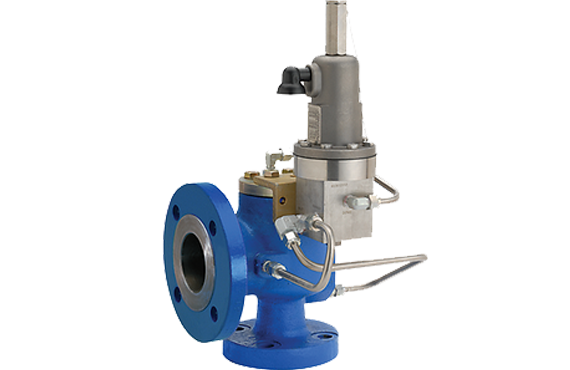

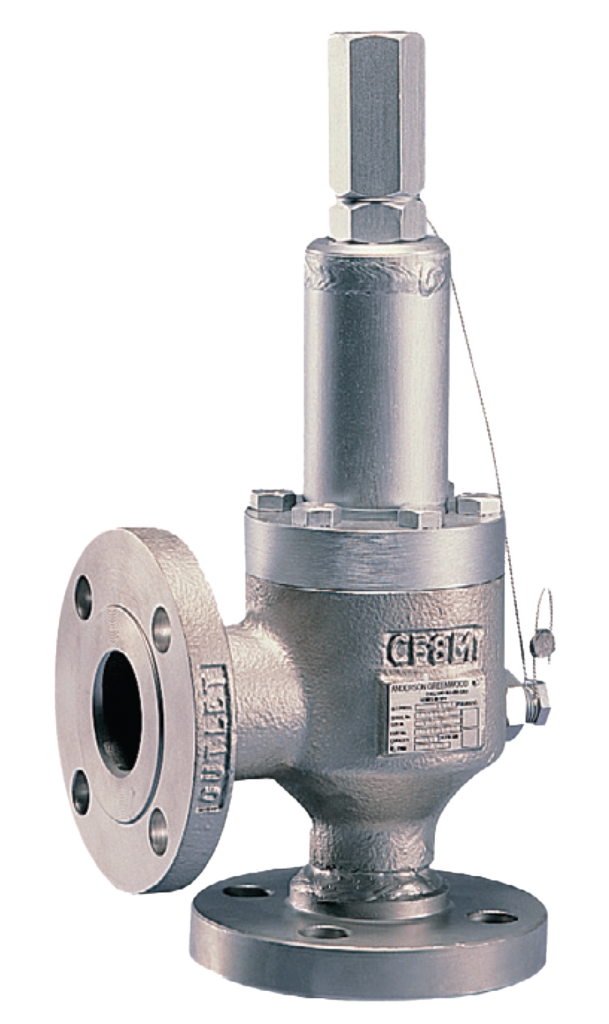

anderson greenwood pressure safety valve for sale

Through our “VR” certification from the National Board of Boiler and Pressure Vessel Inspectors, Cornerstone provides “24/7” asset management and repair services for all brands of pressure relief products in ASME Section I and VIII applications and is capable of testing on steam, air/gas, and liquid medias.

Anderson Greenwood pressure relief valves, tank protection products, primary isolation valves, and instrumentation set the industry standard for repeatable service and long service life. The breadth of Anderson Greenwood product offerings for both standard and specialized installations combined with unmatched application expertise, product quality, and availability provides for complete valve solutions in the oil and gas, chemical, power generation, and refining industries.

About AG’s 63B Safety ValveType 63B valves are direct spring-operated safety valves suitable for medium set pressure gas, vapor and liquid or gas thermal relief applications. Specific valve types are available for gas, vapor, liquid; gas or liquid thermal relief, steam, cryogenic and chemically active applications.

The 63B’s brass construction offers an economical valve for carbon dioxide, natural gas and general gas or vapor services. Yet, these relief valves use special internals and soft seals to provide optimum accurate performance.

About Seal Tightness Performance SpecsAll pressure relief valves are checked for seal leakage per procedures outlined in API 527. The following operating pressures will allow for bubble-tight seat sealing performance.

Bubble-tight seats near set pressure: Allows higher system operating pressure and, therefore, maximum process output; not as sensitive to vibrational and pulsating service; reduces product loss.

Modulating action available: Minimized product loss per relief situation; reduced environmental pollution; avoids oversizing consequences; not as sensitive to inlet pressure losses as pop action.

Full lift at set pressure: No overpressure required for full lift; allows D.O.T. installation to be set higher than Maximum Allowable Operating Pressure (MAOP) when pop action is used.

High Gain Modulating Action available on 400 Series pilots providing full main valve lift by 5% overpressure while minimizing product loss during relief events.

An innovative, comprehensive portfolio of pressure management solutions that define industry standards for repeatable, bubble-tight shutoff and long life.

Anderson Greenwood™ pressure relief valves, tank protection products, primary isolation valves, and instrumentation set the industry standard for repeatable service and long service life. The breadth of Anderson Greenwood product offerings for both standard and specialized installations combined with unmatched application expertise, product quality, and availability provides for complete valve solutions in the oil and gas, chemical, power generation, and refining industries.

Gas-tight valve seat close to the set pressure: allows higher system operating pressures and therefore achieves maximum process output; insensitive to vibration applications; reduced product loss.

Adjustable actions are available: minimize product loss at each pressure release; reduce environmental pollution; avoid oversize consequences; not as sensitive to inlet pressure loss as prominent actions.

Full lift at set pressure: no overpressure is required for full lift; D.O.T. is allowed to be set higher than MAOP (maximum allowable operating pressure) when using a protruding action.

If the determined valve type and model are provided by the customer, the customer should correctly explain the meaning and requirements of its model, and sign the contract under the conditions that the supply and demand sides understand and agree.

Steven Levy Enterprises buys and sells new, unused, and used industrial surplus relief valves. Browse our inventory of relief valves from major manufacturers such as Consolidated, Crosby, Farris and more that are available for purchase. A relief valve is a type of safety valve used to control or limit the pressure in a system. A relief valve are divided into pop-type, direct-operated, pilot-operated, and internal relief valves. The primary purpose of a pressure relief valve is for safety of system operators and property protection by venting fluid from an over pressurized vessel. Relief valves meet industry needs for overpressure protection in chemical, petrochemical, refinery, power generation and other commercial applications. Relief valves such as Consolidated relief valves, Crosby relief valves, Farris relief valves all come in various material bodies such as alloy, carbon steel, and stainless steel and may require special alloys for specific applications. Tell us what surplus relief valves you have for sale or call us at 713-910-4337.

Looking for the right pressure relief valve to protect your system? Anderson Greenwood and Crosby are the premier suppliers of both direct spring operated and pilot operated pressure relief valves.

Anderson Greenwood offers a high performance alternative to spring and weight-loaded relief devices for low pressure systems. The Series 90/9000 features a broad range of pilot operated pressure and vacuum relief valves, primarily designed for protecting low pressure storage vessels and piping systems.

8613371530291

8613371530291