriver from the outside of the screw. During this process, you hold the screw in place to stop it from turning in the interior. After it has been released, use a cotton swab to remove the dirt from the hole.

Examine the surface for damages and also ensure that there aren’t any structural issues. Also, examine the o-ring to ensure that it isn’t damaged. Change the valve for safety using the new one and tighten it.

Inside, employ a wrench for removing the safety. A screwdriver is used to hold the screw. After letting it go, you can do the same as you did in the previous method. Install the safety valve, and make sure you tighten it again.

Expert Tips:Don’t overtighten the screw as this could cause damage to the valve that protects you. The hand tight that is the minimum is sufficient for the safety valve you have.Can You Repair a Safety Valve?We discussed how to replace a safety valve, but we never discussed the possibility of repairing it.You cannot fix a safety pressure cooker valve!Although you could repair them using DIY methods, don’t try to repair a damaged security valve. It’s only $2-$17 to replace the safety valve. Choose a genuine brand to ensure that you will fix the issue.Should You Use a Damaged Safety Valve?Considering the low cost, you might want to buy a spare one since you can replace it with a single click. If the pressure is unsafe, the safety valve functions as a canary in the mine. It explodes and then explodes. The safety valve tries to bring the air pressure to normal levels.

Please do not use a damaged valve since it does not provide the same level of protection. There are similar issues similar to before, such as leakage from the valve or shutting completely. Both scenarios put you in a dangerous situation.When Should I Replace My Safety Valve?Leaks of the safety valve pose a risk at the first indication of damage. In this regard, leaks are only an example of what could occur with them. It would help if you repaired the safety valve when it gets cracked or becomes hard to handle. If you can see the defect, take it off and replace it.

Check the valve’s safety for wear signs before each use. Another reason manufacturers advise making sure that the pressure cooker is filled to two-thirds full is to ensure that food items don’t stop the valve that protects you. The pressure cooker can build up to dangerous pressure in the event of this happening.

Let’s say that food particles block the valve that releases pressure. The safety valve might melt and release steam. The valve is used to keep high pressures. Even if other options protect you, this one safeguards you.

Don’t make use of anypressure cooker that has a damaged safety valve. Replace it. Leaks do not always pose a risk, but you must determine the kind of leak you’re experiencing.How to Prevent LeaksThorough cleaning after using a Pressure cooker can make a huge difference in keeping it in top condition. Clean the lid using hot water and soap. Do not put pressure cookers in the dishwasher since it could damage the more delicate components, such as the rubber seal and gaskets.

Change the valve for safety or any other components as soon as you notice signs of wear and tear. In most cases, you’ll see cracks appear as the first indications of wear and tear.To Finish - Pressure Cooker Safety Valve LeakingA safety valve not working correctly doesn’t necessarily mean danger, but be sure to determine the source when it stops when you have reached an appropriate PSI. A minor steam leak is average, but you shouldn’t observe excessive amounts of it leaks. It could be the pressure cooker is operating at extreme pressure.

Do not attempt to fix the safety valve that has been damaged. It is possible to replace the valve, but you should hire an expert if you don’t feel confident making it yourself. Please pay attention to leaks since they can prevent the pressure cooker from generating pressure.

Let’s be honest not even Gordon Ramsey likes to have the pressure cooker steam coming out of safety valve, it looks dangerous and we don’t want to be cooking under pressure and noticing the steam making noise and getting out of your cooker.

This thing is that when heat constructs inside a pressure stove and also water starts boiling at extreme temperature levels … and you know that the pressure is very high the idea of a leak or an escape of steam is terrifying, like the top is going to stand out.

The easy truth stays nevertheless that pressure cooker covers are made to launch heavy steam to preserve a safe level of stress. When stress builds to high safety valves open just sufficient to launch excess stress which causes a hissing sound and also a rattle of the wobbler on the cover.

Most people that hear a hissing sound in the kitchen area normally link this sound with a teapot. The suggestion is that the steam obtains so hot that it raises the cover on the pot that causes it to whistle, which is an easy method to discover that the water is ready.

If vapor is releasing or even a little water is appearing of the pressure stove vapor release shutoff then the pot has actually pertained to full pressure as well as is releasing a small amount of excess pressure.

The truth is that the cooker is hissing for the exact same factor as the teapot, but this does not imply that the food on the stove is done food preparation.

A pressure cooker traps steam in the pot to develop warm, which heats up the food rapidly. It likewise controls and also minimizes the quantity of time the food requires to prepare.

The pressure stove elevates the boiling factor of water beyond the normal 212 levels. The spike can rise as high as 250 degrees. The moisture within a stress stove likewise aids some foods like tough meat to soak up moisture a lot quicker, making the meat tender in a short amount of time. It needs to be noted that a stress cooker can also caramelize foods, like veggies, quickly.

Naturally, the pressure cooker can hold up against high-pressure cooking without making the cooker hiss, however, that does not suggest it will certainly not take place.

The first, obviously, is that the pressure cooker is simply not secured appropriately or a valve was inadvertently left open. The pressure within the pot needs to be maintained at a specific pressure to guarantee that the food cooks extensively, so this problem needs to be corrected.

The other reason that a pressure cooker could begin to hiss is due to the fact that the stress is expensive. The pressure stove can not talk with the cook, but it can still seem an alarm informing the chef that the stress needs to be lowered.

There are two methods to tackle lowering the pressure in the pot. The initial is by just reducing the warm with the stove-top’s handle if it heats up using fire. This should have an immediate effect on the pressure cooker and stop it from hissing like a siren.

The pressure from the stove needs to be reduced to see to it does not overcook the food inside. The service for this problem is to have two-burner on. The initial one will assist build up the pressure in the pot. The second aspect should be relied on a simmering temperature to help in reducing the temperature in the pot.

Bear in mind that the elements need to be switched on before the pressure cooker reaches its limitation to ensure that it is preheated prior to the pot is positioned on it. This ought to have a reasonably quick impact on the pressure stove and will certainly remain to cook the food under the appropriate problems. Falling short to do this might result in dry or burned food.

Electric Pressure cookers have different classifications. They are essentially quiet save for the stress launch that happens at the end of the cooking cycle.

Electric units don’t hiss, rattle, or whistle throughout the procedure due to the fact that the warmth and also pressure inside the stove are well regulated by an integrated circuit that can keep temperature level as well as press at very steady degrees.

At the end of food preparation, electrical pressure stoves will hiss a little as they are set to release stress at a rate much faster than an all-natural release. The noise is very little as well as should not create alarm. It is typical.

There is no doubt that cooking with a stress cooker calls for that a chef discover a few extra skills, however, the incentives are indisputable. So are stress cookers intended to hiss? Yes, this alerts the cook that there is too much pressure in the pot which is launching the excess pressure.

Year after year, your water heater serves an important role in your home. Your morning routine just wouldn’t be the same—or nearly as comfortable—without hot water. Yet, water heaters and their components do not last forever. Preventative maintenance is the key to ensuring that your water heater continues to safely provide your home with hot water. In this article, we’ll review a critical safety component of your water heater, the water heater pressure-relief valve.

If your water heater has stopped working, fill out the form to schedule a free VIP plumbing inspection here in the Chicago area. Our plumbers are available 24/7 to help you and your home!

The name is actually quite literal. It’s a valve that relieves excess pressure in the water heater tank. By doing so, it can prevent excess pressure buildup that has the potential to cause a tank burst and flood your home. It’s an unheralded but essential safety mechanism for your water heater.

As your water heater heats up the water in the tank, the water expands and steam is generated. The greater the heat, the more expansion that occurs. This expansion puts pressure on the exterior walls of the tank, but this is to be expected. Some degree of excess pressure escapes through the water pipes connected to the water heater. In the event that it cannot, the pressure-relief valve triggers. By releasing some of the hot water and air, the valve lowers the pressure back down to safe levels.

If the pressure-relief valve is unable to open, the pressure can continue to build inside of the tank past that 100 PSI ceiling. The heavy metal tank can withstand a lot of pressure buildup, but it eventually has its limits. The results are explosive, as the tank gives way, sending hot water flooding outward.

If your water heater has an emergency shutoff valve installed, the burst will be detected and the water supply will automatically shutoff. If not, you’re potentially looking at a flooded home with significant and costly water damage.

So, what causes the pressure-relief valve to fail? In many cases, the valve gets stuck or frozen in place due to the buildup of rust and corrosion inside the tank. Or, the valve is stuck due to a prior instance in which it released hot water.

A broken valve is something that should be fixed right away, but—unless you’re examining your water heater closely on a regular basis—may not be something most homeowners notice. That’s why regular testing and maintenance is important.

We recommend that homeowners here in Chicago test their pressure-relief valve when they flush out their water heater twice every year. Bundling your water heater maintenance tasks together makes sense, since each of these tasks takes about 10 minutes to complete.

Start by positioning a large bucket underneath the valve. You are going to release some hot water during this process, so you want to make sure you’re wearing safe clothes to reduce a scalding risk. Remove the drain pipe attached to the pressure valve.

Then, gently lift the valve switch so that hot water begins to come out of the valve and into the bucket. For the purposes of this test, don’t push the switch all the way up.

So long as water and air are coming out of the water heater during this test, your water heater pressure-relief valve is working as intended. On the other hand, if you’ve flipped the switch up and you’re not seeing any release, that could indicate a problem with the valve.

Did you know that most people use between 80 and 100 gallons of water every day? From using the restroom and showering to cooking and cleaning, your water usage is a crucial part of your daily home routine. Here are just a few daily tasks most homeowners do without thinking, and the corresponding amount of water it takes to complete them: Flushing a toilet: 1-3 gallons per flush

This doesn’t take into account washing your hands, taking a bath, or watering your lawn. Your water use may also skyrocket during the summer, when you’re drinking more water or cooling off in the sprinklers.

Taking all this into account, it’s crucial that your water systems are working at their full capacity. Your water heater delivers hot water to your home, and your water pressure needs to be sufficient for your appliances to work and for your showers to be comfortable.

For all your daily tasks to run smoothly, water pressure is especially important. Imagine not having enough water pressure to flush a toilet or take a shower. There are other consequences to having water pressure that is too high.

To get your water pressure checked and adjusted by a professional, call the team at King Heating, Cooling, & Plumbing in Chicago, Illinois. We’re the experts on all home systems and can make sure your home is running at 100% capacity.

It’s been a long day at work, and you want to come home, take a hot shower, and relax with the family. You turn on the shower to see a small stream of water—or droplets—coming from the shower head. Even when you turn the shower handle to full capacity, only a small amount of water drips out. What’s the problem?

Your water pressure is likely too low. This can be an annoying setback for many homeowners, who depend on high water pressure to shower, clean, cook, and more. How can you properly shower or wash your hands when only a few drops are coming out of the faucet?

On the opposite side of the water pressure spectrum, high water pressure can pose a danger to you and your family inside the home. When water pressure is too high, pipes can become damaged and systems can overwork themselves to bring that water to you. It’s just like the tale of Goldilocks and the Three Bears: you don’t want your water pressure too low or too high—you want it just right.

Low water pressure is usually just a nuisance to homeowners and doesn’t pose a serious problem. High water pressure, on the other hand, can damage fixtures, seals, joints, and more. Water pressure that’s too high can also waste a lot of water in the home, leaving you with a higher utility bill at the end of the month.

As it comes from the municipal water supply to your home, residential water generally ranges from 40 to 80 PSI (pounds per square inch). Anything above or below this range could be considered too low or too high. Some experts will say that any level above 60 PSI is too high of water pressure for your home. It’s best to speak with a professional plumber to get your water pressure checked and to learn more about what level is right for your home. Your PSI range can be affected by elevation, house size, water needs, age of your home, and other factors.

If you haven’t checked your water pressure level in a while, it may be time to call King for a free VIP plumbing inspection. Even if you feel your water pressure and water heater are working great, there could be hidden efficiency problems lurking underneath the surface, such as a water heater that is running too hot and wasting energy. Only a true plumbing professional can get to the bottom of the issue and help you save money, month-over-month.

This goes without saying, but if you’re not comfortable flushing your water heater or checking the valve, don’t just ignore this crucial maintenance need. Give our team a call and have us out to your home to perform this service for you. Remember, this preventative maintenance can help prevent a tank burst and major water damage.

Pressure cooking is the process of cooking food under high pressure steam and water or a water-based cooking liquid, in a sealed vessel known as a pressure cooker. High pressure limits boiling, and creates higher cooking temperatures which cook food far more quickly.

The pressure cooker was invented in the seventeenth century by the physicist Denis Papin, and works by expelling air from the vessel, and trapping steam produced from the boiling liquid. This is used to raise the internal pressure up to one atmosphere above ambient and gives higher cooking temperatures between 100–121 °C (212–250 °F). Together with high thermal heat transfer from steam it permits cooking in between a half and a quarter the time of conventional boiling.

According to New York Times Magazine, 37% of U.S. households owned at least one pressure cooker in 1950. By 2011, that rate dropped to only 20%. Part of the decline has been attributed to fear of explosion, although this is extremely rare with modern pressure cookers, along with competition from other fast cooking devices, such as the microwave oven.

In 1679, French physicist Denis Papin, better known for his studies on steam, invented the airtight cooker used steam pressure to raise the water"s boiling point, thus cooking food more quickly. In 1681 Papin presented his invention to the Royal Society of London as a scientific study; he was later elected as a member.

In 1918, Spain granted a patent for the pressure cooker to José Alix Martínez from Zaragoza. Martínez named it the olla exprés, literally "express cooking pot", under patent number 71143 in the Boletín Oficial de la Propiedad Industrial.360 recipes for cooking with a pressure cooker.

In 1935, the Automa pressure cooker was introduced. Mountaineers attempting to climb Mount Everest took it along with them to cook in higher altitudes.

In 1938, Alfred Vischer presented his invention, the Flex-Seal Speed Cooker, in New York City. Vischer"s pressure cooker was the first designed for home use, and its success led to competition among American and European manufacturers.1939 New York World"s Fair, the National Pressure Cooker Company, later renamed National Presto Industries, introduced its own pressure cooker.

Today, most pressure cookers are variations on the first-generation cookers, with the addition of new safety features such as a mechanism that prevents the cooker from being opened until it is entirely depressurized.

These include an electric heat source that is automatically regulated to maintain the operating temperature and pressure. They also include a spring-loaded valve (as described above) and are typically non venting during cooking.

Second-generation electric, with digital controller. Delayed cooking becomes possible and the controller shows a countdown timer when working pressure is reached.

Third-generation electric, with smart programming, which includes pre-set cooking times and settings based on heating intensity, temperature, pressure and duration.

Some pressure cookers are multifunctional (multicookers): pressure cooker, saute/browning, slow cooker, rice cooker, egg cooker, yogurt maker, steamer, sous vide, canner, and stockpot warmer that can also be used to keep cooked food warm.Ninja Foodi pressure cooker, which was the first pressure cooker that could also air fry, several other pressure cooker manufacturers, including Instant Pot, have come out with their own pressure cookers that can air fry, which are now known as pressure air fryers. Pressure air fryers have two separate lids, one for pressure cooking, and one for air frying.

At standard pressure the boiling point of water is 100 °C (212 °F). With any food containing or cooked with water, once the temperature reaches the boiling point, any excess heat causes some of the water to vaporize into steam efficiently carrying away heat keeping the food temperature at 100 °C.

In a sealed pressure cooker, as the water boils, the steam is trapped in the cooker which raises the pressure. However, the boiling point of water increases with pressure resulting in superheated water.

In a sealed pressure cooker the volume and amount of steam is fixed, so the temperature can be controlled either directly or by setting the pressure (such as with a pressure release valve).

For example, if the pressure reaches 1 bar or 100 kPa (15 psi) above the existing atmospheric pressure, the water will have reached a temperature of approximately 120 °C (248 °F) which cooks the food much faster.

Pressure cookers also use steam and water to rapidly transfer the heat to the food and all parts of the vessel. While, compared to an oven, a pressure cooker"s 120 °C is not particularly high, ovens contain air which is subject to thermal boundary layer effects which greatly slows heating, whereas pressure cookers flush air from the cooking vessel during warm up and replace it with hot steam. For items not placed within the liquid, as this steam condenses on the food it transfers water"s latent heat of vaporization, which is extremely large (2.275 kJ/g), to the surface, rapidly bringing the surface of the food up to cooking temperature. Because the steam condenses and drips away, no significant boundary layer forms and heat transfer is exceptionally efficient, and food heats much faster and more evenly.

However some recipes require browning to develop flavors as during roasting or frying. Higher temperatures are attainable with conventional cooking where the surface of the food can dry out. Such browning occurs via the Maillard reaction, at temperatures higher than the roughly 120 °C (248 °F) achieved in pressure cooking. Because those temperatures are not reached in pressure cooking, foods are generally browned by searing them, either in the open pressure cooker or another pan beforehand.

A pressure cooker can be used to compensate for lower atmospheric pressure at high elevations. The boiling point of water drops by approximately 1°C per every 294 metres of altitude (see: High-altitude cooking), causing the boiling point of water to be significantly below the 100 °C (212 °F) at standard pressure. This is problematic because temperatures above roughly 90°C are necessary to cook many common vegetables in a reasonable time. For example, on the summit of Everest (8,848 m (29,029 ft)), the boiling point of water would be only 70 °C (158 °F). Without the use of a pressure cooker, many boiled foods may remain undercooked, as described in Charles Darwin"s

Having crossed the Peuquenes [Piuquenes], we descended into a mountainous country, intermediate between the two main ranges, and then took up our quarters for the night. We were now in the republic of Mendoza. The elevation was probably not under 11,000 feet (3,400 m) [...]. At the place where we slept water necessarily boiled, from the diminished pressure of the atmosphere, at a lower temperature than it does in a less lofty country; the case being the converse of that of a Papin"s digester. Hence the potatoes, after remaining for some hours in the boiling water, were nearly as hard as ever. The pot was left on the fire all night, and next morning it was boiled again, but yet the potatoes were not cooked.

When pressure cooking at high altitudes, cooking times need to be increased by approximately 5% for every 300 m (980 ft) above 610 m (2,000 ft) elevation. Since the regulators work off the pressure differential between interior and ambient pressure, the absolute pressure in the interior of a pressure cooker will always be lower at higher altitudes.

Weight is a concern with backpackers, so mountaineering pressure cookers are designed to operate at a lower differential pressure than stove-top units. This enables them to use thinner, and therefore lighter materials. Generally, the goal is to raise the cooking temperature enough to make cooking possible and to conserve fuel by reducing heat lost through boiling.Sherpas often use pressure cookers in base camp.

Pressure cookers employ one or more regulators to control the pressure/temperature. All types have a calibrated pressure relief valve, as well as one or more emergency valves.

With the simplest types, once the desired pressure is reached, the valve opens, and steam escapes cooling the vessel and limiting the temperature. More advanced stovetop models have pressure indicators that permit the user to adjust the heat to prevent the steam from escaping. Third generation types automatically measure the state of the vessel and control the power so as to not release steam in operation.

Pressure cookers are available in different capacities for cooking larger or smaller amounts, with 6 litres" capacity being common. The maximum capacity of food is less than the advertised capacity because pressure cookers can only be filled up to 2/3 full, depending on ingredients and liquid (see Safety features section).

Because of the forces that pressure cookers must withstand, they are usually heavier than conventional pots of similar size. The increased weight of conventional pressure cookers makes them unsuitable for applications in which saving weight is a priority, such as camping. Nonetheless, small, lightweight pressure cookers are available for mountain climbers

A gasket or sealing ring, made from either rubber or silicone, forms a gas-tight seal that does not allow air or steam to escape between the lid and pan. Normally, the only way steam can escape is through a regulator on the lid while the cooker is pressurized. If the regulator becomes blocked, a safety valve provides a backup escape route for steam.

The twist-on design has slots on the lid engaging with flanges on the body, similar to a lid on a glass jar, that works by placing the lid on the pot and twisting it about 30° to lock it in place. A common modern design, it has easily implemented locking features that prevent the removal of the lid while under pressure.

The center screw design has a bar that is slotted in place over the lid and a screw tightened downward to hold the lid on. Though an older design, it is still produced due to its ease of construction and simplicity.

The bolt-down design has flanges on both its lid and its body for bolts to be passed through, and usually uses wingnuts that hinge on the body and so are never fully removed from the cooker; this sealing design is typically used for larger units such as canning retorts and autoclaves. It is very simple to produce, and it can seal with simple and inexpensive gaskets.

The internally fitted lid design employs an oval lid that is placed inside and presses outward; the user inserts the lid at an angle, then turns the lid to align it with the pot opening on top because the lid is larger than the opening. A spring arrangement holds the lid in place until the pressure forms and holds the lid tightly against the body, preventing removal until the pressure is released.

Gaskets (sealing rings) require special care when cleaning (e.g., not washed with kitchen knives), unlike a standard lid for a saucepan. Food debris, fats, and oils must be cleaned from the gasket after every use. Gasket/sealing rings need replacing with a new one about once a year (or sooner if it is damaged e.g. a small split). A very dry gasket can make it difficult or impossible to close the lid. Smearing the gasket sparingly with vegetable oil alleviates this problem (using too much vegetable oil can make the gasket swell and prevent it sealing properly). A gasket that has lost its flexibility makes bringing the cooker up to pressure difficult as steam can escape before sufficient pressure is generated to provide an adequate seal; this is usually a sign that the gasket needs replacing with a new one. Oiling the gasket with vegetable oil may alleviate the problem temporarily, but a new gasket is often required.

Early pressure cookers equipped with only a primary safety valve risked explosion from food blocking the release valve. On modern pressure cookers, food residues blocking the steam vent or the liquid boiling dry will trigger additional safety devices. Modern pressure cookers sold from reputable manufacturers have sufficient safety features to prevent the pressure cooker itself from exploding. When excess pressure is released by a safety mechanism, debris of food being cooked may also be ejected with the steam, which is loud and forceful. This can be avoided if the pressure cooker is regularly cleaned and maintained in accordance with the manufacturer"s instructions and never overfilled with food and/or liquid.

Modern pressure cookers typically have two or three redundant safety valves and additional safety features, such as an interlock lid that prevents the user from opening the lid when the internal pressure exceeds atmospheric pressure, preventing accidents from a sudden release of hot liquid, steam and food. If safety mechanisms are not

8613371530291

8613371530291