certified safety valve repair free sample

Do you want to expand your knowledge in safety valve technology? You want to plan and operate your plant in an efficient way? You want to further qualify your maintenance team? For engineers, experts or career changers, LESER offers the ideal training in safety valve technology.

Get detailed knowledge in nine modules: From an introduction to overpressure protection to the operation and maintenance of safety valves and the sizing of complex technical requirements - expand your know-how now!

Technically precise, practice-oriented, interesting and with modern training methods, LESER offers a wide range of training courses. With application examples, cutaway models and individual parts, the technology of safety valves is explained in a practical way. In the LESER Chatroom the functions of the different safety valves are demonstrated live. You will assemble, disassemble and test safety valves.

Valve manufacturers, suppliers, and repairers must pass a variety of certifications before they can perform assembly, repair, and other services on industrial valves. Below is an overview of the main valve certifications and authorizations applicable in the valve industry.

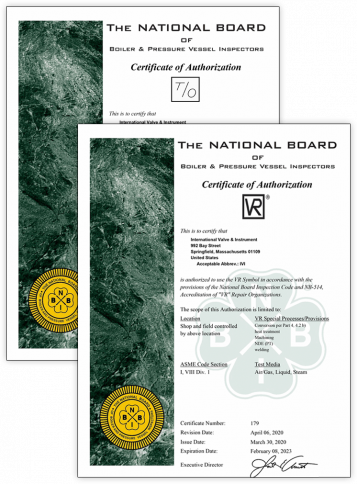

The National Board of Boiler and Pressure Vessel Inspectors sets the industry standards for pressure relief devices and is responsible for accrediting repair and alteration companies. The National Board offers three stamps and one mark. Organizations must obtain separate authorization for each type of valve they service.

An R stamp signifies that an organization has earned a National Board Certificate of Authorization to repair and/or alter pressure-retaining items including boilers and pressure vessels. According to the accreditation guidelines, “Organizations may be authorized to perform repairs only, or repairs and alterations. Organizations may also be authorized to perform design only, metallic or non-metallic repairs and/or alterations, either in the shop only, field only, or in both shop and field.” This authorization must be renewed every three years.

A VR stamp signifies that an organization has earned a National Board Certificate of Authorization to repair pressure relief valves, in the shop and/or in the field. This authorization must be renewed every three years.

An NR stamp signifies that a company has earned a National Board Certificate of Authorization to repair and replace nuclear components, in the shop and/or in the field. To earn this certification, an organization’s activities must be “performed in accordance with the National Board Inspection Code (NBIC) and American Society of Mechanical Engineers Boiler and Pressure Vessel Code (ASME BPV Code) Section XI requirements.” This authorization must be renewed every three years.

The NB mark signifies that a pressure relief device has been certified by the National Board. The NB mark is used jointly with ASME stamps to assure that pressure relief devices have gone through design review, rating factor testing, and production sample testing. Following the successful completion of a quality system review, organizations may become accredited to apply this mark to pressure relief devices.

Valve manufacturer certifications indicate that an organization’s technicians have undergone a comprehensive factory training program for services related to an individual manufacturer’s products.

Consolidated Green Tag Centers are organizations whose technicians have completed GE’s Green Tag training and certification program covering Consolidated pressure relief valves and repair services. GTCs are authorized to carry a large inventory of Consolidated valves as well as to provide a complete package of services including machining, measuring, testing, documentation, and valve repair. The GTC designation also signifies that valves comply with both National Board and ASME standards. To retain their authorization, Green Tag Centers must pass an audit every year.

A Masoneilan Authorized Repair Center (MARC) is a facility whose technicians have been factory-trained and authorized to repair GE’s Masoneilan control valves and valve products.

TSV Service & Sales, a Division of TRIVACO, offers over 55 years of experience in the Industrial, Commercial and Institutional Industry as mechanical specialty sales engineers and application engineering. As the “Factory Authorized Assembler” of Kunkle Relief Valves for the State of Indiana and western Kentucky. We provide Kunkle Safety Valves to Industrial Distributors and carry a local inventory of Kunkle Safety Valves that we can ship to you or drop ship to your customer.

Everyone is encouraged to call us and schedule a sales call to discuss our FREE survey of safety valves in your plant. This allows us to identify any relief valve installation problems and check to see if the valves are for the application and service. You will receive value from this service by addressing any potential safety issues proactively and not waiting until an unfortunate event occurs to act!

TSV also keeps record of manufacturer’s specifications for Kunkle Valve, Farris, Consolidated, Crosby and more to ensure the accuracy and quality of your valves.

We have certified our shop with The National Board and now hold the following code stamps; VR, UV, V and NB. This enables us to repair Kunkle Valve or ANY other manufacturer’s code stamped safety/relief valve, to new condition, right here in Indianapolis!

Everyone is encouraged to call us and schedule a sales call to discuss our FREE survey of safety valves in your plant. This allows us to identify any relief valve installation problems and check to see if the valves are for the application and service. You will receive value from this service by addressing any potential safety issues proactively and not waiting until an unfortunate event occurs.

The ASME BPVC Certification Program conforms to the rules governing the design, fabrication, assembly, and inspection of boiler and pressure vessel components during construction. In 1916, shortly after the first publication of the “Rules for the Construction of Stationary Boilers and for Allowable Working Pressures” (known today as the ASME BPVC), ASME began offering certification to companies in the pressure equipment industry to certify their quality control systems comply. Products manufactured by ASME BPVC Certificate Holders are certified and stamped with the Certification Mark in accordance with the applicable ASME BPVC Section. Today there are more than 6,800 Certificate Holders in the ASME BPVC Certification Program.

Scopes offered by the ASME BPVC Certification Program vary and include but are not limited to: power boilers, heating boilers, pressure vessels, fiber-reinforced plastic vessels, transport tanks and valves.

As one of the leading manufacturers of cavity free plug valves and special valves, AZ supplies to production plants in the chemical, petrochemical, pharmaceutical, paper, food industries as well as for nuclear power plants and many other areas. Special valves for highest demands in areas with high operating pressures and aggressive, toxic or abrasive media are designed and developed together with our customers. In the 50 years of the company’s existence, AZ has continuously developed to meet the increasing requirements of customers active around the world and today AZ manufactures internationally on four continents.

NBBI administers three accreditation programs for organizations that perform repairs and alterations on pressure equipment (R, VR, NR) and one program for organizations that test pressure relief valves (T/O).

Accreditation involves thorough evaluation of an organization’s quality system manual and requires a demonstration of its ability to implement the system. Authorized repair organizations are issued an NBBI stamp that is applied to the equipment nameplate. The stamp signifies strict repair and/or alteration requirements have been met and verified by an NBBI Commissioned Inspector.

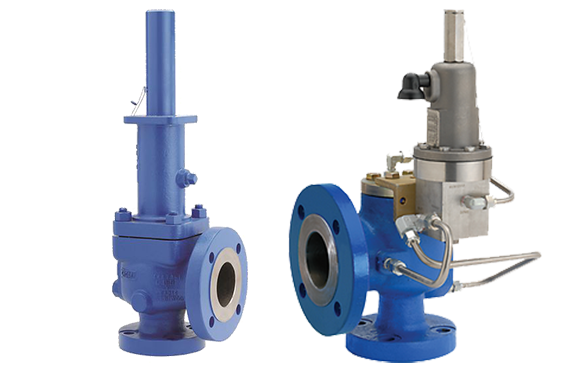

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

Safety valves, when properly maintained, can last a long time—upwards of 30 years or more. Much more. Recently, a century-old valve arrived at NASVI for repair. After machining and lapping […]

William Rock III, NASVI Valve Disassembler Since 2001 When a valve arrives at our facility for remanufacturing, William Rock III (Bill) is ready and waiting on the front line. He […]

Bronze, steel and stainless steel safety relief valves for air, gas, steam, liquid and vacuum service that meet ASME Section VIII, ‘UV’; Section I, ‘V’, are National Board certified and […]

When it comes to safety valve experience NASVI employees have a mountain of knowledge. Guess how many years of collective experience these three long-time employees have in this short video. […]

This direct spring-operated pressure relief valve, part of the Series 60 and 80, uses special internals and soft seats for optimum, accurate performance. Of course, we have them in stock. […]

The NASVI team goes the extra step in safety valve quality control. Before we ship any valve, we set and test them to the end user’s specifications. This is an […]

Q: My customer has a 2-inch line. Do I need to sell them a 2-inch safety valve? A: Safety valves should be sized and selected based on the set pressure […]

Not only is Kunkle’s 6252/6254 among their largest valves, also it’s a very sought-after one. You guessed it; we keep several in stock. For general application, it is suitable for […]

Valve manufacturers are not immune from the supply chain issues plaguing most industries right now. It’s predicted that it will take some time for shipping channels to be adjusted. NASVI […]

With supply chain disruptions hitting manufacturers, it’s important to be proactive as we approach heating season. With 35,000 relief and safety valves in stock & same day shipping, our extensive […]

Supply the following information: Example: 1. Quantity of Valves 4 2. Size of Valve Inlet and Outlet 1 ½” x 2” 3. Type, Model or Figure Number 1905FC 4. Manufacturer Consolidated 5. Inlet and […]

If you’re searching for a new Consolidated 1700 Series Maxiflow™ safety valve, or the 2700 and 1900-P1 Series economizer valves, look no further than NASVI. We’re the only company in […]

Did you know that NASVI has 35,000 safety & relief valves ready to ship at a moment’s notice? Or that warehouse is so huge (63,000 square feet!) we have a […]

NASVI pressure tests over 150 valves every day. Watch the process from adjusting the blow down ring to field service guidelines and performing the test pop, to sealing and shipping […]

If your customers are requesting a Kunkle liquid relief valve, model 218, then it’ll come as no surprise to you that not all distributors stock them and the manufacturer’s lead […]

A cracked valve, a broken part. There are always unwelcome surprises during a scheduled or unplanned shut down. Operations need to be back up and running ASAP. Don’t wait 7-10 […]

A No Brainer. Wearing face masks and social distancing is a no brainer. It isn’t pleasant, but you do what you have to do. Selling safety valves is also a […]

If you’re on the hunt for a new Consolidated 1700 Series Maxiflow™ safety valve, or the 2700 and P1 Series economizer valves, look no further than NASVI. We’re the only […]

What’s the purpose of a drip pan elbow? It provides a means to handle condensate from safety valves used in steam applications. Where are drip pan elbows used? The drip […]

When you sell safety valves, your customers are under pressure to get what they need fast. That’s why NASVI stocks the largest selection of Kunkle Valves for a variety of […]

Suggest a NASVI Valve Exchange Program. If your customer has several safety valves in need of repair but can’t afford to shut down for lengthy repairs, there’s an easy solution: […]

Offer remanufactured safety valves and watch sales grow. More companies today have found that it makes sense to rely on remanufactured safety valves. For most industrial uses, remanufactured valves offer […]

Offer NASVI’s quick turnaround on repair and testing services. At NASVI, our repair services are designed to keep: Your customer’s safety and relief valves at peak operating efficiency, and Put […]

You don’t have to be an expert in the field of safety and relief valves to sell them because that’s our job. And we’re only a phone call away. We’ll […]

Today, many companies are finding when maintenance budgets need to be stretched; a safe way to save is to rely on remanufactured safety valves. For most industrial uses, remanufactured valves […]

Increase profits, make our new Repair Facility your first stop. North American’s new Service Center is equipped to handle any safety valve repair. NASVI has the specifications for nearly every […]

Our goal is to make it easy for you to profit from the sales of safety and relief valves. Call us for assistance. We can help you with sales planning, […]

Earlier this year, I shared a little product education on safety valves that can make you look really smart to customers, which usually means more orders for everything you sell. […]

• More than 35,000 valves in 3,100 varieties • Currently set and ship over 200 valves per day • We repair over 40 valves a week with plenty of capabilities […]

Offer North American’s remanufactured safety valves as an alternative and watch your sales grow. Many companies have found that it makes sense to rely on remanufactured safety valves. For most […]

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. In addition to an experienced, skilled staff, NASVI’s Service Center is equipped […]

Our giant inventory and remarkable selection awaits your call. One of the customers recently inquired about the availability of five 4-inch liquid flanged valves. The end user had made a […]

Today, many companies are finding when maintenance budgets need to be stretched; a safe way to save is to rely on remanufactured safety valves. For most industrial uses, remanufactured valves […]

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. And put extra profits in your pocket. North American’s Service Center is […]

Offer NASVI’s quick turnaround on repair and testing services. At NASVI, our repair services are designed to keep: Your customer’s safety and relief valves at peak operating efficiency, and Put […]

For some reason I get asked pretty frequently if I’m a surgeon. Believe me, you don’t want me operating on you. I tell people I’m the Safety Value Doctor because […]

Offer NASVI’s quick turn-around on repair and testing services. Over the years, our Service Center has proven popular with maintenance managers. It allows your customer’s plant to have their valves […]

IVI is a VR certified safety valve repair facility, approved by the National Board of Boiler and Pressure Vessel Inspectors as a VR certificate holder (stamp 179). We certify pressure relief valves in the shop and in the field for sections V and UV. We also perform on-site testing (while the plant operates) providing documented reports for all valves tested. We are also certified to administer special process conversions regarding machining, welding, heat treating, and N.D.T. (non-destructive testing) with our VR certificate.

With our VR stamp, we repair all types of pressure relief valves such as Consolidated, Crosby, Kunkle, Farris, Spence, Anderson Greenwood, and numerous other O.E.M. safety and pressure relief valves.

The plate mounted on the side of your Kunkle valves is small yet mighty — it’s full of concise information that can help inform your next purchase decision or develop plans for new processes. But like most data snapshots (think the jargon on your “About this Mac” or “About my PC” window), it’s not always clear what everything means.

The ASME stamp is typically in the top corner of your nameplate. This stamp means that the valve has been assembled and set to meet the standards of a specific ASME code section. In this example, the valve has a “V” stamp. That indicates the valve is certified for an ASME Section I application.

Some Kunkle valves are non-coded by design, often for liquid applications that don’t require an ASME certified valve (e.g. Models 19, 20) or for vacuum service (Model 215V).

On the top of your nameplate, you’ll notice an NB stamp, which is associated with theNational Board of Boiler and Pressure Vessel Inspectors. If your pressure relief valve bears the NB stamp, it means it has a relief capacity certified by the NBBPVI in accordance withNB-501. Most Kunkle valves have certified capacities.

Often located near the top of the plate, and in this example, directly to the right of the NB stamp, you’ll notice the manufacturer and assembler name. This particular valve has been set by the factory, which makes Emerson (“EMRN”) the assembler.

Note: The value directly below the product and manufacturer names beginning with “CRN” is the Canadian Registration Number and will not be present on all Kunkle Valves.

Your valve’s nameplate also contains the model number, which is extremely useful for when you need to reorder the same valve. In this case, the model number is6010HGM01. The first two to four digits are generally the series or model the valve belongs to — here,6010.

In most cases, the letter indicating service will be somewhere further along in the model number. However, this letter could be in various positions depending on the valve series, making it tricky to recognize. For the most accurate information, check the product catalog of your valve series.

The size on the nameplate will tell you the nominal pipe diameter of the inlet (the connection on the bottom of the valve), which is 1 ½” in the case of this valve.

To the right of the size on this nameplate is the set pressure, which is 150 psig (pounds per square inch gauge). So in this pressure relief valve’s case, it will open as soon as it detects 150 psig at the inlet of the valve.

On Kunkle nameplates, the rated capacity is abbreviated as CAP. This value needs to meet or exceed your required capacity. In other words, the valve you purchase must be able to relieve pressure at least as quickly as your system’s worst-case overpressure scenario can generate it.

Knowing what all of these values and stamps mean is incredibly helpful when you’re reordering the same part. In most cases, you can just provide your distributor with the model number and be on your way! But if you need assistance specifying a valve for another application, or even to improve your current process,check out this articleor give our experts a call at (314) 665-1741.

8613371530291

8613371530291