co2 safety valve manufacturer

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

This control valve is used in control circuits for neutral and aggressive media in the chemicals, process engineering and plant construction industries. Positioners (pneumatic or electro-pneumatic) are used for precise ...

The combination of the sliding gate valve with piston actuator and integrated positioner offers a compact valve assembly, chracterized by a high control quality and control dynamics. Due to the direct ...

This compact motor valve is used in a wide range of process engineering control tasks. It is particularly characterised by its very short design. Most media such as steam, fluids, gases, etc. can be excellently controlled ...

... applications: the pneumatic pinch valve VZQA with silicone diaphragm comes in a normally open (NO) variant with a declaration of conformity in accordance with Regulation (EC) No 1935/2004 as well as FDA 21 CFR 177.2600. ...

Sporlan Type GC and FGB series gas cooler and flash gas cooler valves are stepper motor driven pressure regulating valves designed to maintain gas cooler and flash tank system pressures for superior control ...

Gas ball valves are mainly used to shut off the gas flow in gas trains or gas installations before and after other equipment like gas pressure regulators, gas meters etc.

Energy saving valve for the precise and economical control at low loss of pressure of liquids and gases that can be either clean or contain particles.

... butterfly valve Elara is available in forged or cast executions and different body, disc and seat materials. Application fields cover power generation, district cooling and heating as well as chemical processes up to ...

Triple offset metal to metal seat butterfly valve Titania is specially designed to ensure a perfect tightness in steam, gas, chemical, petrochemical and cryogenic applications.

... are wafer butterfly valves and are integrated with a disc constructed out of stainless steel, an ISO 5211 mounting pad, a long neck for isolation, and a body divided into 2 parts. It also incorporates ...

... efficiency and accuracy. KOSA software control valve selection, a code generation control valve comprehensive performance parameters, such as control valves, control valve ...

... range has been expanded to include a version for operation with CO2 refrigerant at high absolute and differential pressure values, combining the versatility and efficiency of the E2V ...

Pressure reducer for CO2 in nickel-coated brass and thermoplastic material with automatic pressure regulation system according to temperature. Regulations values as per the following schemes. Junctions ¼ " Gas female.

The compact dimensions and use of high-performance materials places the 3061E valve from Castel as a reliable safety device suitable for installation in all refrigeration systems, especially in CO2 transcritical applications.

Transcritical applications not only feature extremely high working pressures, up to 150bar; they also show very high temperatures at the compressor discharge line. This brand new safety valve perfectly complies with these extreme conditions, since it can reach set pressures up to 150 bar and 150°C working temperatures!

Safety valves type 3061E guarantee repeatable performance. This means that, after the valves haveoperated, open/close, the initial setting conditions are maintained.

“Pop-type” relief valves are designed for use as secondary relief valves in carbon dioxide transports & stationary storage tanks. The relief valves are designed to protect tanks from excessive pressure in event of fire /other emergencies. Small throttling-type primary relief valves must be provided to control boil-off and maintain tank pressures. Provisions must be made to prevent accumulation and build-up of water and foreign material in valves.

This 1-way distributor with nickel-plated brass body and toggle shut-off helps you control air flow in your beer system when pressurizing a single keg. The built-in safety valve helps meet requirements if you are in a state which requires your beer dispensing system to have a minimum of 2 safety relief or blow-off valves.

In a single line system, the keg coupler provides one safety release and this air distributor would provide the second. This beer gas distributor also allows you to stop the air supply without having to go all the way back to the tank valve. Convenient brackets for vertical or horizontal mounting are included.

Relief valves are safety valves specifically created to safeguard pressurized devices and / or systems from any over-pressurized situation. An over-pressurization problem occurs when a device generates enough pressure beyond its threshold limit value. Since high enough pressure can lead to hardware failure or even fire, it is of the utmost importance that relief valves are installed in many devices.

A relief valve works by releasing pressurized fluid through an additional passage, sending it out of the system. The relief valve (also referred to as pressure relief valve) opens at a pre-agreed set pressure and lets the selected fluid capacity flow until automatic closure (when the pressure of the device has reached a stable and secure point).

Moreover, these valves are commonly designed with elements that are well suited with the process fluids, ranging from air or water to the most abrasive media.

This CMBecker CO2 regulator (1-product / 1-pressure) features a CGA 320 nut for connecting to your CO2 cylinder. The locking knob allows you to set and keep your desired serving pressure.

CMBecker CO2 Regulators were collaboratively designed by draft beer professionals in Germany, USA and Portugal. These CO2 regulators are professional grade and built to last. The CMBecker line of regualtors has one of the best warranties in the business. The dual gauge feature of this regulator allows you to view remaining CO2 cylinder pressure as well as pressure output to your draft system. The on-body PRV (pressure relief valve) is an additional feature that allows you to depressurize your system at the regulator, rather than at the keg.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Sea™l stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

Our investment cast stainless steel is specified by leading industrial gas companies for storage tank and yard operations. Special order bonnet extensions are available for cold box applications. Valves for hydrogen use can be supplied

The RegO® Goddard 231 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, hydrogen, helium and argon.

The RegO® Goddard 232 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, helium and argon.

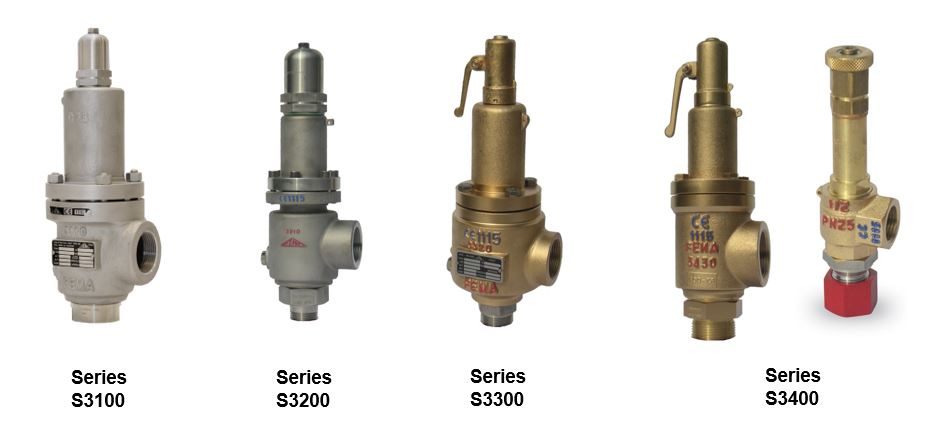

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

All Castel safety valves CO2 are equipped with NPT inlet connections. At the outlet, depending on the type, they are provided with SAE flare or thread connections. Each safety valve is individually tested and adjusted. Each safety valve has a unique serial number which is also mentioned on the supplied PED certificate.

Beginning July 8, 2019 H56xx series relief valves coming from Hansen will include both POP-EYE self-alarming technology and the new Anti Corrosion Technology (ACT) coating. They have discontinued the old style pressure relief valves. We have a limited amount of stock of the old style. Please call or email us if we can help.

POP-EYE is Hansen’s standardization of self-alarming relief valve technology. It provides positive indication (bright, flashing LED) when a relief valve lifts, helps eliminate subjectivity and personnel hazard in trying to identify the valve that lifted.

8613371530291

8613371530291