blower safety valve free sample

The popular pressure setting for truck mounted blowers is 20 PSI. Valves are available for other applications with temperature compensated pressure settings of between 3 PSI and 24 PSI. Customer should request set pressure at time of order.

The 2182 valve will relieve at the ordered set pressure at a temperature of 400 F / 204 C. At room temperature 73 F / 22 C the 2182 valve will relieve approximately 4 PSI higher than the ordered set pressure.

The product label shows the set relief pressure at the blow operating temperature, plus the relief pressure at 73 F / 22 C (for testing purposes). Depending on the blower type, amount of vibration and operating temperature a difference of observable set pressure may occur.

Example: 2182-18 is set to relieve at 18 PSI while at operating temperature. This same valve will test at 22 PSI while at room temperature on a test bench. Both set points are listed on the label.

The popular pressure setting for truck mounted blowers is 20 PSI. Valves are available for other applications with temperature compensated pressure settings of between 3 PSI and 24 PSI. Customer should request set pressure at time of order.

The 2182 valve will relieve at the ordered set pressure at a temperature of 400 F / 204 C. At room temperature 73 F / 22 C the 2182 valve will relieve approximately 4 PSI higher than the ordered set pressure.

The product label shows the set relief pressure at the blow operating temperature, plus the relief pressure at 73 F / 22 C (for testing purposes). Depending on the blower type, amount of vibration and operating temperature a difference of observable set pressure may occur.

Example: 2182-18 is set to relieve at 18 PSI while at operating temperature. This same valve will test at 22 PSI while at room temperature on a test bench. Both set points are listed on the label.

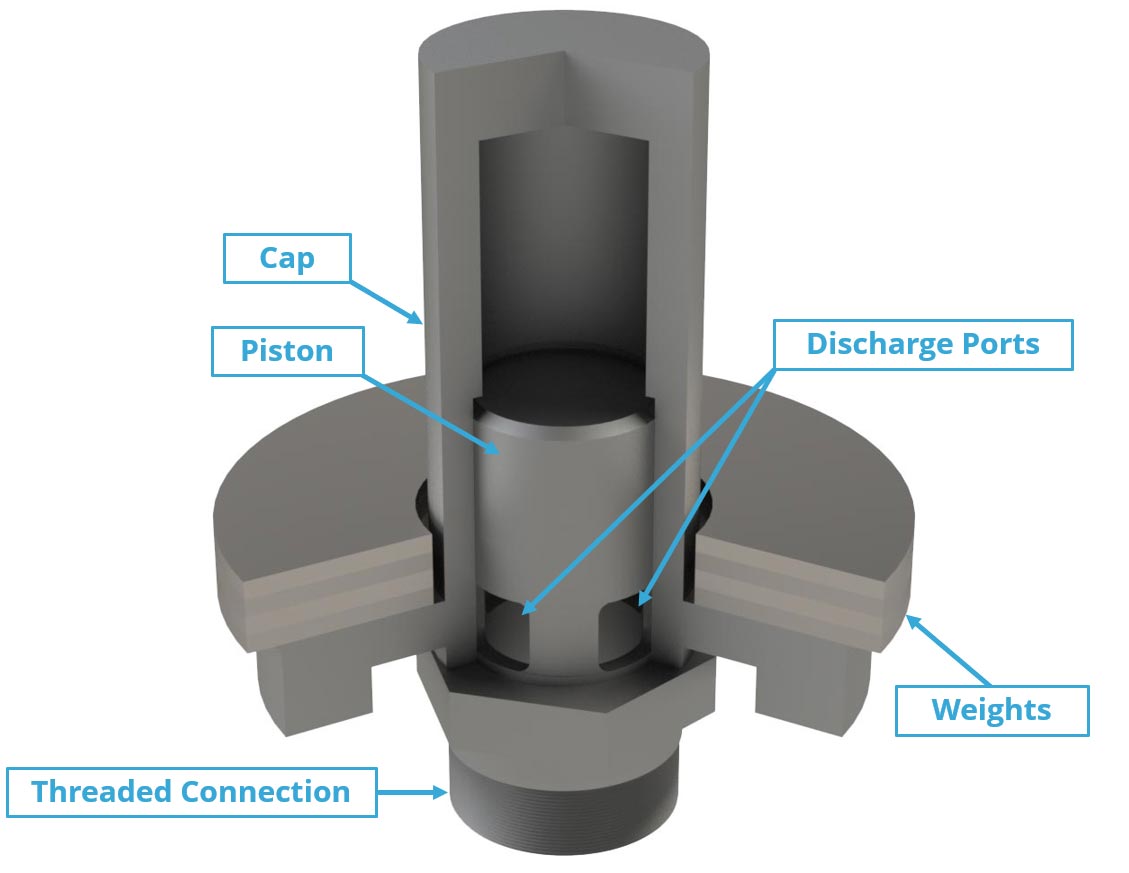

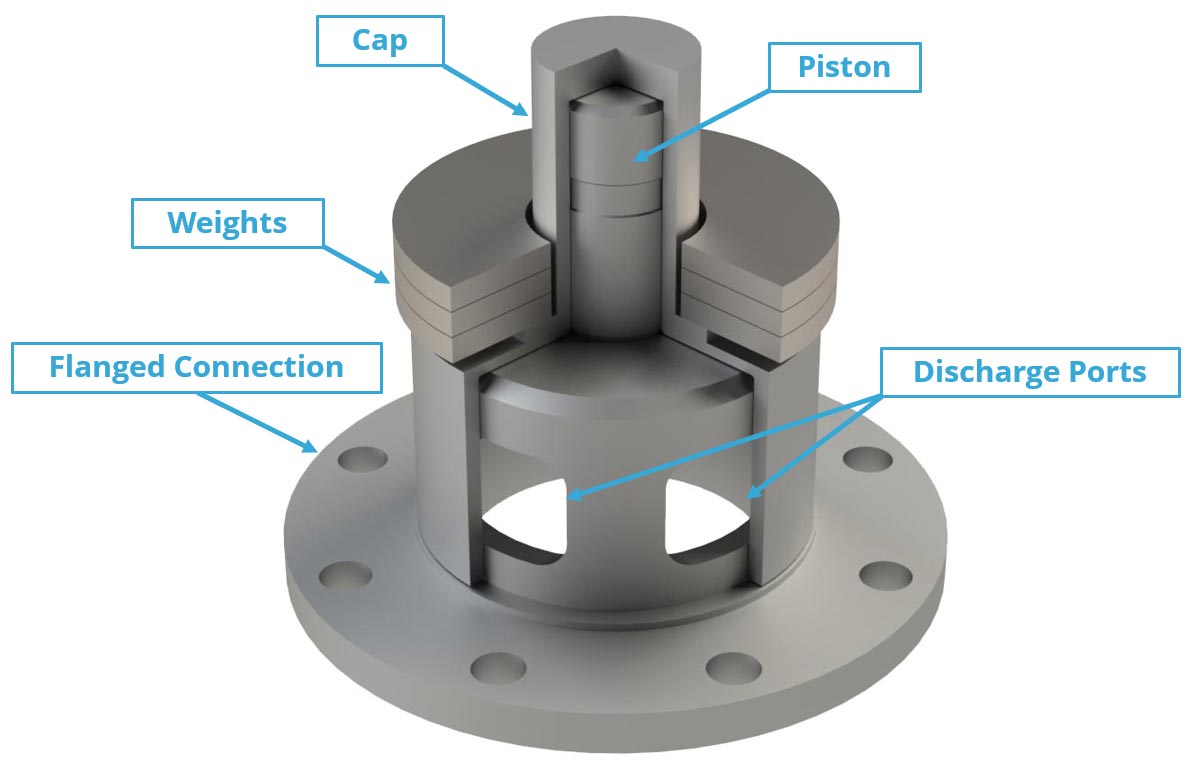

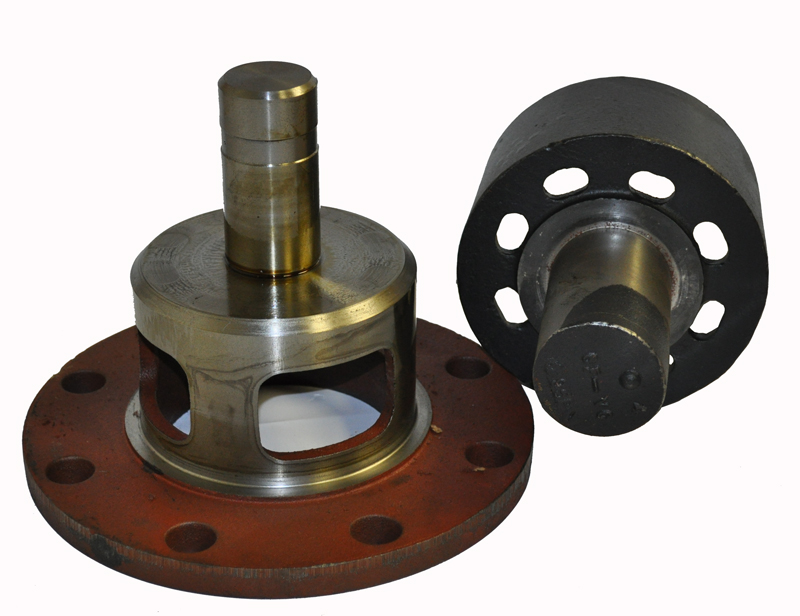

ApplicationsDesigned specifically for use on tractor mounted air blowers. The 2181 air relief valves have a temperature compensated pressure relief setting to accommodate the high temperatures and dynamic air produced by the blower. If a system blockage were to occur, the valves are designed to vent to atmosphere once the valve pressure setting is achieved.

NoteThe popular pressure setting for truck mounted blowers is 20 PSI. Valves are available for other applications with temperature compensated pressure settings of between 3 PSI and 24 PSI. Customer should request set pressure at time of order.

The 2182 valve will relieve at the ordered set pressure at a temperature of 400°F / 204°C. At room temperature 73°F / 22°C the 2182 valve will relieve approximately 4 PSI higher than the ordered set pressure.

The product label shows the set relief pressure at the blow operating temperature, plus the relief pressure at 73°F / 22°C (for testing purposes). Depending on the blower type, amount of vibration and operating temperature a difference of observable set pressure may occur.

Example: 2182-18 is set to relieve at 18 PSI while at operating temperature. This same valve will test at 22 PSI while at room temperature on a test bench. Both set points are listed on the label.

ApplicationsDesigned specifically for use on tractor mounted air blowers. The 2181 air relief valves have a temperature compensated pressure relief setting to accommodate the high temperatures and dynamic air produced by the blower. If a system blockage were to occur, the valves are designed to vent to atmosphere once the valve pressure setting is achieved.

NoteThe popular pressure setting for truck mounted blowers is 20 PSI. Valves are available for other applications with temperature compensated pressure settings of between 3 PSI and 24 PSI. Customer should request set pressure at time of order.

The 2182 valve will relieve at the ordered set pressure at a temperature of 400°F / 204°C. At room temperature 73°F / 22°C the 2182 valve will relieve approximately 4 PSI higher than the ordered set pressure.

The product label shows the set relief pressure at the blow operating temperature, plus the relief pressure at 73°F / 22°C (for testing purposes). Depending on the blower type, amount of vibration and operating temperature a difference of observable set pressure may occur.

Example: 2182-18 is set to relieve at 18 PSI while at operating temperature. This same valve will test at 22 PSI while at room temperature on a test bench. Both set points are listed on the label.

2" 20 PSI male air relief valve designed specifically for use on tractor mounted air blowers. The 2181 air relief valves have a temperature compensated pressure relief setting to accommodate the high temperatures and dynamic air produced by the blower. If a system blockage were to occur, the valves are designed to vent to atmosphere once the valve pressure setting is achieved.

The 2182 valve will relieve at the ordered set pressure at a temperature of 400°F / 204°C. At room temperature (73°F / 22°C) the 2182 valve will relieve approximately 4 PSI higher than the ordered set pressure.The popular pressure setting for truck mounted blowers is 20 PSI. Valves are available for other applications with temperature compensated pressure settings of between 3 PSI and 24 PSI. The product label shows the set relief pressure at the blower operating temperature, plus the relief pressure at 73°F / 22°C (for testing purposes). Depending on the blower type, amount of vibration and operating temperature a difference of observable set pressure may occur.

Example: 2182-18 is set to relieve at 18 PSI while at operating temperature. This same valve will test at 22 PSI while at room temperature on a test bench. Both set points are listed on the label.

Safety valves and pressure relief valves are crucial for one main reason: safety. This means safety for the plant and equipment as well as safety for plant personnel and the surrounding environment.

Safety valves and pressure relief valves protect vessels, piping systems, and equipment from overpressure, which, if unchecked, can not only damage a system but potentially cause an explosion. Because these valves play such an important role, it’s absolutely essential that the right valve is used every time.

The valve size must correspond to the size of the inlet and discharge piping. The National Board specifies that the both the inlet piping and the discharge piping connected to the valve must be at least as large as the inlet/discharge opening on the valve itself.

The connection types are also important. For example, is the connection male or female? Flanged? All of these factors help determine which valve to use.

The set pressure of the valve must not exceed the maximum allowable working pressure (MAWP) of the boiler or other vessel. What this means is that the valve must open at or below the MAWP of the equipment. In turn, the MAWP of the equipment should be at least 10% greater than the highest expected operating pressure under normal circumstances.

Temperature affects the volume and viscosity of the gas or liquid flowing through the system. Temperature also helps determine the ideal material of construction for the valve. For example, steel valves can handle higher operating temperatures than valves made of either bronze or iron. Both the operating and the relieving temperature must be taken into account.

Back pressure, which may be constant or variable, is pressure on the outlet side of the pressure relief valve as a result of the pressure in the discharge system. It can affect the set pressure of the upstream valve and cause it to pop open repeatedly, which can damage the valve.

For installations with variable back pressure, valves should be selected so that the back pressure doesn’t exceed 10% of the valve set pressure. For installations with high levels of constant back pressure, a bellows-sealed valve or pilot-operated valve may be required.

Different types of service (steam, air, gas, etc.) require different valves. In addition, the valve material of construction needs to be appropriate for the service. For example, valves made of stainless steel are preferable for corrosive media.

Safety valves and relief valves must be able to relieve pressure at a certain capacity. The required capacity is determined by several factors including the geometry of the valve, the temperature of the media, and the relief discharge area.

These are just the basic factors that must be considered when selecting and sizing safety valves and relief valves. You must also consider the physical dimensions of the equipment and the plant, as well as other factors related to the environment in which the valve will operate.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale air blower safety valve on Alibaba.com. When you search for air blower safety valve and related items, you will be able to find many types of air blower safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of air blower safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

The Supreme Court has reinforced the theory of the First Amendment as a "safety valve," reasoning that citizens who are free to to express displeasure against government through peaceful protest will be deterred from undertaking violent means. The boundary between what is peaceful and what is violent is not always clear. For example, in this 1965 photo, Alabama State College students participated in a non-violent protest for voter rights when deputies confronted them anyway, breaking up the gathering. (AP Photo/Perry Aycock, used with permission from the Associated Press)

Under the safety valve rationale, citizens are free to make statements concerning controversial societal issues to express their displeasure against government and its policies. In assuming this right, citizens will be deterred from undertaking violent means to draw attention to their causes.

The First Amendment, in safeguarding freedom of speech, religion, peaceable assembly, and a right to petition government, embodies the safety valve theory.

These and other decisions rest on the idea that it is better to allow members of the public to judge ideas for themselves and act accordingly than to have the government act as a censure. The Court has even shown support in cases concerning obscenity or speech that incites violent action. The safety valve theory suggests that such a policy is more likely to lead to civil peace than to civil disruption.

Justice Louis D. Brandeis recognized the potential for the First Amendment to serve as a safety valve in his concurring opinion in Whitney v. California (1927) when he wrote: “fear breeds repression; . . . repression breeds hate; . . . hate menaces stable government; . . . the path of safety lies in the opportunity to discuss freely supposed grievances and proposed remedies; and the fitting remedy for evil counsels is good ones.”

8613371530291

8613371530291