cdtp safety valve made in china

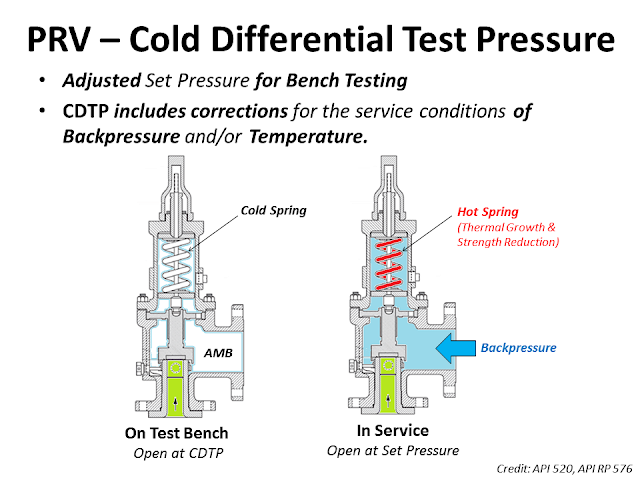

The Cold Differential Test Pressure (CDTP)of thePressure Relief Valve (PRV) is a set pressure that is adjusted to be used for the PRV (Bench Testing). Because in actual use conditions, the PRV may be affected by the Backpressure. And the operating temperature. Therefore, when testing at room temperature and without backpressure, it is necessary to adjust the set pressure to compensate for these factors. In other words, the shop test pressure = CDTP.

An example of aCold Differential Test Pressure (CDTP)with abackpressure (superimposed)effect. In this case, CDTP is equal to Set Pressure minus Backpressure.

An example of aCold Differential Test Pressure (CDTP)with different temperature compensations for use and testing. And an example ofCDTP that has been adjusted to compensate for both Backpressure (Superimposed) and temperatureeffects.

Test Stand or Test Bench is a set of equipment used for Pressure Relief Valve (PRV) in Pop Test (Set Pressure Test), Blowdown and Seat Tightness Test (Leakage Test)

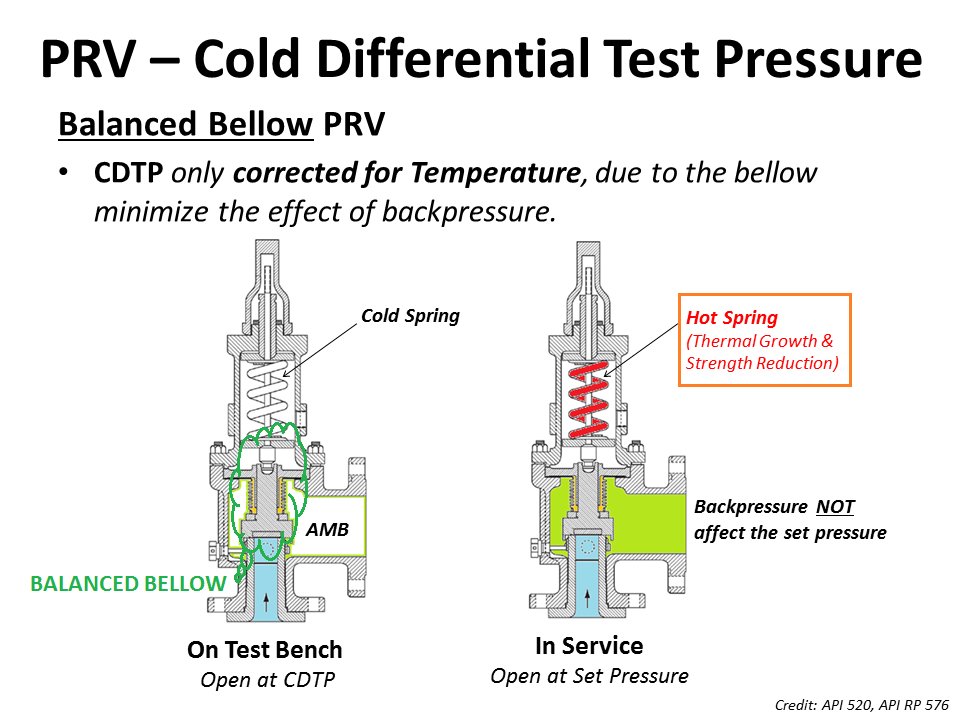

As for theBalanced Bellow Pressure Relief Valve, which has a bellowfor reducing the impact of theBackpressure, the Cold Differential Test Pressure (CDTP) of the Balanced Bellow Type PRV will compensate only for the impact of different temperatures between the Shop Test and In-service.

Proper repair of a Pressure Relief Valve starts with knowing the PRV Manufacturer and Model Number. All Pressure Relief Valves are similar, but being aware of the differences is the first step to being a qualified PRV Technician. Identification and interpretation of Nameplate Data is the basis for a proper repair.

CDTP(Cold Differential Test Pressure) may be stamped on PRVs certified to ASME Section VIII service. CDTP compensates for Elevated Temperature and/or Back Pressure. CDTP is an item of Nameplate Data that is much misunderstood. Simply put, the use of a CDTP means that the PRV Technician does not have to recreate "In-Service" conditions at the Test Bench. Elevated system temperature and/or Back Pressure can be accounted for during testing by application of the CDTP.

Vatac Flanged Bronze Safety valve is a high capacity and used for boilers, piping lines and vessel protection. Designed and engineered for heavy-duty industrial use. ASME approved and National Board flow-rated for capacity. » Manufactured under ISO 9001:2008 Management...

Vatac Thread Bronze Safety valve is a high capacity and used for boilers, piping lines and vessel protection. Designed and engineered for heavy-duty industrial use. ASME approved and National Board flow-rated for capacity. » Manufactured under ISO 9001:2008 Management System,...

We"re professional bronze safety valve manufacturers and suppliers in China, supplying the best industrial valves. Feel free to buy high quality bronze safety valve made in China here from our factory.

A question we commonly receive is why a valve appears to open, or actuate, earlier than expected. Often, we find that the valve is not, in fact, opening early. Rather, the perception that it is actuating early is due to a misunderstanding of set pressure.

The set pressure, also called the opening pressure, of a safety or relief valve is the inlet pressure at which the valve begins to open as required by code.

A valve should be set to open at the maximum allowable working pressure (MAWP) of the vessel the valve is intended to protect. There is some tolerance to actual set pressure, which means that a valve set at 100 psig may open slightly above or slightly below this level.

The first step is to determine if your valve really is opening early. Sometimes safety and safety relief valves appear to open before they reach the set pressure — there may be an audible or visible release of fluid between the seat and the disc. This is known as “simmer” or “warn,” and it is not the same as a full open.

Simmer, or warn, occurs when a valve opens slightly, discharging only a small percentage of its rated capacity. For example, direct spring-operated safety valves may simmer or warn at 90% of the nameplate set pressure. A valve that is simmering is not considered open.

The next step is to check your gauge to ensure that it is reporting the set pressure correctly. The gauge should be calibrated properly and located upstream of the valve, close to the valve inlet. Rapid increases in system pressure can make it appear that a valve is opening early because the gauge can’t accurately report the pressure.

If you still believe your valve is opening early, assess the operating factors that might be contributing to the situation. Valves are factory set using standard conditions, and factors like high temperature, vibration, and back pressure can cause them to open early. These conditions can be compensated for using cold set pressure, aka cold differential test pressure (CDTP). Learn more about CDTP from the National Board.

As we had discussed the backpressure that relief valve faces in a closed system would not be present during testing in the shop and this needs to be compensated for conventional relief valves.

However as discussed above the parameter of Temperature correction factor would still be applicable to Bellows and pilot-operated relief valve if the PRV temperature is significantly different from that of ambient temperature.

Project Scenario : A Relief valve of Dresser 1900 Series (Conventional relief valve) valve is required to open at 800 Psig where the service temperature is 400°F and backpressure is 100 Psig.

8613371530291

8613371530291