boiler safety valve setting formula supplier

In order to ensure that the maximum allowable accumulation pressure of any system or apparatus protected by a safety valve is never exceeded, careful consideration of the safety valve’s position in the system has to be made. As there is such a wide range of applications, there is no absolute rule as to where the valve should be positioned and therefore, every application needs to be treated separately.

A common steam application for a safety valve is to protect process equipment supplied from a pressure reducing station. Two possible arrangements are shown in Figure 9.3.3.

The safety valve can be fitted within the pressure reducing station itself, that is, before the downstream stop valve, as in Figure 9.3.3 (a), or further downstream, nearer the apparatus as in Figure 9.3.3 (b). Fitting the safety valve before the downstream stop valve has the following advantages:

• The safety valve can be tested in-line by shutting down the downstream stop valve without the chance of downstream apparatus being over pressurised, should the safety valve fail under test.

• When setting the PRV under no-load conditions, the operation of the safety valve can be observed, as this condition is most likely to cause ‘simmer’. If this should occur, the PRV pressure can be adjusted to below the safety valve reseat pressure.

Indeed, a separate safety valve may have to be fitted on the inlet to each downstream piece of apparatus, when the PRV supplies several such pieces of apparatus.

• If supplying one piece of apparatus, which has a MAWP pressure less than the PRV supply pressure, the apparatus must be fitted with a safety valve, preferably close-coupled to its steam inlet connection.

• If a PRV is supplying more than one apparatus and the MAWP of any item is less than the PRV supply pressure, either the PRV station must be fitted with a safety valve set at the lowest possible MAWP of the connected apparatus, or each item of affected apparatus must be fitted with a safety valve.

• The safety valve must be located so that the pressure cannot accumulate in the apparatus viaanother route, for example, from a separate steam line or a bypass line.

It could be argued that every installation deserves special consideration when it comes to safety, but the following applications and situations are a little unusual and worth considering:

• Fire - Any pressure vessel should be protected from overpressure in the event of fire. Although a safety valve mounted for operational protection may also offer protection under fire conditions,such cases require special consideration, which is beyond the scope of this text.

• Exothermic applications - These must be fitted with a safety valve close-coupled to the apparatus steam inlet or the body direct. No alternative applies.

• Safety valves used as warning devices - Sometimes, safety valves are fitted to systems as warning devices. They are not required to relieve fault loads but to warn of pressures increasing above normal working pressures for operational reasons only. In these instances, safety valves are set at the warning pressure and only need to be of minimum size. If there is any danger of systems fitted with such a safety valve exceeding their maximum allowable working pressure, they must be protected by additional safety valves in the usual way.

In order to illustrate the importance of the positioning of a safety valve, consider an automatic pump trap (see Block 14) used to remove condensate from a heating vessel. The automatic pump trap (APT), incorporates a mechanical type pump, which uses the motive force of steam to pump the condensate through the return system. The position of the safety valve will depend on the MAWP of the APT and its required motive inlet pressure.

This arrangement is suitable if the pump-trap motive pressure is less than 1.6 bar g (safety valve set pressure of 2 bar g less 0.3 bar blowdown and a 0.1 bar shut-off margin). Since the MAWP of both the APT and the vessel are greater than the safety valve set pressure, a single safety valve would provide suitable protection for the system.

Here, two separate PRV stations are used each with its own safety valve. If the APT internals failed and steam at 4 bar g passed through the APT and into the vessel, safety valve ‘A’ would relieve this pressure and protect the vessel. Safety valve ‘B’ would not lift as the pressure in the APT is still acceptable and below its set pressure.

It should be noted that safety valve ‘A’ is positioned on the downstream side of the temperature control valve; this is done for both safety and operational reasons:

Operation - There is less chance of safety valve ‘A’ simmering during operation in this position,as the pressure is typically lower after the control valve than before it.

Also, note that if the MAWP of the pump-trap were greater than the pressure upstream of PRV ‘A’, it would be permissible to omit safety valve ‘B’ from the system, but safety valve ‘A’ must be sized to take into account the total fault flow through PRV ‘B’ as well as through PRV ‘A’.

A pharmaceutical factory has twelve jacketed pans on the same production floor, all rated with the same MAWP. Where would the safety valve be positioned?

One solution would be to install a safety valve on the inlet to each pan (Figure 9.3.6). In this instance, each safety valve would have to be sized to pass the entire load, in case the PRV failed open whilst the other eleven pans were shut down.

If additional apparatus with a lower MAWP than the pans (for example, a shell and tube heat exchanger) were to be included in the system, it would be necessary to fit an additional safety valve. This safety valve would be set to an appropriate lower set pressure and sized to pass the fault flow through the temperature control valve (see Figure 9.3.8).

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

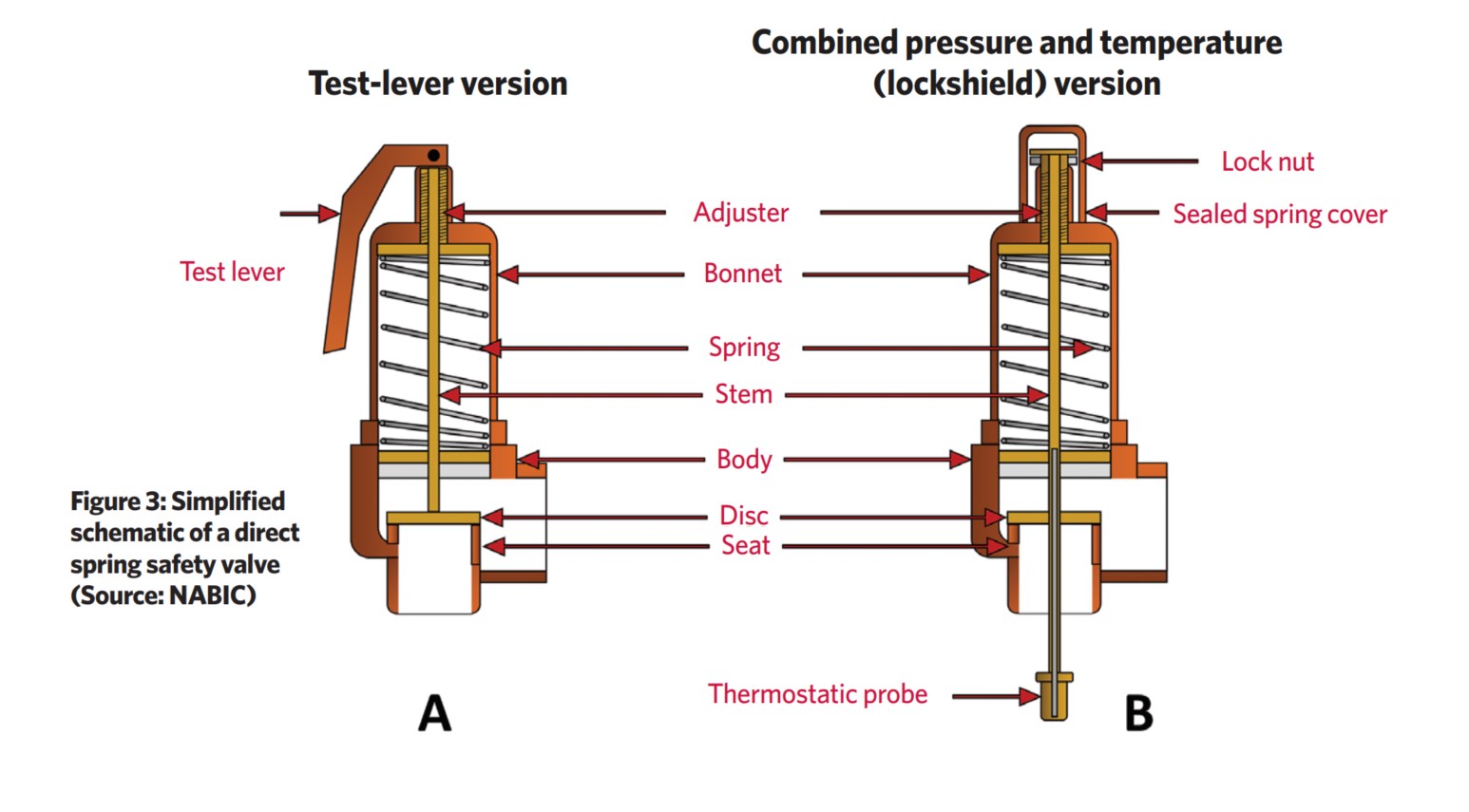

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

Chatter is devastating to the internals of a Boiler Safety Valve. However, there is an even more important reason to avoid chatter at all cost. Chatter prevents the Safety Valve from reaching or sustaining full lift. This results in the Boiler is not being protected from a catastrophic overpressure event. Chatter may be the result of several issues. The least likely is an inaccurately adjusted Safety Valve. More than likely, chatter is an issue of piping or installation. Inlet or outlet piping may be the culprit. Reduced Piping, too much length or too many bends (or some combination of those three) on the Inlet or the Outlet may result in Chatter. On some occasions, the Safety Valve is improperly sized resulting in chatter due to insufficient flow through the Safety Valve when it is called on to operate. In other words, the Safety Valve is oversized and there is enough pressure to cause the Safety Valve to lift, but not enough flow to keep it open. Bigger is not always better. All the issues referred to above result in pressure drop at the PRV Inlet, which causes chatter.

The only mentions of pressure drop in ASME Sec I, Power Boiler Code, are in PG-68.1 for Superheater Safety Valve Set Pressure calculation and in PG-68.4 for Reheater Outlet Safety Valve Set Pressure calculation. PG-72.1 is a requirement designed to ensure the Safety Valve does not chatter. Notice PG-72 has a title that refers to “Operation of Pressure Relief Valves.” It is referring to the Blowdown Ring Settings, not the inlet Pressure Drop due to piping losses.

In a related code, ASME Sec VIII-1, UG-135, INSTALLATION, in UG-135(b)(1) states, “The opening through all pipe, fittings, and nonreclosing pressure relief devices (if installed) between a pressure vessel and its pressure relief valve shall have at least the area of the pressure relief valve inlet . The characteristics of this upstream system shall be such that the pressure drop will not reduce the relieving capacity below that required or adversely affect the proper operation of the pressure relief valve.”

ASME Sec VIII-1, Non-Mandatory Appendix M, M-6 (a) states, “M-6 INLET PRESSURE DROP FOR HIGH LIFT, TOP-GUIDED SAFETY, SAFETY RELIEF, AND PILOT-OPERATED PRESSURE RELIEF VALVES IN COMPRESSIBLE FLUID SERVICE (a) The nominal pipe size of all piping, valves and fittings, and vessel components between a pressure vessel and its safety, safety relief, or pilot-operated pressure relief valves shall be at least as large as the nominal size of the device inlet, and the flow characteristics of the upstream system shall be such that the cumulative total of all nonrecoverable inlet losses shall not exceed 3% of the valve set pressure. The inlet pressure losses will be based on the valve nameplate capacity corrected for the characteristics of the flowing fluid.

Following the requirements for Safety Valve installation in ASME Code, Sec I, Power Boilers, will resolve the chatter issue without calculating pressure losses in piping. Refer to ASME Sec I, PG-71, “Mounting of Pressure Relief Valves.” The restrictions on size and length of piping should be sufficient to prevent chatter due to piping losses.

Regarding the least likely cause of chatter, i.e. Safety Valve adjustment, if the Upper Adjusting Ring (Guide Ring) is too high, the Safety Valve will pop, but will not remain open. It will reclose and immediately pop again resulting in chatter. This is due to the Upper Ring providing an "outer wall" to the Huddling Chamber to keep the Steam underneath the Disc long enough to achieve full lift. Setting the Upper Ring too high removes the "outer wall" of the Huddling Chamber resulting in chatter. Setting the Safety Valve in accordance with PG-73.5.2 (a), which states, “Pressure relief valves for steam service shall be tested with steam. The blowdown control elements of the pressure relief valve shall be set to the manufacturer"s specifications,” should eliminate the possibility of chatter due to an adjusting ring setting. It should be noted that the typical, ASME Sec VIII, Pressure Relief Valve, is a single ring design, Safety-Relief Valve. The Adjusting Ring Setting of the Single Ring Design, Safety-Relief Valve will not result in Chatter.

Trevi test is use for set pressure of safety valve with online while safety valve in service without adding pressure in whole system approaching the set pressure. Trevi test kit use the Hydraulic lift assist device to help pull spindle of safety valve to overcome spring force without increasing pressure in a system.

In early time in power plant we were not using trevi test for checking the pressure of safety valve instate of that we increase the pressure of system till the safety valve will not pop up than by comparing the control room valve pressure data we can set the pressure by tightening or loose the adjusting screw. But this method can be risky as well as time consuming and it can be reason of generation lose in the power plant.

Ask Running line pressure to operation department and enter that pressure in software, Calculate the pulled force from above formula then enter it in software then operate pressure applying switch that plot the graph in software the first deflection in the graph indicates the operate value of safety valve if this value is more then set value than we open lock nut of safety valve then tight adjusting screw if the value is less then set value than we open lock nut of safety valve then lose adjusting screw then tight lock nut, then take second trial to set the setting pressure.

Before attempting to adjust the safety valves of any boiler,its essential to verify the accuracy of the boiler pressure gauge,safety valves must be set at a pressure not exceeding 3% above the approved working pressure each safety valve is adjusted independently.

You will hear a hissing sound, this is the floating condition of the valve and subsequently the valve will lift. if the valve lifts before the set pressure is achieved tighten the compression nut. if the valve fails to lift at the set pressure loosen the compression nut, maintain the boiler pressure constant while adjusting, reduce boiler pressure, remove gagging tool and fit to other valve for setting.

After both valves are set, remove the gagging tool and fire the boiler to maximum capacity. note full flow of waste steam from waste steam pipe. note pressure on gauge, the pressure should not exceed 10% of set pressure. after completion refit caps, cotter, locks and easing gear.

8613371530291

8613371530291