consolidated pilot operated safety valve in stock

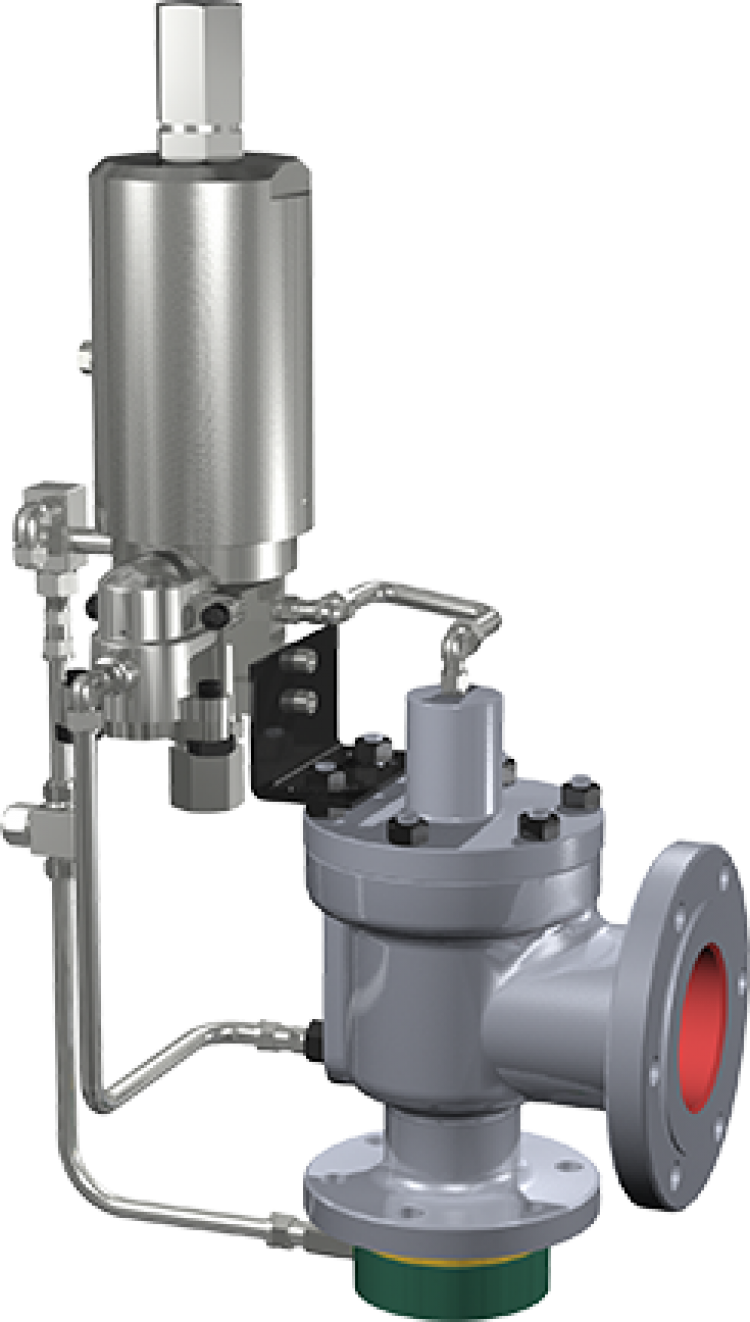

The 2900/2900 TM Series Gen II is a full-nozzle pilot-operated safety relief valve (POSRV) matching API 526 direct-spring PRV dimensions. Its patented full-nozzle integral sense design allows for easy maintenance as well as simple spring-loaded to pilot-operated PRV conversions throughout the lifecycle of the valve. The 2900 Triple Media (TM) Series is the first full nozzle POSRV engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both valve series use the same pilot valve technology as the 3900 Series including the ‘True Zero Leakage’ modulating pilot, providing a modernized overpressure protection solution for reducing carbon footprint and emissions.

Consolidated 3900/3900 TM Series Pilot-Operated Safety Relief Valves (POSRVs) feature a semi-nozzle main valve design that meets API 526 center-to-face dimensional requirements for POSRVs. The 3900 Triple Media (TM) Series is one of the first POSRVs engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both 3900 series come standard with a non-flowing pilot valve that is suitable for compressible and incompressible fluids. Optional pilot valve constructions are available for either pop or modulating action functionality to meet various pressure range, seat tightness, and blowdown requirements. Highly versatile, these valve technologies offer ease of maintenance, high reliability, flexibility, and efficient operation and performance.

The Consolidated 3900 MPV Series Pilot-Operated Safety Relief Valve offers a unique design that combines enhanced performance, capabilities, and features within an economical, modular assembly.

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

For system applications that require large discharge releasing capacities, GE’s 13900 valve series provides very reliable working economy and a simple, efficient valve design. In addition, its valve configuration simplifies valve installation and in-line valve maintenance.

Greater Total System Efficiency. The main valve can handle extremely large relieving capacities, in excess of 3 million pounds of steam per hour 1,360,777 kg/hr). It has a seven-to-one discharge capacity over a “T” type orifice, and a two-toone discharge capacity over a “W” type orifice.

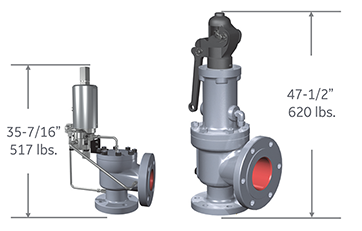

Improved Design. The total valve external configuration is considerably smaller in size, and the valve is lighter in weight than a comparable spring-loaded valve. Because of these features, less space is required for valve installation.

A simple, efficient, and reliable direct acting valve design with few components eliminates the need for excessive spare parts inventory and reduces maintenance time.

Easy Installation and Maintenance. Valve configuration is considerably smaller in size and lighter in weight than a comparable spring-loaded valve. This simplifies installation, field handling, testing, and valve maintenance.

Valve maintenance is relatively simple and straightforward. The simple valve design means fewer parts, so less can go wrong, malfunctions can be readily diagnosed, and maintenance cost and process downtime can be very limited.

To simplify valve maintenance, all main valve components are removable through the top bonnet of the valve. The pilot valve can be field tested and repaired without breaking inlet and outlet piping connections on the main valve. The pilot valve opening and closing is easily adjusted on a small test facility.

The Consolidated Type 2900-40 pilot-operated safety relief valve offers exceptional performance and meets demanding ASME Section I Economizer and Boiler Applications.

The Consolidated Type 2900 pilot-operated safety relief valve combines the advantages of two products into one— the 1900 safety relief valve and the 3900 POSRV. The 2900 POSRV can replace spring-loaded relief valves without requiring modified outlet piping.

The Consolidated Type 3900 pilot-operated safety relief valve is a non-flowing design available in a modulating or pop-action pilot. The 3900 POSRV is suitable for the overpressure protection of many pressurized systems and vessels in the chemical, petrochemical, paper mill, oil and gas production and transmission industries.

At each of our 12 convenient locations, the Chalmers & Kubeck Valve and Actuation Technicians are factory trained and certified. Each expert Technician is required to meet stringent factory standards prior certification so you can be confident that we will provide the expert, efficient, and comprehensive service that you expect.

Our services include field trouble shooting, actuator refurbishment, control enhancement, electronic valve testing, torque verification, turnkey overhauls / repairs, retrofits, and valve testing / certification. We offer complete reconditioning of ball valves, butterfly valves, check valves, control valves, gate valves, globe valves, parallel slide valves, pilot operated valves, plug valves, pressure relief valves, pressure safety valves, vacuum break valves, and other specialty valves.

Baker Hughes manufactures the premier boiler safety valves and pressure relief valves in the industry, Consolidated®, and authorizes a very select group of companies to be their exclusive factory authorized repair and service centers, known as Green Tag Centers® (GTC). Ten of the 12 C&K Service Locations are GTCs, which means that you will receive best-in-class aftermarket product support. With our OEM trained and certified valve technicians, you know that your relief valves will be rebuilt correctly to exacting standards. Prior to certification, each of our valve technicians must go through Baker Hughes classroom training that includes applicable codes and standards, proprietary repair procedures, and practical hands-on instruction. The technician must prove their proficiency during both written and practical examinations covering relief valve repair, assembly, and testing. With our certified Green Tag Technicians, you can rest assured that your valves will be serviced in compliance with ASME and NBBI (National Board of Boiler and Pressure Vessel Inspectors) standards so they perform their critical safety function as intended.

Each of our GTC service locations has compete machining capabilities, calibrated measuring and testing equipment, specialized electronic valve testing equipment, and ValvKeep, a proprietary electronic data management system, so you can track and trend the repair history of your valves. We also carry significant inventory of Consolidated pressure relief valves and OEM certified replacement parts ensuring rapid response to your urgent repair needs. If for some reason we don’t have a part in stock locally, we have access to all parts stocked by GTCs throughout the entire United States and can have them overnight shipped to one of our service centers. We are your trusted local pressure relief valve service center whether your valves are Consolidated or another manufacturer’s brand.

Since the first installation of its Limitorque Machine (limit & torque capable) in 1929, Limitorque has been manufacturing some of the most innovative and dependable motor-operated valve actuators for demanding industrial applications. Flowserve, the parent company of Limitorque, authorizes a select group of companies to be their “Limitorque Blue Ribbon” service and repair centers. Chalmers & Kubeck is proud to be the largest Limitorque Distributor east of the Mississippi River and that all twelve (12) of our locations are Limitorque Blue Ribbon Service Centers. With over 20 years providing outstanding Blue Ribbon Service, C&K is your go-to solution for actuator sizing, selection, adaptation, installation / certification, maintenance, repair, and field service.

This team of valve and instrument specialists works closely together to provide customer assistance in technical sales, quotations and delivery. Chalmers & Kubeck maintains around-the -clock service, which includes the assembly and test of new CONSOLIDATED® pressure relief valves, plus full machining and repair operations for industrial valves of many types and manufacturers. Additionally, C&K provides comprehensive design and manufacturing services to adapt your existing manual valve or a new manual valve to a motor operated actuator for enhanced process control and operator safety.

Like other pressure relief valves (PRV), pilot-operated relief valves (PORV) are used for emergency relief during overpressure events (e.g., a tank gets too hot and the expanding fluid increases the pressure to dangerous levels). PORV are also called pilot-operated safety valve (POSV), pilot-operated pressure relief valve (POPRV), or pilot-operated safety relief valve (POSRV), depending on the manufacturer and the application. Technically POPRV is the most generic term, but PORV is often used generically (as in this article) even though it should refer to valves in liquid service.

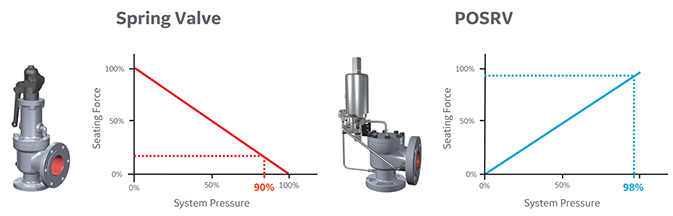

In conventional PRVs, the valve is normally held closed by a spring or similar mechanism that presses a disk or piston on a seat, which is forced open if the pressure is greater than the mechanical value of the spring. In the PORV, the valve is held shut by piping a small amount of the fluid to the rear of the sealing disk, with the pressure balanced on either side. A separate actuator on the piping releases pressure in the line if it crosses a threshold. This releases the pressure on the back of the seal, causing the valve to open.

The essential parts of a PORV are a pilot valve (or control pilot), a main valve, a pilot tube, the dome, a disc or piston, and a seat. The volume above the piston is called the dome.

The pressure is supplied from the upstream side (the system being protected) to the dome often by a small pilot tube. The downstream side is the pipe or open air where the PORV directs its exhaust. The outlet pipe is typically larger than the inlet. 2 in × 3 in (51 mm × 76 mm), 3 in × 4 in (76 mm × 102 mm), 4 in × 6 in (100 mm × 150 mm), 6 in × 8 in (150 mm × 200 mm), 8 in × 10 in (200 mm × 250 mm) are some common sizes.

The pressure from the pilot tube to the dome is routed through the actual control pilot valve. There are many designs but the control pilot is essentially a conventional PRV with the special job of controlling pressure to the main valve dome. The pressure at which the control pilot relieves is the functional set pressure of the PORV. When the pilot valve reaches set pressure it opens and releases the pressure from the dome. The piston is then free to open and the main valve exhausts the system fluid. The control pilot opens either to the main valve exhaust pipe or to atmosphere.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat (see blowdown in relief valve article).

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure. Blowdown is typically short.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

8613371530291

8613371530291