boiler safety valve testing procedure manufacturer

Distributor of pipe, valves, piping accessories, industrial pumps & valve automation. Fluid handling products such as steam traps, control & high performance valves, corrosion resistant piping & grooved piping systems are also available. Valves include sanitary butterfly, plug, ball, check, gate, globe, sampling & rising stem valves. Instrumentation include actuators, limit switches, instrumentation fittings, transmitter manifolds, low pressure brass fittings, quick connectors, thermometers, gauges, RTDs, thermocouples, temperature & pressure sensors, pressure & temperature regulators, fluid & gas meters & sensors, positive displacement & turbine meters, positioners, switch boxes & pneumatic cylinders. Pumps & process equipment include rotary, positive displacement, air operated double diaphragm, progressive cavity, centrifugal, vertical & horizontal, end suction & submersible pumps.

When it comes to understanding pressure relief valve testing requirements, there’s a lot of information out there, but not all of it seems conclusive. If you’re new to pressure relief valves or are getting started in a new industry, it can be tough to decipher what testing requirements your facility needs to meet.

While we can’t provide the specific testing requirements for every industry, we can offer a few general testing requirements, and point you in the right direction to find the information you need for your facility’s unique testing requirements:

It’s good to keep in mind that every industry and region has unique pressure relief valve testing requirements. Your facility may be required to just bench test pressure relief valves every five years, or you may have to test valves every year, but bench test and repair valves every three to five years. There is a large variance in the testing requirements for pressure relief and safety valves depending on your industry and your region. That said, there are a few general testing requirements we can look at to start with.

The National Board Inspection Code, created by the National Board of Boiler and Pressure Valve Inspectors, makes the following recommendations on the frequency of testing for safety and pressure relief valves, depending on the temperature, psi, and function of your boiler:

High-pressure steam boilers greater than 15 psi and less than 400 psi should be manually checked every 6 months and pressure tested annually to verify nameplate set pressure.

High-pressure steam boilers greater than 400 psi should be pressure tested to verify nameplate set pressure every three years, or as determined by operating experience as verified by testing history.

High-temperature hot water boilers operating at greater than 160 psi and/or 250° F should be pressure tested annually to verify nameplate set pressure.

It’s important to remember that these are general pressure valve testing recommendations. For specific requirements, you’ll have to verify your unique jurisdictional and industry code requirements. See the resources below for more information.

The National Board Inspection Code is an industry-recognized name offering quality information on pressure relief valve testing requirements. Here, you’ll find a wealth of information and testing best practices.

The ASME is another organization setting pressure relief valve testing requirements, and offering the necessary training engineers need to test and understand the testing procedures for pressure relief valves. In addition to testing requirements and standards, the ASME offers a variety of online courses on pressure relief valves, from fabrication and proper installation to inspection and repair.

For specific testing standards, it’s best to check with your industry and your regional jurisdiction. Pressure relief valve testing requirements can vary by state or region and are most often industry-specific. Check your industry’s standards, and check local code requirements to ensure your facility is adhering to the most relevant pressure relief valve testing requirements.

When you’re looking for the pressure relief valve testing requirements relevant to your facility, it’s important to understand the different testing methods that are available to you. It’s likely that regardless of your industry if you have safety and pressure relief valves in use at your facility, you’ll have to bench test those valves at least every five years.

In addition to those bench tests, though, you’ll also have to perform manual or on-site pressure relief valve testing. Here’s a quick look at the three most common pressure relief valve testing methods you’ll see when researching pressure relief valve testing requirements:

The most commonly mandated form of pressure relief valve testing, bench testing is unique in that it requires you completely shut down your facility’s system and remove all pressure relief valves. The valves are then transported to a lab where they are tested and repaired as necessary. Tested valves are then re-installed in your system.

Bench testing is the most involved method of pressure relief valve testing, but as this is how valves are tested when they’re manufactured, the industry considers this to be the most thorough testing method.

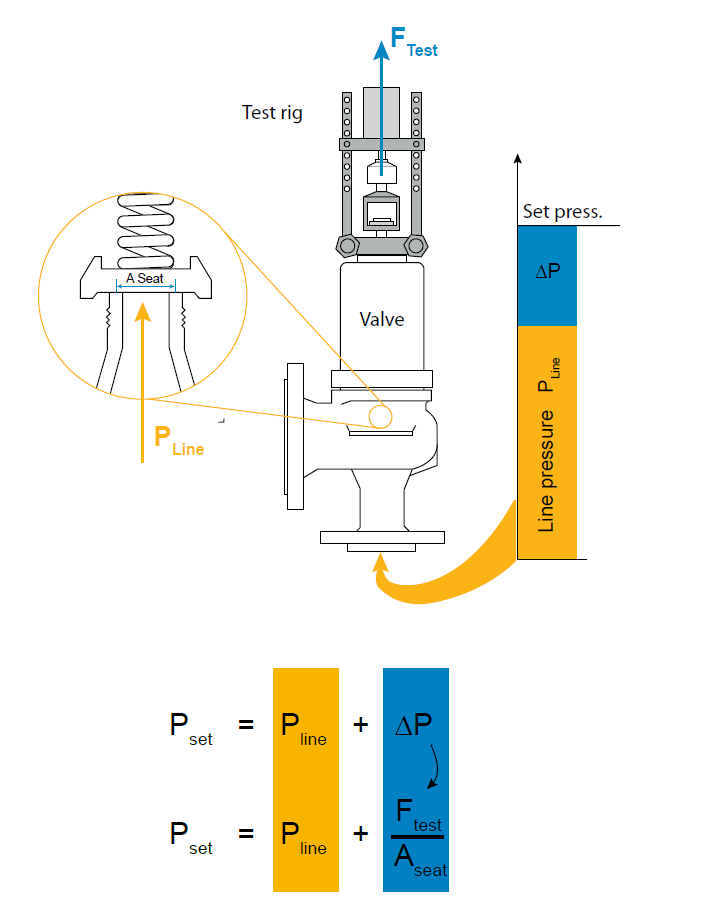

Inline testing is another accurate pressure relief valve testing method that doesn’t require the removal of valves or facility downtime. With inline safety relief valve testing equipment, a trained technician can test valves in the system to calculate the real setpoint of a valve in the system.

While inline testing cannot take the place of mandated bench testing, it is a more efficient form of testing for other regular testing requirements. Inline pressure relief valve testing is the ideal choice for any required testing that does not have to be bench testing, as it eliminates the need for downtime while still providing exceptionally accurate results.

Some pressure relief valve testing requirements will call for regular manual testing for freedom of operation. This is a basic test that can be done on-site. To complete an operated-in-place test, the test lever on the valve is manually activated. This test functions to ensure that the valve can open and shut tightly, but it does not verify at what pressure the valve opens and shuts. This is a test that may be required quarterly or bi-annually, to ensure the most basic functionality of safety relief valves.

Pressure relief valve testing is necessary for any facility with safety relief and pressure relief valves. For more information about the equipment you need for pressure relief valve testing, the profitability of certain testing methods, and more, head to the AccuTEST blog. There, you’ll find a variety of resources on everything from implementing inline safety relief valve testing to minimizing plant downtime.

If your company requires regular pressure relief valve testing, you might be interested in AccuTEST’s high-tech equipment. Offering inline testing with accurate, repeatable results, our system is the best on the market. See how our equipment works in real-time — schedule a live webinar demo today.

The Pressure Safety Valve Inspection article provides you information about inspection of pressure safety valve and pressure safety valve test in manufacturing shop as well as in operational plants.

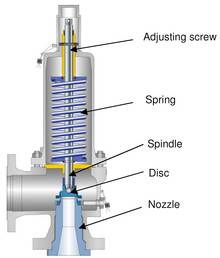

Your pressure safety valve is a direct spring-loaded pressure-relief valve that is opened by the static pressure upstream of the valve and characterized by rapid opening or pop action.

Your construction code for pressure safety valve is API Standard 526 and covers the minimum requirements for design, materials, fabrication, inspection, testing, and commissioning.

These are:API Recommended Practice 520 for Sizing and SelectionAPI Recommended practice 521 Guideline for Pressure Relieving and Depressing SystemsAPI Recommended Practice 527 Seat Tightness of Pressure Relief Valves

For example in the state of Minnesota the ASME Code application and stamping for pressure vessel and boiler is mandatory which “U” and “S” symbols are designated for stamping on the nameplate.

For example if there is pressure vessel need to be installed in the state of Minnesota then the pressure vessel nameplate shall be U stamped and pressure vessel safety valve shall be UV stamped.

National Board Inspection Code (NBIC) have own certification scheme for pressure safety valves and using NB symbol. The NBIC code book for this certification is NB 18.

There are some other standards and codes which are used in pressure safety valve such as:ASME PTC 25 for pressure relief devices which majorly is used for assessment of testing facility and apparatus for safety valvesBS EN ISO 4126-1, 4126-2 and 4126-3 which is construction standard similar to API STD 526.

This API RP 527 might be used in conjunction of API RP 576 as testing procedure for seat tightness testing of pressure safety valve for periodical servicing and inspection.

These are only important points or summery of points for pressure safety valve in-service inspection and should not be assumed as pressure safety valve inspection procedure.

Pressure safety valve inspection procedure is comprehensive document which need to cover inspection methods to be employed, equipment and material to be used, qualification of inspection personnel involved and the sequence of the inspection activities as minimum.

You may use following content as summery of points for Pressure Safety Valve Inspection in operational plantDetermination pressure safety valve inspection interval based API STD 510 and API RP 576 requirementsInspection of inlet and outlet piping after pressure safety valve removal for any foulingInspection of pressure safety valve charge and discharge nozzles for possible deposit and corrosion productsTaking care for proper handling of pressure safety valves from unit to the valve shop. The detail of handling and transportation instruction is provided in API RP 576.Controlling of seals for being intact when the valves arrived to the valve shop.Making as received POP test and recording the relieving pressure.

If the POP pressure is higher than the set pressure the test need to be repeated and if in the second effort it was near to the set pressure it is because of deposit.If in the second effort it was not opened near to the set pressure either it was set wrongly or it was changed during the operationIf the pressure safety valve was not opened in 150% of set pressure it should be considered as stuck shut.If the pressure safety valve was opened below the set pressure the spring is weakenedMaking external visual inspection on pressure safety valve after POP test. The test need contain following item as minimum;the flanges for pitting and roughness

Making body wall thickness measurementDismantling of pressure safety valve if the result of as received POP test was not satisfactoryMaking detail and comprehensive visual and dimensional inspection on the dismantled valve parts (after cleaning)Making special attention to the dismantled valves seating surfaces inspection e.g. disk and seat for roughness, wear and damage which might cause valve leakage in serviceReplacing the damaged parts in dismantled valves based manufacture recommendation and API RP 576 requirementsMaking precise setting of the pressure safety valve after reassembly based manufacture recommendation or NB-18 requirements

Making at least two POP test after setting and making sure the deviation from set pressure is not more than 2 psi for valves with set pressure equal or less than 70 psi or 3% for valves with set pressure higher than 70 psiMaking valve tightness test for leakage purpose after approval of the setting pressure and POP tests. The test method and acceptance criteria must be according to the API RP 576.The API RP 527 also can be used for pressure safety valve tightness test.Recording and maintaining the inspection and testing results.

Testing the safety relief valve is extremely important to the overall safety of your boiler system. In this post, we’ll be talking about what goes into testing a steam relief valve, but safety valve repairs should only be performed by a company holding a current Certificate of Authorization (VR) from the National Board of Pressure Vessel Inspectors.

Using certified and calibrated gauges is essential to accurate testing. WARE’s own Rick Walker recommends using two gauges, for maximum accuracy and in case one isn’t properly functioning.

Relief valves need to open and close at very specific pressures, and also need to open smoothly. A smooth opening contains a clean “pop” sound, and not a simmering or chattering sound. Responding to the appropriate pressures and opening and closing cleanly are both important signs a professional maintenance provider will look for in a safety valve.

Safety valves contain a compression screw, which puts pressure on a spring and causes the valve to function. The compression screw is where a maintenance provider will try to dial in your valve’s functionality and make set-pressure adjustments. It’s important to note if a valve is cold it might test higher, but as the valve gets hotter its metal will expand and its innerspring will slightly decompress.

Once the valve is warm and has stabilized, it’s best to give it more than one test (Rick does three) to make sure the valve is consistent and within ASME code.

ASME defines a safety valve as properly functioning at 150 psi if it tests within 3% of the set pressure. If your valve tests within 3% of the set pressure three times in a row on properly calibrated gauges, you’re likely good to go.

Remember, this procedure should only be done by professionals. If you’d like to schedule maintenance for your boiler, need assistance, or just want to learn more, contact us and check out our maintenance and service options at https://www.wareinc.com/boiler-services

Pressure safety valves are designed to protect process piping and equipment in case of an overpressure event. TEAM Valve Solutions inspects, tests, repairs and re-certifies safety valves at 17 service centers across three continents, and in our fleet of mobile facilities, all of which are audited under the jurisdiction of relevant governing bodies.

Our solutions cover all major safety valve brands and support our customers through an inventory of spare parts and loose-assembled valves. In addition, our facilities are audited and governed by the National Board of Boiler and Pressure Vessel Inspectors. Testing, repair, and assembly are performed under license and guidelines of NBIC, and ASME Section I and VIII.

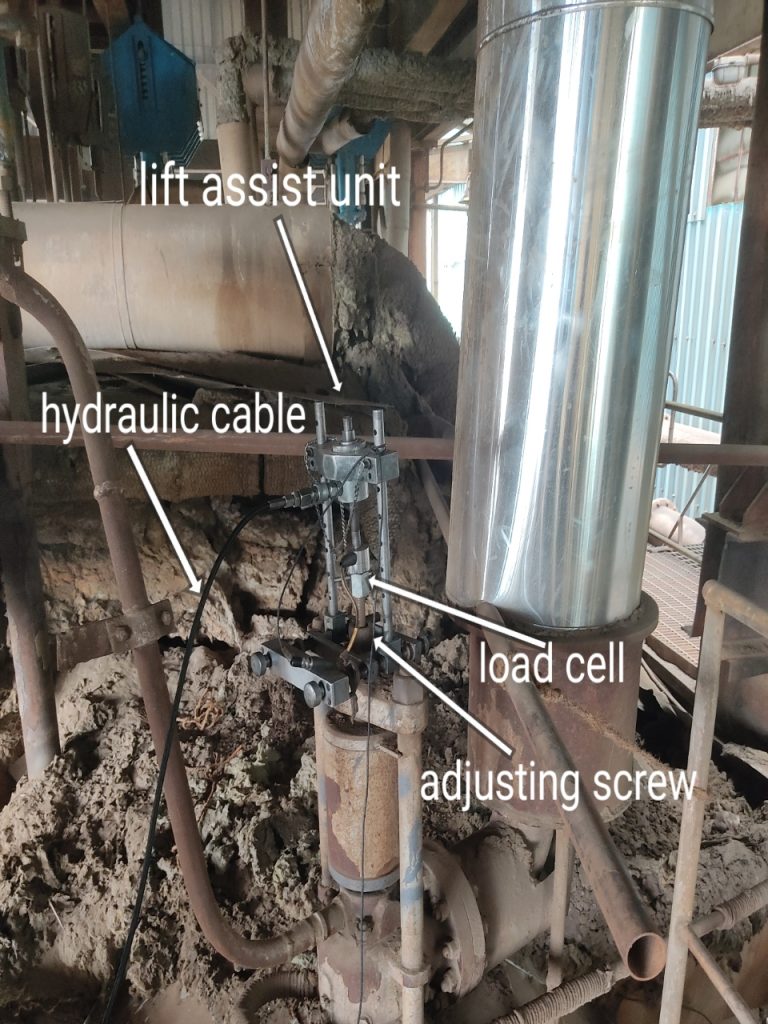

To ensure accurate in-line setpoint verification, TEAM Valve Solutions utilizes Trevitest, the pioneering system for validating safety valve performance in Conventional and Nuclear Power plants, as well as in other industrial process facilities.

When I teach my steam classes, I ask the attendees, "Do you test the pop safety valve?" Most do not. When I ask why, they tell me the same reason; the safety valve will leak. I joke during the classes that you do not want to test the pop safety valve on a Friday afternoon because it will almost certainly leak. I then ask, Do you check the low water cutoff? They look at me like I have a third eye and say they always check the low water cutoff. If you test the low water cutoff, you should test the pop safety valve. It is the last line of defense against a potential catastrophe. One of the things I do when performing a boiler service call is to explain the duty of the pop safety valve and ask the customer if they would like to have it tested. I explain that it could leak and if they refuse to test it, I will notate it on my service call in case something happens. In this way, my company is protected.

The best way to understand the pop safety valve is to read the instructions which came with the valve. I don"t have a life, and while you are watching the Masked Singer, I read O & M manuals. I know, I"m weird. I figure it"s my job to share things I find while reading these page-turners. The manufacturer hides all sorts of useful tidbits on the installation and maintenance of their valve. I have enclosed some information I gleaned while reading the instructions for a Conbraco/Apollo pop safety valve.

The valve must be mounted in a vertical, upright position directly to a clean, tapped opening in the top of the boiler. I see many safety valves installed horizontally and wonder if that voids the warranty. There should be no restrictions or valves in the piping to or from the safety valve. The installation instructions require the discharge piping to be schedule 40 pipe. They specifically say not to use schedule 80 pipe, which is 50% thicker than schedule 40 pipe. Many installers use copper tubing for the discharge, which does not meet the instructions. The other thing which confuses me the manufacturer instructs you not to use a pipe wrench to install the safety valve. I would wager 99% of all valves are installed using a pipe wrench. I wonder what kind of valve they want you to use.

I consult the pop safety manufacturer or the building insurance company to determine the frequency of tests. Apollo recommends quarterly testing using the Try Lever Test unless the valve is located in a severe service condition, and then it should be done more often. They further state the pop safety valve should have a Pressure Test annually before the heating season or at the end of any non-service period. This test will check your courage as you have to jump out the pressure controls and watch the operation of the boiler as the pressure builds. If the pop safety valve opens at the set pressure, the valve is working properly. This is not a test a novice should do alone.

Apollo suggests checking the pop safety valve at or near the maximum operating pressure by holding the test lever fully open for at least 5 seconds and letting it pop closed. On a low-pressure steam system, the pop safety valve is set for 15 psi. I like to run the boiler steam pressure up to 12 psi or higher to check the pop safety valve. After the test, I drop it to the operating pressure the owner requires. If the valve does not open, the boiler should be shut down until it is checked by a licensed contractor or qualified service person.

The pop safety manufacturer requires a minimum pressure differential of five psi between the pressure relief valve set pressure and the boiler operating pressure. It further states, Under no circumstances should the margin be less than five psig. On a low-pressure steam boiler, the pop safety valve will be set for 15 psi. That means the boiler steam pressure should be ten psi or lower. In breweries, it is common to see the boiler pressure set at 12-14 psi. This is less than the five psi differential and could create a dangerous condition.

SVI Industrial offers both shop and field diagnostic and control valve repair services. By utilizing “Bench Mark” diagnostic equipment, we can input your control valve’s configuration information, run baseline tests, then provide detailed documentation that will show the valve’s performance. This information can be used to determine if your control valve needs minor instrumentation calibrations or possibly a major overhaul.

We can work independently or with your reliability engineers to establish a database of your safety relief devices throughout your plant. You can count on our experience and knowledge to establish a recommended frequency of safety valve testing and repairs of your safety valves, that meet your corporate requirements and requirements set by your state inspector and insurance auditor based on “best practices” from the National Board.

SVI Industrial holds three “VR” certificates from the National Board of Boiler and Pressure Inspectors authorizing our technicians to repair, set and certify safety pressure valves inline, on our customer’s site and at any of our shop locations for both ASME Section I and VIII code stamped safety valves. Our skilled valve technicians will evaluate the condition of your safety valve, make the proper recommendations and work diligently to get your safety valves tested, repaired and set to the correct specifications and back in-line as quickly as possible in order to minimize interruption of your daily operations.

We are a turnkey service provider with the capability to service, repair or replace your welded in-line steam safety valves, including pipe prep, welding, removal and heat treating. SVI Industrial is your one-stop source for all of your industrial safety valve repair and other maintenance needs.

Safety is of the utmost importance when dealing with pressure relief valves. The valve is designed to limit system pressure, and it is critical that they remain in working order to prevent an explosion. Explosions have caused far too much damage in companies over the years, and though pressurized tanks and vessels are equipped with pressure relief vales to enhance safety, they can fail and result in disaster.

That’s also why knowing the correct way to test the valves is important. Ongoing maintenance and periodic testing of pressurized tanks and vessels and their pressure relief valves keeps them in working order and keep employees and their work environments safe. Pressure relief valves must be in good condition in order to automatically lower tank and vessel pressure; working valves open slowly when the pressure gets high enough to exceed the pressure threshold and then closes slowly until the unit reaches the low, safe threshold. To ensure the pressure relief valve is in good working condition, employees must follow best practices for testing them including:

If you consider testing pressure relief valves a maintenance task, you’ll be more likely to carry out regular testing and ensure the safety of your organization and the longevity of your

It’s important to note, however, that the American Society of Mechanical Engineers (ASME) and National Board Inspection Code (NBIC), as well as state and local jurisdictions, may set requirements for testing frequency. Companies are responsible for checking with these organizations to become familiar with the testing requirements. Consider the following NBIC recommendations on the frequency for testing relief valves:

High-pressure steam boilers greater than 15 psi and less than 400 psi – perform manual check every six months and pressure test annually to verify nameplate set pressure

High-pressure steam boilers 400 psi and greater – pressure test to verify nameplate set pressure every three years or as determined by operating experience as verified by testing history

High-temperature hot water boilers (greater than 160 psi and/or 250 degrees Fahrenheit) – pressure test annually to verify nameplate set pressure. For safety reasons, removal and testing on a test bench is recommended

When testing the pressure relief valve, raise and lower the test lever several times. The lever will come away from the brass stem and allow hot water to come out of the end of the drainpipe. The water should flow through the pipe, and then you should turn down the pressure to stop the leak, replace the lever, and then increase the pressure.

One of the most common problems you can address with regular testing is the buildup of mineral salt, rust, and corrosion. When buildup occurs, the valve will become non-operational; the result can be an explosion. Regular testing helps you discover these issues sooner so you can combat them and keep your boiler and valve functioning properly. If no water flows through the pipe, or if there is a trickle instead of a rush of water, look for debris that is preventing the valve from seating properly. You may be able to operate the test lever a few times to correct the issue. You will need to replace the valve if this test fails.

When testing relief valves, keep in mind that they have two basic functions. First, they will pop off when the pressure exceeds its safety threshold. The valve will pop off and open to exhaust the excess pressure until the tank’s pressure decreases to reach the set minimum pressure. After this blowdown process occurs, the valve should reset and automatically close. One important testing safety measure is to use a pressure indicator with a full-scale range higher than the pop-off pressure.

Thus, you need to be aware of the pop-off pressure point of whatever tank or vessel you test. You always should remain within the pressure limits of the test stand and ensure the test stand is assembled properly and proof pressure tested. Then, take steps to ensure the escaping pressure from the valve is directed away from the operator and that everyone involved in the test uses safety shields and wears safety eye protection.

After discharge – Because pressure relief valves are designed to open automatically to relieve pressure in your system and then close, they may be able to open and close multiple times during normal operation and testing. However, when a valve opens, debris may get into the valve seat and prevent the valve from closing properly. After discharge, check the valve for leakage. If the leakage exceeds the original settings, you need to repair the valve.

According to local jurisdictional requirements – Regulations are in place for various locations and industries that stipulate how long valves may operate before needing to be repair or replaced. State inspectors may require valves to be disassembled, inspected, repaired, and tested every five years, for instance. If you have smaller valves and applications, you can test the valve by lifting the test lever. However, you should do this approximately once a year. It’s important to note that ASME UG136A Section 3 requires valves to have a minimum of 75% operating pressure versus the set pressure of the valve for hand lifting to be performed for these types of tests.

Depending on their service and application– The service and application of a valve affect its lifespan. Valves used for clean service like steam typically last at least 20 years if they are not operated too close to the set point and are part of a preventive maintenance program. Conversely, valves used for services such as acid service, those that are operated too close to the set point, and those exposed to dirt or debris need to be replaced more often.

Pressure relief valves serve a critical role in protecting organizations and employees from explosions. Knowing how and when to test and repair or replace them is essential.

When it comes to the safe function of a boiler, a pressure relief valve is hugely important. For a boiler to function effectively and to the best of its ability, it is important that the pressure relief valve is maintained on a regular basis. But what does the pressure relief valve do on a boiler that makes it so crucially important? Leading pressure control equipment suppliers, Fluid Controls Ltd answer this and explore how to test pressure relief valves on boilers.

On a boiler, the pressure relief valve is one of the most important safety aspects. It is used to ensure that the build-up of intensive pressure within the boiler can be relieved in order to avoid catastrophic accidents. It works as an open-close feature: opening when the pressure has built up to dangerous levels and closing once normal pressure levels have been reached.

It is because of this reason, the maintenance of the pressure relief valve is so important. Should the pressure relief in your boiler fail, it can lead to catastrophic accidents within industrial settings.

The recommended timescale for carrying out maintenance and testing on a pressure relief valve is 6 months. Leakage is usually one of the main things to look for when understanding what causes a pressure relief valve to fail in a boiler. This is usually caused by a build-up of substances such as mineral salt, rust, or corrosion.

This build-up of debris can prevent the pressure relief valve from seating properly. This can stop the water flowing through the boiler pipe as it should do so. This issue should be fixed or replaced as soon as the issue is identified to avoid a disastrous incident.

So, the importance of regularly testing the pressure relief valve in a boiler has been defined. It is now important to understand how to test pressure relief valves on boilers. It is actually relatively simple and can be broken down into three simple steps.

If no water flows through or very little flows through, then there is an issue with the pressure relief valve that will either need fixing or replacing as soon as possible.

Testing all of these components is extremely important for the correct function of your boiler. Identifying these issues before they have the opportunity to escalate into a bigger problem makes it easier to find a solution, and maintain the high performance of your boiler moving forward.

Many people probably know that the National Board operates a capacity certification program and a valve repair program where we test many pressure relief devices. I want to talk about the background and requirements of that program and the applicability of our testing data to reliability for industry. As a result of years of testing, we have accumulated a good deal of data that helps us analyze the quality and reliability of the equipment. We want to use the data to determine what industry can expect when they receive a certified pressure relief device, pressure relief valve, or rupture disk device.

Two samples are selected every six years and tested at an ASME-certified lab. All test requirements come from the ASME Boiler and Pressure Vessel Code. Through the code, the National Board has been designated the responsibility to manage and run that certification program using the ASME boiler code rules. National Board inspectors travel to the manufacturers’ sites. We also deal with valve assemblers and rupture disk manufacturers. A big part of their responsibility when visiting the site is to look at the manufacturing, assembly, and test procedures, and make sure we get a good representative sample of what that manufacturer is capable of doing.

In some cases we will actually take valves right from shelf stock, particularly from manufacturers that mass produce their product and have large quantities of valves in stock. One selection technique is to go into the warehouse and say, “Give me one of those and one of those.” Sometimes they will dust off the box, but we are trying to get an accurate sample. Sometimes they are testing a valve they are building for the inspector while he"s there, but in that case they are looking at the assembly and test procedures and trying to see if it’s a good representative sample.

The program for individual design is not meant to be statistical in nature, so we are not testing a certain percentage of devices: just those two products every six years. It may be more than two if a test failure occurs. If there is a failure, the manufacturer has to test two additional samples. If they get past that test and still have a problem, a formal corrective action program is implemented. They have to analyze their failure, report on what happened (the cause), and explain what corrective actions they will take. And potentially, a manufacturer could actually lose the ability to put the code stamp on their product, so it"s an important test. The manufacturers have a lot riding on it because if the product passes, they can produce that valve for a six-year period of time. The tests are conducted at ASME/National Board-certified test labs, which include the National Board Testing Lab in Columbus, Ohio, but there are also about 10 other laboratories that are operated by valve manufacturers and rupture disk manufacturers.

We are involved in an ASME certification process. The labs all compare to one another to show that they can essentially attain the same results; they get the same measured capacity. And when any certification test is done at those labs, our inspector goes to witness the test and ensure it meets our requirements and procedures; so all tests are considered on the same basis. We have collected a lot of test data over the years and I looked for trends and patterns to analyze what the data was telling us.

Slide 5: We analyzed information starting with the year 2000. I chose that year because it gave me a lot of tests, but also the code rules for rupture disk certification went into effect in the "98 code, and by the year 2000, rupture disks were a well-certified device under ASME Code Section 8, and manufacturers had started to certify those devices. So it gave them a wider variety of equipment than we had seen before, because until then we were just testing pressure relief valves, and the non-reclosing devices were not well represented in the formal testing that we did, although they were being used out in the industry. It includes valve repair verification tests.

So although we talked about testing done on new product, as part of the valve repair certification process, the valve repair applicant has to repair several sample valves. Those are sent to a certified test lab and tested to exactly the same procedure that a new device is tested under. And while we always say a goal of the valve repair program is to return the valve to a like-new condition, as far as a user is concerned, if we get a repaired pressure relief valve, you should be able to expect that valve to do exactly what a new valve would do. It"s a certified device to begin with. It"s put through a program to inspect it, repair it as necessary, reset it, and get it back to that like-new condition. So I included all these valve repair verification tests. The typical test program for a repair outfit is doing a steam valve, an air valve, and a water valve, depending on the scope of work. And I threw those into the hopper; I treated those just like any other new valve that would be coming from the manufacturer.

We do tests for research and development projects and informational tests (what we call provisional testing). Provisional testing is the test a manufacturer does when they are first getting their design certified. Those tests are essentially prototypes. They are not valves that have truly gone into production, which doesn"t happen until a two-valve test is performed. So none of that was included, because they are still tweaking their design and getting it to the point at which they think it"s capable of being put through the final tests, and then to the production tests, which are the proof of the pudding.

It doesn"t include what we call investigation tests. I will talk a little bit about some of that test data. We don"t have a lot of it, but we do have enough to draw a couple conclusions, but it"s not indicative of the new product going out the door. Some of the limitations of this information based on the economics represents the lower pressures and smaller sizes of valves. So what we and other test labs can do is go up to three-, four-inch inlet sizes. Our pressures and capacities are necessarily limited because to put a pressure relief valve through a full-flow test, you need a lot of support equipment. We run boilers (we previously ran large air compressors but we"ve switched to a nitrogen system) but we have a lot of capital tied up in that. And as you double the pressure, the costs go up exponentially. So our tests are limited; we don"t do eight- and twelve-inch valves. The theory is that the valves are scaled up appropriately, but most of the testing we do is lower sizes and pressures. Hopefully that reflects more typical industrial equipment. We don"t get super-critical boilers, but there are large numbers of boilers with a 150-pound safety valve, and we have covered those pretty well.

Section III – 12 tests (These Section III valves were likely nuclear valves that got repaired as part of a repair demonstration. We don"t normally test many nuclear valves. They are the same physical equipment as you see in either Section 1 or Section 8.)

This is the bulk of the work we do; a wide variety of all different types of Section 8 pressure relief devices. In regards to test medium used: steam is about 25 percent and air is almost half. Air represents all the industrial gases. And then water tests are at about 25 percent. That represents valves for liquid service.

The test outcomes are based on the criteria we put in our database. After we run a test, we give it a designation as to the outcome of the test. Eighty-five percent of the valves passed. The biggest ones are set pressure failures and failures of capacity, with the next biggest elements, and I will talk a little bit about each category.

What I have is a plot of all the pressure relief valves, looking first at set pressure. Anything we called a failure is a failure to meet the ASME code set pressure tolerance. It"s cut and dried. If you fail it, you have to retest. But what we tried to do is see how wide those failures were, their distribution, and where test failures might potentially affect the pressurized equipment where that valve might be installed.

Slides 11-12: This distribution is the measured set pressure over the nameplate set pressure. The numbers below the 100% line are valves that opened underneath the nameplate set pressure requirement. The little tilted spot in the middle is all the valves that passed. And then as we go up on the right-hand side, those are the valves that failed but where the set pressure was actually high. And that to me is the real area of concern. A valve that opens low indicates an operational issue. But what we don"t want are valves that open high.

One glitch we discovered were a few valves that showed up at 400% above the set pressure. Normally we stop a test essentially at one and a half times the set pressure of the valve.

Occasionally we had some valves where set pressure was in bars, the test pressure was in psi, and if you tried to compare those numbers you didn’t necessarily get the right answer. Then what is the unsafe level? Where should we be concerned? A lot of times when people do this analysis, they will look at the hydrostatic test pressure. I do not believe that is conservative enough. That was good when a pressure vessel or boiler was manufactured.

We did an overload test on it and made sure it was good. But as that equipment goes into service over time, we know it"s degraded and there are other things happening to it. The criteria I used for what I call ‘the real bad actors’ was all of the devices that were over 116 % of the nameplate set pressure. That is the Section 8 overpressure limit for a system with multiple pressure relief devices. And if we get above that, we also reference it in the NBIC as a place for taking up the valve for an inservice test. We are going to stop at that point. I"m concerned with anything above that. So that was my first set of data where I"m thinking these are really not the way we would want them to be.

Then we get to valve capacity. The capacity includes valves that didn"t flow what they were rated to flow. A common cause is when valves are over pressured, they will hit a point where they get a secondary lift, and if someone doesn"t fine tune that valve properly, secondary lift isn"t quite achieved. It’s a test-and-tune issue; it"s not necessarily a design issue, but people really understanding how the equipment works. We do have a number of liquid valves that showed up, and again, if a valve doesn"t meet its rated capacity by the code-specified overpressure, it"s a test failure. But we have a number of liquid valves that would open just above whatever the specified overpressure is, typically 10 percent for a Section 8 valve.

So we did have a number of comments for those. And this also includes rupture disks where the flow resistance, which is the Kr valveor minimum net flow area, did not meet specifications.

Slides 13-14: This is my first graph of the distribution of our valve capacity. These are valves that were designated as failures, and we have the measured capacity divided by what the valve is actually rated for. So you can see, it starts at zero and works its way up. It should end at one but I had two or three tests where we called it a capacity failure, but it actually flowed more than the nameplate. Every so often we do run across valves that are misidentified, and sometimes that can be an issue. What I used as a measuring stick was stuff that was less than half of what it was rated at. That tells me it"s a valve that probably was not just a secondary lift issue. There was something really wrong with it. And that ended up being about a half percent of all the tests that were done.

We had about 1% of tests where we just didn"t have a measured capacity. Many were liquid valves. So we will take that test (the set pressure on those is where it first starts to have a trickling flow) and we will keep increasing the pressure until that valve pops open. And if that pressure occurred more than 10% above the set pressure, that valve was a capacity failure. We had a number of those that were about 12-15% above the set point. That information goes to the manufacturer and it can help them figure out their problem. Those valves were not counted in the case where we knew where they opened. We know that once they did open, they would probably work fine. But if you don"t hit it by that 10%, you have got to go through and do another test and improve your product to make it better. The rupture disk Kr number is used a little bit differently.

Slide 17: We had about two percent of what we reported as blow-down failures. These are not included in the final analysis because in reality we look at blow-down ultimately as more of an operational issue. It"s a concern to the user and to the boiler operator. It took two examples: one, we did have some Section 1 valves that were occasionally flagged. There is a minimum blow-down under Section 1. If it"s less than that, again, it"s a test failure and you have to address it. In most cases the capacity is probably fine in those valves.

Under Section 8 there is a requirement for manufacturers to demonstrate the capability to make certain valves meet a 7% blow-down requirement, and ones that fell in this category were valves that the capacity was fine because we actually do test that in that case, but they could not make that blow-down be less than 7%, which is the Section 8 specification. And that"s only for certain designs that are deemed what we call adjustable.

Slide 18: For whatever reason, they couldn"t adjust it. And in that case, the service condition you see is the valve stayed open a little bit longer. We had about .2 percent that we called failed operation. Mostly this is the adjustment of the lifting lever. It"s a lack of attention to detail when the valve was being put together.

I had about a tenth of a percent of valves that we deemed incorrect lift. This is from valves that are certified primarily in Section 8 where they will have restricted lift design. The manufacturer could make a valve that would pass all the criteria, but if set incorrectly, there would be too much lift and the design would not meet capacity. We don"t want somebody to pass because they put the valve together wrong.

Slide 19: So to summarize, I took what I classified as my bad actors: the set pressures that were more than 16 percent above the set pressure; the valve capacity failures that were less than half; the rupture disk Kr and rupture disk failures to open; and it all adds up to about one percent of our test total. And thus my initial estimate of what"s the reliability of this equipment ultimately to do its overpressure protection job is that it comes to about 99 percent, which is good.

We also compare that to the actual test failures. They were higher, and it obviously shows there is still room for improvement in the industry. We deemed a number of tests ‘investigation tests.’ These were valves that either had been received from chief inspectors in a few cases or received from private organizations to do a test to see if it possibly contributed to an accident.

Slide 20: We had 130 tests. About half of them were not applicable, but about 37 valves actually passed. Some failed set pressures, some failed capacity, a few failed blow-down. In all of the tests I have personally witnessed, the majority of the problems were ultimately due to how it was applied or maintained. I can pick up a valve and look inside the inlet and tell you if it will pass or not. We will put it on the test stand and test it. But if it"s all clogged up with rust or corrosion, or if the outlet is clogged with product, that valve is not capable of doing its job. And it"s nothing to do with how it was built. It was ultimately how it was maintained when it was inservice.

Slides 21-22: Looking at all of this information, what can we take away from it? One, we do want to recognize the value of the ASME code/National Board capacity certification program. It ultimately is a program that makes the manufacturers and organizations toe the line. They have got to work hard to meet the standard, and the standard has some very tight tolerances that are associated with it. They are there for a reason: this is safety equipment. We want it to be available 100 percent of the time. But that tight margin does give us a little bit of leeway. For example, if we get a valve that opens at four percent above the set pressure, that"s not a good thing and we will want the manufacturer to do better than that, but it still is well below the area where potentially we are going to have a problem when that valve goes into service.

Many times those test issues cause the organization to tighten up their procedures, and that"s typically what we find when people have a problem. They report back on their corrective action. A lot of times it"s training. People will look at the service manual and say, “Oh, I adjusted it this way.” They don"t understand what those adjustments mean and don"t make them properly. Perhaps they have to improve their calibration or setting techniques.

To increasing our test capabilities, the National Board Testing Lab has gone through an expansion project. We have up-rated our air testing capabilities specifically. I have also gone through some refitting of our steam system trying to improve our test capabilities. You may be hearing more about that over the next year or so.We are quite proud of the work that"s been done and we hope to improve what we do.

And then, finally, the statistics that we are looking at are new equipment going into service. And the one thing that we don"t account for in this information, other than the stuff we get from the investigation tests, is now once it goes into service, it"s not like wine, it doesn"t get better with age. Ultimately we need to inspect it, we need to look at this equipment periodically and make sure that when the inspections are done, they are not just a visual inspection, but we want to know for pressure relief devices, there needs to be testing associated with that to assure the device is working properly.

Make sure you have good inspection history to know how often we should be looking at these pressure relief devices. Some industry standards have a ten-year inspection period, which to me is way too long, particularly in a lot of the more aggressive services. You really need to look at the pressure relief devices more often because of the important function that they serve. But this preliminary data gives you an idea of how good a valve is once it goes into service, at least from a new product perspective. However, because of the data quirks, I wouldn"t necessarily quote any of this yet and put it into a publication.

For example on a residential water heater the TPR is typically set to open at a pressure of 150 psi or if the water temperature reaches 210°F. On older water heaters using older TPR valves you may find the valve rated to open at 125 psi.

In all events the opening pressure of a pressure or temperature relief valve should never exceed the working pressure of the tank - such a condition is unsafe and violates water heater warranties and plumbing codes.

An inspection of a T&P valve for its ability to perform safely includes a number of checkpoints such as looking for leaks, mechanical damage, blockage, or for a TPRV that is not properly sized or matched to the equipment it"s supposed to protect.

In our photo I"m pointing to the test lever on the temperature/pressure relief valve on a residential water heaters. These safety devices are required on all heated water or steam vessels or tanks and are found on both residential and commercial water heating equipment.

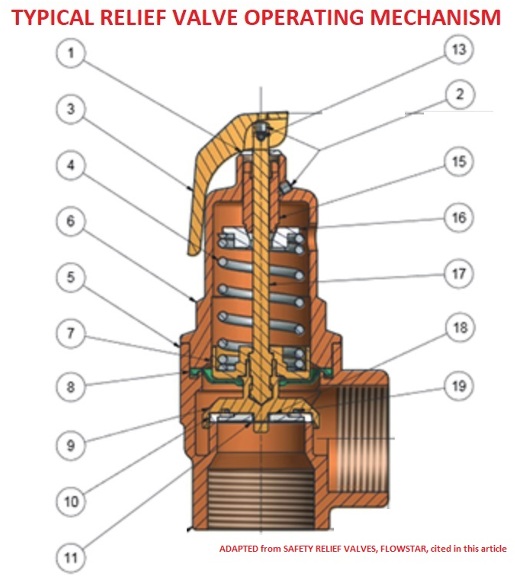

Illustration: typical parts of the operating mechanism of a relief valve, adapted from FlowStar Safety Relief valves cited below. Note that in this illustration the temperature sensing probe that would extend into the hot water from the valve base is not shown. Flowstar is a safety relief valve provider in the UK.

In this illustration key operating or moving parts of this relief valve are identified as (3) Lifting lever, (4) Spring, (6) Bonnet, (9) Disk, (12) Inlet body, (16) Spring Carrier, (17) Spindle or lifting rod operated by (3) the test lever.

It"s a holiday (stores are closed) or a Sunday or late at night such that if the valve fails to close you will not be able to arrange prompt repairs, leaving the building and occupants with no hot water or no heat

Observe the valve discharge: lifting the test lever should result in (hot) water flushing through the valve and its discharge tube into a bucket placed below the discharge tube for that purpose or into a floor drain.

the installation of any relief valves.- TANKLESS WATER HEATER USE & CARE MANUAL [PDF] for Rheem®, RUUD®, Richmond®, Paloma®, and Sure Comfort® residential tankless water heaters.

After lifting the easing lever or relief valve opening lever, lower it gently back to its closed position. You can let the TPR valve "snap" closed on its own - as is recommended by typical water heater TPR valve instructions but Rheem points out [citation needed] that rough handling of the relief valve test lever, such as allowing it to "snap" closed, can damage the temperature and pressure relief valve - a dangerous condition that could lead to a water heater explosion

OPINION: I think that the "snapping relief valve shut" problem is likely to occur principally when testing an old valve whose valve seat washer is already dry and brittle. Letting a newer valve (5 years old or less) test lever snap shut under control of the lever"s own spring ought cause no damage.

If water does not flow freely when the temperature/pressure relief valve is opened, the valve should be replaced by a licensed plumber, making sure that an approved, properly-rated TP valve is installed.

If your temperature/pressure relief valve has not been tested or replaced sooner than five years, Rheem recommends that the TP valve should simply be replaced. More frequent replacement of the safety valve may be needed in areas where hard water is found.

Watch out: some of the TPR valve test procedures and articles we reviewed point out that testing the valve by operating it more often than recommended risks damaging the valve, causing leaks, and possibly making it unsafe.

If the relief valve closes but continues to drip, you might be able to stop the drip by flushing the valve seat (lifting the test lever) a time or two.

When that does not work, try tapping gently on the center lift pin or rod to try to re-seat the valve washer. Don"t bang the heck out of the valve or you may convert a small leak into a dangerous hot water catastrophe.

If water continues to flow you may need to remove pressure from the hot water system or boiler; at a water heater this may be achieved by running hot water at nearby sinks or tubs

Considering the risks and costs of a bad T&P valve flooding a home at any time, particularly one that"s in the process of being sold, at least some home inspectors will eschew actually testing the T&P valve by lifting the test lever.

Watch out: if you do not test the T&P valve at a home inspection you should explain why (risk of a building flood) and you should advise your client to have such a test performed by their plumber promptly on taking control of the property. Avoid an ugly surprise by explaining what could go wrong.

Excessive temperature or pressure: A heating appliance that is at a too-high temperature or too-high pressure (a first check is to look at the temperature settings on the equipment and on a heating boiler to look at the system pressure: both should be below the valve-opening temperature and pressure given on the TPR valve label)

Watch out: the reasons that a dripping or leaking relief valve is dangerous include failure to notice that the system the valve is intended to protect is already operating at an unsafe temperature or pressure, OR the risk that continued leakage leads to scale clogging of the valve so that it cannot open in an emergency.

Virtually every temperature / pressure relief valve manufacturer whose product line includes TPR valves with a test lever or mechanism recommends that the temperature and pressure safety relief valve be tested, though the test interval recommended ranges from three years to six months, varying by type of inspection and valve type.

Really? In nearly 50 years of building inspection and repair work I [DF] have never once found a residential water heater installation at which the T&P valve is inspected regularly much less annually.

Typically the valve is noticed and replaced when the building occupants or owner observe a leak. Nevertheless we urge readers, plumbers, and other building occupants and owners to be sure that the recommendations of their TPR or easing valve manufacturer are followed. Failing to do so is dangerous.

Details of TPR valve inspection, including other inspection points beyond the actual valve testing (discussed just below) are at RELIEF VALVES - TP VALVES - home

The answer is: it"s debatable. Some inspectors test the valve, providing an extra level of expert safety inspection, while others, afraid of a flood or hoping to shorten their job-time by reducing their inspection scope, skip this step.

OPINION: The T&P valve is a critical safety device on water heaters and heating boilers and is a standard safety device found in most buildings. In our opinion, omission of any inspection of the TPR valve whatsoever would be malpractice, putting building occupants at risk. A building professional should know better.

But what about going beyond visual inspection? Under most home inspection standards that expect the inspector to operate "normal homeowner or user controls" on building equipment, one could argue that the inspector both can and should "test" the TPR valve by lifting the test lever.

Watch out: The results of testing a T&P valve, if the valve won"t close again, can be a flood of hot water in the building, risking burns, water damage, and considerable shouting.

Speaking from personal experience, I [DF] have operated a T&P valve only to see the old valve spit out its valve seat washer, leading to a horrible hot water flood.

Back in the day before I knew much about this hazard, during a plumbing job I made an emergency "Sunday night" replacement TPR valve seat washer (cut out of a piece of Tupperware©) to permit the owners to have hot water until the valve could be replaced the next day. Under normal circumstances this is not something you should attempt.

Watch out: If the lift/test lever on a temperature/pressure relief valve is blocked from movement that prevents the valve from being tested - a step recommended at least annually by relief valve manufacturers.

Watch out: Depending on the relief valve model and design, a blocked relief valve test lever may prevent the valve from opening in response to pressure or temperature.

Special thanks to home inspector "anonymous", a member of the ASHI Technical Review Committee, for suggesting clarification of the hazards of blocked pressure or temperature relief valve test lever hazards - by private email 2017/04/21

American Water Heater Co., INSTALLATION INSTRUCTIONS FOR TEMPERATURE AND PRESSURE VALVE [PDF] - Retrieved 2018/04/21, original source: http://www.americanwaterheater.com/media/23796/6500260.pdf

ANSI: Relief Valves and Automatic Gas Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22, and the Standard CAN1-4.4 Temperature, Pressure, Temperature and Pressure Relief Valves and Vacuum Relief Valves

Ball, Joseph F., P.E., Field Repairs of Pressure Relief Valves Part 2: Testing Mr. Ball is the Director, Pressure Relief Department, National Board of Boiler and Pressure Vessel Inspectors,

Technology of Steam, Bulletin of National Board of Boiler and Pressure Vessel Inspectors, (2014 pp 8-10) - Retrieved 2018/04/21, original source: https://www.nationalboard.org/SiteDocuments/Bulletins/SU2014.pdf

Mr. Ball is director of the National Board Pressure Relief Department. He is responsible for pressure relief device new construction and repair certification programs, and test lab operations. He is also responsible for the conduct of shop reviews of valve and rupture disk manufacturers, assemblers, repair organizations, and test laboratories, and is an ASME Authorized Observer for the National Board Testing Laboratory.

National Board of Boiler and Pressure Vessel Inspectors Mailing Address: 1055 Crupper Avenue Columbus, Ohio 43229-1183 USA, Phone: 614.888.8320 Email: information@nationalboard.org

California, City of Merced, RELIEF VALVE DISCHARGE PIPING PLUMBING CODE [PDF] based on UPC 608.5, building code interpretation regarding the discharge piping from water heater temperature-pressure relief valves based on the California Plumbing Code, Merced Civic Center

CROSBY PRESSURE RELIEF VALVE ENGINEERING HANDBOOK [PDF] Technical Document No. TP-V300, (1997), Crosby Valve, Inc., retrieved 2018/04/21, original source: http://www.isibang.ac.in/~library/onlinerz/resources/enghandbook3.pdf

CROSBY RELIEF VALVE Series 800, 900 PRESSURE RELIEF VALVE INSTALLATION, MAINTENANCE, ADJUSTMENT INSTRUCTIONS [PDF] - Op. Cit. retrieved 2018/04/22, original source: http://50.244.15.10/techlib/Crosby/Crosby_ReliefValve_800_900_iom_D498.pdf

Pentair Valves & Controls, PENTAIR PRV ENGINEERING HANBOOK [PDF] (2012) - Anderson Greenwood, Crosby and Varec Products, Pentair Valves & Controls, Retrieved 2018/04/21, original source: http://www.iomosaic.com/diersweb/docs/pvcmc-0296-us_tcm106-35825.pdf

Spirax Sarco, STEAM SYSTEM SAFETY VALVE INSTALLATION [PDF], Spirax Sarco Limited, Tel: K+44 (0) 1242 521361, Offices world wide, Website: http://www.spiraxsarco.com/ retrieved 2018/04/22, original source: http://www.spiraxsarco.com/Resources/Pages/Steam-Engineering-Tutorials/safety-valves/safety-valve-installation.aspx

An exploding 30-gallon water heater has the force of about one pound of dynamite.and has the power to destroy a house and injure or kill those inside. Thankfully, explosions have been significantly reduced because temperature and pressure (T&P) relief valves are now being used nationally to protect water heaters from explosion.

T&P relief valves, when installed properly, prevent high water temperatures, which can cause flashing of hot steam at faucets or any water outlets in the system, or cause an explosion. And, they prevent high pressures, which can damage the water heater system piping or components.

Watts Water Technologies Co., WATTS LFN30 N30 INSTALLATION INSTRUCTIONS, RELIEF VALVES (DIAPHRAGM ACTUATED) [PDF] Retrieved 2018/04/21, original source: http://media.wattswater.com/1910203.f

These valves protect against excessive pressure only. To prevent excessive temperature above 212°F, which might result in a hot water explosion, combined temperature and pressure protection is essential. WATTS Combination Temperature and Pressure Relief Valves give this protection.

Series 53L Pressure Relief Valves are used in residential applications to protect against excessive pressure on domestic storage tanks and tankless water heaters..... ANSI Z21.22 approved, design certified and listed by CSA, and UL listed.

I recently tested the T&P valve on my electric water heater. I let it the snap back closed, as this is what a lot of websites said, and it appeared to test fine. However, I then found on your website, which said the lever is supposed to gently raised and lowered, or the valve could be damaged. I tested the valve again in this manner. Water flowed freely and it appears to have closed back properly.

Indeed typical water heater manufacturer"s instructions mention TPR valve testing procedures. Letting the valve "snap back" closed helps assure that the stop valve seats securely against the washer. I"ve done exactly that when the valve was dripping after a test.

To actuate the valve, hold the trip lever fully open for approximately five seconds in order to flush the valve seat free of any sediment. Then permit the valve check to snap shut.- source: American Water Heater Co., - Source: AMERICAN WATER HEATER INSTALLATION INSTRUCTIONS FOR TEMPERATURE AND PRESSURE VALVE [PDF] -

However in this article we noted that Rheem has pointed out [citation needed] that rough handling of the relief valve test lever, such as allowing it to "snap" closed, can damage the temperature and pressure relief valve - a dangerous condition that could lead to a water heater explosion or BLEVE EXPLOSION.

At least once a year, lift and release the lever handle on the temperature pressure relief valve, located near the top of the water heater, to make certain the valve operates freely. Allow several gallons to flush through the discharge line to an open drain. - Source: RHEEM ELECTRIC WATER HEATER MANUAL [PDF]

I don"t think that the snap-back is going to damage a valve that"s otherwise in good condition. But an old TPR valve that has not been tested in sometime may have a dried-out washer that will fail when the valve is tested. In that case the valve needed to be replaced even before

On

8613371530291

8613371530291