alfa laval safety valve made in china

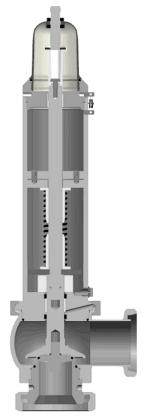

It is used to prevent inadmissible overpressures of fluids in tanks, containers, and plant sections. From the factory, the valve is configured with a set pressure upon request that is created than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontally the set pressure will be a bit lower than specified due to the missing weight of the piston.

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Alfa Laval Tank Bottom Valve , alfa laval tank bottom valve , Tank Bottom Valve , Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality solutions and perfect pre-sales /after-sales service is our idea some clients had cooperated with us for more than 5 years.

In 2023, the sales of Pressure Relief Valve in Global Market is expected to reach US$ 4,509.8 Mn. and is projected to expand steadily at a CAGR of 4.6% to reach a market valuation of close to US$ 7,070.9 Mn by 2033.

In recent past valve costs have increased globally, which can be attributed to growing tariffs from the North American region, particularly the US. Leading players from the European and American regions have facilities in both high- and low-income nations. In contrast, labor-intensive production processes like the creation of rough castings for valves and valve components take occur in low-cost manufacturing nations like China. These processes include design, research and development, and testing. Due to low prices and quality maintenance, OEMs are able to do so. However, growing US government tariffs on steel and aluminum imports from China have had a substantial negative influence on pressure relief valve profit margins and costs.

However, the rapid growing industrialization and increasing safety precaution are the factors that are expected to fuel the market growth of Pressure relief valves across the globe during the assessment period, the Pressure relief valve market is expected to experience demand growth with CAGR of 4.6% during the forecasted period.

From 2017 to 2022, the Global Pressure Relief Valve Market expanded at a CAGR of around 2.4%. The advancement in product technology to connect the valves digitally enables end users to monitor pressure in various applications digitally which has generated significant demand from the various industry sector during the forecasted period.

Numerous applications where pressure levels are crucial for continuous and efficient machinery performance demand for the utilization of pressure relief valves. These include the various sectors operating with steam, air, gas, or liquid such as oil and gas, power generation and the petrochemicals industry. Multiphase applications and chemical processing systems both have high installation rate of pressure relief valves. With rapid development industrial sector & expansion of oil & Gas pipelines across the developing as well as developed economies the demand for PRV is also expected to expand, Persistence Market Research expects the market to expand at a 4.6% CAGR through 2033.

Both emerging and advanced regions have seen a surge in oil and gas consumption. In order to meet the rising demand and supply for oil and gas, industries are concentrating on expanding their production facilities through onshore and offshore exploration. Since the oil and gas sector is one of the key end uses for the global pressure relief valves market thus expanding oil & gas Sector is generating lucrative opportunity for the demand growth of PRVs in upcoming period.

Furthermore, growing regulation for use of pressure relief valves in power generation sector is further set to create opportunities for the market. For instance, there are currently about 50 nuclear reactors under development. By safeguarding turbines, super heaters, and boilers to enable the stations to operate at prescribed pressures, pressure relief valves play a crucial part in the successful and safe operations of nuclear facilities.

Manufacturing businesses will be significantly and directly impacted by the Asia Pacific region"s volatile and uncertain markets. The operational costs of the manufacturing processes, which are the main concern of manufacturers, will be directly impacted by rising tariffs and raw material costs used to manufacture valves. Rising raw material costs immediately impact the integrity of the supply chain and the selling price of a product. Manufacturers in the Asia Pacific region are becoming increasingly concerned about the steady growth in cost of the raw materials used to make pressure relief valves. This is expected to, restrain the market"s expansion for pressure relief valves.

With an absolute dollar opportunity of around US$ 600.0 Mn, North America is expected to be the most lucrative market for pressure relief valves suppliers. U.S is leading the North American market, and is expected to witness a 1.5X growth during 2023-2033. The market for pressure relief valves has recently experienced considerable growth in sales as a result of growing industrialisation and advancements in urban waste water management systems. Apart from that U.S. is also second largest importer & Exporter of Pressure relief valves, which makes it a targeting region for the manufacturers & Suppliers.

In 2023, the German Pressure Relief Valve market is likely to hold around 25% of the market by value share in Europe. Germany"s extensive remanufacturing capabilities are likely to play a crucial part in development of industrial growth. Sales growth for pressure relief valves is anticipated to be boosted in the upcoming years as manufacturers are planning to invest more in safety & developments of industrial Sites.

With a CAGR of 5.9%, India is expected to lead the South Asian market throughout the assessment period and experience significant expansion. Pressure relief valve demand is anticipated to increase as a result of India"s low production and labour costs, as well as less regulations & certifications required for PRVs, which are encouraging various industry players, including oil & gas, pharmaceutical, chemical, and textile manufacturers, to expand their manufacturing facilities in India.

By the end of the assessment period, spring-loaded pressure relief valves will hold a value share of over 40% of the market for pressure relief valves worldwide. Due to its broad range of applications and other technological advantages over other valves, this valve is widely utilized. The design and use of pressure relief valves is covered by a number of international codes and standards, the most popular of which being the ASME (American organization for mechanical engineers) Boiler and Pressure Vessel Code, also known as ASME code. Despite the fact that this code varies by region.

In 2023, the demand for pressure relief valves is primarily driven by the Medium Pressure segment in Set Pressure segment of the market. By the end of the forecast period, it is projected that pressure relief valves with a medium pressure range will still be widely utilized in a variety of end use sectors. The market for medium pressure relief valves is expected to continue expanding due to rising end-use sectors including oil and gas, chemical, and others.

/INS. To complete the strongest safety valve portfolio in the market, we now introduce a true spring-loaded safety valve: The Alfa Laval Safety Valve.

This new valve is designed to protect both equipment and people. In a potentially dangerous situation it will open at a predetermined set pressure. The compressed spring force, keeping the valve closed, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

These safety valves protect against overpressure in tanks and pipelines caused by e.g. overfilling or fermentation processes. They also protect against implosion due to e.g. vacuum caused by cold rinsing after hot cleaning or blocking of gas supply during emptying.

The Alfa Laval Safety Valve can be combined with the Alfa Laval SB Anti Vacuum House into a combined safety valve, protecting against both vacuum and overpressure in one hygienic valve solution with a single tank connection.

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

Industrial Spring Safety Valves Market Size is projected to Reach Multimillion USD by 2029, In comparison to 2021, at unexpected CAGR during the forecast Period 2022-2029.

This research report is the result of an extensive primary and secondary research effort into the Industrial Spring Safety Valves market. It provides a thorough overview of the market"s current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Industrial Spring Safety Valves Market.

The Global Industrial Spring Safety Valves market is anticipated to rise at a considerable rate during the forecast period, between 2023 and 2029. In 2021, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

Industrial Spring Safety Valve is a valve that acts as a fail-safe, which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

The global Industrial Spring Safety Valves market is projected to reach USD million by 2029 from an estimated USD million in 2022, at a CAGR of during 2023 and 2029.

North American market for Industrial Spring Safety Valves is estimated to increase from USD million in 2022 to reach USD million by 2029, at a CAGR of during the forecast period of 2023 through 2029.

Asia-Pacific market for Industrial Spring Safety Valves is estimated to increase from USD million in 2022 to reach USD million by 2029, at a CAGR of during the forecast period of 2022 through 2029.

The major global companies of Industrial Spring Safety Valves include General Electric, Emerson Electric, Weir, Spirax Sarco, Curtiss-Wright, Watts, LESER GmbH, Alfa Laval and CIRCOR, etc. In 2021, the world"s top three vendors accounted for approximately of the revenue.

The global market for Industrial Spring Safety Valves in Oil and Gas is estimated to increase from USD million in 2022 to USD million by 2029, at a CAGR of during the forecast period of 2022 through 2029.

Considering the economic change due to COVID-19 and Russia-Ukraine War Influence, Low Pressure Valve, which accounted for of the global market of Industrial Spring Safety Valves in 2021, is expected to reach million USD by 2029, growing at a revised CAGR of from

Use of Oil and Gas, Chemical, Power Generation, Paper Industry, Others and in multiple sectors has led to significant growth in demand for Industrial Spring Safety Valves in the market

This Industrial Spring Safety Valves Market Research/Analysis Report Contains Answers to your following Questions ● What are the global trends in the Industrial Spring Safety Valves market? Would the market witness an increase or decline in the demand in the coming years?

● What is the estimated demand for different types of products in Industrial Spring Safety Valves? What are the upcoming industry applications and trends for Industrial Spring Safety Valves market?

● What Are Projections of Global Industrial Spring Safety Valves Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

● What are the factors contributing to the final price of Industrial Spring Safety Valves? What are the raw materials used for Industrial Spring Safety Valves manufacturing?

● How big is the opportunity for the Industrial Spring Safety Valves market? How will the increasing adoption of Industrial Spring Safety Valves for mining impact the growth rate of the overall market?

Global Safety Valve Market, By Material (Steel, Alloy, Cast Iron, Cryogenic, Others), Size (Less Than 1”, 1” to 10”, 11” to 20” and 20’ & Above), End-Use (Oil & Gas, Energy & Power, Chemicals, Food & Beverage, Water &Wastewater Treatment, Others) – Industry Trends and Forecast to 2029.

The importance of safety valves in industrial processes, increased demand from oil and gas, and the growth of nuclear energy generation are some of the key factors driving the safety valves market. Other factors driving market growth include the constant need for safety valve replacement and the use of 3D printers in manufacturing lines.

Data Bridge Market Research analyses that the safety valve market was valued at USD 5.74 billion in 2021 and is expected to reach the value of USD 11.00 billion by 2029, at a CAGR of 8.47% during the forecast period. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

Emerson Electric Co (U.S.), Schlumberger Limited (U.S.), General Electric (U.S.), Curtiss-wright Corporation (U.S.), ALFA LAVAL (Sweden), IMI plc (U.K.), LESER GmbH & Co. K.G. (Germany), The Weir Group PLC (Scotland), Forbes Marshall (India), Danfoss (Denmark), Bosch Rexroth AG (Germany), Spirax Sarco Limited (U.K.)

Safety valves, also known as precautionary and preventive valves, operate automatically when the current safety valve pressure and temperature are exceeded. These valves are critical in protecting employees and the environment around the plants.

Some of the major and impactful factors driving the growth of the safety valve industry are increased awareness of the importance of safety valves in various industrial processes such as power generation, gas and petroleum, including water and sewage processing, mining, oil processing, food manufacturing, increased demand for the product in the oil & gas industry, growth in nuclear energy generation, and increased use of 3D printers in manufacturing lines.

Rising demand for water and power, pollution control regulations, and rapid growth of process industries are some of the major factors driving the safety valve market. These factors are expected to accelerate the growth of the safety valve industry during the assessment period. The market is expanding due to the increased construction of nuclear power plants. The rise in accidental incidents and soaring demand for safety valves in various industrial sectors are propelling the global market forward.

Integration of safety valves into the Internet of Things (IoT) environment is creating an opportunity to increasing the safety valve market industry. The innovations in safety valve systems are expected to fuel the market"s rapid growth.

Rising fabrication costs and low profit margins for companies are the major factors acting as restraints, and will further challenge the safety valve market during the forecast period.

This safety valve market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the safety valve market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The global safety valve market suffers as a result of the lockdown. This pandemic had a significant impact on the safety valve market and the entire world. To reduce the spread of the coronavirus, the government has imposed stringent regulations such as lockdowns, social distance, face masks, manufacturing industry shutdowns, and transportation bans. Despite the pandemic being in its early stages, the safety valve market has declined. New technological innovations and growing awareness regarding the benefits of the safety valve market by the key players are increasing the growth of this market.

The safety valve market is segmented on the basis of material, size & end use. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The countries covered in the safety valve market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific will dominate the safety valve market due to increased infrastructure development, increased investments in various industries such as the construction industry, oil and gas sector, and drastic urbanisation, to name a few factors.

The safety valve market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, Global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to safety valve market.

In accordance with the Unidirectional Knife Gate Valves market is set to grow at a CAGR of 4.5% over a forecast period (2023-2030).A metal-to-metal sealing valve known as a one-way knife gate valve uses an elastomeric seal to stop leaks. One kind of one-way valve that only permits flow in one direction is a knife gate valve. There is no pressure loss through additional apertures or locations where outgassing may take place to the movement produced by the blades on either side of the entrance. Compared to similar products, this makes the device safer and requires less maintenance. The valve"s purpose is to let flow in only one direction, which makes it perfect for applications like water or gas distribution networks and oil refineries where only one direction must be permitted.

8613371530291

8613371530291