boiler safety valve requirements pricelist

After a boiler has been engineered, built and tested for a given operating pressure there is only one reliable way to prevent operation of the boiler above this design pressure. This is a safety valve. The safety valve should be sized so that a single valve can handle the maximum steam production rate of the boiler and once open prevent boiler pressure to continue to rise. Standard operating procedure for the last century has been to install two safety valves on the boiler, one set 3-5 lbs below the design pressure and one valve set at the design pressure.

The 1st valve listed below is a true adjustable differential pop valve. The differential is adjured through the differential rings lock screw hole, from 3 PSI to whatever the operator desires. The pressure of the valve can be adjusted from 40 to 200 PSI.

The other valves listed are adjustable for release pressure and have a "pop" action: The pressure differential is not adjustable on these valves. If the valves are operated above their nominal pressure, the set-reset differential increases. If operated at lower pressure, the differential decreases to the point of disappearing about 10-15% below nominal pressure.

A boiler valve kit is a must-have for any homeowner with a boiler system. This brass valve kit features a vent safety valve that helps to protect your home from dangerous gas build-up. The included instructions make installation easy, and the durable brass construction ensures lasting performance. Keep your family safe with this essential boiler valve kit.

9. When the calibrated pressure is reached, the valve opens automatically and discharges the atmosphere to protect the whole system from safe caused by overpressure

10. This brass boiler valve kit is perfect for any steam-powered project. The kit includes a pressure gauge, safety valve, and two shut-off valves. The pressure gauge helps you monitor the pressure in your boiler, the safety valve keeps your boiler from exploding, and the shut-off valves let you turn off the steam supply without having to drain the boiler.

This brass boiler valve kit is perfect for any steam-related projects you may have. It includes a durable boiler and vent safety valve to keep your project safe and functional. The included instructions make it easy to install this kit in no time. This boiler valve kit is the perfect addition to your tool collection with its high-quality construction and affordable price. This brass boiler valve kit is ideal for any steam-based appliance. The kit includes a boiler valve, vent safety valve, and all the necessary fittings for a quick and easy installation. The included vent safety valve helps to ensure safe operation by releasing excess pressure in the event of a malfunction. This kit is ideal for use with any boiler, including cast iron, steel, or copper boilers.

Vent safety valves are required for all direct-fired appliances; this kit includes everything you need to install one. The boiler valve is brass and has a 1/2-inch pipe thread fitting that can be connected to the vent pipe. It also features an adjustable pressure relief valve with a gauge, protecting your home from high-pressure steam or air from the system. This kit comes with two elbows (1 in., two in.), four nipples (3/4 in., 1/8 in., 3/8 in.), three straight fittings (5/16 inches), and five pipe connectors (3 ways).

This boiler kit includes a brass pressure relief valve with an air vent, which is required by law. It also has a 1/2″ discharge elbow and two unions connecting the pipe inlet to your water heater. The safety valves are designed to prevent excess pressure from building up inside the tank, which can cause dangerous boil-overs or even potential explosions. This kit is excellent for homeowners with existing water heaters without this equipment installed.

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

Parker"s cartridge safety relief valves (CSRV) are designed to offer the highest level of protection while maintaining easy serviceability. The CSRV was designed from the existing Parker ...

Stainless Steel Safety Relief Valve is a safety mechanism deployed in applications to prevent them from bursting under pressure. Suraj Metal Corporationis a leading manufacturer and supplier of the different types such as the Brass Safety Valveand others in various sizes and dimensions. The valves are fitted with the pipelines in a way that when the pressure goes above the threshold level, the Stainless Steel Air Safety Valveopens up and relieves the system of pressure.

This is important to prevent the pipes from being damaged or bursting under high pressure. The Stainless Steel Safety Exhaust Ball Valveis used in the exhaust systems where the temperature plays major role. When the temperature exceeds certain point, it increases pressure and the safety valve opens and balances the pressure in the system. The spring loaded boiler safety valveis used in boilers and heat exchanger systems where steam and hot water are circulated through pipes. There are different gas safety valvetypes and each of these differ in their purpose and functions. Please feel free to contact us for more information on the different types of air compressor pressure relief valveand others with pricing.

We Keep Bulk Stock of CF8 stainless steel Pressure Safety Valve at our stockyard, contact us for Free Sample & stock list, View Brass Safety Valve Dimension chart

find Stainless Steel Safety Exhaust Ball Valve Dimensions, price list, size chart here, Buy ASTM A351 CF8M 316 temperature safety valve at best price in India

Safety valves or pressure relief valves are pressure regulating devices that are responsible for expelling excess pressure from the system when the maximum pressure levels for which they have been designed are exceeded, usually due to a

Safety valves perform their function when the pressure of the system where the fluid is contained, becomes higher than the maximum set pressure of the valve previously adjusted. When the system pressure is higher than the valve’s set

pressure, this opens, releasing the excess pressure to the atmosphere or to containment tanks, depending on the toxicity of the fluid. After releasing the excess, the valve closes again and the system pressure returns to normal.

To ensure total safety of personnel and installation, make sure that the valves have passed all safety tests and meet the requirements of the system where they are to be installed. All our valves are supplied with certificates of materials, cas-

What is the difference between the instantaneous full opening safety valve AIT (PSV) and the normal opening relief valve AN or progressive opening relief valve AP (PRV)?

The Pressure Safety Valve (PSV) opens instantaneously and fully upon reaching the set pressure for which it is designed, expelling the excess pressure from the system immediately. They are optimised for use with steam or gases.

In contrast, the normally or progressively opening Pressure Relief Valve (PRV) opens gradually as the system pressure rises above the set pressure of the valve above its setting. They are optimised to work with liquids.

At VYC Industrial we are specialists in the design and manufacture of all types of safety valves. We have a wide range of safety valves to cover all the needs of the sector.

The Mod. 496 EN safety valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The Mod. 495 EN pressure relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

They are used in places such as power, chemical and petrochemical plants to discharge safety valves, control valves, etc. in pressure lines and equipment that convey compressible substances such as steam, air, carbon dioxide, helium, methane, nitrogen, oxygen and other gases.

Test bench for regular inspections and setting and resetting safety valves. Ideal for distributors, maintenance companies or with in-house maintenance. It allows safety valves to be adjusted, tested and/or checked to the test pressure (setting) Pe wile cold (simulating service conditions), matching the opening pressure Ps and the closing pressure Pc, in accordance with the standard regulations.

Controlled safety pressure relief system CSPRS valves are mainly used where conventional direct-loaded spring action valves cannot guarantee the opening and closing margins that certain specifi c conditions of service demand.

The objective is to help the closure by means of pressure so that the valve remains completely watertight until reaching the set pressure and/or to activate the opening with pressure.

Increase the operating pressure of the system up to 99.9% of the set pressure.The control safety pressure relief system CSPRS device can be used with any safety valve available in the market and in particular, with models VYC Mod. 485, 486, 494, 495 and 496.

When temperatures dip below a comfortable range, having the right boiler installed can help ensure that heating costs remain low without sacrificing the level of preferred warmth. Choosing a new residential water boiler can be daunting, but armed with the right information, it’s easier to make an informed decision about your heating system. Size is not the only consideration when choosing a new boiler: the efficiency rating and the heating method are considerations, too. The costs to run a boiler can also vary depending on the current prices of heating methods such as oil and propane. Residential boiler prices vary based on size, efficiency rating, and fuel type (which includes oil, electric, propane, steam, or a combination of these) with the national average being $5,678, a price that includes installation.

Residential boiler prices are primarily determined by the size of the unit, which correlates to the BTU (British Thermal Unit) output. The average cost of a residential boiler unit without installation ranges between $2,700 and $7,700 with corresponding BTU outputs of 80,000 and 200,000, respectively.

Owners of homes that are more than 20 years old are advised to use the higher number to ensure the boiler can accommodate older construction materials that may not insulate as well as new construction materials.

Homeowners can install residential boilers using existing pipelines or electric grids if the infrastructure already exists. Without the infrastructure, costs can increase, especially in more rural areas. Not only are boilers powered by several sources like oil, gas, propane, electricity, and steam, but they can also be a combination of two of these power sources. Combining power sources can be a cost-efficient decision in some cases. These are some of the main factors that affect residential boiler prices.

In terms of installation, combi boilers are generally the least expensive, while conventional boilers are the most expensive. Standard boilers are used to heat just the air in the home as opposed to system boilers, which have an additional water tank to heat the water in the home as well. Each of these kinds of boilers are available in standard and high-efficiency options.

Homeowners may prefer one fuel source over another, especially if the infrastructure already exists in the neighborhood. Propane boilers are popular options and run efficiently, but they can cost more than gas boilers. Oil boilers, like condensing boilers, can cost more per month since a large tank is needed to hold the oil and oil prices fluctuate frequently, but they offer more heat per BTU and may be an ideal option for rural areas. Electric boilers use electricity to power the unit, making them efficient, but they are not always powerful enough to heat homes in cooler climates. Steam boilers are less common in new homes, but they operate by heating water or steam and pushing it to baseboard heaters and radiators through a network of pipes.

A general rule of thumb is that the larger the residential boiler, the higher the cost. While large, efficient boilers may seem cost-effective to ensure adequate heating, if the unit is too large for the home, the boiler may be unable to heat the space properly before turning off as a safety measure. Using the calculation to determine the correct BTU output for the area of the home is an important factor in ensuring that the monthly costs are not a waste of your resources. Additionally, larger heaters will require additional labor and infrastructure to install, potentially increasing the up-front costs.

New residential boilers installed in existing locations can run into some increased costs if any upgrades are needed to ensure safety and proper operation of the new boiler. These costs could include the installation of new pipes, ductwork, electrical outlets and wires, valves, or modifications to the power source. This is especially true if switching from one fuel source to another. For instance, switching from oil to gas would require digging out the existing tank for disposal and installing new piping.

Residential boiler prices can also be affected by the cost of permits required for new construction, safety inspections, and upgrades of existing equipment in the home. While some installations may require the complete replacement of ductwork, others may only need a thorough cleaning. Climate and geographic locations also influence how powerful the boiler needs to be and how much insulation may be required in the home.

HVAC professionals typically charge between $75 and $125 per hour and sometimes up to $200 for installing new residential boilers. After a technician has reviewed the work needed, labor may be charged as a flat rate fee. Installation permits can cost between $50 to $300, with the higher end most commonly for new builds. If inspection fees are needed, the cost can run between $40 and $75.

Regular repairs shouldn’t be expected as frequent costs, but when they happen, homeowners can expect to pay between $200 and $600 per repair on average. An easy method to determine when it’s time to replace a worn-out boiler is to multiply the years the boiler has been in use by the cost of repairs. If the answer is more than $5,000, it’s worth investing in a replacement.

Not all boilers require ductwork to operate, which helps reduce dust and allergens. If ductwork is used with an existing boiler, HVAC professionals can test the system for the presence of leaks and dirt and recommend installing new ductwork if needed. This can cost between $2,000 and $3,000 on average.

Most new homes are built with plenty of insulation to help regulate the internal house temperature. These homes are efficient at maintaining hot and cold temperatures. Older homes typically have less insulation or insulation that has broken down over time. Heat loss occurs easily in these homes, so boilers will have to work extra hard to keep the house comfortably warm.

Depending on the location, when a replacement gas boiler is being installed, it’s likely that a new gas line will need to be installed as well to ensure that it’s correctly lined up to the new system, free from damage, and safe to use.

Before the cold weather even sets in, you may want to start thinking about how to heat your home. Residential boiler prices are often less expensive in the summer months than they are in the wintertime.

An unexpected cost could arise in older homes when an inspection is completed on existing ductwork. If asbestos is found, the cost to replace or repair a residential boiler will likely increase because of the time and labor involved to remove asbestos according to hazardous material guidelines. Some contractors charge a minimum of $1,500 to $3,000 to remove asbestos.

Residential boilers may require storage tanks for heated water, depending on if a standard, combi, or system boiler is chosen. Boilers without tanks can reduce the footprint of the unit in the home for a lower cost, but they may be less effective for large homes without a storage tank of hot water. A combination boiler can fit in small spaces while allowing a reduction in costs, as water and air are heated together.

Conventional or standard boilers are commonly used for new home constructions and cost $3,500 on average. A single unit heats water rapidly and sends that hot water through pipes to faucets. These models also work well for radiant heat flooring when pipes are installed under hardwood floors to radiate warmth from the heated pipes. Though this is an additional cost up front, it can save some money in the long run as the radiant flooring heat helps maintain a warmer temperature in the house overall.

Combi boilers are often wall-mounted units that are convenient for small spaces since they do not require a storage tank. They can heat both water and air at the same time, which can be more cost efficient in the long run. These units work best in milder climates rather than frigid climates where the additional reserve water tank may be helpful to keep a steady supply of hot water and heat. The average price for combination boilers ranges between $2,600 and $6,800.

System boilers can cost between $3,000 and $5,500. They are best suited for average-size and larger homes where the hot water tank helps ensure that hot water is available instantly from any faucet. With a system boiler, the water tank stores preheated water, offering a large supply of hot water on demand.

In general, boilers need to be replaced every 15 years. This helps ensure that old boilers are replaced with more energy-efficient systems to reduce monthly costs and maintain safe operation. However, there are also signs that indicate you need a new boiler. For example, a boiler needs to be replaced if it requires frequent repairs that use funds better spent on a new and more efficient boiler. Odd sounds, leaks, and fluctuations in water temperature are other indications that it’s time to consider replacing an old boiler.

While most home appliances make some sounds, when a residential boiler starts making a lot of noisy sounds, it’s time to have a professional investigate whether sludge has built up in the system or the pipes and valves are wearing out. If there is a new smell like rotten eggs coming from the boiler or if it’s leaking anywhere, calling a licensed professional is highly recommended to ensure it’s operating safely or to know whether it needs to be replaced.

Residential boilers have been improved over the last decade. Old boilers operate less efficiently and often require additional power or fuel to maintain the desired level of warmth. If the cost to run the boiler has increased in recent months or it takes longer to heat water than it used to, it’s probably time to consider replacing the boiler to a newer and more efficient system.

When boilers reach their lifespan, their efficiency rating deteriorates due to corrosion, sediment buildup, and thermal efficiency declines. An AFUE (Annualized Fuel Utilization Efficiency) rating of 56 to 75 percent is common for older boilers, and this translates to higher costs to power the boiler to maintain hot air and water. Newer models have efficiency ranges from 80 to 98 percent. Boilers with an efficiency rating above 90 percent can reduce heating costs by up to 30 percent.

With a newly installed residential boiler, homeowners can worry less about having hot water and a warm house when needed. New units are reliable, operate at the model’s optimum efficiency, and reduce the risk of safety hazards that older units can pose. Choosing a brand and installation company that have trusted reviews and safety records can help ensure that you get a reliable boiler and installation.

Many prospective home buyers are interested in homes that offer energy savings that range from solar panels to high-efficiency boilers. Choosing to install a residential boiler that has a high efficiency rating can boost the value of your home and offers a green alternative to homes that do not have upgraded systems. This also offers a peace of mind value to buyers who want to move into a home with updated features.

When a boiler experiences a challenge during operation, it can be frustrating to wonder how soon the problem will be fixed and how much it will cost. However, not every problem will require the help of a licensed professional. In some cases, knowing a few tips and tricks can help ensure the boiler is operating smoothly or give you an idea of how serious a problem is and if it will require additional or professional help.Check for a faulty thermostat. In some cases a problem may not be with the boiler but rather with a thermostat that has outlived its usefulness. Thermostats can be replaced fairly easily once diagnosed.

Check the pilot light. For boilers that still have a pilot light, it’s possible that the light has blown out and needs to be relit. If the light cannot be quickly relit, debris may be clogging the nozzle and require some cleaning.

Check for loss of pressure. If a boiler has lost pressure, a water leak is the most common culprit, but the problem could also be a faulty pressure valve. This will require the assistance of a professional, as leaks of any kind are abnormal in boilers.

Check the pressure relief valve before using. When a boiler is operating normally, it needs to release any excess buildup of steam or heat. When a pressure relief valve operates normally, signs of recent water or steam escaping from the valve should be obvious. If not, a technician will need to check it out.

Avoid storing anything near a boiler. While modern boilers are considered safer than early models, it’s still a good practice to avoid storing anything potentially flammable near a boiler.

Schedule an annual service appointment. Boilers are carefully designed machines that require regular maintenance to ensure they operate safely. If a boiler is only used part of the year, it can be serviced within a couple of months of turning it on.

Keep an eye on the boiler yourself. Rather than letting an unobserved problem get out of hand, set a reminder to do a visual inspection of your boiler each month. Check for cracks and leaks, or look to see if no steam is escaping if it’s a steam boiler. Call a professional if any of these problems occur.

Check boiler pressure occasionally. The boiler manual will specify the proper pressure range for your boiler. Checking the gauge can help ensure it’s functioning optimally.

While working with a residential boiler may be tempting for those who love to tackle DIY projects at home, there are times that it’s best to leave certain jobs to trained professionals. Some states require that boilers are installed only by licensed professionals. Installing residential boilers is a job best left to a licensed professional who is trained and certified in connecting and operating appliances, especially those connected to a power source like gas or electricity. Licensed professionals are able to install a boiler without spilling water that could damage any nearby flooring, and they carry insurance in case an accident happens.

Some professional HVAC companies don’t install units that they did not also supply. This helps ensure their technicians are qualified and comfortable installing the chosen model, which ensures homeowner safety in the long run.

After a new boiler is installed, homeowners are encouraged to actively make sure the boiler is operating properly. Checking valve pressures and identifying leaks and odd smells are a regular part of home maintenance. Boilers often come with a manual for homeowners to review and help them become familiar with how their boiler operates. There are troubleshooting sections that are specific to their boiler model.

For the bigger problems that can’t be solved quickly, the company that installed the boiler can also complete any major repairs that may be necessary when cracks, banging sounds, or foul smells are discovered. While repairing a boiler may cost between $200 and $600 on average, it’s considered worth the cost to keep a boiler running smoothly and safely.

Saving money on a new residential boiler is possible. Not only do HVAC companies offer discounts at different times of the year, but there may also be rebates or tax-cut incentives available. Here are a few tips to keep in mind if you are searching for a new boiler.Obtain at least two or three quotes for a new boiler installation and negotiate for a lower price.

Check the Database of State Incentives for Renewables & Efficiency for any available rebates or tax-cut incentives for buying a high-efficiency boiler.

If buying a new or replacement boiler is imminent, there are questions you can ask that can help clarify if you are making the right choice for your needs. Consider asking the following questions when deciding to install a new or replacement boiler.How much more can I save with a high-efficiency boiler?

Choosing the right kind of boiler is the first step to ensuring a home is properly heated. Here are some frequently asked questions that can help guide the decision-making process when determining residential boiler prices.

Steam boilers have few moving parts and provide dust-free heat and do not force air through ductwork. According to HomeAdvisor, steam boilers heat water with gas or oil until they produce steam that gets forced through the pipes that lead to radiators, baseboard heaters, or under-the-floor piping that provides radiant heat.

No. Furnaces heat air and use a blower to force the air into open spaces within the house via ductwork. Boilers heat water or steam and push the air through pipework to generate heat anywhere the pipes run in the walls or floors. Furnaces can dry out the air in a home, while boilers can produce extra humidity. Similarly, furnace cost will not be the same as the price of a boiler.

Propane is typically cheaper to use as a power source for a residential boiler by up to one-third less overall per the U.S. Department of Energy. Propane is also able to produce a more consistent, higher temperature of 120 degrees compared to the 95 degrees that electricity can produce.

Frequently breaking down and needing repair is the most common sign that a boiler needs to be replaced, particularly if it is 15 years old or older. Leaks, valve problems, fluctuating water temperatures, banging sounds, and odd smells are additional indicators that the boiler may need to be replaced rather than repaired.

Since issuing our price list in 1883, great strides have been taken in the use of steel for all purposes, and for none more than for Boiler plates. The uniform ductility now attained has made it the favourite material of both Boiler makers and Boiler users, so long as good Standard Brands are used and care exercised in the manipulation, (especially the re-heating of the whole plate after any local heating has been done.) Boilers made of steel will excel anything yet produced in iron, either as to first cost, efficiency, or durability. With increased knowledge in the manufacture of steel, and in the subsequent use of it, all those difficulties of unaccountable cracks, etc., have disappeared.

Having had an experience of 17 years, during which we have made over 3,100 boilers, we feel justified in offering our services to any of our customers who want advice as to what kind of Boiler is best suited to his requirements, and in all cases orders left in our hands will have the same care in manufacture as those undergoing professional and independent inspection.

All our Boilers are numbered, stamped with test pressure, and registered, so that we can at any time give a certificate of the test of any particular one made by us, if required.

Amongst our numerous patrons we may mention “The English Admiralty,” who have over 30 of our Boilers in use, The Queensland, New Zealand, natal, and Indian State Railways have all numbers of our Boilers at work; also the Metropolitan Fire Brigade, and Metropolitan Asylums Board; and several of our Boilers of special design are giving great satisfaction on the Congo River.

For the convenience of our customers we have adopted Code names for all our various Boilers, etc., in this list, and for more extended use of the code system we refer our friends to the “A.B.C Code,” (Mr Clauson Thue’s 4th Edition) which we use, and copies of which we shall be pleased to supply to friends at cost price, if required.

We have found that the demand in the colonies is always for a Squat Boiler, and although this design is not quite so economical for coal as the higher ones in List No. 1, it meets the requirements of wood-burning markets, and gives a large grate area. For Fishing Smacks & Steam Cranes also these sizes seem preferred. They are made similar to those in List No. 1, but with double rivetted vertical seams from 3 feet diameter, and strengthening rings round the mud holes.

Mountings include Spring Safety Valve, Stop Valve, Feed Valve, Water Gauge, 2 Gauge Cocks, Pressure Gauge, Scum and Blow-off Cock. Lock-up Safety Valve to meet board of trade requirements charged extra, according to size.

Boilers are made entirely of Steel, and stayed according to Board of Trade rules; but if Board of Trade survey and certificate is required, the fees must be paid by the purchaser.

This engraving represents the type of Boiler made by us for the English Admiralty, for use in their Steam Pinnaces. It is very similar to the Cutter Boilers, but has the front of the Furnace more enclosed, thus keeping a cooler stoke hold. Prices quoted on receipt of size required.

The design of this Boiler will recommend itself to all who want a tsrong boiler with the weight well down at the bottom. These boilers can be placed very snugly under deck, and yet have a large steam capacity. Prices quoted on receipt of size required.

These Boilers are well adapted for high pressure, and where good water is obtainable. They can be modified in design in numerous ways to meet special conditions, and we shall be happy to send quotations on receipt of particulars as to power wanted, space available, kind of fuel used, and working pressure required for Engine. Fire boxes can be had in Steel, Iron, or Copper. Tubes in Iron or Brass, and working pressure fom 50 to 250lbs. per square inch.

The above engraving represents a Vertical Cross Tube Boiler, with all Fittings, Mountings, and Injector, as made by us for the Indian States Railways. We make endless varieties of Vertical Boilers, and shall be pleased to supply designs and quotations for any special purpose, when required.

The above are the sizes of Mountings supplied with our Boilers, and we shall be happy to send any odd parts when the complete set is not required. Prices on application.

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

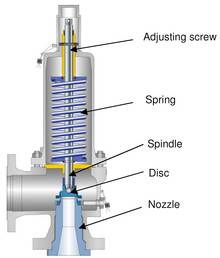

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The documents are meant to be used as a guide for developing local laws and regulations and also may be used to update a jurisdiction’s existing requirements. As such, they’re intended to be modifiable to meet any jurisdiction’s local conditions.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

At almost every show I attend, I ask a few engine owners and operators if they are satisfied with their new-style safety valves. It would be only a small exaggeration to say that I get just two responses. “I have been using a new-style valve for 15 years and I haven’t had any trouble with it” or “They are junk!” I have cleaned up the second response to spare the reader the unpleasant expletives.

As the result of these conversations, I have attempted to understand why there is such a discrepancy between the reactions to modern safety valves. It now appears that there are a few simple steps we can take when purchasing and installing these valves that might improve our satisfaction with the new-style valves, which are the only ones currently available.

To understand the issues involved in the selection of a safety valve, it is necessary to review the history of safety valves used on hand-fired boilers. I am referring to hand-fired boilers rather than historical boilers because the issues are determined by how the boilers are fired, not how they are constructed or how old they are. The requirements for a modern welded boiler made to the American Society of Mechanical Engineers (ASME) code are the same as for a 100-year-old riveted boiler, if both boilers are hand-fired. The requirements for a safety valve for a boiler that is automatically fired are dramatically different.

With automatic firing, the safety valve’s function as defined by Anderson Greenwood Crosby, a manufacturer of modern safety valves, is to protect life and property if all other safety measures fail. A safety valve on a hand-fired boiler, as defined by ASME almost a hundred years ago, is to give notice of the highest pressure permissible and to give alarm that more water or less fuel is needed. (The evolution of the purpose of the safety valve is summarized in “The Purpose of a Safety Valve,” at the end of this article.)

When hand-fired boilers, such as found on traction engines, steam cranes and locomotives disappeared, most of the boilers that remained were automatically fired. The safety valve manufacturers adapted their designs accordingly. The old-style valves with bottom guided, beveled seats were capable of withstanding vibration and operating near their setpoint, and were replaced by smaller top-guided valves with flat seats.

At the same time, steam system designs were adapted so there was no need to operate within 10 percent of the setpoint of the safety valve. Not all old-style valves had beveled seats, but the ones that didn’t were designed much differently from the modern flat-seated valves.

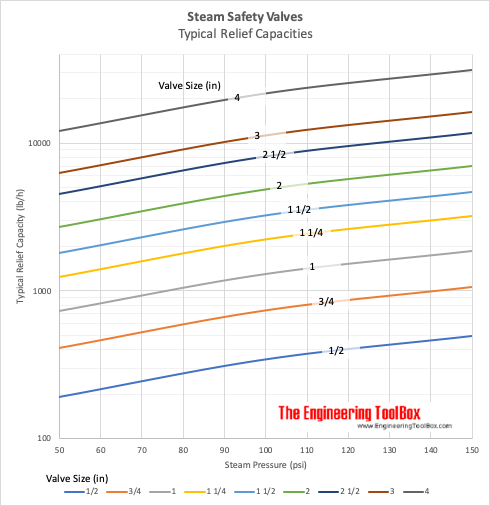

When I speak of a modern-style safety valve, I am referring to a valve shown in the second diagram of this article’s image gallery. An example of an old-style safety valve can also be seen in the image gallery. Changes in the design of safety valves had a dramatic effect on their capacity in pounds of steam per hour. If a boiler built in 1920 required a valve capable of releasing 1,000 pounds of steam per hour at a pressure of 100 pounds per square inch, it would have been equipped with a 2-inch safety valve. Today, 3/4-inch valves are available to release that much steam at that pressure.

The evolution of the safety valve did not end with the development of the modern, flat-seated valve. In the last 20 years, the design of safety valves has continued to evolve.

In 1985, a new-style 3/4-inch valve set at 150 pounds per square inch could have a capacity of 1,497 pounds of steam per hour. In 2002 this same valve could have a capacity of 1,651 pounds of steam per hour.

From 1914 until 1998, the blowdown allowed by the ASME boiler code was 2 to 4 percent of the setpoint. In 1998, this was changed to allow the blowdown to be as high as 6 percent. Beginning with the 2004 ASME code, there is no limit on blowdown. The code has not required that the amount of blowdown be stamped on a safety valve since 1986.

When I asked owners and operators how well they liked their new-style safety valves, I was not aware of the need to ask about the age of the valve. Instead, I would ask about the amount of blowdown. In almost every case, the people who were satisfied had valves that would blowdown 4 percent or less. It appears that this is almost the same as if I had asked the age of the valve. If the valve were purchased prior to 1998, it would have been set for 4 percent blowdown. If purchased after that date, unless specified otherwise, it would have been set for 6 percent. The change from 4 to 6 percent causes a 50 percent increase in the amount the pressure changes in a boiler each time the valve pops. The resulting increase in the flexing of the components of the boiler may be associated with a corresponding increase in seepage at stay bolts and tubes.

When you order a new safety valve, you will need to provide four pieces of information: the setpoint, the capacity in pounds of steam per hour, the blowdown and the requirement that the valve be stamped with the ASME “V” stamp. If you specify the pipe size, you may get a valve with far too much capacity, as I have already explained. To determine the capacity you need, do not use the capacity stamped on the old valve. First, if the valve has been replaced, it might not be the right capacity. Secondly, the capacity stamped on the valve is probably the capacity of the smallest valve available and might be significantly larger than the required capacity.

Calculating the heating surface of the boiler, in square feet, and multiplying the number by a factor can determine the required capacity. The ASME code requires a factor of 5 pounds of steam per hour per square foot of heating surface. Ohio requires a factor of 7. The heating surface is the area above the grates that is exposed to the fire. This includes the firebox, the tubes and the front tube sheet.

As I talked to many owners, they would offer other comments regarding their valves. One comment I heard from several owners who were satisfied with the new-style valves was that their valves were larger in pounds per hour than the minimum required by the ASME code. I am not certain as to exactly how the capacity affects the operation of the valve. What I do know is the larger the valve, the more force it takes to raise it off its seat. The force of the steam on the boiler-side of the valve cannot overcome the force of the spring in the safety valve until the pressure in the boiler rises to the setpoint of the valve.

When this happens, the valve pops open. It seems the larger diameter, and thus the greater forces, may result in more stable operation of the valve near its setpoint. There is a concern in the boiler code that safety valves should not be so large that water is drawn out of the boiler. It would seem, because of the relatively small size of portable and traction boilers, the pressure would drop so quickly that little water, if any, would be lost. I have seen boilers where the owners have installed modern safety valves of the same pipe size as the old style valves installed by the factory. The capacity of these valves was far greater than I believe anyone would recommend, but I am not aware that they caused water to be discharged from the boiler. It is important to be careful when sizing a safety valve. I suggest owners talk to each other and share their experiences before making such a decision.

If you would prefer to have a top-discharge safety valve, which looks more authentic, shop around. They are available in a few sizes. You might also want to consider specifying that the valve have a non-metallic seat.

When installing a safety valve, do not install any fitting smaller than the inlet to the valve and do not install any kind of valve between the safety valve and the boiler. Examples of what not to do can be seen in the image gallery. Do not use a pipe wrench on a safety valve, it can damage or destroy the valve.

Once you have carefully selected your safety valve and have installed it on your boiler, it is important to verify the setpoint and the blowdown have been set according to your specifications. The first step in this process is to have the accuracy of your steam gauge checked with a dead-weight gauge tester. If your gauge does not agree with the setpoint of your new safety valve do not assume that the gauge is wrong.

Do not use the lifting lever to lift the valve from its seat until the boiler pressure is up to 75 percent of the setpoint of the valve. If the valve is lifted from its seat at a lower pressure, any dirt or foreign material in the valve might not be blown clear of the seat and could damage the seats when the valve closes.

Because new-style safety valves are not designed to be operated within 10 percent of their setpoint, many owners have elected to install the new valve along with an old-style valve. In doing so, the old style valve operates in the range of 5 to 10 percent below the setpoint of the new valve. With this arrangement, the new valve satisfies the code requirements while the old-style valve performs the function for which it was designed. Two possible arrangements can be seen in the image gallery.

In response to complaints from owners of historical boilers who had recently purchased new safety valves, Dean Jagger, Ohio’s chief boiler inspector, requested that the National Board test valves from the manufacturer to determine if the valves complied with the requirements of the ASME boiler code. As a result of these tests the Ohio Department of Commerce issued a safety notice:

“The State of Ohio Boiler Division has been made aware of the fact that some recently purchased Kunkle safety valves, which were assembled by Allied Industries, have been tested by the National Board Testing Laboratory and found not to be in compliance. The tests indicated that the valves blowdown and setpoint pressure settings were out of tolerance as established by Section I of the ASME Boiler Code.”

This may be an indication that all of the problems with modern safety valves are not entirely the result of design issues, but insufficient oversight of manufacturing and quality control processes may also be a factor. A new valve may be “junk” as has been so often alleged.

The errors found by the National Board Laboratories were significant. One of the valves was stamped 165 psi but popped low at 148.8 psi. Another was stamped 150 psi and popped high at 164.5 psi. On the other three valves the pop was consistent with the setting stamped on the valve. The 2001 edition of the ASME Boiler Code specifies that for pressures from 70 to 300 psi the tolerance, plus or minus from the set pressure, shall not exceed 3 percent of the set pressure. The 165 psi valve popped 9.6 percent below the set pressure stamped on the valve, and the 150 psi valve popped 9.7 percent above the set pressure stamped on the valve.

The blowdowns on all of the valves that were tested were out of tolerance. The 2001 edition of the ASME Boiler Code specifies that for pressures from 67 to 250 psi the blowdown shall not be greater than 6 percent of the set pressure. With such a wide range of variations in both setpoint and blowdown, in a sample of just five valves, it seems reasonable to suspect that even greater variations may exist. The results of the tests are shown in the image gallery.

Complaints about quality problems are not limited to the five valves recently tested by the National Board; for example, an engine owner told me of purchasing a new 1-1/4-inch valve stamped 175 psi. When installed on a traction engine, the valve consistently popped at 185 psi and blew down 15 psi. (A pressure of 11.1 psi equals the allowed 6 percent.) The manufacturer told the owner that the valve had been tested properly prior to shipment but accepted it back. The owner had verified the accuracy of the pressure gauge prior to contacting the manufacturer.

The ASME and National Board procedures for safety valves merely confirm the adequacy of the design of the valve and do not assure the adequacy of production and quality control practices. Each boiler owner and operator must carefully confirm the accuracy of the setpoint and blowdown on every safety valve and not rely on the ASME and National Board stamps as assurances of quality. At this time, I have no reason to believe the monitoring of the ASME and National Board requirements at other valve manufacturers and assemblers is any different than what existed at Kunkle and Allied.

One scenario that concerns me is the owner who installs a new safety valve on his boiler and, seeing that the pop does not coincide with the reading on his 80- or 100-year-old gauge, decides that obviously his gauge must be wrong. This is a conclusion I am sure I would have considered when I first began my study of safety valves.

Incorrect settings of safety valves are more likely to be detected when the valves are used on hand-fired boilers than when used on modern boilers. If the controls on a modern boiler are to limit the pressure to 10 percent or more below the setpoint of the safety valve, the valve can be set as much as 10 percent below its rating and the error might not be apparent. Errors above the setpoint also wouldn’t be obvious even if the boiler were operated up to the setpoint stamped on the valve. Also, incorrect setting of the blowdown would not be apparent until the valve had operated.

1909: “The function of the safety valve is two fold: (A) it gives notice of the highest pressure permissible; (B) it gives alarm that more water or less fuel is needed.”

Today: “A PRV (pressure relief valve) is a safety device intended to protect life and property if all other safety measures fail.” – Anderson Greenwood Crosby, 2001 (safety valve manufactuer)

Bob Ferrell, Bob Schuler and Fred Harrison of the National Board of Boiler and Pressure Vessel Inspectors were instrumental in helping to obtain the information from the old editions fo the ASME boiler codes. Their assistance is greatly appreciated.

(a) Each power boiler, nuclear boiler, and high temperature water boiler shall have safety valves or pressure relieving devices constructed, stamped and installed in accordance with the applicable section of the Code, except:

(2) Upon written request by the employer, the Division may permit three-way two-port valves to be installed under two safety valves, each with the required relieving capacity, provided they are so installed that both safety valves cannot be closed off from the boiler at the same time and provided the three-way valve will permit at least full flow to the safety valve in service at all time.

(b) The user shall maintain all pressure relieving devices in good operating condition. Where the valves cannot be tested in service, the user shall maintain and make available to the inspector records showing the test dates and set pressure for such valves.

Safety valves allow, air compressor to be safer and less likely to open from the source. Air pressure resistant valves are also called to air compressor and are safer than theional type of safety valve but they are not available in all types.

Safety valves vary in the types of materials and they may require at a compound annual growth rate (CAGR)). Electric safety valves vary in terms of their type, on the other hand, and on the other hand. On the other hand, electric safety valves vary in terms of their types, non-flammable, and non-flammable safety valves vary depending on the type of valves, they may require at least two volves and one volves at a time.

8613371530291

8613371530291