blower safety valve manufacturer

US Valve offers a range of Vacuum and Low-Pressure Valves for use in many industrial applications. These low-pressure relief valves are ideal for use with vacuum pumps, fans, and blowers, as well as for venting vessels on filling or draining.

We maintain an extensive inventory of valves, parts, and components in a wide variety of materials so we can respond to your needs quickly. Low-pressure relief valves are typically assembled and tested within 1 to 2 days after receipt of an order.

Engineering data, including available materials, dimensions, exploded view, part numbers and descriptions, standard models, valve Cv, pressure loss curves, and other information for low-pressure relief valves and vacuum relief valves are available in our brochure.

The blower safety valve is used to protect the blower and equipment. When the pressure in the blower and equipment is abnormally raised to a certain value (the opening pressure of the safety valve), the safety valve can automatically open and discharge the medium to prevent the pressure from continuing to rise. When the pressure in the blower and equipment falls to a certain value (the back seat pressure of the safety valve), the safety valve automatically closes.

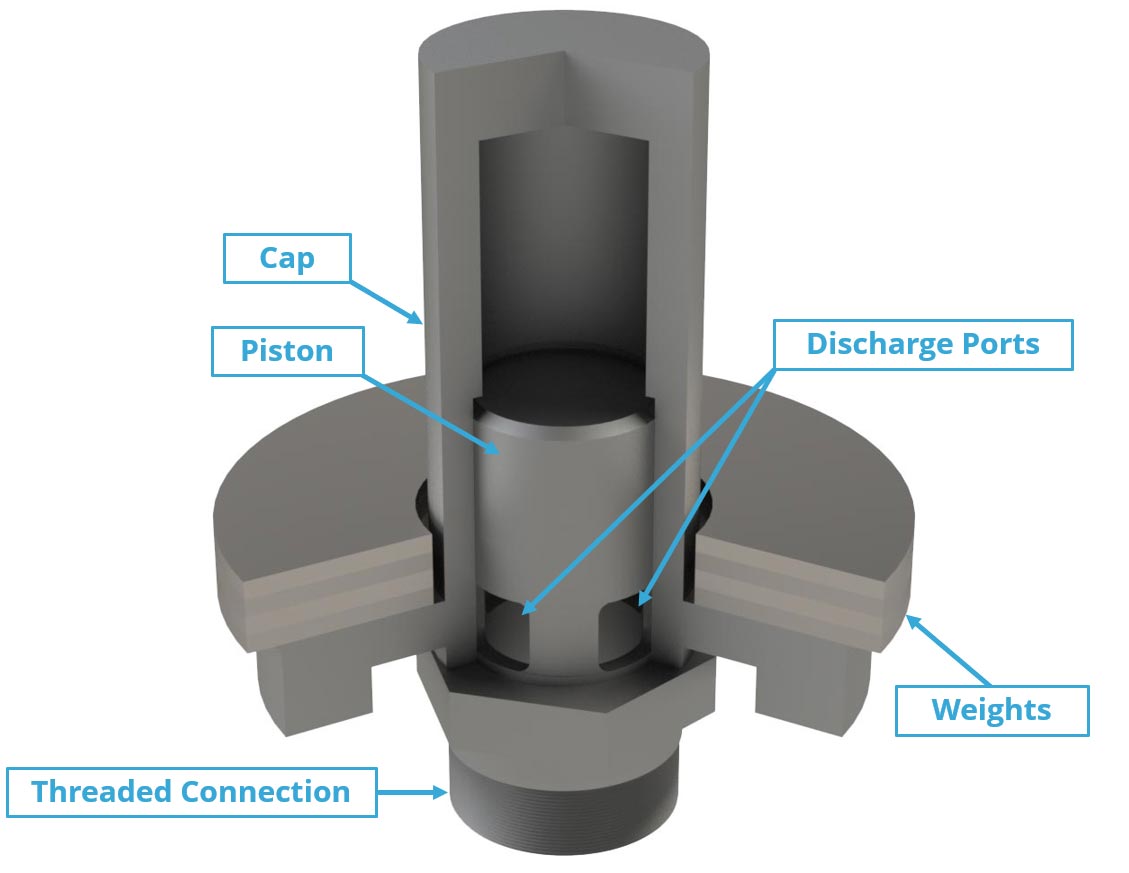

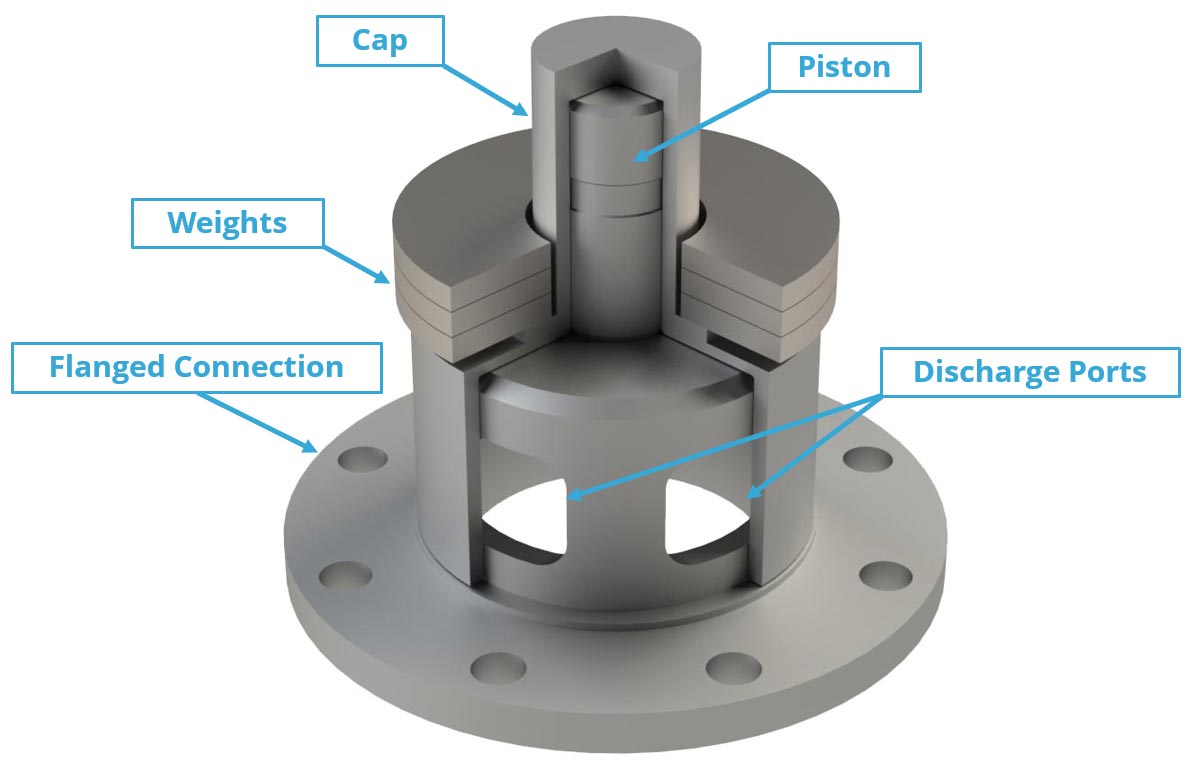

1. Since blower is mainly used for low-pressure air medium, blower safety valve doesn’t have outlet discharge flange. Instead, it uses the small holes evenly distributed around the

2. Blower safety valve uses the patented structure of pressure accumulation tank between valve flap and valve seat. Compared with a traditional safety valve that uses regulating ring and positioning screw, it has a simpler structure, and it’s more convenient to use the valve, and the valve has more stable performance.

3. The minimum opening pressure of a traditional safety valve is generally 0.1MPa. For the blower safety valve, its opening pressure is often required to be less than 0.1MPa. Even if the traditional safety valve uses a spring of smaller stiffness, it can’t operate accurately and sensitively under low pressure. The opening pressure range of the blower safety valve is 0.02~0.2MPa, so the blower safety valve can accurately and sensitively operate under low pressure.

4. The point of force of the spring of the blower safety valve on the valve flap through the valve stem is very close to the sealing surface of the valve flap whereas the point of force of the traditional safety valve is far away from the sealing surface of the valve flap. Thus, compared with traditional safety valves, the performance of the blower safety valve is more stable and reliable.

5. Traditional safety valve discharges medium through outlet channel in one direction, so the discharge of medium is likely to cause the vibration of the system. The blower safety valve evenly discharges medium to the surroundings through the small holes evenly distributed on the valve body. Therefore, the operation of the valve is stable, with no vibration.

6. There is no regulation ring on the blower safety valve, so it’s easy to use it. The safety valve has been debugged according to the opening pressure required by the user, so the user can directly install it on the system to use it.

The primary purpose of a blower safety valve is the protection of life, property, and the environment. A blower safety valve is designed to open and relieve excess pressure from vessels or equipment and to reclose and prevent the further release of fluid after normal conditions have been restored.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale air blower safety valve on Alibaba.com. When you search for air blower safety valve and related items, you will be able to find many types of air blower safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of air blower safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Blocker & Wallace Service offers a variety relief valves from the leading manufactures including Kunkle, Dixon Bayco and more.. We stock various types including, pressure relief valves and vacuum relief valves which are also available in a wide range of construction materials and sealing materials to suit your application for air systems to corrosive gas conveying systems. Relief valves should be properly sized per application, including CFM requirements & overall system design. Please contact ussales@blockerandwallace.com. for relief valve sizing assistance or if you don"t see the specific relief valve you require.

Kunkle pressure relief valvecan be purchased preset per your requirements up to a pressure of 25 psig and a minimum pressure of 3 psig.Kunkle Model 337 pressure relief valves for positive displacement blowers are designed with 3 inch NPT port connections to accommodate handle high air flow capacities.

The Kunkle Model 337 pressure relief valve that can be purchased preset per your requirements up to a pressure of 25 psig and a minimum pressure of 3 psig.Pressure relief valves protect blowers from excessive back pressure and are commonly referred to as a "pop off valve" in the pneumatic conveying industry.

Blocker & Wallace Service LLC has been a leading Gardner Denver Factory Authorized Distributor, Repair, & Warranty Center for over 27 years. We have a over 100 years of combined experience in the Pneumatic conveying Industry specializing in new & remanufactured PD blower sales, system design, consulting, blower packaging & blower repair. We have been recognized by Gardner Denver as a top distributor and have received multiple distributor achievement awards on sales and service since 1983. We are on of the only distributors authorized to market and repair the majority of PD blower lines owned or operated by Gardner Denver.

Vacuum relief valves are installed on the suction side of the side channel blower and open when a preset vacuum (by preload) is reached. With the additional intake air from the vacuum protection valve, overheating is avoided. If the vacuum is frequently lower than preset (air flow through the vacuum protection valve) a filter has to be installed.

Pressure relief valves are installed on the pressure side of the side channel blower and open when a preset pressure (by preload) is reached. Due to the additional air flow, overheating is avoided.

Safety valves for side channel blower Because of the air compression side channel compressor produce a lot of heat, which is normally removed with the outgoing air stream. Too... read more »

Vacuum relief valves are installed on the suction side of the side channel blower and open when a preset vacuum (by preload) is reached. With the additional intake air from the vacuum protection valve, overheating is avoided. If the vacuum is frequently lower than preset (air flow through the vacuum protection valve) a filter has to be installed.

Pressure relief valves are installed on the pressure side of the side channel blower and open when a preset pressure (by preload) is reached. Due to the additional air flow, overheating is avoided.

Standard pressure setting for truck mounted blowers is 18 psi, however, for other applications, valves are available with temperature compensated pressure settings of between 3 psi and 24 psi. Customer should request set pressure at time of order.

8613371530291

8613371530291