bellows safety valve quotation

Q4. How to proceed an order for valve?A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions.

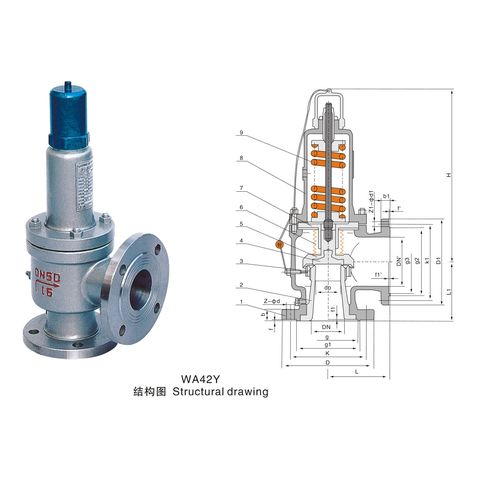

API 520 Bellow Balanced Safety Valve Manufacturer: API 520 Balanced Bellows Safety Valve with Flange, Inlet Class 900, Outlet Class 300 LB, 3 X 4 Inch.

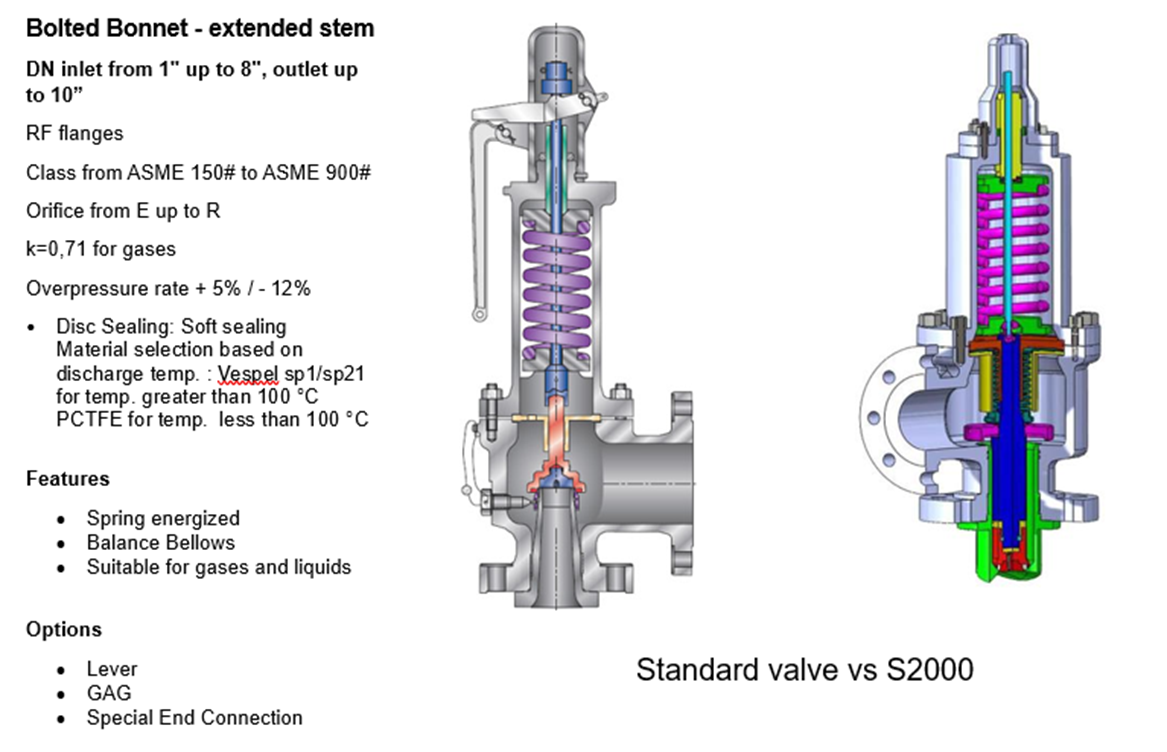

Bonnet: The bonnet of the safety valve is open, allowing the spring chamber to communicate with the atmosphere, which is beneficial to reduce the temperature of the spring, and is mainly suitable for containers of high temperature gas in which the medium is steam and does not pollute the atmosphere.

Lever: The safety valve can be opened manually by the lever when the media pressure over 75% of the setting pressure (On the premise of ensuring safety).

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

240 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

250 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

271 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function ...

Relief Valves GLV-Series are spring loaded pressure relieving devices, suitable for discharge of incompressible fluids. GLV-series relief valves are used to protect personnel and equipment by preventing ...

The imported bellows safety valve produced by Breer can be driven automatically or flanged for connection. Fully open type can be used for sealing. Bellows can be used for sealing structure. The pressure range is PN150 ~ 1500LB. 200mm, the material can choose WCB, 304,316, alloy steel, etc. Because the valve is used in a very wide range, the same valve has different combinations in different situations and working conditions.

Imported bellows safety valve-American Buhrer brand connection form flange, main material carbon steel, structural form spring full-open safety valve, closed valve body structure, pressure pipes and vessels as overpressure protection devices, stainless steel formed bellows, To ensure zero leakage of the medium, it can balance the back pressure at the outlet of the safety valve and ensure the set pressure.

The safety valve body adopts a dead zone-free design, which avoids the medium that may remain during the safety valve discharge and the corrosion that may cause the safety valve body

If the determined valve type and model are provided by the customer, the customer should correctly explain the meaning and requirements of its model, and sign the contract under the conditions that the supply and demand sides understand and agree.

Balanced Bellow Safety valve is used for the equipment and pipelines with unstable back pressure or containing poisonous or corrosive ore pulp media. Its max working temperature is 300 Deg C.

Balanced bellow safety valve is often used for the pipelines with toxic or corrosive medium.It"s often supplied with closed bonnet with or without lever. We Goole can also offer Jacketed Bellow Type Balanced Safety Valve.

3. When a conventional safety relief valve discharges against a back pressure, the opening pressure is the set pressure with atmospheric back pressure augmented by the actual superimposed back pressure just before the valve opens.

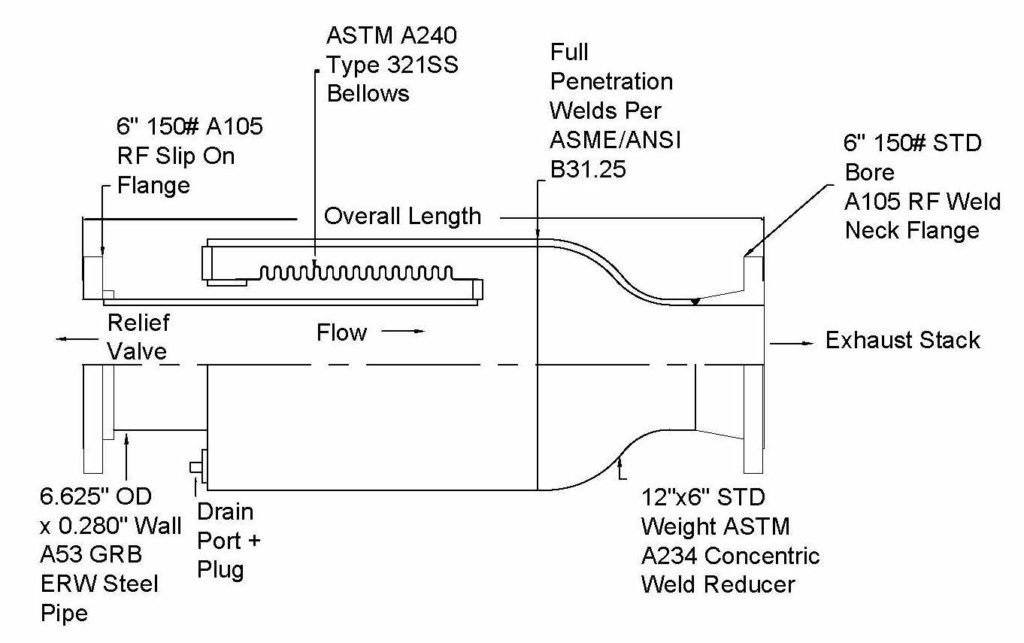

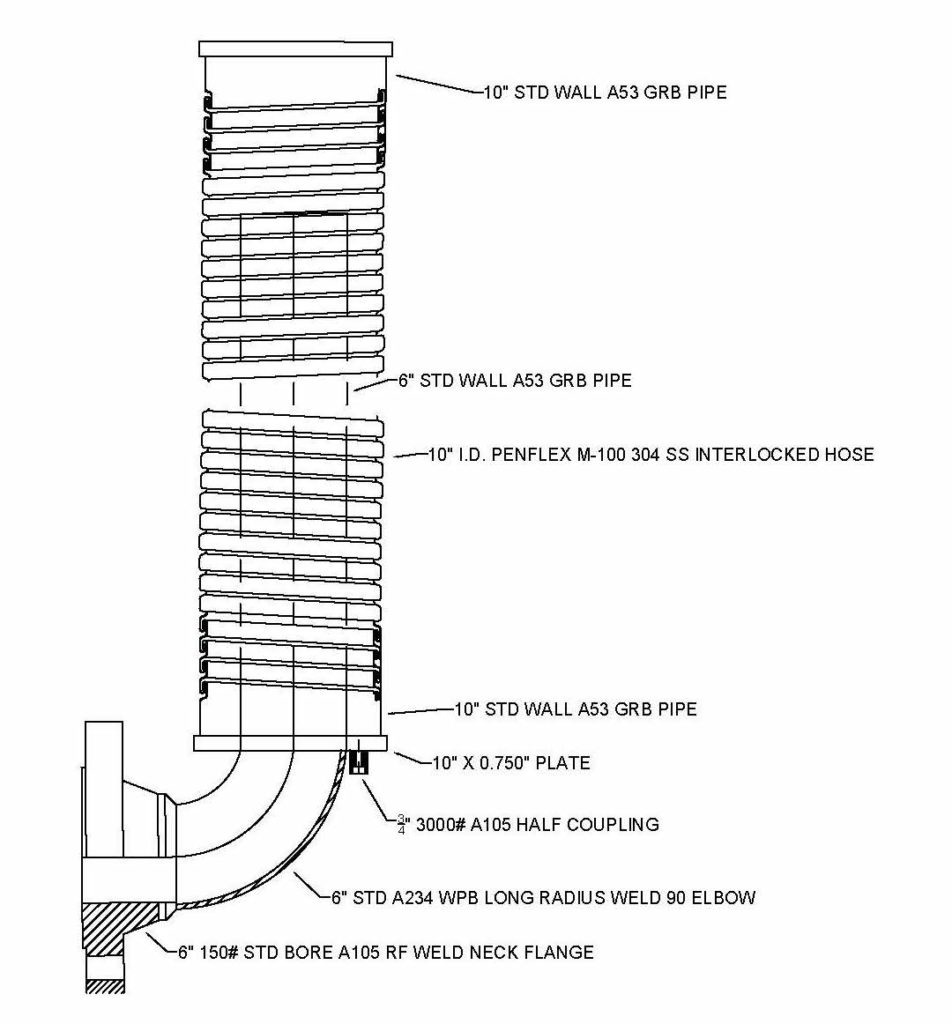

To solve this problem, it is highly recommended to use a balanced bellows safety relief valve. The effective area of the bellows is substantially the same as the seating area of the disc on the nozzle and the bellows is vented to atmosphere through a hole drilled into the bonnet wall. The opening pressure of the safety relief valve is then independent of the back pressure.

We "V Tech Valves & Controls" are engaged in manufacturing a high-quality assortment of Ball valve, Diaphragm Valve, Globe Valve, etc. We are a Proprietorship company that is established in the year 2013 at Ahmedabad, Gujarat and are connected with the renowned vendors of the market who assist us to provide a qualitative range of products as per the global set standards. V-MAK Brand is a manufacturing brand.

Large orifice closed bonnet pressure relief valves. Also available with open bonnet as Styles HS/HSU; and as large orifice pilot operated pressure relief valves. Style JPV-A, for air, gas and steam. Ask for Catalog No. 307. Specifications:

A unique, completely sealed pressure relief valve for transportation and storage of chlorine and other toxic and corrosive fluids. Ask for Catalog No. 306. Specifications:

A sanitary pressure/vacuum pressure relief valve for the beverage, food processing and pharmaceutical industries. This valve provides three modes of self actuated operation:

Non-flowing, snap-acting, pilot operated, pressure relief valves. High performance valves for overpressure protection of pipes and vessels containg gases and vapors. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of gas, vapor, liquid and steam. Mounted on the same main valve used with Style JPV. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of high temperature fluids including hydrocarbons, inert gases and steam. Ask for Catalog No. 318. Specifications:

Pressure relief valve with single trim for liquid, gas and steam service. Precision lapped flat metal to metal seats or elastomer and TFE O-ring soft seats provide the ultimate in seat tightness. Blowdown is typically less than 20%. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Series 800 pressure relief valves are designed for use on air, gas, vapor and steam service. External precise blowdown control provides shorter blowdown then the Series 900, typically in the range of 5 to 15 percent. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Nozzle type safety valve for saturated and superheated steam service. Seat tightness up to 95% of valve set pressure. Ask for Catalog No. 408. Specifications:

Protect superheaters from overheating during startup, prolong the life and reduce maintenace of safety valves. Ask for Catalog No. 403. Specifications:

Operational characteristics of this pressure relief valve are directly affected by back pressure changes. For conventional safety relief valve, only the superimposed back pressure affects the opening characteristic and set pressure value, but the combined back pressure (superimposed backpressure plus built up backpressure) affects the blowdown characteristic and re-seat pressure value. A conventional pressure relief valve is not used when the built-up backpressure is greater than 10% of the set pressure at 10% overpressure. A higher maximum allowable built-up backpressure may be used for overpressure greater than 10%.

Advantages of conventional relief valves are reliability and versatility. These relief valves are most reliable when sized properly and can be used in a wide range of services.

Disadvantage of these relief valves is the effect of backpressure on the relieving pressure of valve and hence pressure accumulation in the protected equipment. Also for high built up backpressure values generated by higher pressure loss in the relief valve discharge line, chattering can occur in these relief valves.

Effect of back pressure on the operational characteristics of the valve is minimized by incorporating bellows. The bellows encircle an area equal to the inlet orifice area. This area is maintained free from the effect of back pressure from the discharge side of the relief valve. The space enclosed by bellows is freely vented to air. Thus the opposing pressure on the inlet fluid is generated by the spring alone without contribution from any sort of backpressure. For these relief valves allowable back pressure is 10 - 50% of the set pressure.

Advantage of using balanced bellows relief valves is no effect of back pressure on the relieving pressure and pressure accumulation. The spring is isolated from discharge fluid from the bellows, hence risk of corrosion mitigated. These relief valves get special consideration when there is high combined backpressure on the relief valve.

Disadvantage can be said to be the susceptibility of bellows to fatigue and failure and possibility of release of flammable or toxic process fluids being discharged to atmosphere through bellows vent.

In pilot operated setup, main relief is combined with and controlled by a smaller self actuated pilot valve. This relief valve valve uses the process fluid itself, circulated through a pilot valve, to apply the closing force on the safety valve disc. The pilot valve is itself a small safety valve with a spring. The main valve does not have a spring but is controlled by the process fluid from pilot valve. This arrangement allows operation of pilot operated valves with a very narrow margin between set pressure of the relief valve and operating pressure of the protected equipment. Hence these relief valves are particularly used for services where relief valve inlet line pressure drop is high (typically higher than 3% of set point) or when back pressure is high. Allowable back pressure is typically more than 50% of the set pressure.

Disadvantage of using pilot operated relief valves can be blockage of the pilot valve inlet outlet tubing by foreign matter such as hydrate, ice, wax etc.

8613371530291

8613371530291