alfa laval safety valve supplier

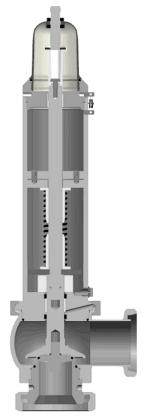

It is used to prevent inadmissible overpressures of fluids in tanks, containers, and plant sections. From the factory, the valve is configured with a set pressure upon request that is created than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontally the set pressure will be a bit lower than specified due to the missing weight of the piston.

Central States Industrial (CSI) is a master distributor of Alfa Laval sanitary equipment and their Tri-Clover® product range. Alfa Laval is a leading global supplier of products and solutions for heat transfer, separation, and fluid handling through their essential products: heat exchangers, separators, pumps, valves, and fittings.

The Alfa Laval name has long been recognized as a supplier of high-quality products. While quality remains a top priority, their mission is to provide value to customers by optimizing the performance of your processes. With more than 2000 patents, they offer worldwide solutions in areas that are vital to society both today and for the future. Their products are used in a wide variety of industries, including the manufacturing of food, chemicals, pharmaceuticals, starch, sugar, and ethanol.

Alfa Laval’s innovative valves enables gentle and sustainable production of a wide range of food and beverage products. Their innovative and robust solutions allow customers to achieve a never before seen level of hygiene and safety in their industrial processes and at the same time improve taste, nutritional value, texture and appearance of the food and beverage products. No matter how complex your process line or plant are, their specialists work closely with the customers to tailor the right solution. They are committed to ensuring maximum uptime and continuous optimization of your processes.

January 19, 2016 - Alfa Laval announces Safety Valves that protect against overpressure in tanks and pipelines caused by overfilling or fermentation processes.

In a potentially dangerous situation it will open at a predetermined set pressure. The compressed spring force, keeping the valve closed, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

These safety valves protect also protect against implosion due to vacuum caused by cold rinsing after hot cleaning or blocking of gas supply during emptying.

The Alfa Laval safety valve can be combined with the Alfa Laval SB anti vacuum house into a combined safety valve, protecting against both vacuum and overpressure in one hygienic valve solution with a single tank connection.

Pressure can build inside vessels or systems due to blocked discharge, thermal expansion, chemical reactions, or a combination of these events. The Alfa Laval Safety Valve is designed to flexibly relieve excess pressure from vessels or equipment at all times and under any circumstances. As the last and vital component in accident prevention, a high-quality, hygienic safety valve is an essential part of your operations.

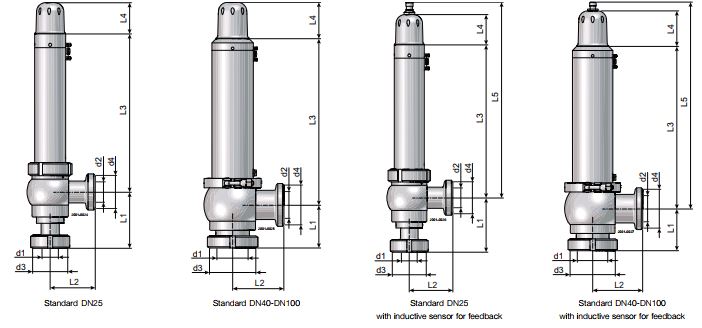

Depending on the causes of excess pressure, a different mass or volume flow may need to be discharged. With this type of variable flow, a perfectly fitted safety valve is essential. The Alfa Laval Safety Valve comes in sizes from DN25 to DN100 with a spring-loaded set pressure range between 0.2 and 12.0 bar depending on the size of the valve.

In a potentially dangerous situation, the Alfa Laval Safety Valve is designed to open at a predetermined set pressure. The compressed spring force, which keeps the valve closed below the set pressure, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

The Alfa Laval SB Anti Vacuum House minimizes the risk of implosion in closed process tanks that are subject to vacuum conditions, such as while filling or emptying the tank, cool rinsing after hot-cleaning, or caustic cleaning in a CO2 atmosphere. Capable of being integrated into a SCANDI BREW® tank top system, the valve is designed for hygienic processes in the brewery, dairy, food and beverage industries.

Safety Valves are used to prevent inadmissible over pressures of fluids in tanks, containers and plant sections. In the factory the valve is configured with a set pressure upon request that is greater than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontal the set pressure will be a bit lower than specified due to the missing weight of the piston. Highest effect on DN80 and DN100.

The Alfa Laval Safety Valves are available in sizes from DN25 to DN100 with spring loaded set pressure range from 0.2 to 12 bar. A valve can be pneumatic or manually operated and are delivered with PED certificate.

The Alfa Laval Safety Valve protects your equipment, your environment, and the health and safety of your workers. This safety device is designed to open and relieve excess pressure from vessels or equipment and then reclose and prevent the further release of fluid when the system returns to normal.

The Alfa Laval Safety Valve is a spring loaded safety valve used to prevent overpressure in tanks and vessels in the dairy, food and beverage, and biopharm industries to reliably avoid damages to human beings and equipment.

It is used to prevent inadmissible over pressures of fluids in tanks, containers and plant sections. From the factory the valve is configured with a set pressure upon request that is greater than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontal the set pressure will be a bit lower than specified due to the missing weight of the piston. Highest effect on DN80 and DN100.

The Alfa Laval Safety Valve comes in sizes from DN25 to DN100 with spring loaded set pressure range from 0.2 to 12 bar. The valve can be pneumatic or manually operated. Alfa Laval Safety Valve is delivered with PED certificate. Compliance to EN 4126-1 Compliance to PED 97/23/EC of the European Community. Fluid group II (Non-hazardous fluids).

Alfa Laval manufacturers valves and automation for hygienic use. Customers in the food, biopharm and other demanding industries rely on Alfa Laval valves for process performance and hygiene in the most demanding applications.

Ball Valves ~ Butterfly Valves ~ Control/Check Valves ~ Diaphragm Valves ~ Double Seal Valves ~ Double Seat Valves ~ Regulating Valves ~ Safety Valves ~ Sampling Valves ~ Shutter Valves ~ Single Seat Valves

They combine the innovation of Alfa Laval with the time-proven reliability of Tri-Clover brand valves, providing the options required to meet your processing needs.

From compression and relief valves to sampling and CPM valves, Alfa Laval has the products and technology to provide you with sanitary, efficient and economical valve solutions to suit your unique application.

/INS. To complete the strongest safety valve portfolio in the market, we now introduce a true spring-loaded safety valve: The Alfa Laval Safety Valve.

This new valve is designed to protect both equipment and people. In a potentially dangerous situation it will open at a predetermined set pressure. The compressed spring force, keeping the valve closed, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

These safety valves protect against overpressure in tanks and pipelines caused by e.g. overfilling or fermentation processes. They also protect against implosion due to e.g. vacuum caused by cold rinsing after hot cleaning or blocking of gas supply during emptying.

The Alfa Laval Safety Valve can be combined with the Alfa Laval SB Anti Vacuum House into a combined safety valve, protecting against both vacuum and overpressure in one hygienic valve solution with a single tank connection.

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

8613371530291

8613371530291