bellows safety valve factory

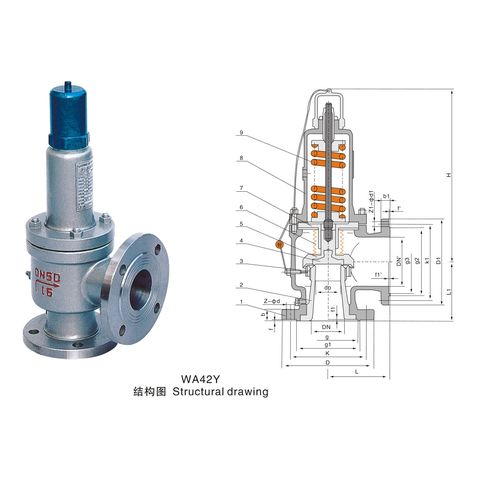

These safety valves are used for the equipment and pipeline of the poisonous gas, quality with corrode medium what the working temperature are less than 200℃.Take for extra pressure protection devices.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

240 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

250 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

271 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function ...

Relief Valves GLV-Series are spring loaded pressure relieving devices, suitable for discharge of incompressible fluids. GLV-series relief valves are used to protect personnel and equipment by preventing ...

Bellow balanced safety valves are designed to reduce the effetc of back pressure accumulation, the "Bellows" located between the bonnet and the valve body, where maintained free from the effetc of back pressure, the opposing pressure on the inlet fluid is only generated by the spring without contribution from any sort of backpressure. The space enclosed by bellows is freely vented to air, the back pressure is expetced to be 10 - 50% of the set pressure. The Bellows can also protetc the spring and other trim components from corrosive media.

As over-pressure safe protected devices, balance bellows back pressure safety valves are suitable for equipment or piping systems of the working temperatures=300℃ , and which systems exist back pressure changes, toxic flammable or corrosive medium. Using bellows, it can balance the back pressure of safety outlet, and ensure the accuracy of setting pressure.

There is a wide range of safety valves available to meet the many different applications and performance criteria demanded by different industries. Furthermore, national standards define many varying types of safety valve.

The ASME standard I and ASME standard VIII for boiler and pressure vessel applications and the ASME/ANSI PTC 25.3 standard for safety valves and relief valves provide the following definition. These standards set performance characteristics as well as defining the different types of safety valves that are used:

ASME I valve - A safety relief valve conforming to the requirements of Section I of the ASME pressure vessel code for boiler applications which will open within 3% overpressure and close within 4%. It will usually feature two blowdown rings, and is identified by a National Board ‘V’ stamp.

ASME VIII valve- A safety relief valve conforming to the requirements of Section VIII of the ASME pressure vessel code for pressure vessel applications which will open within 10% overpressure and close within 7%. Identified by a National Board ‘UV’ stamp.

Full bore safety valve - A safety valve having no protrusions in the bore, and wherein the valve lifts to an extent sufficient for the minimum area at any section, at or below the seat, to become the controlling orifice.

Conventional safety relief valve -The spring housing is vented to the discharge side, hence operational characteristics are directly affected by changes in the backpressure to the valve.

Balanced safety relief valve -A balanced valve incorporates a means of minimising the effect of backpressure on the operational characteristics of the valve.

Pilot operated pressure relief valve -The major relieving device is combined with, and is controlled by, a self-actuated auxiliary pressure relief device.

Power-actuated safety relief valve - A pressure relief valve in which the major pressure relieving device is combined with, and controlled by, a device requiring an external source of energy.

Standard safety valve - A valve which, following opening, reaches the degree of lift necessary for the mass flowrate to be discharged within a pressure rise of not more than 10%. (The valve is characterised by a pop type action and is sometimes known as high lift).

Full lift (Vollhub) safety valve -A safety valve which, after commencement of lift, opens rapidly within a 5% pressure rise up to the full lift as limited by the design. The amount of lift up to the rapid opening (proportional range) shall not be more than 20%.

Direct loaded safety valve -A safety valve in which the opening force underneath the valve disc is opposed by a closing force such as a spring or a weight.

Proportional safety valve - A safety valve which opens more or less steadily in relation to the increase in pressure. Sudden opening within a 10% lift range will not occur without pressure increase. Following opening within a pressure of not more than 10%, these safety valves achieve the lift necessary for the mass flow to be discharged.

Diaphragm safety valve -A direct loaded safety valve wherein linear moving and rotating elements and springs are protected against the effects of the fluid by a diaphragm

Bellows safety valve - A direct loaded safety valve wherein sliding and (partially or fully) rotating elements and springs are protected against the effects of the fluids by a bellows. The bellows may be of such a design that it compensates for influences of backpressure.

Controlled safety valve - Consists of a main valve and a control device. It also includes direct acting safety valves with supplementary loading in which, until the set pressure is reached, an additional force increases the closing force.

Safety valve - A safety valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored. Note; the valve can be characterised either by pop action (rapid opening) or by opening in proportion (not necessarily linear) to the increase in pressure over the set pressure.

Direct loaded safety valve -A safety valve in which the loading due to the fluid pressure underneath the valve disc is opposed only by a direct mechanical loading device such as a weight, lever and weight, or a spring.

Assisted safety valve -A safety valve which by means of a powered assistance mechanism, may additionally be lifted at a pressure lower than the set pressure and will, even in the event of a failure of the assistance mechanism, comply with all the requirements for safety valves given in the standard.

Supplementary loaded safety valve - A safety valve that has, until the pressure at the inlet to the safety valve reaches the set pressure, an additional force, which increases the sealing force.

Note; this additional force (supplementary load), which may be provided by means of an extraneous power source, is reliably released when the pressure at the inlet of the safety valve reaches the set pressure. The amount of supplementary loading is so arranged that if such supplementary loading is not released, the safety valve will attain its certified discharge capacity at a pressure not greater than 1.1 times the maximum allowable pressure of the equipment to be protected.

Pilot operated safety valve -A safety valve, the operation of which is initiated and controlled by the fluid discharged from a pilot valve, which is itself, a direct loaded safety valve subject to the requirement of the standard.

The common characteristic shared between the definitions of conventional safety valves in the different standards, is that their operational characteristics are affected by any backpressure in the discharge system. It is important to note that the total backpressure is generated from two components; superimposed backpressure and the built-up backpressure:

Subsequently, in a conventional safety valve, only the superimposed backpressure will affect the opening characteristic and set value, but the combined backpressure will alter the blowdown characteristic and re-seat value.

The ASME/ANSI standard makes the further classification that conventional valves have a spring housing that is vented to the discharge side of the valve. If the spring housing is vented to the atmosphere, any superimposed backpressure will still affect the operational characteristics. Thiscan be seen from Figure 9.2.1, which shows schematic diagrams of valves whose spring housings are vented to the discharge side of the valve and to the atmosphere.

By considering the forces acting on the disc (with area AD), it can be seen that the required opening force (equivalent to the product of inlet pressure (PV) and the nozzle area (AN)) is the sum of the spring force (FS) and the force due to the backpressure (PB) acting on the top and bottom of the disc. In the case of a spring housing vented to the discharge side of the valve (an ASME conventional safety relief valve, see Figure 9.2.1 (a)), the required opening force is:

In both cases, if a significant superimposed backpressure exists, its effects on the set pressure need to be considered when designing a safety valve system.

Once the valve starts to open, the effects of built-up backpressure also have to be taken into account. For a conventional safety valve with the spring housing vented to the discharge side of the valve, see Figure 9.2.1 (a), the effect of built-up backpressure can be determined by considering Equation 9.2.1 and by noting that once the valve starts to open, the inlet pressure is the sum of the set pressure, PS, and the overpressure, PO.

In both cases, if a significant superimposed backpressure exists, its effects on the set pressure need to be considered when designing a safety valve system.

Once the valve starts to open, the effects of built-up backpressure also have to be taken into account. For a conventional safety valve with the spring housing vented to the discharge side of the valve, see Figure 9.2.1 (a), the effect of built-up backpressure can be determined by considering Equation 9.2.1 and by noting that once the valve starts to open, the inlet pressure is the sum of the set pressure, PS, and the overpressure, PO.

Balanced safety valves are those that incorporate a means of eliminating the effects of backpressure. There are two basic designs that can be used to achieve this:

Although there are several variations of the piston valve, they generally consist of a piston type disc whose movement is constrained by a vented guide. The area of the top face of the piston, AP, and the nozzle seat area, AN, are designed to be equal. This means that the effective area of both the top and bottom surfaces of the disc exposed to the backpressure are equal, and therefore any additional forces are balanced. In addition, the spring bonnet is vented such that the top face of the piston is subjected to atmospheric pressure, as shown in Figure 9.2.2.

The bellows arrangement prevents backpressure acting on the upper side of the disc within the area of the bellows. The disc area extending beyond the bellows and the opposing disc area are equal, and so the forces acting on the disc are balanced, and the backpressure has little effect on the valve opening pressure.

Bellows failure is an important concern when using a bellows balanced safety valve, as this may affect the set pressure and capacity of the valve. It is important, therefore, that there is some mechanism for detecting any uncharacteristic fluid flow through the bellows vents. In addition, some bellows balanced safety valves include an auxiliary piston that is used to overcome the effects of backpressure in the case of bellows failure. This type of safety valve is usually only used on critical applications in the oil and petrochemical industries.

In addition to reducing the effects of backpressure, the bellows also serve to isolate the spindle guide and the spring from the process fluid, this is important when the fluid is corrosive.

Since balanced pressure relief valves are typically more expensive than their unbalanced counterparts, they are commonly only used where high pressure manifolds are unavoidable, or in critical applications where a very precise set pressure or blowdown is required.

This type of safety valve uses the flowing medium itself, through a pilot valve, to apply the closing force on the safety valve disc. The pilot valve is itself a small safety valve.

The diaphragm type is typically only available for low pressure applications and it produces a proportional type action, characteristic of relief valves used in liquid systems. They are therefore of little use in steam systems, consequently, they will not be considered in this text.

The piston type valve consists of a main valve, which uses a piston shaped closing device (or obturator), and an external pilot valve. Figure 9.2.4 shows a diagram of a typical piston type, pilot operated safety valve.

The piston and seating arrangement incorporated in the main valve is designed so that the bottom area of the piston, exposed to the inlet fluid, is less than the area of the top of the piston. As both ends of the piston are exposed to the fluid at the same pressure, this means that under normal system operating conditions, the closing force, resulting from the larger top area, is greater than the inlet force. The resultant downward force therefore holds the piston firmly on its seat.

If the inlet pressure were to rise, the net closing force on the piston also increases, ensuring that a tight shut-off is continually maintained. However, when the inlet pressure reaches the set pressure, the pilot valve will pop open to release the fluid pressure above the piston. With much less fluid pressure acting on the upper surface of the piston, the inlet pressure generates a net upwards force and the piston will leave its seat. This causes the main valve to pop open, allowing the process fluid to be discharged.

When the inlet pressure has been sufficiently reduced, the pilot valve will reclose, preventing the further release of fluid from the top of the piston, thereby re-establishing the net downward force, and causing the piston to reseat.

Pilot operated safety valves offer good overpressure and blowdown performance (a blowdown of 2% is attainable). For this reason, they are used where a narrow margin is required between the set pressure and the system operating pressure. Pilot operated valves are also available in much larger sizes, making them the preferred type of safety valve for larger capacities.

One of the main concerns with pilot operated safety valves is that the small bore, pilot connecting pipes are susceptible to blockage by foreign matter, or due to the collection of condensate in these pipes. This can lead to the failure of the valve, either in the open or closed position, depending on where the blockage occurs.

The terms full lift, high lift and low lift refer to the amount of travel the disc undergoes as it moves from its closed position to the position required to produce the certified discharge capacity, and how this affects the discharge capacity of the valve.

A full lift safety valve is one in which the disc lifts sufficiently, so that the curtain area no longer influences the discharge area. The discharge area, and therefore the capacity of the valve are subsequently determined by the bore area. This occurs when the disc lifts a distance of at least a quarter of the bore diameter. A full lift conventional safety valve is often the best choice for general steam applications.

The disc of a high lift safety valve lifts a distance of at least 1/12th of the bore diameter. This means that the curtain area, and ultimately the position of the disc, determines the discharge area. The discharge capacities of high lift valves tend to be significantly lower than those of full lift valves, and for a given discharge capacity, it is usually possible to select a full lift valve that has a nominal size several times smaller than a corresponding high lift valve, which usually incurs cost advantages.Furthermore, high lift valves tend to be used on compressible fluids where their action is more proportional.

In low lift valves, the disc only lifts a distance of 1/24th of the bore diameter. The discharge area is determined entirely by the position of the disc, and since the disc only lifts a small amount, the capacities tend to be much lower than those of full or high lift valves.

Except when safety valves are discharging, the only parts that are wetted by the process fluid are the inlet tract (nozzle) and the disc. Since safety valves operate infrequently under normal conditions, all other components can be manufactured from standard materials for most applications. There are however several exceptions, in which case, special materials have to be used, these include:

Cast steel -Commonly used on higher pressure valves (up to 40 bar g). Process type valves are usually made from a cast steel body with an austenitic full nozzle type construction.

For all safety valves, it is important that moving parts, particularly the spindle and guides are made from materials that will not easily degrade or corrode. As seats and discs are constantly in contact with the process fluid, they must be able to resist the effects of erosion and corrosion.

The spring is a critical element of the safety valve and must provide reliable performance within the required parameters. Standard safety valves will typically use carbon steel for moderate temperatures. Tungsten steel is used for higher temperature, non-corrosive applications, and stainless steel is used for corrosive or clean steam duty. For sour gas and high temperature applications, often special materials such as monel, hastelloy and ‘inconel’ are used.

Standard safety valves are generally fitted with an easing lever, which enables the valve to be lifted manually in order to ensure that it is operational at pressures in excess of 75% of set pressure. This is usually done as part of routine safety checks, or during maintenance to prevent seizing. The fitting of a lever is usually a requirement of national standards and insurance companies for steam and hot water applications. For example, the ASME Boiler and Pressure Vessel Code states that pressure relief valves must be fitted with a lever if they are to be used on air, water over 60°C, and steam.

A test gag (Figure 9.2.7) may be used to prevent the valve from opening at the set pressure during hydraulic testing when commissioning a system. Once tested, the gag screw is removed and replaced with a short blanking plug before the valve is placed in service.

The amount of fluid depends on the particular design of safety valve. If emission of this fluid into the atmosphere is acceptable, the spring housing may be vented to the atmosphere – an open bonnet. This is usually advantageous when the safety valve is used on high temperature fluids or for boiler applications as, otherwise, high temperatures can relax the spring, altering the set pressure of the valve. However, using an open bonnet exposes the valve spring and internals to environmental conditions, which can lead to damage and corrosion of the spring.

When the fluid must be completely contained by the safety valve (and the discharge system), it is necessary to use a closed bonnet, which is not vented to the atmosphere. This type of spring enclosure is almost universally used for small screwed valves and, it is becoming increasingly common on many valve ranges since, particularly on steam, discharge of the fluid could be hazardous to personnel.

Some safety valves, most commonly those used for water applications, incorporate a flexible diaphragm or bellows to isolate the safety valve spring and upper chamber from the process fluid, (see Figure 9.2.9).

An elastomer bellows or diaphragm is commonly used in hot water or heating applications, whereas a stainless steel one would be used on process applications employing hazardous fluids.

Safety valves are used in a variety of applications, including air/gas, vapor, steam and liquid service. Flotech has been approved by the National Board of Boiler and Pressure Vessel Inspectors to perform safety and relief valve testing, repair and certification.

Our valve experts will focus on getting your valves tested, repaired and quickly set to the exact specifications. We evaluate the repair condition of every valve and will recommend the right solution to manage your maintenance program.

Mercer Valve Co., Inc® is committed to safely providing the highest quality pressure relief valve featuring our patented “Auto Seat Technology”® at a competitive price, delivered on time, and serviced by our trained professionals.We continue to improve our products and services, while meeting industry standards to satisfy our customer’s expectations.

Mercer Valve Company provides a Made in the USA manufactured high-quality safety relief valve. Our patented “Auto Seat Technology”® has a proven extended seat life that will allow your valve to open, close, seat and seal over and over again.

1 Piece Ball Valve1 Piece Cast Iron Screwed Ball Valve1 Piece Flanged Ball Valve1 Piece Screwed Ball Valve2 Piece Ball valve2 Piece Cast Steel Ball Valve2 Piece Flanged Ball Valve2 Piece Forged Steel Ball Valve2 Piece Screwed Ball Valve3 Piece Ball Valve3 Piece Cast Iron Ball Valve3 Piece Cast Steel Ball Valve3 Piece Flanged Ball Valve3 Piece Forged Steel Ball Valve3 Piece Reduced Port Ball Valve3 Piece Screwed Ball Valve3 Way Converging and Diverging Control Valve3 Way Plug Valve3 Way Pneumatic Diaphragm Control ValveAir ValveAlloy 20 2 Piece Ball ValveAlloy 20 2 Piece Screwed Ball ValveAlloy 20 3 Piece Ball ValveAlloy 20 3 Piece Screwed Ball ValveAlloy 20 Ball ValveAlloy 20 Dual Plate Check ValveAlloy 20 Floating Ball ValveAlloy 20 Swing Check ValveAlloy 20 Trunnion Mounted Ball ValveAlloy 20 ValvesAlloy Butterfly ValveAlloy Check valveAlloy Flanged Gate ValveAlloy Flanged Globe ValveAlloy Gate ValveAlloy Gate ValvesAlloy Globe ValvesAlloy Lug Butterfly ValveAlloy Plug ValveAlloy Pressure Seal Globe ValveAlloy Wafer Butterfly ValveAluminium Bronze 3 Piece Ball ValveAluminium Bronze Ball ValveAluminium Bronze Butterfly ValveAluminium Bronze Check ValveAluminium Bronze Floating Ball ValveAluminium Bronze Gate ValveAluminium Bronze Lug Butterfly ValveAluminium Bronze Swing Check ValveAluminium Bronze Triple offset Lug Butterfly ValveAluminium Bronze Trunnion Ball ValveAluminium Bronze valvesAluminium Bronze Wafer Butterfly ValveAluminium Dual Plate Wafer Check ValveAluminum Bronze Globe ValveAngle Globe ValveAPI Aluminium Bronze Triple offset Lug Butterfly ValveAustenitic Steel Big Size Ball ValveAustenitic Steel ValvesAWWA Butterfly ValveAWWA Gate ValveAWWA Non Rising Stem Gate ValveAWWA OS&Y Gate ValveAWWA StrainerAWWA Wafer Butterfly ValveAWWA Y StrainerBalancing ValveBall Float Steam TrapBall ValveBellow Safety ValveBellow Seal Globe ValveBi Directional Knife Gate ValveBimetallic Steam TrapBrass Ball ValveBrass Ball ValvesBrass Check ValvesBrass Flanged Ball ValveBrass Flanged Gate ValveBrass Flanged Globe ValveBrass Gate ValveBrass Gate ValvesBrass Globe ValveBrass Globe ValvesBrass Safety ValveBrass Swing Check ValveBrass ValveBrass Vertical Check ValveBrass Y StrainerBronze Butterfly ValveBronze Check ValveBronze Dual Plate Check ValveBronze Flanged Gate ValveBronze Flanged Globe ValveBronze Floating Ball ValveBronze Gate ValveBronze Gate ValvesBronze Globe ValveBronze Globe ValvesBronze Swing Check ValveBronze ValveBronze Wafer Butterfly ValveButterfly ValveCarbon Steel Bellow Seal Globe ValveCast Floating Ball ValveCast Iron And Cast Steel Ball ValveCast Iron Diaphragm ValveCasting Trunnion Ball Valvecheck valveConnection Lift Plug ValveControl ValveConventional Safety ValveCryogenic Ball ValveCryogenic Check ValveCryogenic Emergency Cut off ValveCryogenic Gate ValveCryogenic Globe ValveCryogenic Long Stem Globe ValveCryogenic Pneumatic Actuated Globe ValveCryogenic Short Stem Globe ValveCryogenic Steam Jacket Globe ValveCryogenic Trunnion Ball ValveCryogenic ValveDiaphragm ValveDirect Acting Pressure Reducing ValveDouble Block and Bleed Ball ValveDouble Disc Gate ValveDouble Eccentric Butterfly ValveDouble Flanged Butterfly ValveDouble Orifice Air Release ValveDouble Orifice Kinetic Air ValveDual Plate Check ValveDuctile Iron Diaphragm ValveDuplex 1B 3 PC Ball ValveDuplex 3 Piece Ball ValveDuplex Basket StrainerDuplex Butterfly ValveDuplex Check ValveDuplex Dual Plate Check ValveDuplex Floating Ball ValveDuplex Gate ValveDuplex Globe ValveDuplex High Pressure Ball ValveDuplex Lug Type Butterfly ValveDuplex Steel Ball ValveDuplex steel ValveDuplex Swing Check ValveDuplex Top Entry Ball ValveDuplex Trunnion Mounted Ball ValveDuplex Wafer Butterfly ValveEccentric Plug ValveElectric Actuated 2 Piece Ball ValveElectric Actuated 2 Piece Flanged Ball ValveElectric Actuated 2 Piece Screwed Ball ValveElectric Actuated Ball ValveElectric Actuated Butterfly ValveElectric Actuated Casting Trunnion Ball ValveElectric Actuated Floating Ball ValveElectric Actuated Forged Trunnion Ball ValveElectric Actuated Gate ValveElectric Actuated Globe ValveElectric Actuated Lug Butterfly ValveElectric Actuated Three Piece Ball ValveElectric Actuated Three Way Ball ValveElectric Actuated ValvesElectric Actuated Wafer Butterfly ValveF22/Alloy Steel Pressure Seal Globe ValveF317L Gate ValveF317L Globe ValveF317L ValvesF321 Gate ValveF321 Globe ValveF321 ValvesF347 3 Piece Ball ValveF347 Ball ValveF347 Butterfly ValveF347 Check ValveF347 Dual Plate Check ValveF347 Floating Ball ValveF347 Gate ValveF347 Globe ValveF347 Lug Type Butterfly ValveF347 Swing Check ValveF347 Trunnion Mounted Ball ValveF347 ValvesF347 Wafer Butterfly ValveF44 Gate ValveF44 Globe valvesF44 ValvesF51 Super Duplex Ball ValveF53/F55 Super Duplex Globe ValveFlanged Knife gate ValveFloat Control ValveFloating Ball ValveFluorine Lined Single Seat Control ValveFoot ValveForged Floating Ball ValveForged Steel Ball ValveForged Steel Gate ValveForged Steel Globe ValveForged Steel Swing Check ValveForged Trunnion Ball ValveFully Welded Ball ValveGate ValveGlobe ValveHastelloy Ball ValveHastelloy C276 2 Piece Flanged Ball ValveHastelloy C276 2 Piece Screwed Ball ValveHastelloy C276 3 Piece Screwed Ball ValveHastelloy C276/B3 3 Piece Ball ValveHastelloy C276/B3 Dual Plate Check ValveHastelloy C276/B3 Floating Ball ValveHastelloy C276/B3 Gate ValvesHastelloy C276/B3 Globe ValveHastelloy C276/B3 Lug Butterfly ValveHastelloy C276/B3 Swing Check valveHastelloy C276/B3 Trunnion Mounted Ball ValveHastelloy C276/B3 ValvesHastelloy C276/B3 Wafer Butterfly ValveHastelloy Check ValveHeavy Duty Investment Casting Ball ValveIncoloy 2 Piece Ball ValveIncoloy 3 Piece Ball ValveIncoloy Gate ValveIncoloy Globe ValveIncoloy ValvesInconel 2 Piece Ball ValveInconel 3 Piece Ball ValveInconel Ball ValveInconel Butterfly ValveInconel Check ValveInconel Dual Plate Check ValveInconel Floating Ball ValveInconel Gate ValveInconel Globe ValveInconel Lug Butterfly ValveInconel safety relief valveInconel Swing Check ValveInconel Trunnion Mounted Ball ValveInconel ValveInconel Wafer Butterfly ValveInverted Bucket Steam TrapInvestment Casting Ball ValveIron Globe ValveJacketed Ball ValveJacketed Plug ValveKnife Gate ValveLift Check valveLubricated Plug valveLug Butterfly ValveMonel 2 Piece Ball ValveMonel 3 Piece Ball ValveMonel 400 2 Piece Flanged Ball ValveMonel 400 ValvesMonel Ball ValveMonel Butterfly ValveMonel Check ValveMonel Dual Plate Check ValveMonel Floating Ball ValveMonel Forged Trunnion Mounted Ball ValveMonel Gate ValveMonel Globe ValveMonel High Pressure Ball ValveMonel Lug Butterfly ValveMonel Swing Check ValveMonel Top Entry Ball ValveMonel Trunnion Mounted Ball ValveMonel ValvesMonel Wafer Butterfly ValveNeedle valveNon Rising Stem Gate ValveNon-Lubricated Sleeved Plug ValveNRS Carbon Steel Gate ValveNRS Cast Iron Gate ValveNRS Ductile Iron Gate ValveOrbit Plug ValvePilot Operated Pressure Reducing ValvePilot Operated Safety ValvePilot Operated ValvePressure Relief ValvePiston ValvePlug ValvePlunger ValvePneumatic Actuated 2 Piece Ball ValvePneumatic Actuated 2 Piece Flanged Ball ValvePneumatic Actuated Ball ValvePneumatic Actuated Butterfly ValvePneumatic Actuated Flanged Butterfly ValvePneumatic Actuated Gate ValvePneumatic Actuated Globe type Control ValvePneumatic Actuated Lug Butterfly ValvePneumatic Actuated ValvesPneumatic Actuated Wafer Butterfly ValvePneumatic Angle Control ValvePneumatic Angle Seat Control ValvePneumatic Bi Directional Knife Gate valvePneumatic Cage Control ValvePneumatic Control ValvePneumatic Double Seat Control ValvePneumatic Flow Control ValvePneumatic Knife Gate ValvePneumatic Single Seat Globe Control ValvePneumatic Sleeve Type Control ValvePneumatic Three piece Ball ValvePneumatic Three Piece Flanged Ball ValvePneumatic Three Way Ball ValvePneumatic Three Way Flanged Ball ValvePneumatic Trunnion Ball ValvePneumatic Unidirectional Knife Gate ValvePressure Reducing ValvePressure Safety ValvePressure Seal Gate ValvePressure Seal Globe ValvePressure Seal Swing Check ValveRising Stem Carbon Steel Gate valveRising Stem Cast Iron Gate ValveRising Stem Ductile Iron Gate valveRising Stem Gate ValveRising Stem Stainless Steel Gate ValveSafety ValveSimplex Basket StrainerSingle Orifice Air ValveSingle Plate Check ValveSlab Gate ValveSlurry Knife Gate ValveSpeciality ValveSS304 Bellow Seal Globe ValveSS316 Bellow Seal Globe ValveSteam Pressure Reducing ValveSteam Safety ValveSteam TrapSteel Globe ValveStrainersSuction DiffuserSuper Duplex 2 Piece Ball ValveSuper Duplex 3 Piece Ball ValveSuper Duplex 5A Flanged Gate ValveSuper Duplex 5A Globe ValveSuper Duplex 5A Swing Check ValveSuper Duplex Ball ValveSuper Duplex Butterfly ValveSuper Duplex Check ValveSuper Duplex Dual Plate Check ValveSuper Duplex Floating Ball ValveSuper Duplex Gate ValveSuper Duplex Gate ValvesSuper Duplex Globe ValveSuper Duplex High Pressure Ball ValveSuper Duplex Knife Gate ValveSuper Duplex Lug Butterfly ValveSuper Duplex Pressure Reducing ValveSuper Duplex Top Entry Ball ValveSuper Duplex Trunnion Mounted Ball ValveSuper Duplex ValvesSuper Duplex Wafer Butterfly ValveSurge Anticipator ValveSwing Check ValveThermal Safety ValveThermodynamic Steam TrapThermostatic Steam TrapThree Piece Flanged Ball ValveThree Way Ball ValveThrough Conduit Knife Gate ValveTitanium 3 Piece Ball ValveTitanium Ball ValveTitanium Butterfly ValveTitanium Check ValveTitanium Dual Plate Check ValveTitanium Floating Ball ValveTitanium Forged Trunnion Mounted Ball ValveTitanium Gate ValveTitanium Globe ValveTitanium Gr.2 2pc Flanged Ball ValveTitanium Gr.2 3pc Ball ValveTitanium Gr.5 2pc Flanged Ball ValveTitanium Gr.5 3pc Ball ValveTitanium Lug Butterfly ValveTitanium Swing Check ValveTitanium Trunnion Mounted Ball ValveTitanium valvesTitanium Wafer Butterfly ValveTop Entry Ball ValveTriple Duty ValveTriple Eccentric Butterfly ValveTrunnion Ball ValveTwin Seal Plug ValveUL/FM Approved ValvesUnidirectional Knife Gate ValveWafer Butterfly ValveWater Pressure Reducing ValveY StrainerY Type Globe ValveZirconium Floating Ball ValveZirconium Gate ValveZirconium Globe ValveZirconium Valves

8613371530291

8613371530291