farris safety valve free sample

Providing a safe and hazard-free work environment is just one of the many complex challenges facing modern process facilities. For those facilities who fall under the jurisdiction of OSHA 29 CFR 1910.119, creating an effective PSM program is not only sound engineering practice, it’s the law. Whatever stage of your facilities life cycle, Farris Engineering Services (FES) offers comprehensive pressure relief system management solutions to help you achieve PSM compliance.

Farris Engineering Services has a comprehensive understanding of overpressure scenarios. We know how to correctly identify the appropriate relief protection for any application. Use our expertise to help you design your pressure relief system right from the start. Our services will provide design options which maximize process production while minimizing unnecessary costs.

Accurately size and select a pressure relief valves for various process applications using SizeMaster™, a web-based engineering software tool. The SizeMaster™ software brings unprecedented integration of recognized and generally accepted good engineering practices (RAGAGEP) to the task of sizing and selecting pressure relief valves.

Accessing the SizeMaster™ sizing tool through one’s modern web browser, a user can perform a steady-state sizing analysis by first defining at least one, if not all, of the recommended overpressure failure scenarios identified within the API 521 Standard and then calculating the required discharge area to satisfy the upset conditions. Design details such as relieving conditions, fluid characteristics, and sound engineering principles are supplied to the software for such scenarios like fire, thermal expansion, control valve failure, and tube rupture. Suitable candidate Farris pressure relief valve(s) are presented to the user for selection based on the supplied application requirements which then can be further customized and configured for a specific criterion.

This software aims to take a complicated task of determining required capacities and orifice areas by merging together the wide-range of Farris products to produce a concise yet comprehensive tool for the specification of overpressure protection.

All sizing equations and selection algorithms are based on ASME Code requirements, API standards and best engineering practice as determined byFarris Engineering. The equations and flow algorithms are internally calculated within an innovative worksheet engine which checks selected conditions and any intermediate calculations against the constraints of industry standards, informing the user of any non-compliance issues it encounters. Using supplied sizing conditions and application-specific details, suitable candidate valve(s) are cross-checked against their appropriate temperature and pressure tables including any backpressure constraints. Once the software determines the orifice area required to relieve the supplied overpressure scenario(s), SizeMaster™ recommends an optimum Farris pressure relief valve series and orifice size. The user can further customize its materials, soft goods, and other options and accessories to meet their facility and device needs.

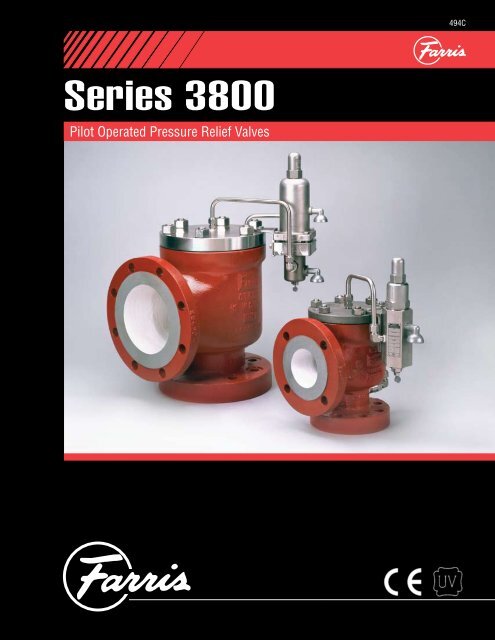

SizeMaster includes catalog information forFarris 2400, 2600, 2700, 3800, 6400/6600, 4200, 1890, 1896, and 4700seriespressure relief valves,including black and white cross-section dimensional drawings. The registered user can select and customize a candidate Farris model number, SizeMaster™ will ensure a valve is suitable for the supplied process parameters (such as a liquid-trim valve for a vapor scenario), and on-line help is available to assist in the determination of each of the digits of the Farris model number configuration. SizeMaster™ can manage the sizing and selection work-flow process for jobs/plants, from request for quotation through order generation.

Whether the user is quoting safety valves for a large-scale Job/Plant or performing a single yet fast Quick Sizeoption, SizeMaster™ makes the task of sizing and selecting pressure relief valves straight-forward and globally accessible. The design of this web-based software allows for the development team to automatically deploy updated versions of the tool to remain up-to-date with the latest changes in industry best practices and new product features and offerings.

Farris products from Curtiss Wright are a world leader in the design and production of a wide range of spring-loaded and pilot-operated pressure relief valves. They are used as safety devices to prevent over-pressurisation of vessels, pipelines and equipment. Providing protection of employees, plants and the environment. Used on Gas, Air, Water, Vapour, liquid and Steam service.

With Farris, a high quality trustworthy valve design is only part of our promise. Using the Farris Engineering Sizing and Selection tools, Farris provides customers with total pressure relief management solutions that support a facility’s entire lifecycle, transforming the way you ensure plant safety on a bespoke basis. With a full set pressure range, Flange standards available include ANSI, API, MSS, BS, PN and ISO. A full range of construction materials are available, which includes Carbon Steel, Stainless Steel, Duplex & Super Duplex, Aluminium Bronze, Monel, Titanium, Zirconium, plus many others.

Check ValvesCheck Valve – A check valve, clack valve, non-return valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Gate Valve – A gate valve, also known as a sluice valve, is a valve which opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired Globe Valve – A Globe valve is a type of valve used for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body. Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug can be screwed in to close (or shut) the valve. The plug is also called a disc or disk. In globe valves, the plug is connected to a stem which is operated by screw…

Curtiss-Wright’s selection of Pressure Relief Valves comes from its outstanding product brands Farris, and Target Rock. We endeavour to support the whole life cycle of a facility, and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of their pressure relief valves are guaranteed to give your equipment and machinery effective relief from pressure when needed.

A pressure relief valve, an umbrella term which includes safety valves and expansion relief valves, is designed to do exactly that: relieve pressure on a system. Pressure reducing valves use spring-loaded mechanisms to control and relieve any excess pressure, and prevent any more fluid passing through until normal pressure conditions have been restored. Depending on the model, control can be provided to both dynamic and static flow conditions.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes all forms of valve, from flanged to spring loaded, threaded to wireless, pilot operated, and much more.

The Supreme Court has reinforced the theory of the First Amendment as a "safety valve," reasoning that citizens who are free to to express displeasure against government through peaceful protest will be deterred from undertaking violent means. The boundary between what is peaceful and what is violent is not always clear. For example, in this 1965 photo, Alabama State College students participated in a non-violent protest for voter rights when deputies confronted them anyway, breaking up the gathering. (AP Photo/Perry Aycock, used with permission from the Associated Press)

Under the safety valve rationale, citizens are free to make statements concerning controversial societal issues to express their displeasure against government and its policies. In assuming this right, citizens will be deterred from undertaking violent means to draw attention to their causes.

The First Amendment, in safeguarding freedom of speech, religion, peaceable assembly, and a right to petition government, embodies the safety valve theory.

These and other decisions rest on the idea that it is better to allow members of the public to judge ideas for themselves and act accordingly than to have the government act as a censure. The Court has even shown support in cases concerning obscenity or speech that incites violent action. The safety valve theory suggests that such a policy is more likely to lead to civil peace than to civil disruption.

Justice Louis D. Brandeis recognized the potential for the First Amendment to serve as a safety valve in his concurring opinion in Whitney v. California (1927) when he wrote: “fear breeds repression; . . . repression breeds hate; . . . hate menaces stable government; . . . the path of safety lies in the opportunity to discuss freely supposed grievances and proposed remedies; and the fitting remedy for evil counsels is good ones.”

Our type numbering system simplifies the selection and specifying of Farris pressure relief valves because the digits that comprise a specific type number

have a distinct significance. The digits describe the basic valve series, orifice, seat and internal construction, inlet temperature range, body, bonnet and

4. For a valve in complete stainless steel, add “N4” to suffix. Example: 26HB10-120/N4. For optional complete Inconel bellows, add “N4/SP”. Example: 26HB10-120/N4/SP.

1. Standard seat tightness for “O” ring valves is no bubbles at 90% of set pressure for both conventional and bellows valves. At set pressures of 50 psig and below, leakage test shall

1. All valves supplied with plain caps unless otherwise specified. Standard suffix for type number is “-120”. For other cap construction, refer to page 69.

6. Optional equipment includes: air set device for set pressure testing, extra large lapping glass for valve seat maintenance, spring compression device for set

While this information is presented in good faith and believed to be accurate, Farris Engineering, division of Curtiss-Wright Flow Control Corporation, does not guarantee satisfactory

fitness or any other matter with respect to the products, nor as a recommendation to use any product or process in conflict with any patent. Farris Engineering, division of

8613371530291

8613371530291